Low-temperature plasma processing device capable of realizing on-line self-cleaning and use method thereof

A low-temperature plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems of bulky, unrealizable, high manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

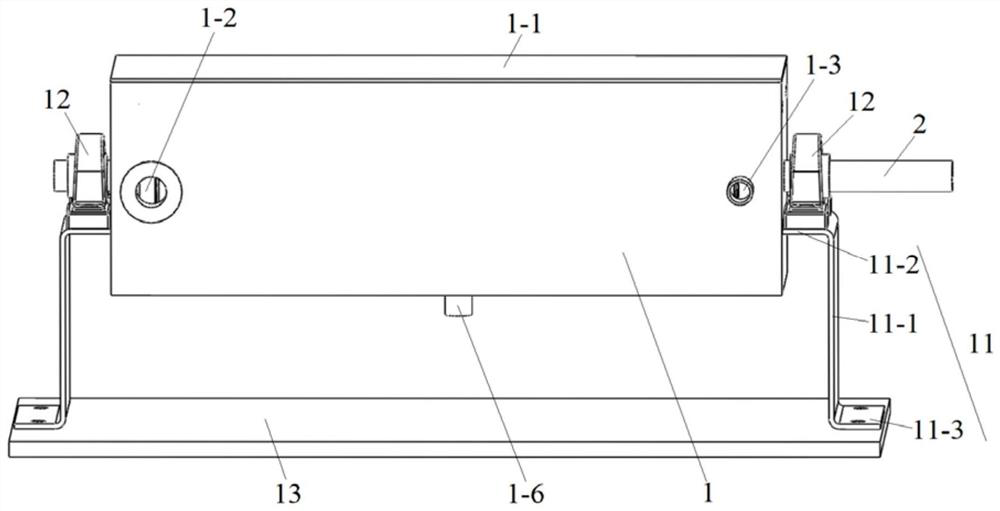

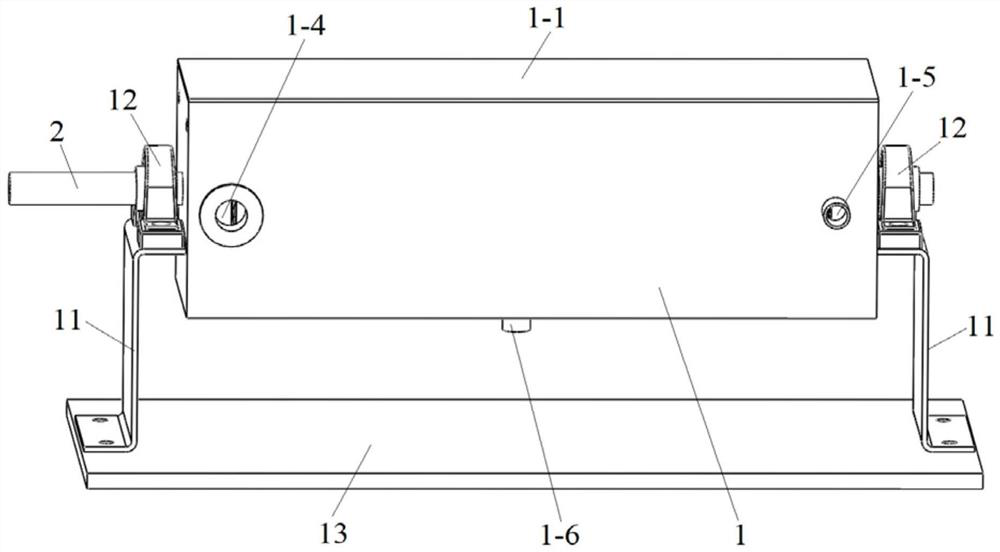

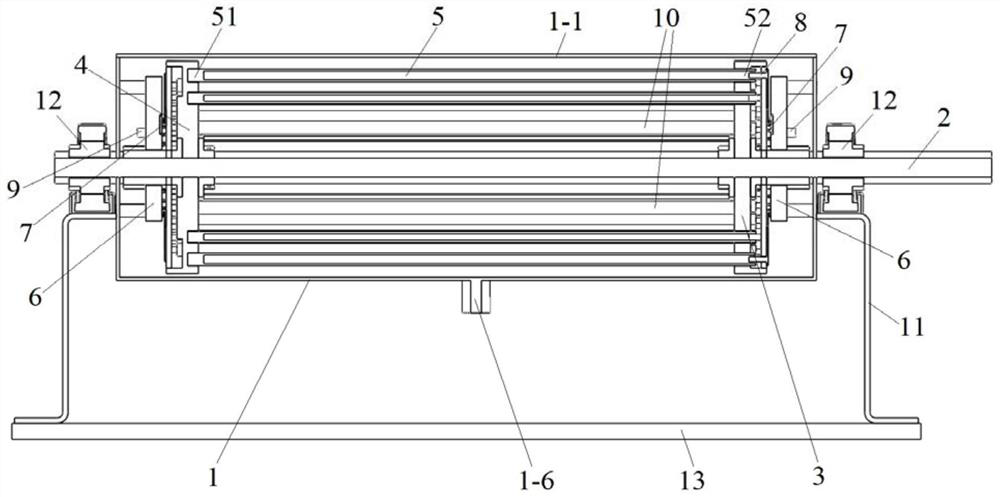

[0034] Please combine Figure 1 to Figure 10 As shown: a low-temperature plasma processing device capable of realizing online self-cleaning provided by this embodiment includes a sealable box 1, and a rotating shaft 2 is arranged in the transverse direction of the sealable box 1. The rotating shaft 2 in the box body 1 is rotatably connected with a positive fixed disc 3 and a negative fixed disc 4, and an N-layer discharge tube 5 is perforated between the positive fixed disc 3 and the negative fixed disc 4, where N is A natural number greater than or equal to 2, each layer of discharge tubes is formed by a plurality of similar discharge tubes that are uniformly distributed at 360 degrees around the axis of rotation, and the electrical properties of the adjacent two layers of discharge tubes are opposite (in this embodiment, N is 3 Example, wherein the outermost layer and the innermost layer are both positive electrode layers, and the middle layer is a negative electrode layer; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com