Normalized support system and construction method of weather-proof PVC (polyvinyl chloride) composite plastic template

A technology of composite plastics and support systems, which is applied to the preparation of formwork/formwork/work frame, formwork/formwork components, and building components on site. It can solve the problems of low turnover rate of plywood formwork, large wood consumption, and high labor costs. problems, to achieve the effect of avoiding drop damage, saving labor, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

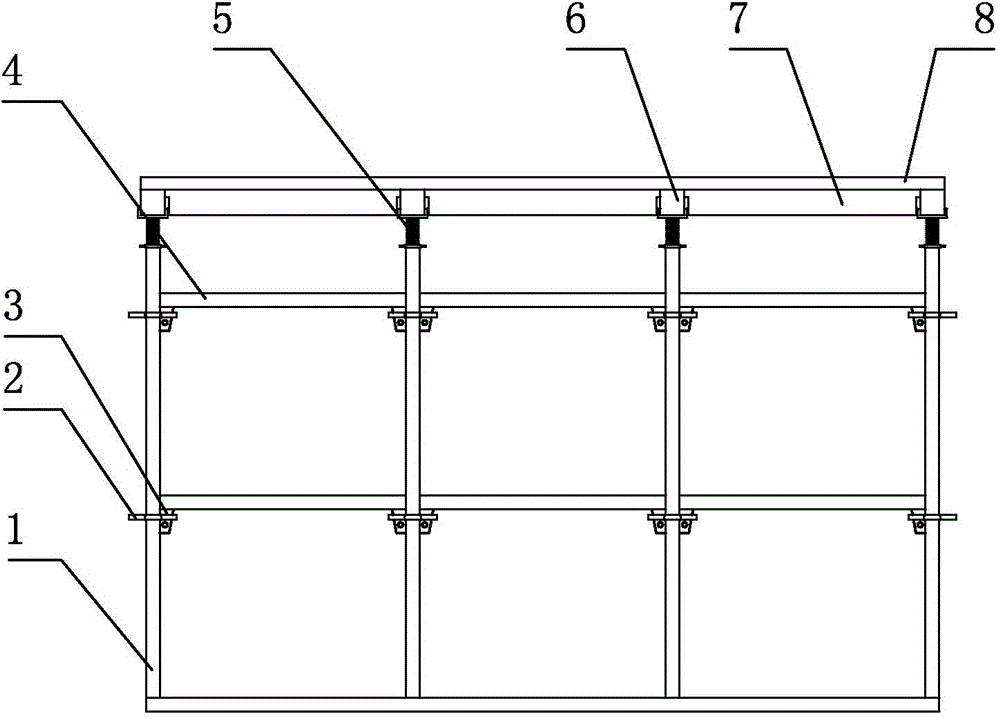

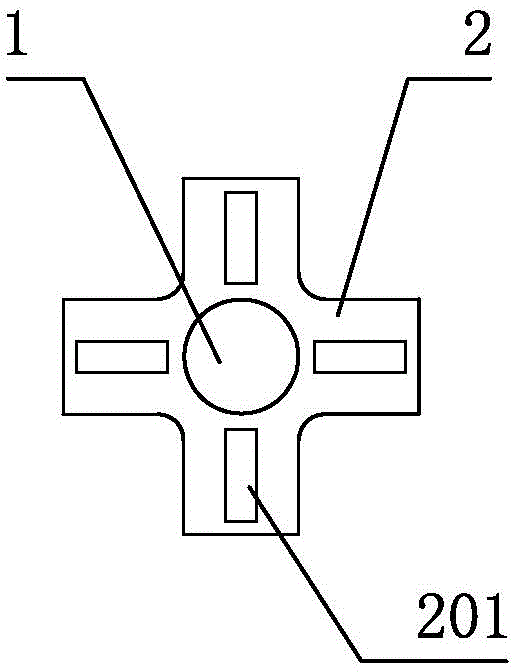

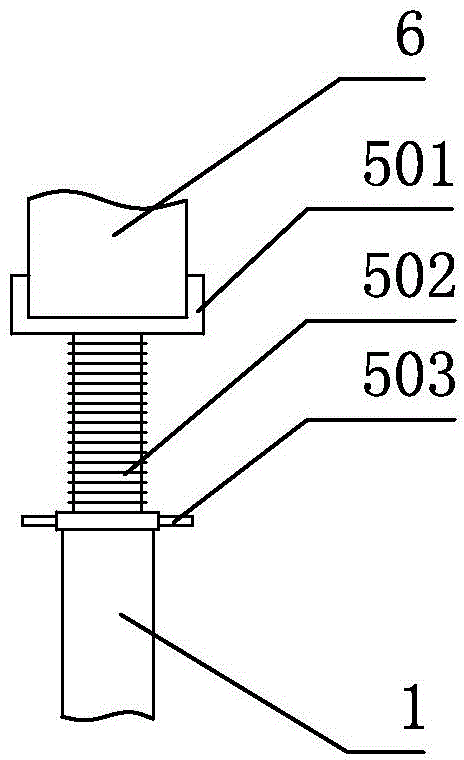

[0025] Such as Figure 1~4 As shown, the standardized support system of the weather-resistant PVC composite plastic formwork includes a vertical bar 1 and a horizontal bar 4. The vertical bars 1 are connected by the horizontal bar 4. Two adjacent uprights 1 are connected by independent crossbars 4. A connection seat 2 is provided on the uprights 1. The connection seat 2 is cross-shaped, the middle part of which is fixed on the upright 1, and its four claws are provided with Jack 201, cross bar 4 two ends are provided with claw 3, and claw 3 is wedge-shaped, and its side near the lower end is provided with threaded hole, is used for bolt fixing, and claw 3 cooperates to insert in the jack 201, along with the clip When the claw 3 is inserted, its wedge-shaped surface is clamped, and the vertical bar 1 and the horizontal bar 4 form a three-dimensional netw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com