A new type of multi-phase flow buffer equipment used after the heat exchanger of the black water system in the coal chemical industry

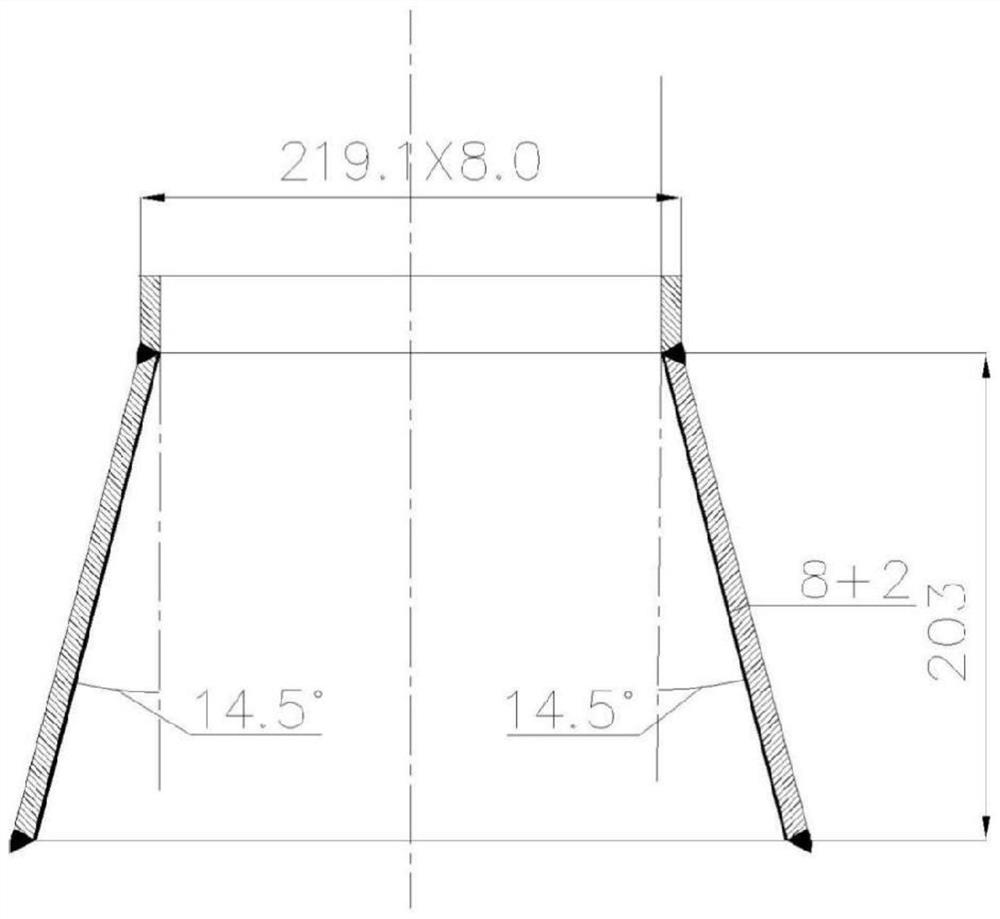

A multi-phase flow, coal chemical technology, applied in mechanical equipment, heating water/sewage treatment, pipeline damage/wear prevention, etc., can solve the problem of unreasonable structural design of the blind plate part of the bottom flange blind plate and the impact angle of large solid particles. , poor wear resistance and other problems, to achieve the effect of ensuring long-term safe and stable operation, reducing wear rate, and reducing shear wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

