Buried oxygen blowing and decarburization process for electric-arc furnace steelmaking and control method

An oxygen blowing decarburization and electric arc furnace technology, applied in electric furnace, process efficiency improvement, furnace and other directions, can solve the problems of slow decarburization speed, poor control effect, low life of electric arc furnace cover and flue gas system, etc. The effect of improving decarburization speed and high flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] 1. 60 tons electric arc furnace

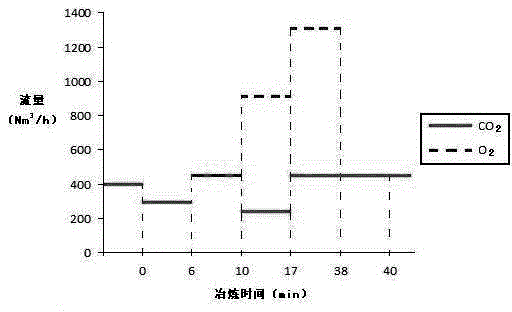

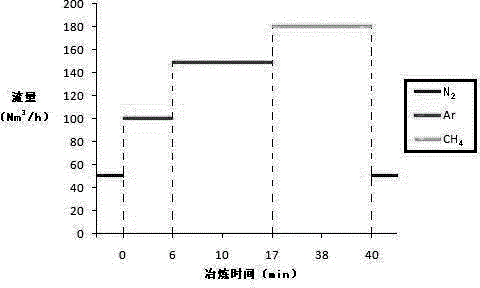

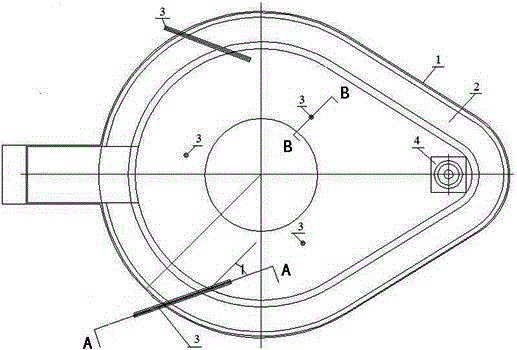

[0049] The invention is applied to a 60t ultra-high power electric arc furnace. Oxygen, carbon dioxide, nitrogen and argon respectively enter the bottom side blowing nozzle under the liquid steel surface along the conveying pipeline, and the nozzle is made of stainless steel. Two nozzles are arranged on both sides of the steel mouth of the electric arc furnace, and the included angle with the normal line of the furnace wall is 75°, and the included angle with the horizontal of the liquid steel surface is 3°. The gas flow is controlled by time intervals:

[0050] 1) Keep the central nozzle spraying N before smelting 2 , with a flow rate of 400 Nm 3 / h, annular gap injection N 2 , with a flow rate of 50 Nm 3 / h.

[0051] 2) From 0 to 6 minutes after the smelting starts, the central nozzle stops blowing N 2 , change to inject O 2 , with a flow rate of 400 Nm 3 / h, ring seam N 2 Flow rate of 70 Nm 3 / h.

[0052] 3) 6~12min, cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com