High-elongation low-temperature-resistant special material for PP building formwork and preparation method of special material

A high elongation, building formwork technology, applied in the field of building formwork materials, can solve the problems of difficulty in preparing PP materials, low PP melt flow rate, low elongation, etc., achieving light weight and high recycling times , easy to shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

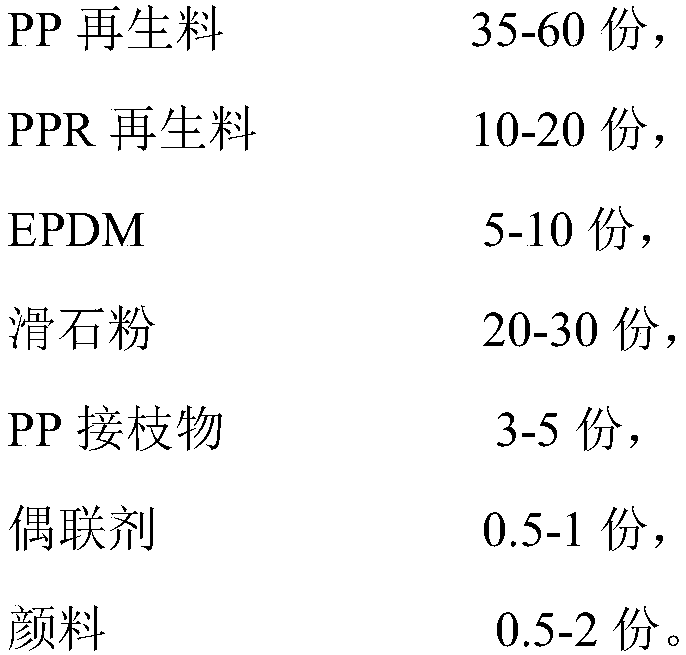

[0032] A high-elongation, low-temperature-resistant PP building formwork special material, comprising the following components in parts by weight:

[0033]

[0034] The PP regenerated material is composed of 25 parts by weight of PP battery shell regenerated material and 13 parts by weight of PP Wantong board regenerated material;

[0035] The particle size of the talc powder is 1250 mesh; the melt flow rate of the PPR recycled material is 1-2g / 10min, the elongation is ≧150%, and the EPDM is selected from Dow 4820P;

[0036]The graft rate of described PP graft is 0.8%, is prepared by the following method: earlier maleic anhydride (MAH) and dicumyl peroxide (DCP) are diluted together in acetone, and then with Maoming Petrochemical's Polypropylene K8003 (PP K8003) is mixed, wherein the mass ratio of polypropylene K8003 (PP K8003), maleic anhydride (MAH), dicumyl peroxide (DCP) is 92:2:0.5, and the extruder is heated up to After starting up normally at 190-210°C, lower the te...

Embodiment 2

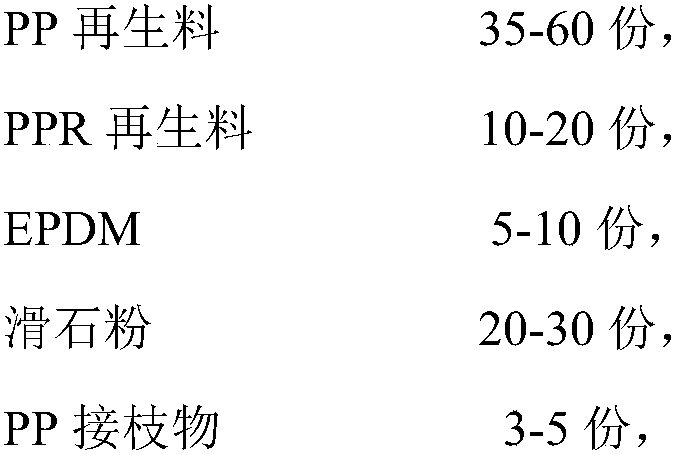

[0041] A high-elongation, low-temperature-resistant PP building formwork special material, comprising the following components in parts by weight:

[0042]

[0043] The PP regenerated material is composed of 30 parts by weight of PP battery shell regenerated material and 10 parts by weight of PP Wantong board regenerated material;

[0044] The particle size of the talc powder is 1250 mesh; the melt flow rate of the PPR recycled material is 1-2g / 10min, the elongation is ≧150%, and the EPDM is selected from Dow 4820P;

[0045] The graft rate of described PP graft is 0.8%, is prepared by the following method: earlier maleic anhydride (MAH) and dicumyl peroxide (DCP) are diluted together in acetone, and then with Maoming Petrochemical's Polypropylene K8003 (PP K8003) is mixed, wherein the mass ratio of polypropylene K8003 (PP K8003), maleic anhydride (MAH), dicumyl peroxide (DCP) is 92:2.5:0.6, and the extruder is heated up to After starting up normally at 190-210°C, lower the...

Embodiment 3

[0048] A high-elongation, low-temperature-resistant PP building formwork special material, comprising the following components in parts by weight:

[0049]

[0050] The PP regenerated material is composed of 30 parts by weight of PP battery shell regenerated material and 18 parts by weight of PP Wantong board regenerated material;

[0051] The particle size of the talc powder is 1250 mesh; the melt flow rate of the PPR recycled material is 1-2g / 10min, the elongation is ≧150%, and the EPDM is selected from Dow 4820P;

[0052] The graft rate of described PP graft is 0.8%, is prepared by the following method: earlier maleic anhydride (MAH) and dicumyl peroxide (DCP) are diluted together in acetone, and then with Maoming Petrochemical's Polypropylene K8003 (PP K8003) is mixed, wherein the mass ratio of polypropylene K8003 (PP K8003), maleic anhydride (MAH), dicumyl peroxide (DCP) is 98:3.5:0.8, and the extruder is heated up to After starting up normally at 190-210°C, lower the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com