A method for high-temperature molten iron gas atomization decarburization steelmaking

A water-gas atomization and high-temperature technology, applied in the field of decarburization steelmaking, can solve the problems of long process, low temperature, and complexity, and achieve the effects of good powder compressibility, long cooling time, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

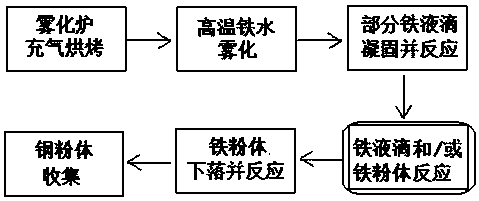

[0028] The method of high-temperature molten iron gas atomization decarburization steelmaking, the specific method is to fill the high-temperature atomization chamber of the atomization furnace with a mixture of high-pressure oxidizing water vapor and hydrogen with an initial temperature of 0.42 MPa at 1170 ° C; The technology breaks the high-carbon high-temperature molten iron with a carbon content of 3.2% into fine iron droplets within an atomization time of less than 1s. Under the action of its own kinetic energy and gravity, a large number of fine iron droplets fall in the high-pressure oxidizing gas for 15-60s. During the time of flight and solidification, iron powder is formed; during the atomization time and flight time, the mixture of 80% iron droplets and 20% iron powder with a diameter of 10-50 μm chemically reacts with the oxidizing gas to form CO or CO 2 The gas, and finally the cooled iron powder turns into steel powder and falls into the lower collector of the at...

Embodiment 2

[0030] A method for high-temperature molten iron gas atomization decarburization steelmaking, the specific method is to fill the high-temperature atomization chamber of the atomization furnace with a mixture of high-pressure oxidizing water vapor, hydrogen and argon with an initial temperature of 0.25 MPa at 1250 ° C; Then, through the gas atomization technology, the high-carbon high-temperature molten iron with a carbon content of 3.9% is broken into fine iron droplets within an atomization time of less than 1s. Falling 15~60s flight time and solidification, forming iron powder; during the atomization time and flight time, the mixture of 70% iron droplet and 30% iron powder with a diameter of 10~50μm, chemically reacts with the oxidizing gas reaction to form CO or CO 2 The gas, and finally the cooled iron powder turns into steel powder and falls into the lower collector of the atomizing furnace.

Embodiment 3

[0032] A method for high-temperature molten iron gas atomization decarburization steelmaking, the specific method is to fill the high-temperature atomization chamber of the atomization furnace with a mixture of high-pressure oxidizing carbon dioxide and argon with an initial temperature of 1280 ° C and 0.3 MPa; The atomization technology breaks the high-carbon high-temperature molten iron with a carbon content of 3.6% into fine iron droplets within an atomization time of less than 1 second. Under the action of its own kinetic energy and gravity, a large number of fine iron droplets fall in the high-pressure oxidizing gas for 15~ 60s flight time and solidification to form iron powder; during the atomization time and flight time, the mixture of 65% iron droplets and 35% iron powder with a diameter of 10~50μm chemically reacts with the oxidizing gas to form CO or CO 2 The gas, and finally the cooled iron powder turns into steel powder and falls into the lower collector of the ato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com