Circular-handle cutter rapid clamp

A cutting tool and fast technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of low reuse rate, inability to replace fixtures, low clamping efficiency, etc., and achieve large clamping force and high clamping efficiency , Reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

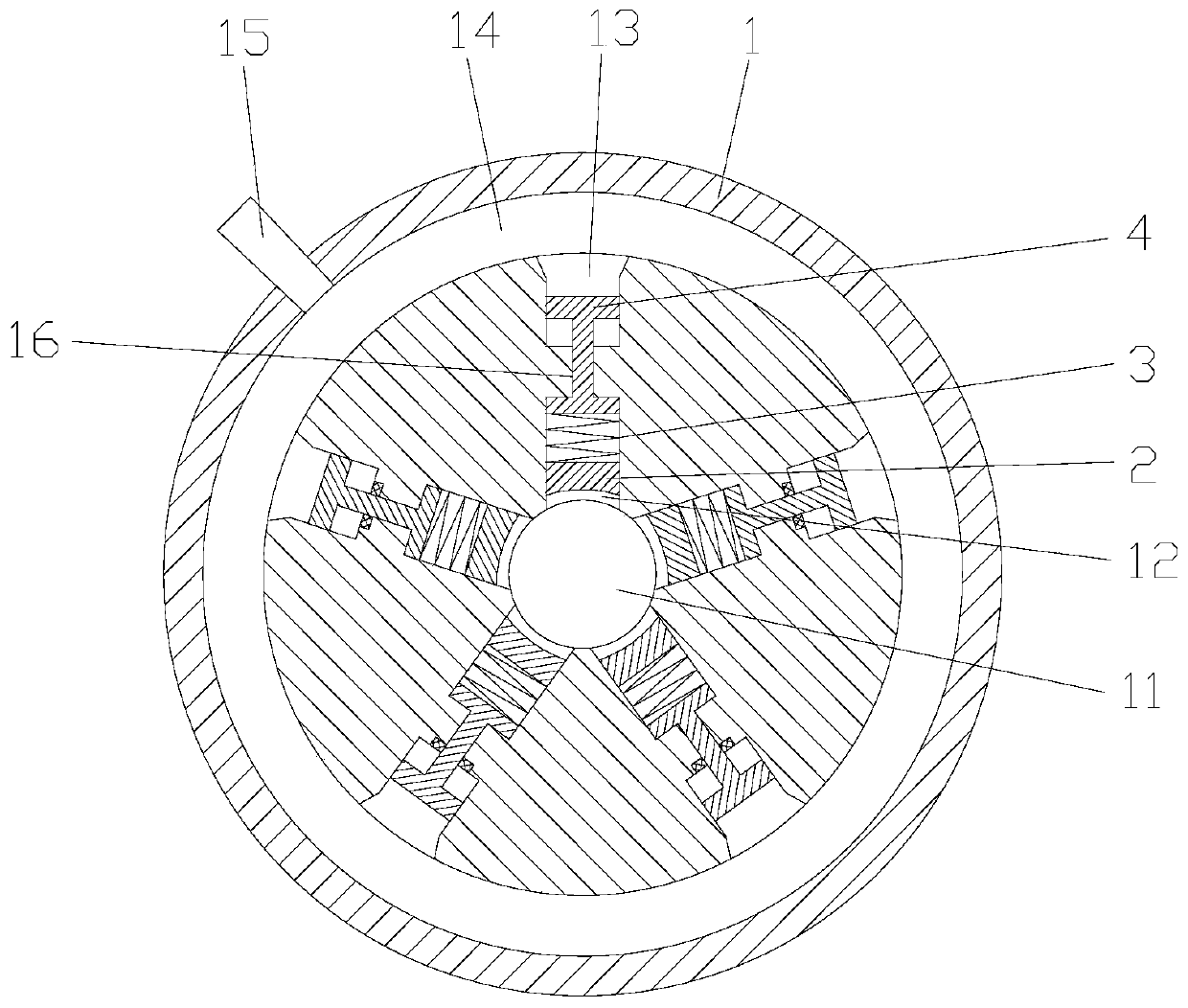

[0024] Example 1: Reference figure 1 , a round shank tool quick clamp, including a cylindrical clamping body 1, five chucks 2, the axis of the clamping body 1 is provided with a clamping hole 11 for placing the round shank tool, and the surrounding of the clamping hole 11 is provided with a clamping hole 11. There are five chutes 12 along the radial direction. The chutes 12 are evenly distributed along the circumferential direction. The front end of the chutes 12 communicates with the clamping hole 11. The line and the axis line of the chute 11 are on the same radial straight line. There is a spring 3 in the air pressure chamber 13, and the ejector rod 4 is slidingly matched with the air pressure chamber 13. The front end of the ejector rod 4 extends to the rear of the spring 3 and is connected with the rear end of the spring 1. The clamping body 1 The rear part corresponding to the air pressure chamber 13 is provided with an annular air pressure chamber 14 which communicates...

