Plastic formwork which is provided with frame and used repeatedly and circularly and construction method of plastic formwork

A technology of plastic formwork and construction method, which is applied in the fields of formwork/formwork components, formwork processing, and on-site preparation of building components, etc. The effect of using times, simplifying construction technology and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

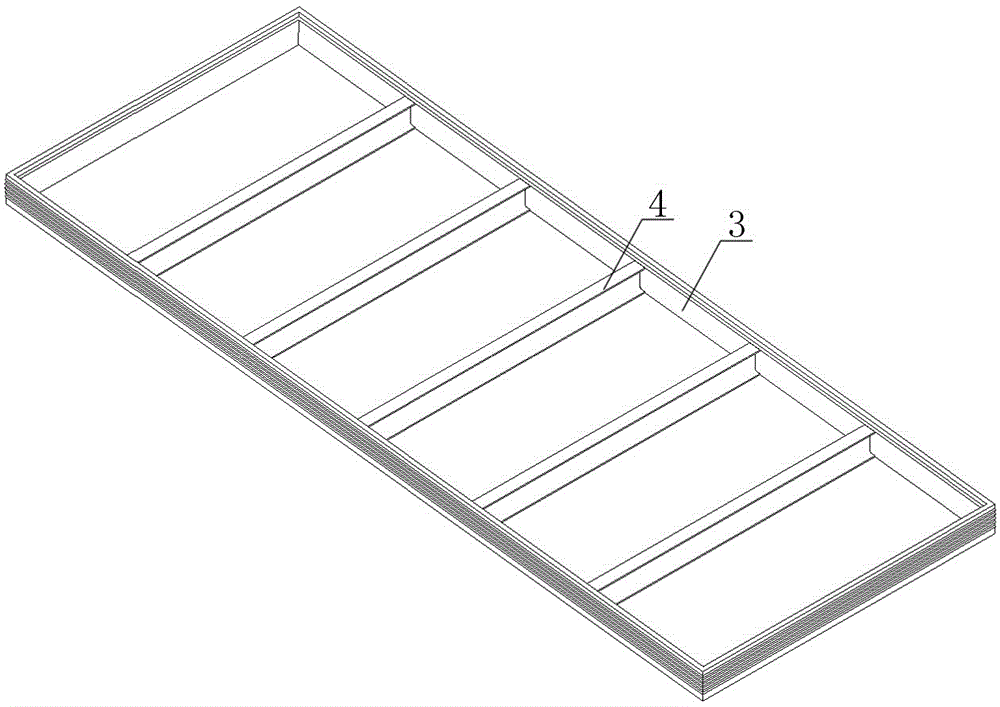

[0044] Embodiment one sees Figure 5 As shown, the framed plastic formwork used for multiple turnovers includes a panel 2, the panel 2 is embedded in the upper end of the frame 3, the upper surface of the panel 2 and the outer side of the frame 3 are tightly covered with a plastic skin 1, and the panel 2 The upper surface of the upper surface is flush with the upper end of the frame 3, the lower port of the epidermis 1 is flush with the lower end of the frame 3, and the side of the epidermis 1 matches the shape of the side of the frame 3.

