Technology for disassembling negative rings of TBM (tunnel boring machine) arrival hole

A receiving hole and negative ring technology, which is applied in shaft lining, tunnel lining, underground chamber, etc., can solve the problem of large distance between the 7-ring negative ring segment and the surrounding rock wall, difficulty in removing the negative ring segment, and the need for hoisting and lifting Problems such as limited equipment, to achieve the effect of safe and reliable construction, fast construction speed and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

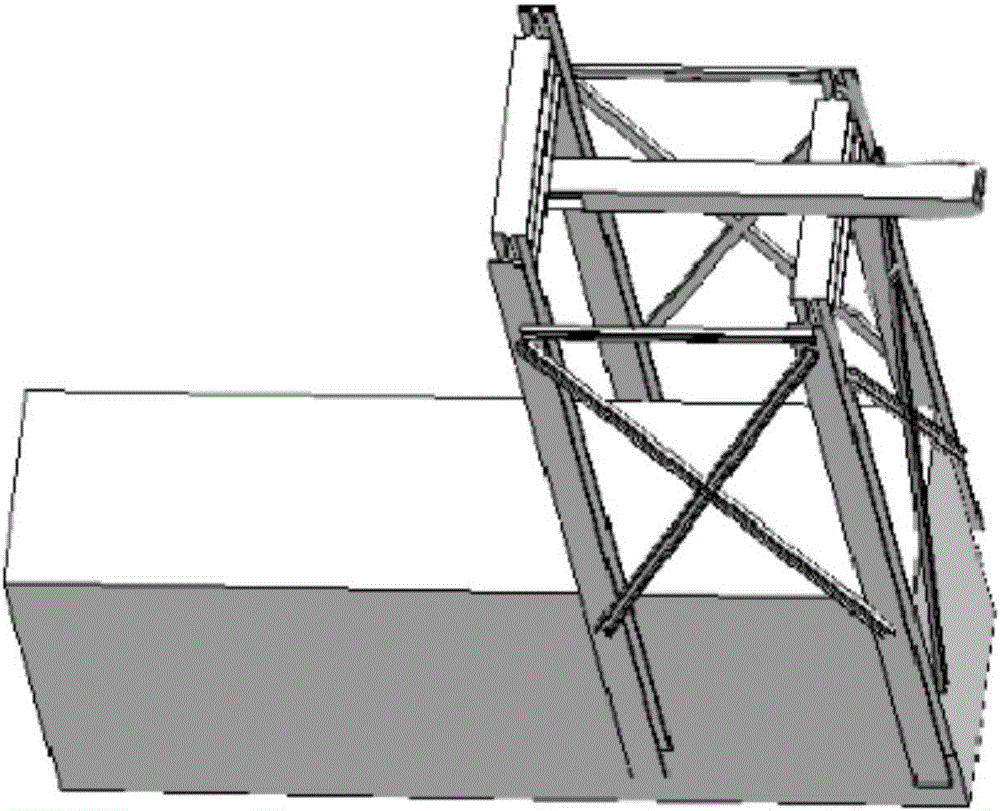

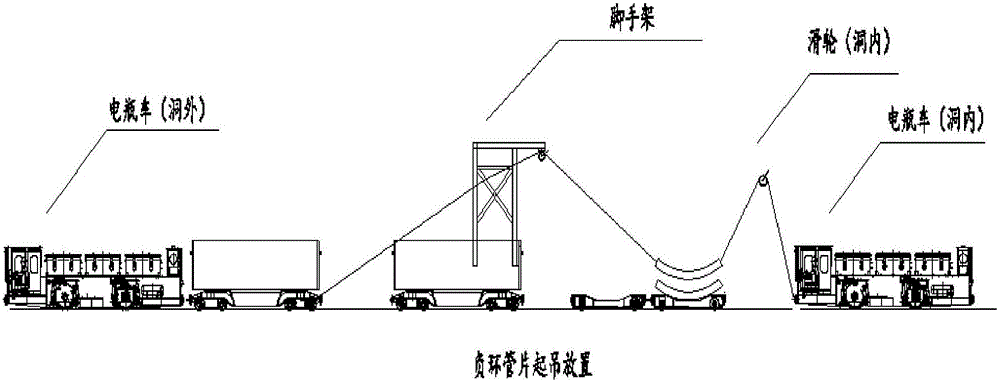

[0024] The slag box of the battery car is used as the movable base, the H-section steel beam and the channel steel are welded into a steel bracket, and the horizontally movable pulley is used as the hoisting point. The hoisting system simulates hoisting by a crane with the help of wire ropes, hoisting bolts, lifting lugs, bolts, and hoisting rings.

[0025] The slag box of the battery car must be filled with soil slag to increase its own weight and prevent the base from overturning and shaking.

[0026] This specific embodiment adopts technical scheme: its technological process:

[0027] 1. Preparatory work before removing the negative ring

[0028] 1. Clean up the work site before removing the negative ring:

[0029] (1) Before removing the negative ring segments, the electric wires, water pipes, and high-voltage cables within the starting area of the station should be removed or safely avoided to ensure that the work site is safe and controllable.

[0030] (2) Before rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com