3D printing assembled monolithic catalyst and preparation method thereof

A monolithic catalyst and 3D printing technology, which is applied in the direction of catalyst activation/preparation, oxidation reaction preparation, chemical instruments and methods, etc., can solve the problem that the scalability of the monolithic catalyst cannot be realized, the monolithic catalyst cannot be fixed, and the mechanical strength is insufficient and other issues, to achieve the effect of simple structure, easy design and manufacture, and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

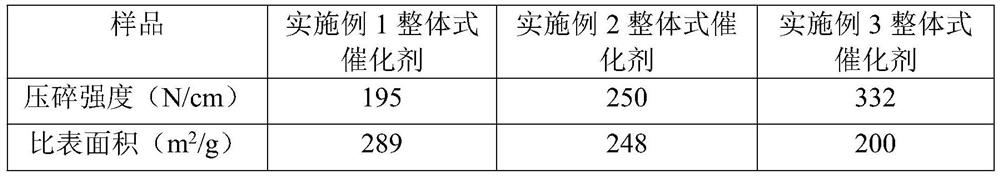

[0032] Embodiment 1, a kind of preparation method of 3D printing can assemble monolithic catalyst, comprises the following steps:

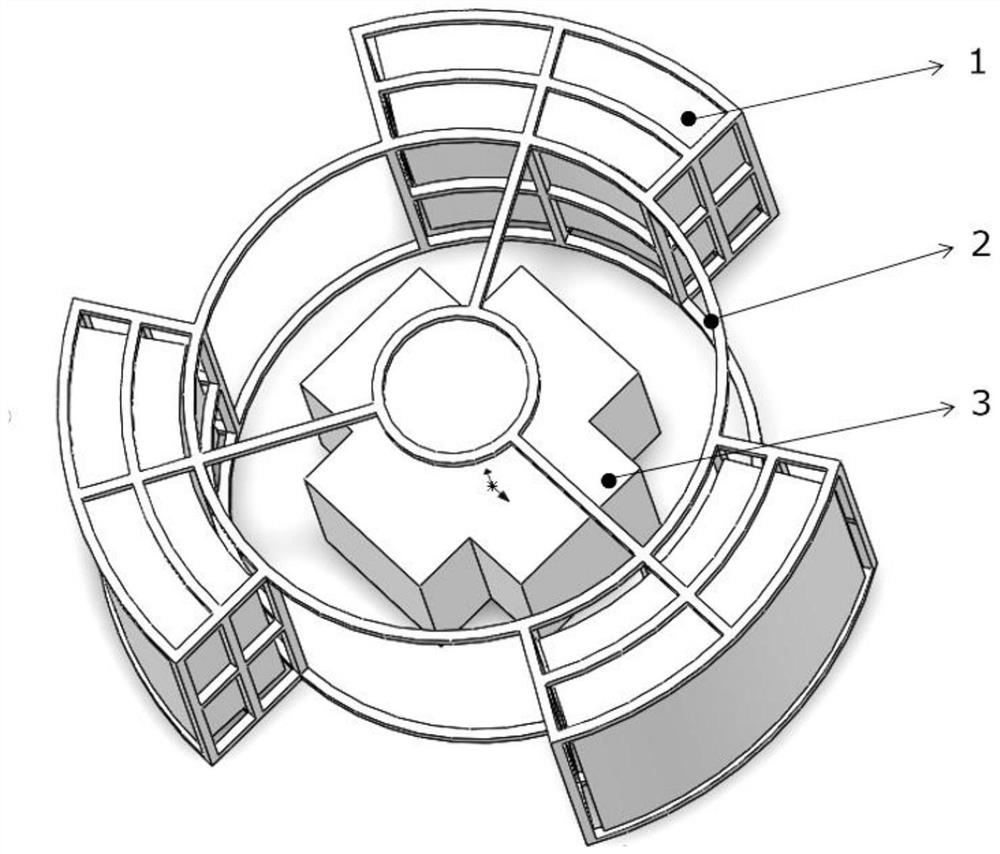

[0033] 1) According to the structure of the reactor, the cage-type catalyst protection frame 2 and the monolithic catalyst 1 are designed;

[0034] In this embodiment, a three-dimensional model of monolithic catalyst 1 is designed, and simulated by using Fluent to obtain monolithic catalyst 3 with optimal structure (mass transfer, heat transfer, conversion efficiency, etc.) under theoretical conditions;

