Supercritical fluid pressure boost metering device

A technology of supercritical fluid and metering device, which is applied in the field of pressurization generation and precise metering and conveying devices, can solve problems such as sudden change in pressure of truncated conveying pipeline, and achieves the effect of high cost performance, high output pressure and solving sudden change in pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

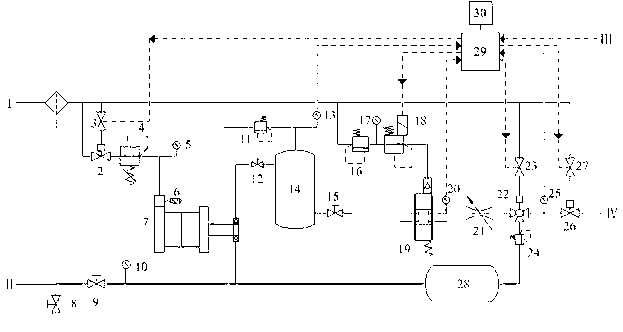

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] The supercritical fluid pressurization and metering device in this embodiment is composed of a supercritical fluid generating part and a supercritical fluid metering part.

[0021] Among them, the supercritical fluid generation part includes the first pneumatic shut-off valve 2, the first solenoid valve 3, the pressure regulating valve 4, the first pressure gauge 5, the muffler 6, the pneumatic booster pump 7, the exhaust valve 8, the shut-off valve 9, A second pressure gauge 10 , a safety valve 11 , a first high-pressure cut-off valve 12 , a first pressure sensor 13 , a supercritical fluid storage tank 14 , a second high-pressure cut-off valve 15 , and a control unit 29 .

[0022]Among them, the inlet of the filter 1 is connected with the compressed air source I, and the outlet of the filter 1 is connected with the first pneumatic stop valve 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com