Tensioning and cushioning units for traction gear drives

A buffer unit and traction mechanism technology, applied in transmission, machine/engine, mechanical equipment, etc., can solve the problem that the buffer characteristics cannot be adjusted accurately, and achieve the effect of compact structure, space saving and assembly cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

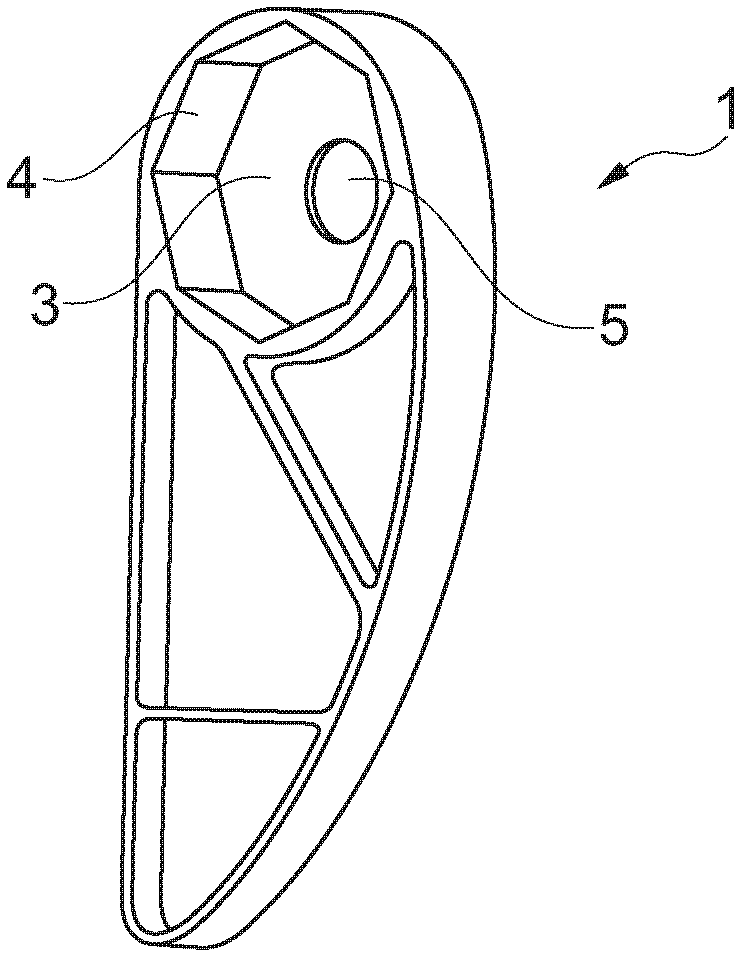

[0035] exist figure 1 Shown is a tensioning rail 1 into which a tensioning and damping unit 2 can be inserted, see Figure 5 and 6 . In connection with this, the tensioning rail 1 has a recess 3 with an octagonal inner profile 4 .

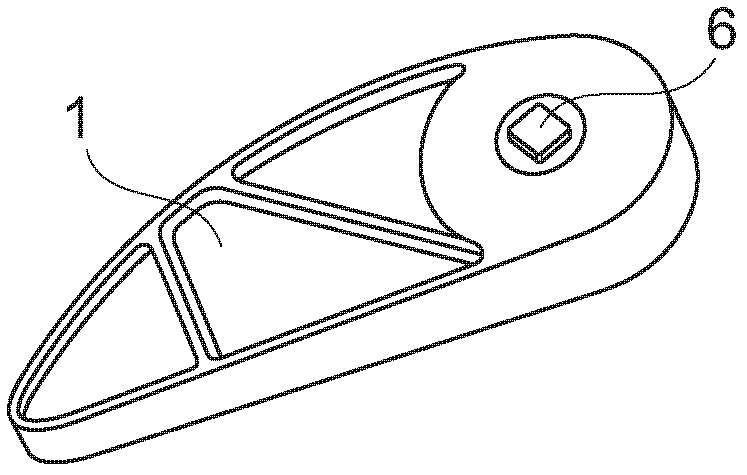

[0036] The tensioning rail 1 is made of plastic. Recess 3 also has center hole 5, fixing bolt 6 (referring to Figure 4 ) can be loaded into the center hole 5. figure 2 The state in which the fastening bolt 6 is inserted into the tensioning rail 1 is shown.

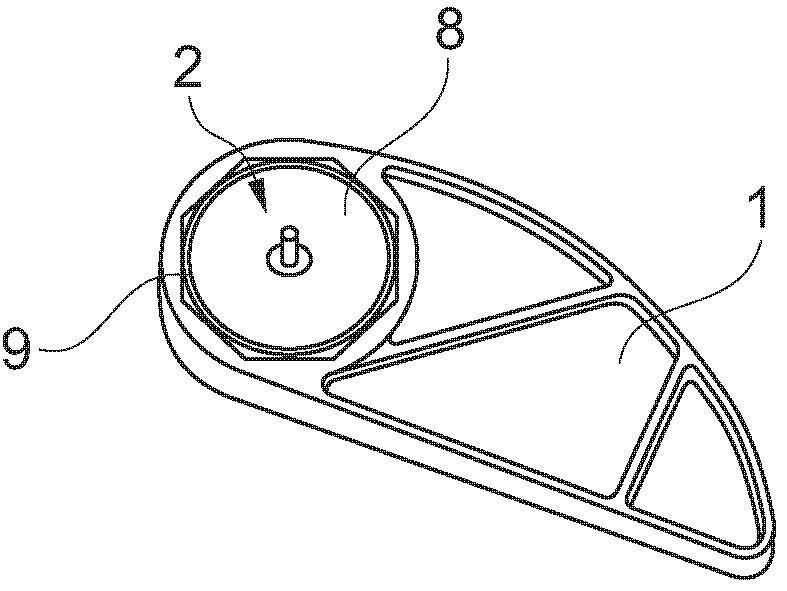

[0037] From figure 2 start from the icon, image 3 The other side of tensioning rail 1 is shown. The tensioning and damping unit 2 inserted into the recess 3 has a cover 7 which closes the housing 8 in a sealing manner on one side. cover 7 in Figure 5 and 6 It can be clearly seen in , while in image 3 In the middle, only the housing 8 and the spring 9 wound around the housing 8 on the outside are visible. The spring 9 is fixed in the slot 10, see for example Figure 7 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com