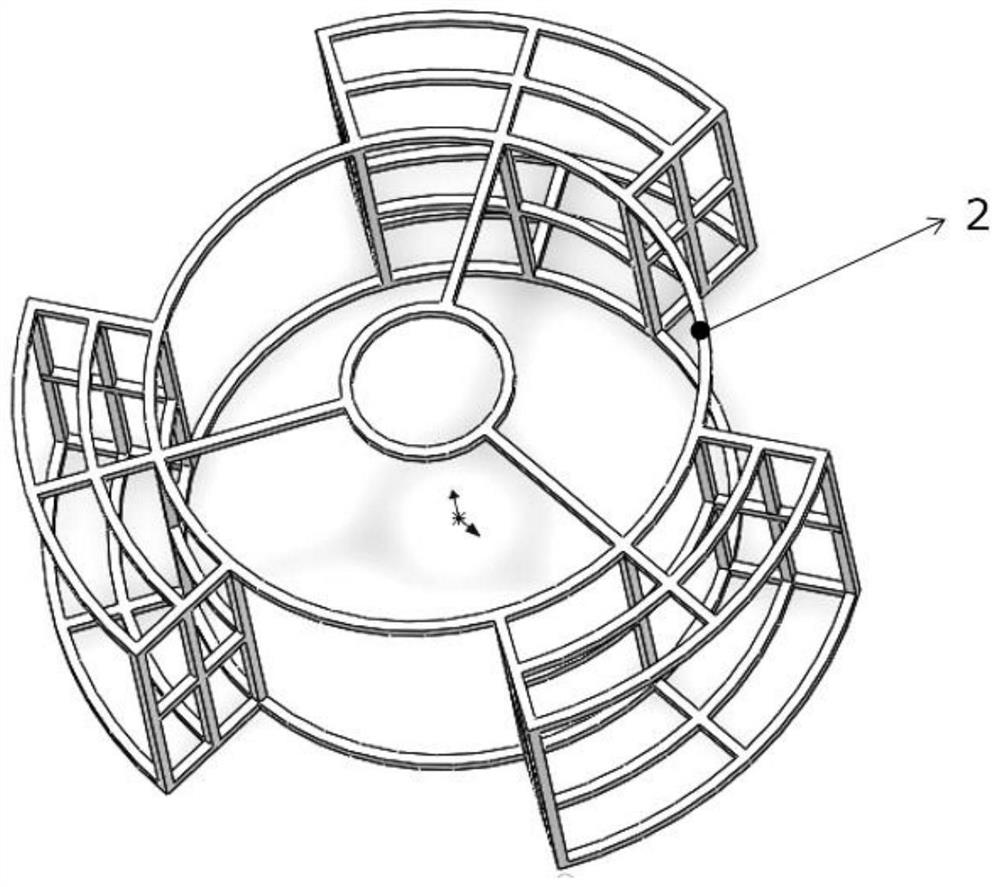

[0035] 2) Use powder bed fusion technology to 3D print cage catalyst protection frame 2;

[0036] 3) The catalytic active agent, ceramic carrier material, and auxiliary materials are mechanically stirred and mixed to form a catalyst 3D printing slurry, and the monolithic catalyst blank is 3D printed by direct writing molding equipment;

[0037] In this embodiment, the catalytic active agent takes 60g titanium silicon powder, the ceramic carrier ...

Embodiment 2

[0041] Embodiment 2, a kind of preparation method of 3D printing can assemble monolithic catalyst, comprises the following steps:

[0042] 1) According to the structure of the reactor, the cage-type catalyst protection frame 2 and the monolithic catalyst 1 are designed;

[0043] In this embodiment, a three-dimensional model of monolithic catalyst 1 is designed, and simulated by using Fluent to obtain monolithic catalyst 3 with optimal structure (mass transfer, heat transfer, conversion efficiency, etc.) under theoretical conditions;

[0044] 2) Use powder bed fusion technology to 3D print cage catalyst protection frame 2;

[0045] 3) Mechanically stir and mix the catalytic active agent, ceramic carrier material, and auxiliary materials into a catalyst 3D printing slurry, and 3D print the monolithic catalyst blank through a direct writing molding device;

[0046] In this embodiment, the catalytic active agent takes 45g titanium silicon powder, the ceramic carrier material is a...

Embodiment 3

[0050] Embodiment 3, a kind of preparation method of 3D printing can assemble monolithic catalyst, comprises the following steps:

[0051] 1) According to the structure of the reactor, the cage-type catalyst protection frame 2 and the monolithic catalyst 1 are designed;

[0052] In this embodiment, a three-dimensional model of monolithic catalyst 1 is designed, and simulated by using Fluent to obtain monolithic catalyst 3 with optimal structure (mass transfer, heat transfer, conversion efficiency, etc.) under theoretical conditions;

[0053] 2) Use powder bed fusion technology to 3D print cage catalyst protection frame 2;

[0054] 3) Mechanically stir and mix the catalytic active agent, ceramic carrier material, and auxiliary materials into a catalyst 3D printing slurry, and 3D print the monolithic catalyst blank through a direct writing molding device;

[0055] In this embodiment, the catalytic active agent takes 30g titanium silicon powder, the ceramic carrier material is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com