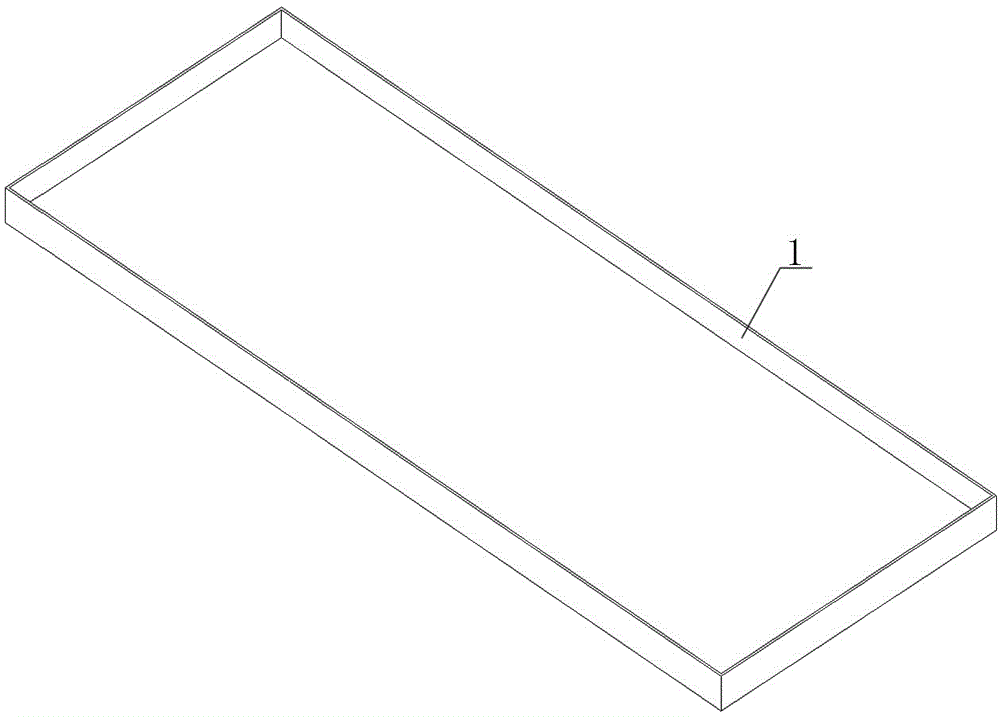

[0045] see figure 1 As shown, the skin 1 has five surfaces, namely the upper surface and four sides, which are formed by extrusion injection molding process, and its length, width and height dimensions match the length, width and height dimensions of the frame. , tightly covering the outer surface of the outer frame of the frame;

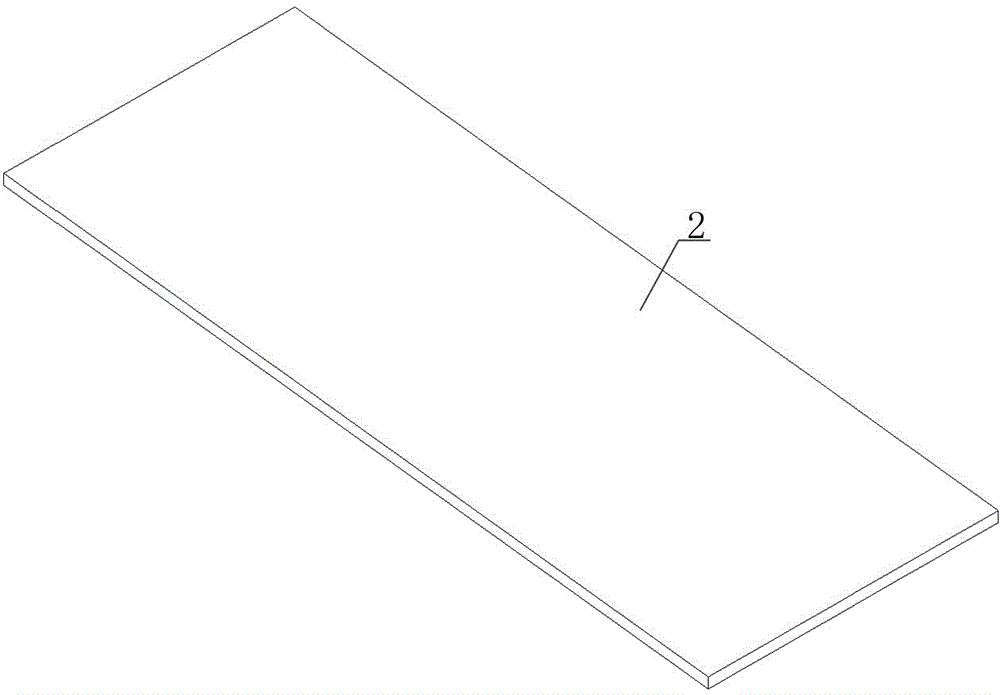

[0046] see figure 2 As shown, the shape of the panel is a thin cuboid structure, and it is a lightweight a...

Embodiment 2

[0050] Embodiment two see Figure 7 , Figure 8 , Figure 9As shown, the difference from the first embodiment is that the four sides of the frame 3 are hollow profiles.

Embodiment 3

[0051] Embodiment three see Figure 10 , Figure 11 , Figure 12 As shown, the difference from the first embodiment is that the boss 7 of the frame 3 is located on the upper part of the frame, and the thickness of the frame in this embodiment is smaller than that of the previous two embodiments.

[0052] A construction method for applying the described plastic formwork with a frame for repeated turnover, the specific steps are as follows:

[0053] Step 1, preparing the skin 1, the panel 2, and the frame 3, and connecting the reinforcing rib 4 to the frame 3.

[0054] Step 2, embed the panel 2 into the upper position of the frame 3 .

[0055] Step 3, cover the skin 1 on the outside of the panel 2 and the frame 3 from top to bottom.

[0056] Step 4, connect and fix the side surface of the skin 1 with the frame 3 to complete the construction of the plastic formwork.

[0057] Step five, the formed plastic formwork can be transported to the construction site as a concrete pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com