Steel wedge hang mould convenient to demount

A technology of wedge opening and hanging formwork is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., which can solve the problems of low reliability of wood formwork reinforcement, mold expansion, unfavorable energy saving and environmental protection, etc. Achieve the effect of avoiding mold expansion, reducing costs, and increasing the number of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

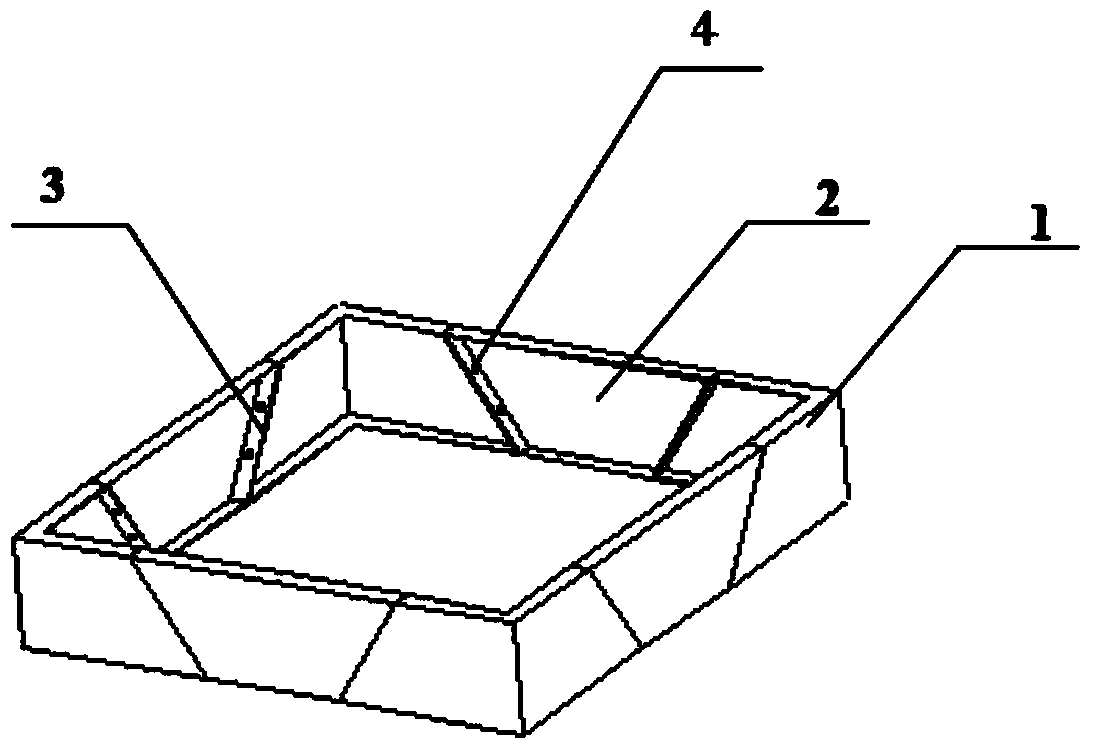

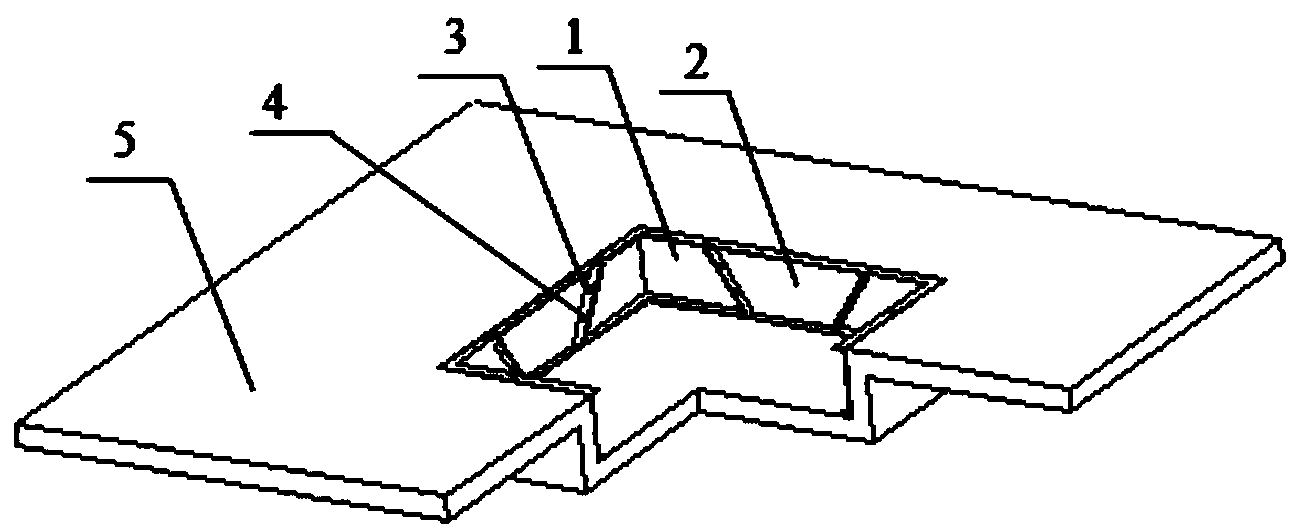

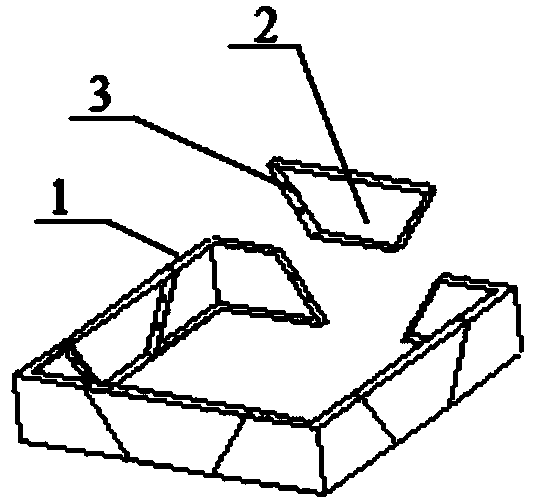

[0015] Such as figure 1 As shown, the present invention includes several steel angle molds 1 and side molds 2, the panel edges of the angle molds and side molds are spliced with each other, and the panel inner side edges of the angle molds and side molds extend inward to form ribs sheet 3, several connecting bolts 4 are pierced between the ribs on the corner form and the ribs on the adjacent side forms. The cutting edge on both sides of the side form 2 is a wedge, and the shape of the side form panel is an inverted trapezoid, which eliminates the friction between adjacent ribs when removing the formwork, and makes the form removal more convenient. The number of the angle die 1 and the wedge-side die 2 is 4 respectively, and the knuckle angle of the angle die is 90 degrees, so as to ensure the squareness of the negative angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com