Embodiment 2

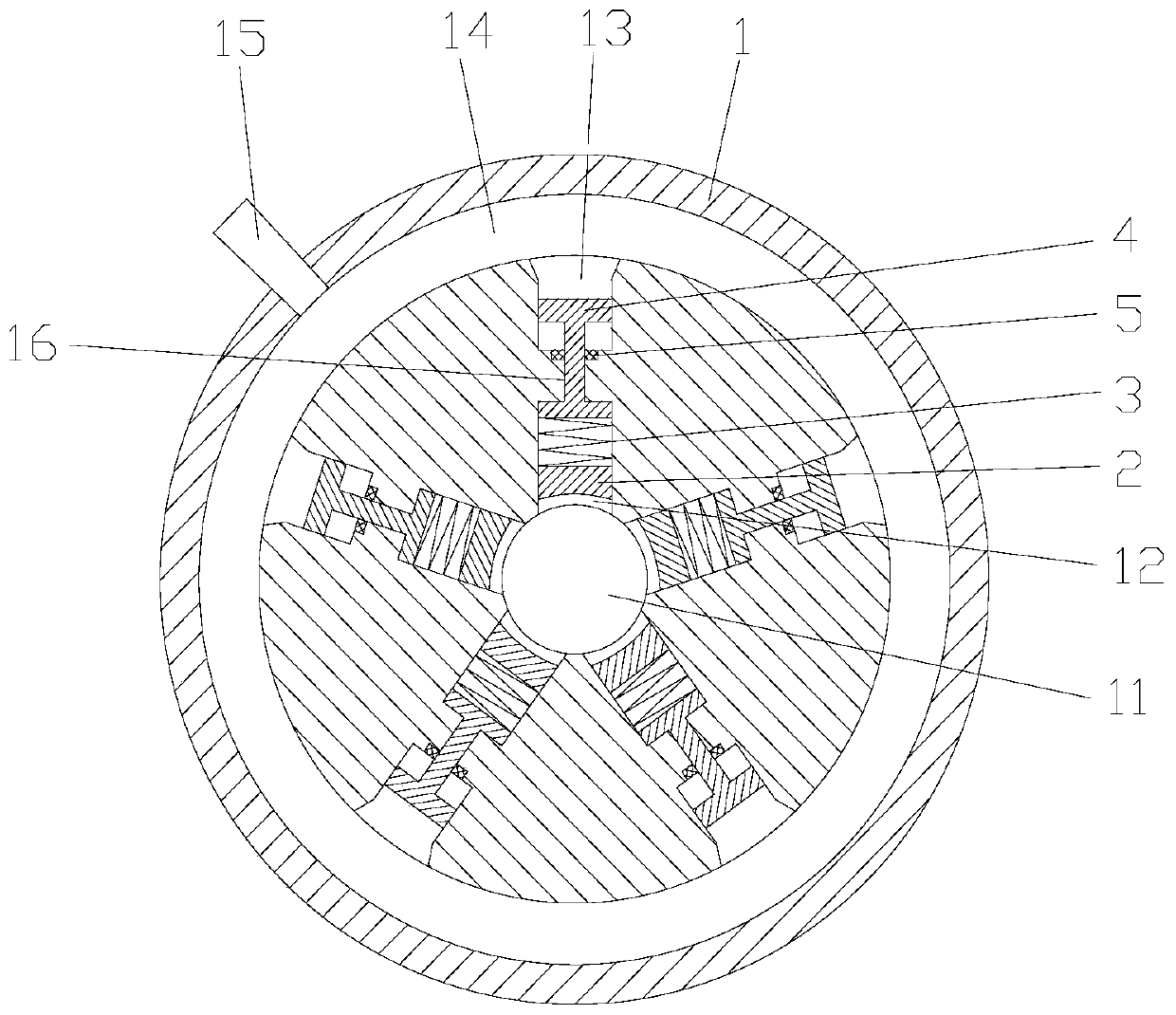

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is: refer to figure 2 , the inner wall of the connecting cavity 16 is provided with an axial sealing ring 5 that seals the sliding fit between the inner wall of the connecting cavity and the ejector cylinder. The efficiency is transformed, the air pressure loss is reduced, and the clamping force of the spring on the tool is guaranteed.

Embodiment 3

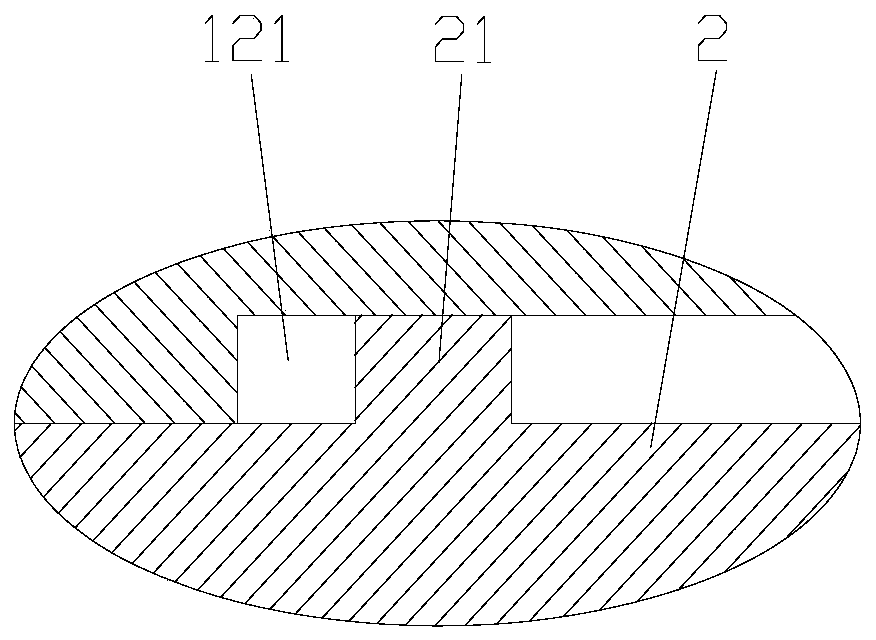

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 is: refer to image 3 , the groove wall of the sliding groove 132 is provided with a matching groove 121 along the radial direction, and the corresponding position on the collet 2 is provided with a limit block 21 that cooperates with the matching groove 121. The limit block 21 slides in the matching groove 121 to limit the collet The position of radial movement can prevent the collet from slipping out, and make the clamp have a certain scope of application and improve the clamping accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com