Fiber reinforced thermoplastic composite material pair-roller mixing equipment

A technology of mixing equipment and composite materials, which is applied in the field of fiber-reinforced thermoplastic composite material processing and production equipment, can solve the problems of serious wear and tear on screw components by reinforcing fibers, limited reinforcement materials, and wear and tear of reinforced fibers, so as to reduce production input costs and Maintenance cost, simple equipment structure, and the effect of reducing shear wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

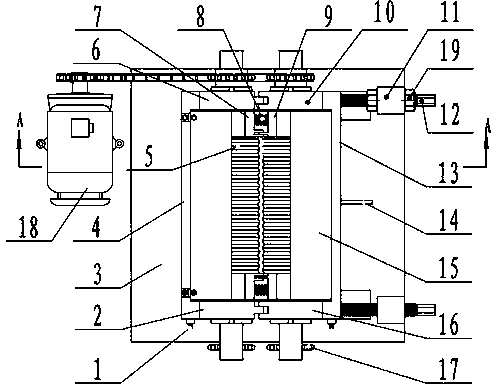

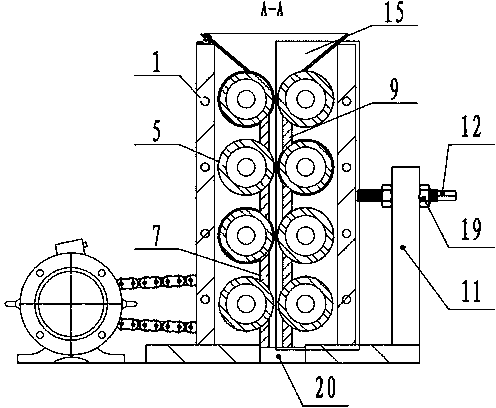

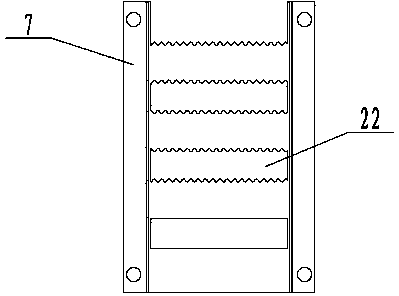

[0021] As shown in the figure: the front left panel (2), left side panel (4) and rear left panel (6) of the mixing device are fixed on the bottom plate (3). The middle part of the bottom plate (3) is provided with a strip-shaped outlet, the upper and lower sides are provided with concave sliding tracks, and the far right is provided with a fixed adjustment pillar (11). The adjustment pillar (11) is equipped with an adjustment screw (12) and a lock The nut (19), the adjusting screw rod is threadedly connected with the right side panel; the front right panel (16), the rear right panel (10) and the right side panel (13) are connected by bolts as an integrated structure, which can be recessed in the bottom plate (3) Move left and right on the sliding track, and adjust the moving distance by adjusting the adjustment screw (12) on the support (11); the tube electric heater (1) is installed on the left panel (4), and the right panel (13) An electric heater (1) and a temperature probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com