Nitrogen making system for ship

A manufacturing system, nitrogen technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, nitrogen purification/separation, etc., can solve the problems of large area occupied by nitrogen generators and high procurement costs, and save equipment investment and energy consumption , the effect of streamlining the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

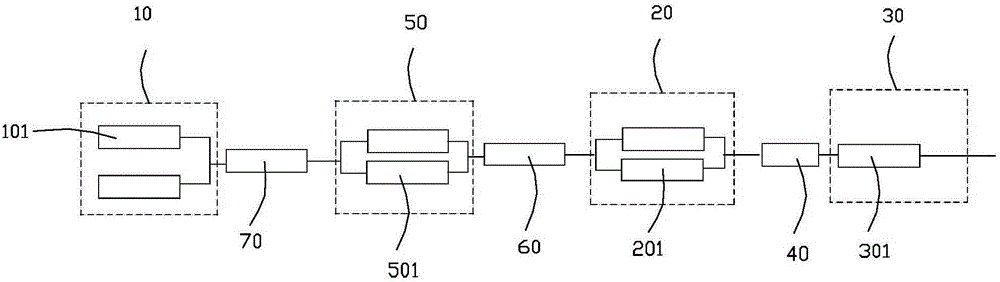

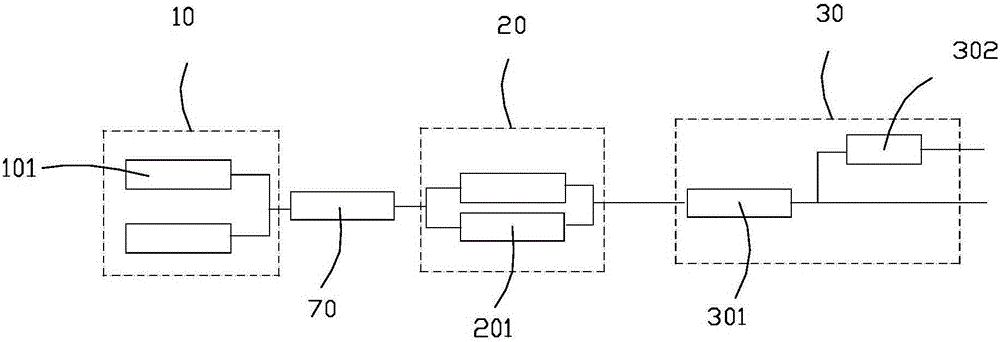

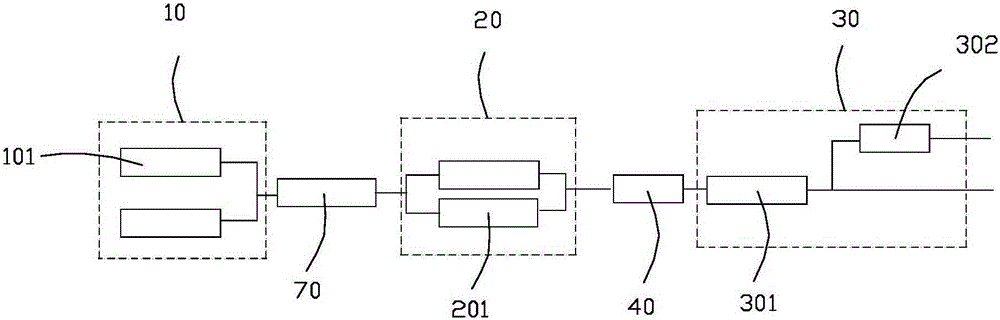

[0053] Example 1: 55,000 tons oil tanker (55KCT) 4,250Nm 3 / h Nitrogen generator installation project, such as figure 2 shown

[0054] The lessor of a 55,000-ton oil tanker needs to obtain a certificate of airworthiness in the North American Emission Control Area. The inert gas system in the original design was a traditional combustion type and was not allowed to operate in North America. The inert gas system, which is necessary for unloading, cannot operate, which means that chemical tankers are not allowed to unload at North American ports. Therefore, a nitrogen generating device needs to be installed. However, the design of the oil and chemical ship did not consider the engine room where the nitrogen generator is placed, nor did it reserve the electricity and cooling water required by the nitrogen generator. Two container-type diesel-driven air compressors can be arranged by adding a platform on the rear deck, and nitrogen generators can be arranged on the side deck an...

example 2

[0055] Example 2: 85,000 square meters of very large ethane carrier (VLEC) nitrogen generator, such as figure 2 shown

[0056] The nitrogen configuration has two sets of nitrogen 1,500Nm 3 / h Nitrogen system with a purity of over 99.8%, one for use and one for backup. It is extremely difficult to arrange in the engine room and leave enough space for equipment maintenance. The nitrogen generating device arranged in the engine room has a height limit. Therefore, it is necessary to reduce the size and height of the equipment. Using this patented technology can remove the cold dryer, air buffer tank, and nitrogen buffer tank to greatly reduce the equipment's footprint. With the combination of multiple nitrogen generating units, the height of a single nitrogen generating unit can be controlled within the allowable range, and at the same time, the investment cost of the nitrogen manufacturing system is reduced as a whole.

[0057] Example 3: 1,500Nm for a 12,500-ton stainless s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com