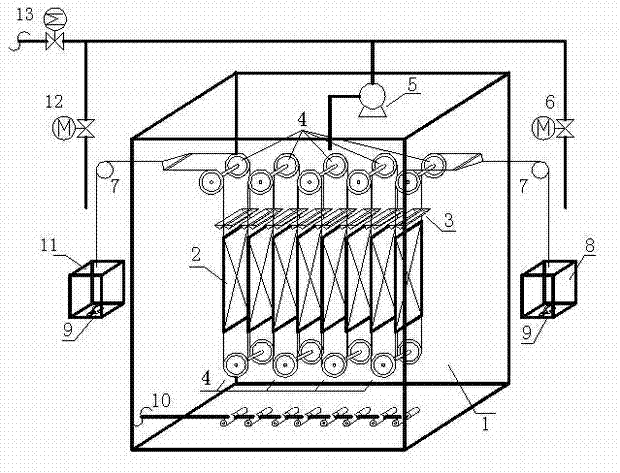

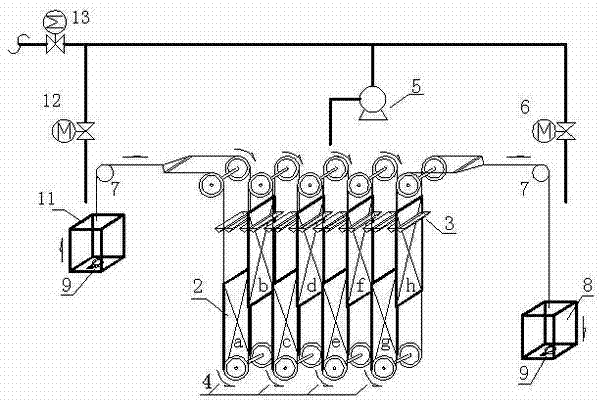

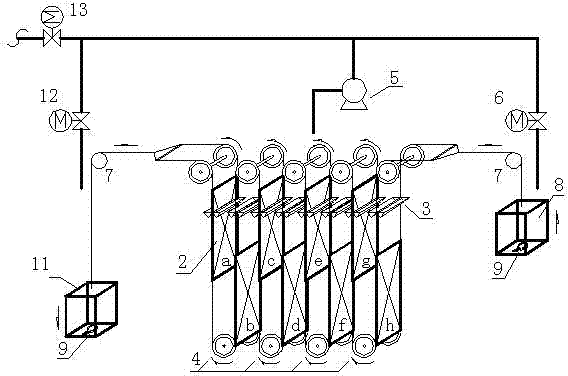

High throughput and low energy consumption online self-cleaning flexible membrane-bioreactor

A bioreactor, flexible membrane technology, applied in biological water/sewage treatment, membrane technology, semi-permeable membrane separation, etc. The economic advantages of the immersed membrane-bioreactor and the increase in the operating cost of the immersed membrane-bioreactor can achieve the effect of fully utilizing the membrane area, reducing the membrane area and floor space, and being light in weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] The invention is used in the treatment of municipal sewage. Sludge concentration 8g / L, membrane flux 50L / m 2 ·H, higher than the critical flux of the membrane module in this case, using a microporous aeration tube, air-water ratio 8:1, automatic cleaning twice a day, V-shaped scraper blade is made of sponge. Stable operation for 45 days, water and electricity consumption per ton is 0.39 yuan, and the total treatment cost per ton is 0.48 yuan.

example 2

[0035] The present invention is used in the treatment of wastewater from supermarket restaurants. Sludge concentration is 15g / L, membrane flux is 40L / m 2 ·H, higher than the critical flux of the membrane module in this case, using microporous aeration tube, air-water ratio 20:1, automatic cleaning 6 times a day, V-shaped scraper blade is made of brush. Stable operation for 23 days, the consumption of water and electricity per ton is 0.60 yuan, and the total treatment cost per ton is 0.90 yuan.

example 3

[0037] The invention is used in the treatment of sewage in a certain rural area. Sludge concentration 8g / L, membrane flux 40L / m 2 ·H, higher than the critical flux of the membrane module in this case, using a microporous aeration tube, air-water ratio 10:1, automatic cleaning once a day, V-shaped scraper blade is made of rubber. Stable operation for 62 days, water and electricity consumption per ton is 0.45 yuan, and the total treatment cost per ton is 0.60 yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com