A multi-segment rubber membrane sealed gas tank

A gas tank and rubber membrane technology, applied in the field of gas tank, can solve the problems of large wasted space and high piston, and achieve the effects of prolonging the service life, running the gas tank stably, and avoiding sudden changes in pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

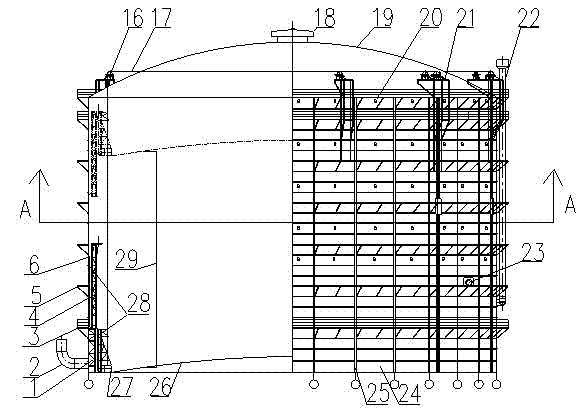

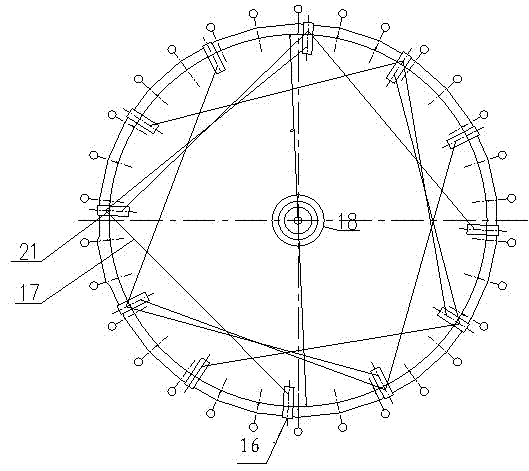

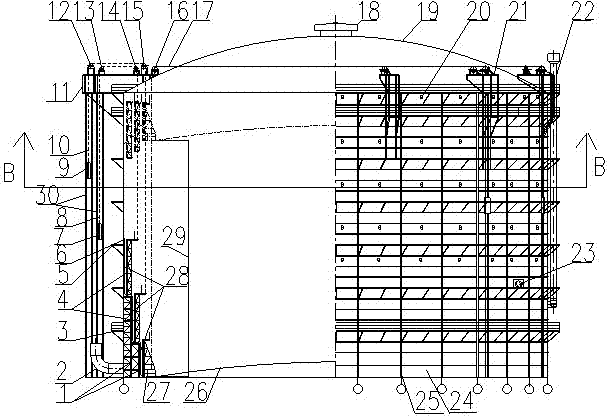

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] Such as image 3 and Figure 4 As shown, in the gas cabinet, two T baffles 4 are arranged on the outer layer of the piston truss 27, and there is a sealed rubber film between the T baffle and the T baffle, and between the T baffle and the piston truss. The gas cabinet sealing system. Each T baffle is actually a cylinder, and the two T baffles are balanced by the outer ring balance weight 7 and the inner ring balance weight 9 respectively. Each T baffle plate is all connected with the steel wire rope with the external counterweight hammer located in the guide rail through a fixed pulley.

[0020] in:

[0021] The weight of the counterweight of the outer ring + the upward force generated by the gap of the rubber film = the weight of the T baffle ring of the outer ring;

[0022] The weight of the counter weight of the inner ring + the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com