Solid absorbent with high CO2 adsorption capacity and preparation method thereof

A technology of adsorption capacity and absorbent, which is applied in the field of solid absorbent with high CO2 adsorption capacity and its preparation, can solve the problems of reducing specific surface area, reducing decarbonization ability of absorbent and pore blockage, etc., achieving large specific surface area and easy automation The effect of improving management and decarbonization capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] above high CO 2 The preparation method of the solid absorbent of adsorption capacity, comprises the following steps:

[0034] Step 1. Mix a certain mass concentration of alkali metal carbonate solution, silane coupling agent with amino groups (γ-aminopropyltriethoxysilane or γ-aminopropyltrimethoxysilane), ethyl orthosilicate Ester and ethanol are mixed in a volume ratio of 1 to 3:1 to 3:1:3, and the mixed solution is stirred until it becomes an emulsion;

[0035] Step 2, placing the emulsion obtained in step 1 in the air, pouring the emulsion at an angle of preferably 45° until the emulsion cannot flow, and obtaining a cross-linked gel;

[0036] Step 3. Place the gel obtained in Step 2 in a closed desiccator for a drying time of 1 to 5 hours, preferably 1 hour;

[0037] Step 4. Soak the gel obtained in Step 3 with ethanol for 24 to 48 hours, preferably 24 hours;

[0038] Step 5. Use the supercritical drying method to dry and sieve the gel obtained in step 4 to prepa...

Embodiment 1

[0043] Weigh 1.3g of sodium carbonate and dissolve it in 50ml of water, measure 50ml of ethyl orthosilicate and 50ml of γ-aminopropyltriethoxysilane respectively, put the above three solutions into 150ml of ethanol, place them on a stirrer and stir for 10 After the solution turns into an emulsion, stop stirring and place it in the air. When the solution is poured at 45° and the solution does not flow, the solution will be cross-linked. Put the cross-linked gel in an airtight dry place and store it for 1 hour. Afterwards, the gel was soaked in ethanol for 24 hours to replace the moisture contained in the gel. Finally, the gel was dried by supercritical drying method and sieved. The drying temperature was 45°C and the drying pressure was 20Mpa, so as to prepare high CO 2 Adsorption capacity of solid absorbents.

[0044] Each component and its mass percentage in the solid absorbent prepared in this example: active component, 15%, wherein sodium carbonate content: 4.1%, amine grou...

Embodiment 2

[0063] Weigh 10g of sodium carbonate and dissolve it in 50ml of water, measure 50ml of ethyl orthosilicate and 100ml of γ-aminopropyltriethoxysilane respectively, put the above three solutions into 150ml of ethanol, place them on a stirrer and stir for 10 minutes , stop stirring after the solution turns into an emulsion, and place it in the air. When the solution is poured at 45° and does not flow, the solution will be cross-linked, and the cross-linked gel will be placed in an airtight dry place for 5 hours. After that, the gel was soaked in ethanol for 48 hours to replace the water contained in the gel. Finally, the gel was dried by supercritical drying method and sieved. The drying temperature was 30°C and the drying pressure was 15Mpa, thereby preparing a high CO 2 Adsorption capacity of solid absorbents.

[0064] Each component and its mass percentage in the solid absorbent prepared in this example: active component, 30%, wherein sodium carbonate content: 17.9%, amine gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

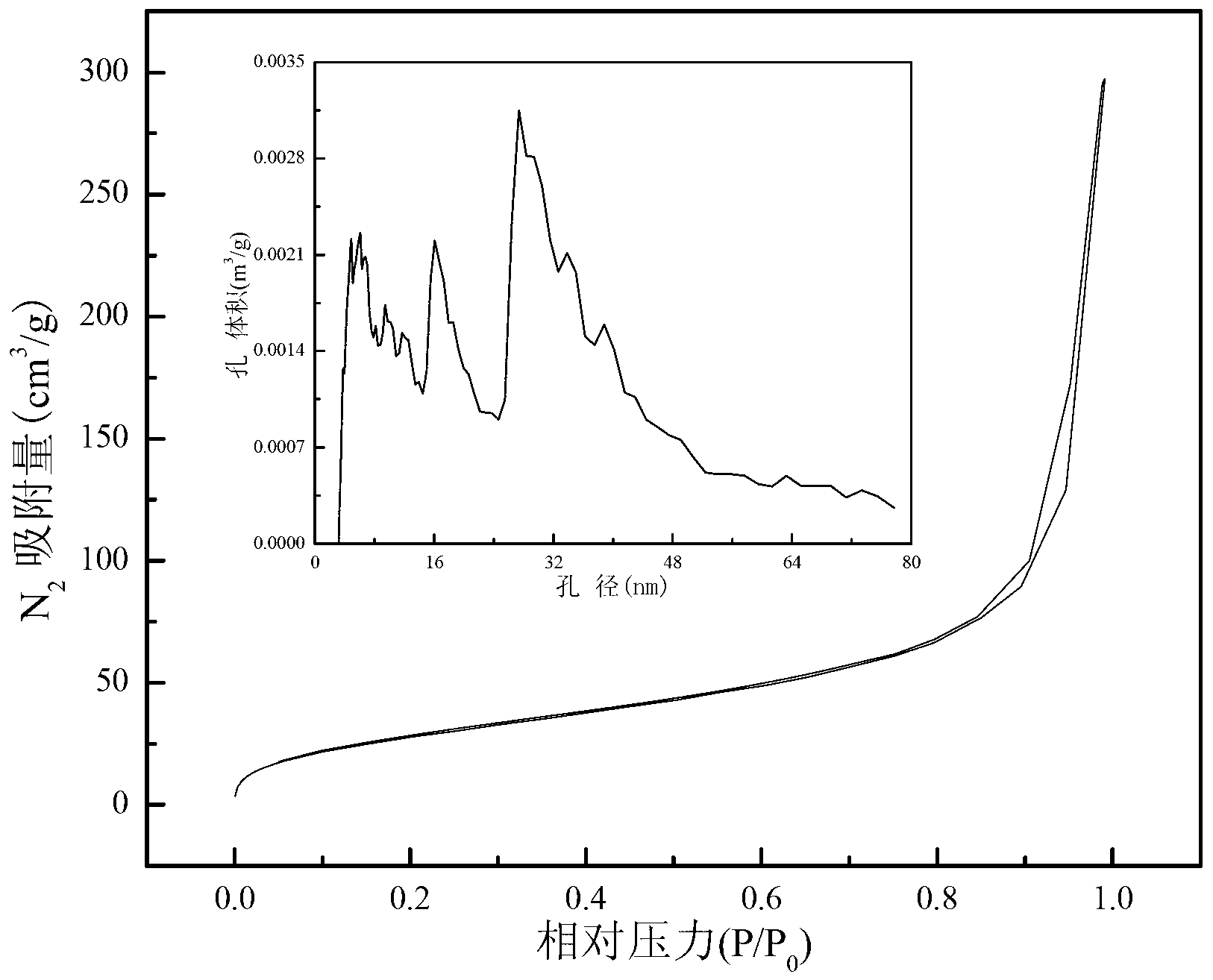

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com