A Product Lightweight Design Method Based on Additive Manufacturing

A lightweight design and additive manufacturing technology, applied in the field of additive manufacturing, can solve problems such as design limitations, inability to achieve specific structural distribution according to performance requirements, and achieve material cost savings, reasonable and efficient lightweight design and manufacturing, The effect of reducing the weight of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

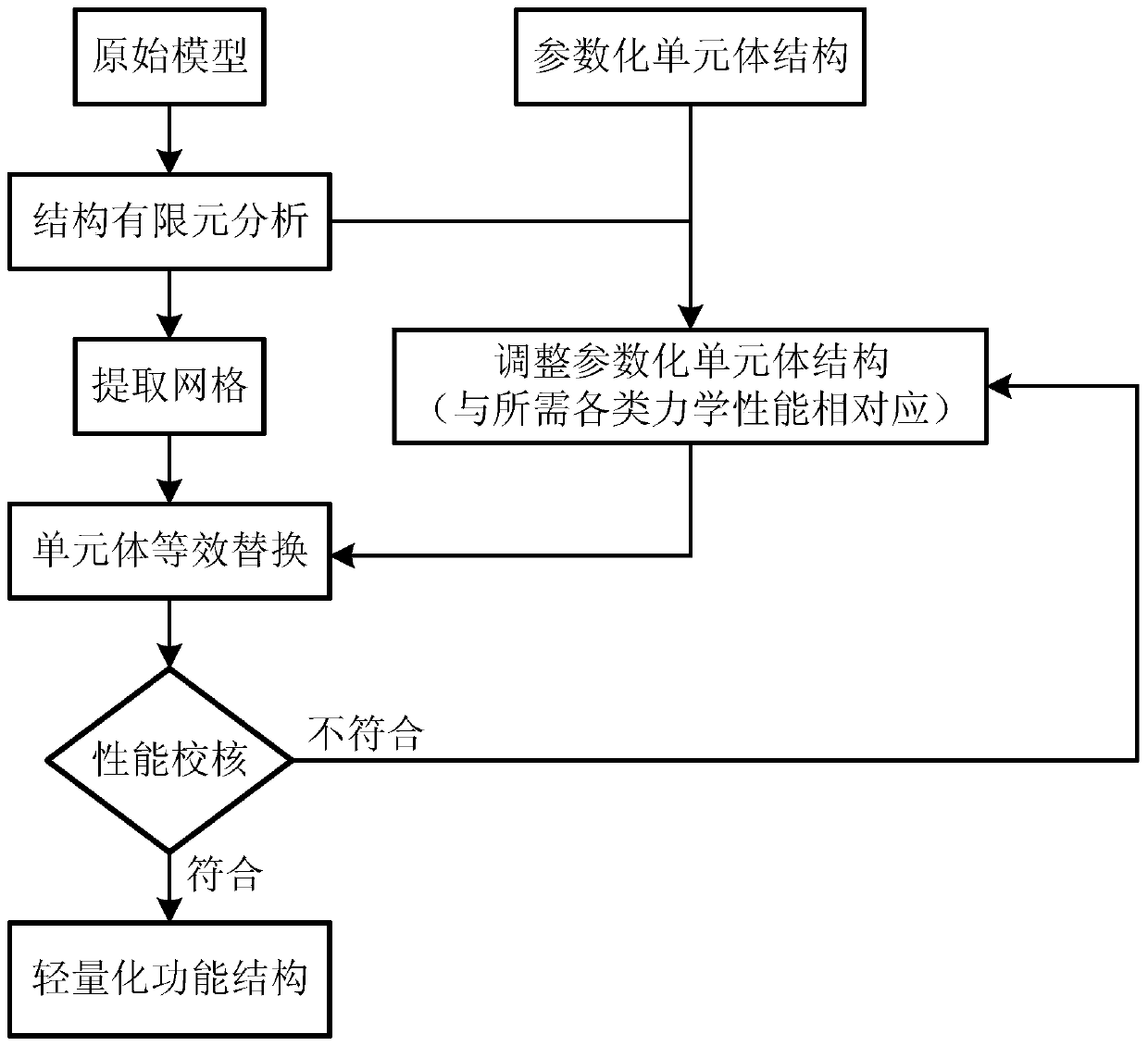

[0025] Such as figure 1 Shown. The invention discloses a product lightweight design method based on additive manufacturing, which includes the following steps:

[0026] Step 1: Establish a parameterized lightweight unit database. The structure of the lightweight unit includes extremely small curved surface units, bone tissue structural units, and truss structural units. It also has different types, sizes, features, and density distributions. Analyze the mechanical properties of the lightweight unit structure under the combined mode, and establish the corresponding relationship between the parameterized structure and the mechanical properties;

[0027] Step 2: Simulate the actual working conditions of the product, perform finite element analysis on the original product model structure, and obtain a stress distribution diagram;

[0028] Step 3: According to the obtained finite element stress analysis results, adjust the type, size, characteristic morphology, density distribution, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com