Device and method for extracting algal polysaccharide by ultrasonic-assisted extraction

A seaweed polysaccharide and auxiliary extraction technology, which is applied in the field of ultrasonic-assisted extraction of seaweed polysaccharide devices, can solve the problems of reduced polysaccharide biological activity, time-consuming, time-consuming and labor-intensive enzymatic extraction, and achieves effective extraction, shortening extraction time, and reducing The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

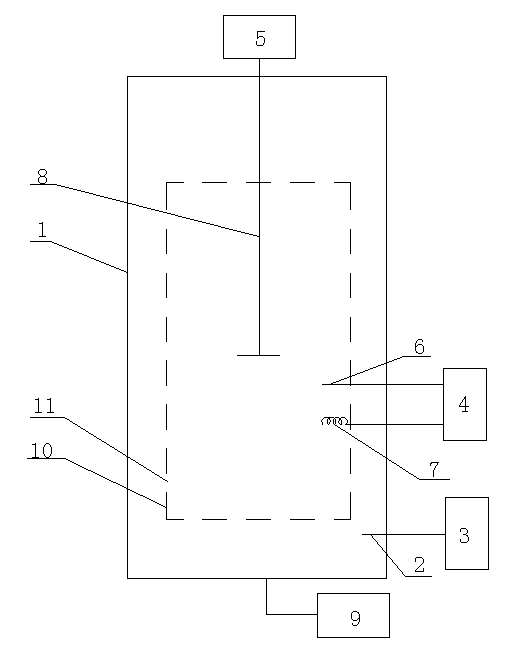

[0041] refer to figure 1 , a device for ultrasonically assisted extraction of seaweed polysaccharides, the device includes an extraction reactor 1, an ultrasonic generator 3, a temperature control device and a stirring device, and the extraction reactor 1 is provided with an extraction tube 10 for placing the extract , the extraction pipe 10 is concentrically located in the extraction reactor 1 .

[0042] The tube wall of the extraction tube 10 is provided with several through holes 11 around, the number of the ultrasonic generator 3 is 1, and the ultrasonic generator 3 is connected with the inner cavity of the extraction reactor 1 through the corresponding ultrasonic probe 2. The ultrasonic probe 2 is arranged on the bottom of the extraction reactor 1 and is located outside the extraction pipe 10; the temperature control device includes a temperature controller 4, a temperature sensing probe 6 and a serpentine heating tube 7, and the temperature sensing probe 6 and the serpen...

Embodiment 2

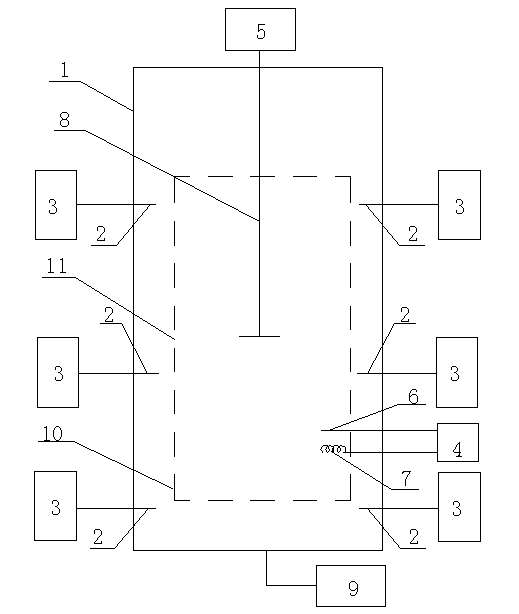

[0047] refer to figure 2 , a device for ultrasonically assisted extraction of seaweed polysaccharides, the device includes an extraction reactor 1, an ultrasonic generator 3, a temperature control device and a stirring device, and the extraction reactor 1 is provided with an extraction tube 10 for placing the extract , the extraction pipe 10 is concentrically located in the extraction reactor 1 .

[0048] The tube wall of the extraction tube 10 is provided with several through holes 11 around, the number of the ultrasonic generators 3 is 6, and each ultrasonic generator 3 is connected with the extraction reactor 1 through a corresponding ultrasonic probe 2, The ultrasonic probe 2 is evenly arranged in the extraction reactor 1 and is located outside the extraction pipe 10; the temperature control device includes a temperature controller 4, a temperature-sensing probe 6 and a serpentine heating tube 7, and the temperature-sensing probe 6 and the serpentine The heating pipes 7 ...

Embodiment 3

[0052] A method for extracting seaweed polysaccharides using the device described in Example 2, comprising the steps of:

[0053] (1) Crush the kelp, pass through a 60-mesh sieve, and place it in gauze to obtain the extract;

[0054] (2) Put the extract to be extracted in the extraction tube, add a certain volume of water to the extraction reactor, and use ultrasonic crushing to extract for a period of time to obtain the extract; wherein, the conditions in the extraction reactor are controlled as follows: the mass ratio of solid to liquid The ratio is 1:32, the ultrasonic frequency is 35kHz, the ultrasonic power is 145W, the extraction temperature is 55°C, and the extraction time is 23min;

[0055] (3) The extract is further centrifuged, concentrated, ethanol precipitated, and filtered to obtain seaweed crude polysaccharides; wherein, the centrifuged extract is concentrated to 1 / 5 of the original volume, and the volume ratio of the concentrate to ethanol is 1:3.7.

[0056] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com