Self-pulsation stirrer for hot metal desulfurization

A technology for desulfurization of molten iron and agitator, which is applied to mixers with rotary stirring devices, chemical instruments and methods, transportation and packaging, etc. In order to improve the kinetic conditions of molten iron KR stirring desulfurization and the economic indicators of desulfurization technology, shorten the desulfurization reaction time, and improve the reaction speed and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

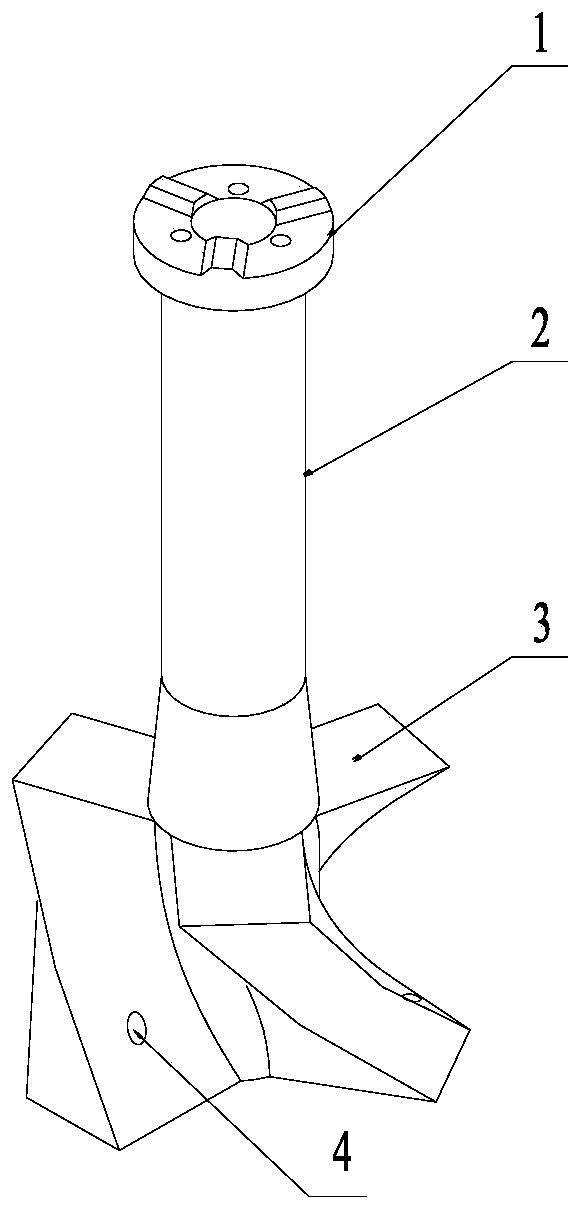

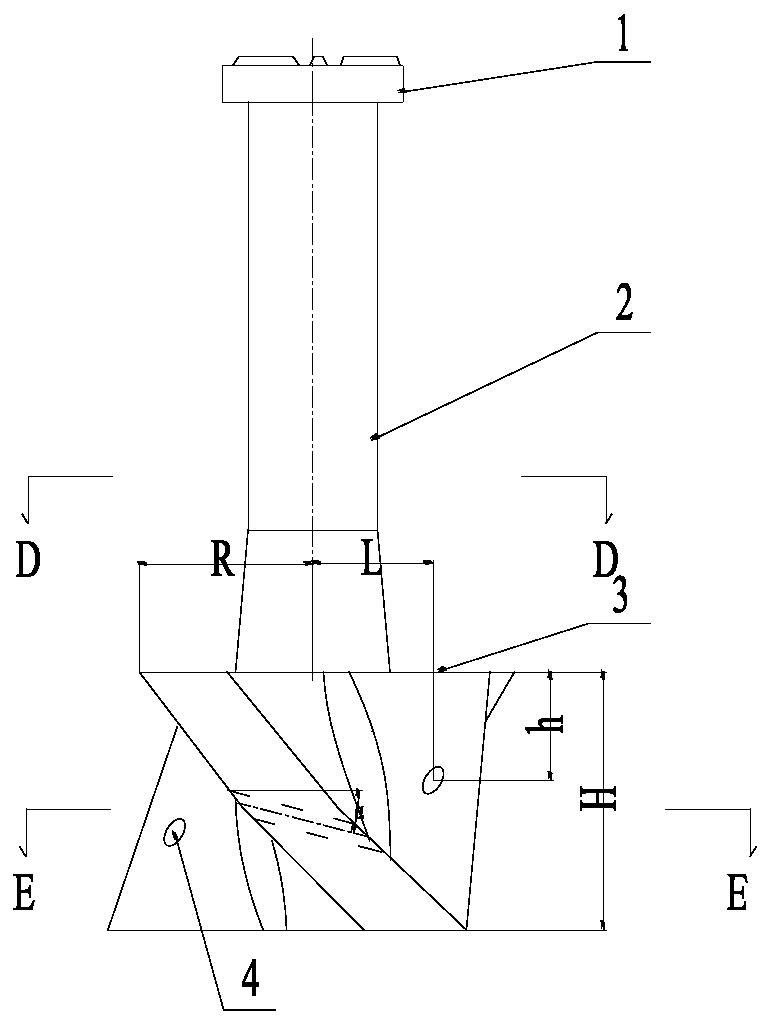

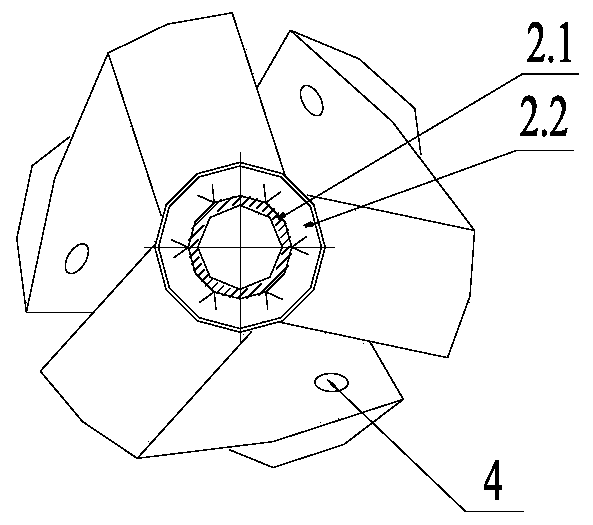

[0029] No matter how much the number of stirring blades 3 is (two, three or four all can be, as figure 2 , Figure 7 shown), each of the stirring blades 3 is provided with a flow field pulse interference through hole 4, and the flow field pulse interference through hole 4 is inclined downward along the stirring rotation circumference, and the downward inclination angle α is 5-20° ( Preferably 10°), in addition, the inner wall of each flow field pulse interference through hole 4 is wrapped with a stirring blade core refractory castable lining 3.2. The area of each flow field pulse interference through hole 4 is 2~10% (preferably 6%) of the area of the iron surface of the stirring blade 3, and the center point of the flow field pulse interference through hole 4 on the stirring blade 3 is far from the stirring blade 3 The distance h of the upper end surface is 1 / 3~2 / 3 (preferably 1 / 2) of the height H of the stirring blade 3, and the distance L between the central point of t...

Embodiment 2

[0031] The difference between embodiment 2 and embodiment 1 is: when the number of stirring blades is an even number of four or more than four, as Figure 5 As shown, the flow field pulse interference through holes 4 can also be provided on the stirring blade 3 at intervals (such as Figure 6 shown), that is, the stirring blade 3 adjacent to the stirring blade 3 provided with the flow field pulse interference through hole 4 is not provided with the flow field pulse interference through hole 4, that is, not all the stirring blades 3 have flow field pulse interference The through-holes 4 and the flow field pulse interference through-holes 4 provided at intervals can be arranged obliquely downward along the stirring rotation circumference, and the downward inclination angle α is 5-20° (preferably 10°).

Embodiment 3

[0033] The difference between embodiment 3 and embodiment 2 is that: the flow field pulse interference through-hole 4 is arranged horizontally along the stirring rotation circumferential direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com