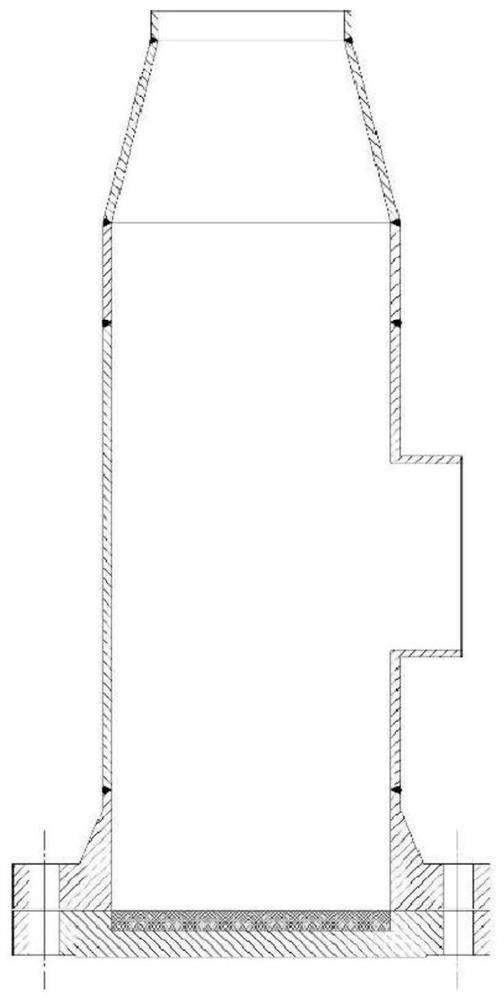

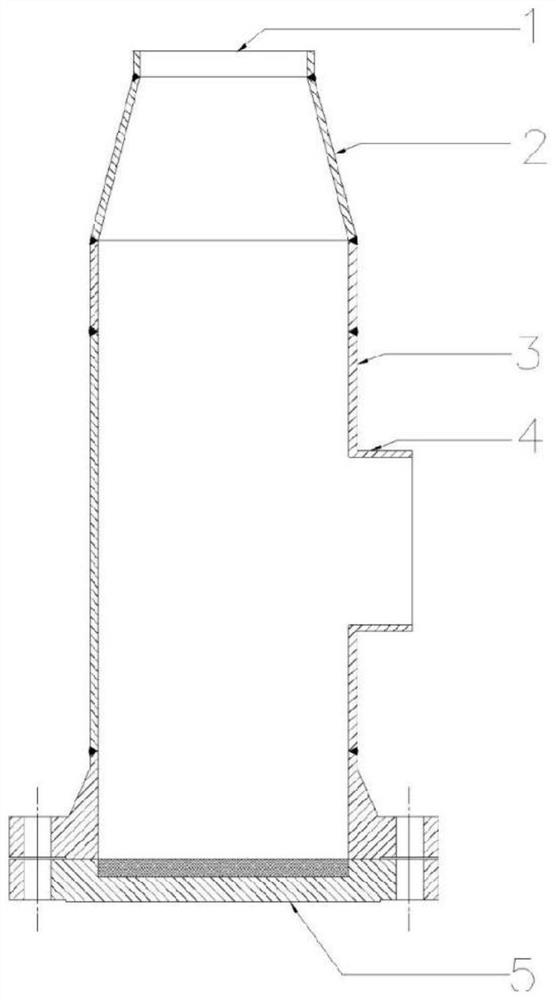

[0051]In recent years, with the rapid development of the domestic coal chemical industry, coal gasification technology has been widely used in coal-to-hydrogen, coal-to-methanol, coal-to-olefins, and coal-to-synthetic ammonia projects. Ningxia, Shandong, Inner Mongolia and other places have combined their regional advantages to build a number of large-scale coal gasification plants to vigorously develop the coal chemical industry. However, the unplanned shutdown of the device caused by the failure of the buffer equipment after the heat exchanger of the coal gasification black water system has severely restricted the safe and stable operation of the enterprise. For example, a coal chemical company's coal-to-methanol gasification unit uses GE's Texaco coal-water slurry gasification technology. The multiphase black water medium containing hard pulverized coal particles flows through the heat exchanger and enters the buffer device. The equipment was put into operation in January 2016, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com