Novel plunger pump device

A plunger pump, a new type of technology, is applied to the components of pumping devices for elastic fluids, pump elements, variable displacement pump components, etc. It can solve the problems of insufficient output pressure and low efficiency, and achieve large specific flow , high efficiency, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

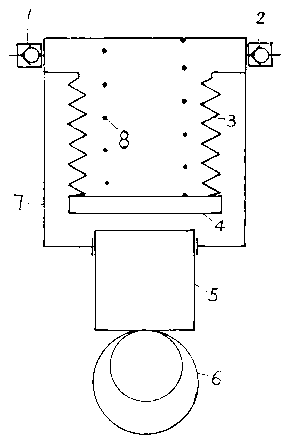

[0015] Such as figure 1 and 2 As shown, the novel plunger pump device of the present invention includes an input check valve 1, an output check valve 2, a folded spring spacer 3, a plate 4, a plunger 5, an eccentric shaft 6, a pump body 7 and a spring 8. The input one-way valve 1 and the output one-way valve 2 are fixed above the side wall of the pump body 7, the folded spring isolation ring 3 is placed in the pump body 7, the upper part is airtightly fixed on the inner wall of the pump body 7, and the lower part is airtightly connected to the flat plate 4, The folded spring isolation ring 3 and the flat plate 4 divide the pump cavity of the plunger pump into an inner cavity part and an outer cavity part; the outer cavity part is filled with oil whose viscosity coefficient is greater than water; the plunger 5 is placed on the column at the bottom of the pump body 7 In the plug hole, the eccentric shaft 6 is located below the plunger 5 and is in contact with the plunger 5. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com