A screw conveying mechanism of extruder that can improve extrusion efficiency

A technology of screw conveying and extruder, which is applied in the field of extruder screw conveying mechanism, which can solve the problems of shear wear, concave surface at the bottom of the feed port, material melt breakage, etc., and achieve the reduction of material conveying fluctuation and shear wear , avoid the bridging phenomenon of the feed inlet, and ensure the effect of extrusion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

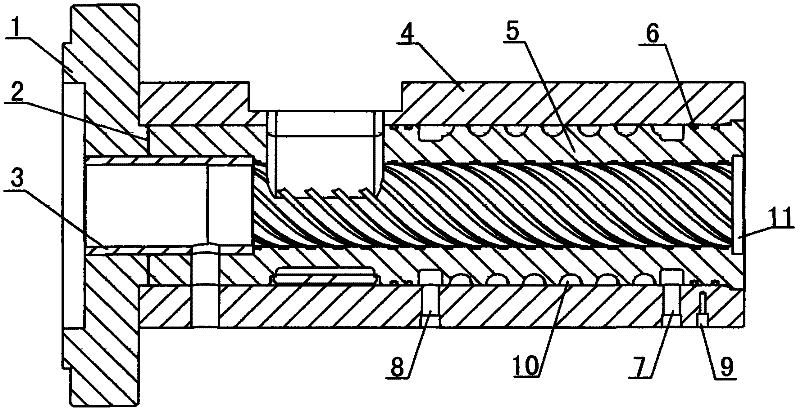

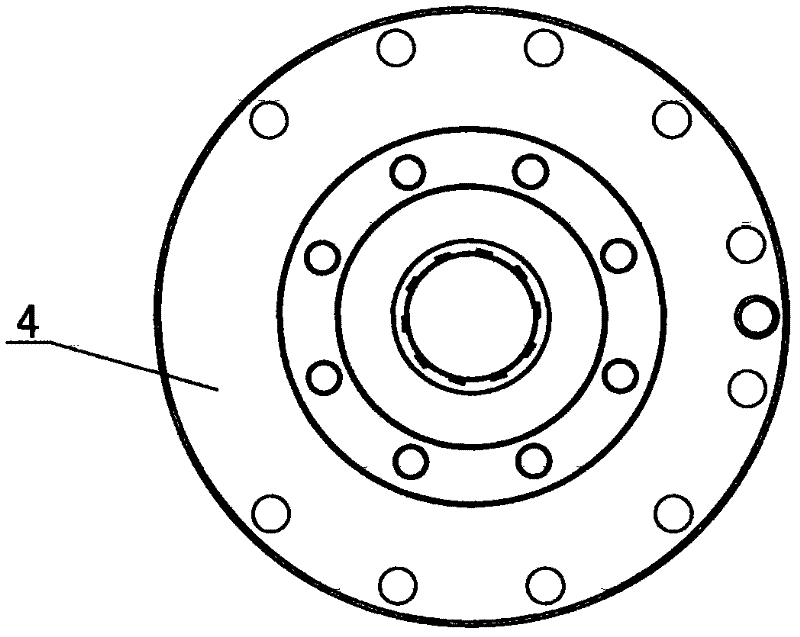

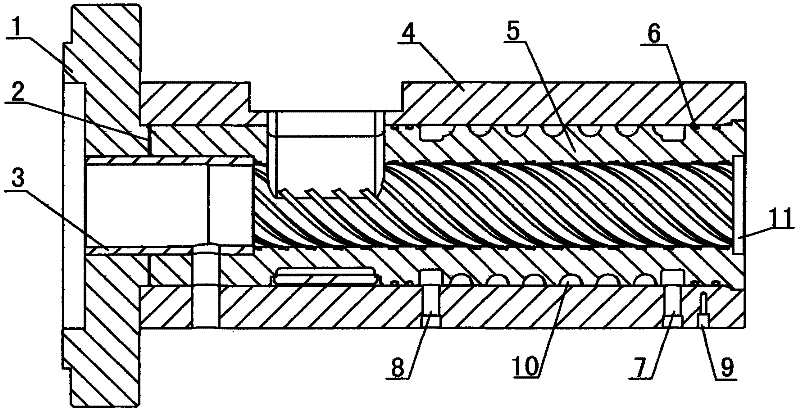

[0017] Such as Figure 1-2 As shown, the extruder screw conveying mechanism that can improve the extrusion efficiency described in the embodiment of the present invention includes a connecting flange 1, an outer bush 4, and an inner screw conveying bush 5, and the outer bush 4 is mounted on the inner side The inner screw conveys the bushing 5 and one end of the bushing 4 is equipped with a connecting flange 1, and the connecting flange 1 is fixedly connected with the outer bushing 4 through bolts 2; the inner screw conveying bushing 5 and the outer bushing 4 The front end between them is installed with a sealing ring 6 to realize the sealing of the cooling medium, and a rear bushing 3 is arranged on the outside of the inner screw conveying bush 5 on the side of the connecting flange 1, and the connecting flange 1 and the transmission of the extruder The mechanism is connected, and then the power is input to the extrusion system. In addition, in order to improve conveying effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com