Cellulose acetate-based nano-material composite ultrafiltration membrane and preparation method thereof

A cellulose acetate, nanomaterial technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problem of water flux decline of cellulose acetate ultrafiltration membrane, CA ultrafiltration membrane water flux decline, ultrafiltration membrane problems such as low porosity, to achieve the effect of improving water flux and anti-pollution ability, low price, and improving water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The halloysite nanotubes weighing 1.0g are dissolved in the Tris-HCl buffer solution of 200ml PH=8.8, ultrasonically dispersed for 0.5-1h, so that the halloysite nanotubes are uniformly dispersed; the dispersed halloysite nanotubes (i.e. HNTS) is put into a constant temperature water bath with magnetic stirring, the temperature of the water bath is 25-30°C, and the rotating speed is 250r / min-300r / min, slowly add 0.4g of levodopa (ie L -DOPA), the stirring time is 12-14h; after the reaction is completed, the halloysite of the load levodopa is centrifuged with a centrifuge, the rotating speed of the centrifuge is 10000r / min, and the centrifugation time is 45-60min; after the centrifugation, use a freeze dryer Removal of water yields levodopa-loaded halloysite nanotubes (ie, LPDHNTS).

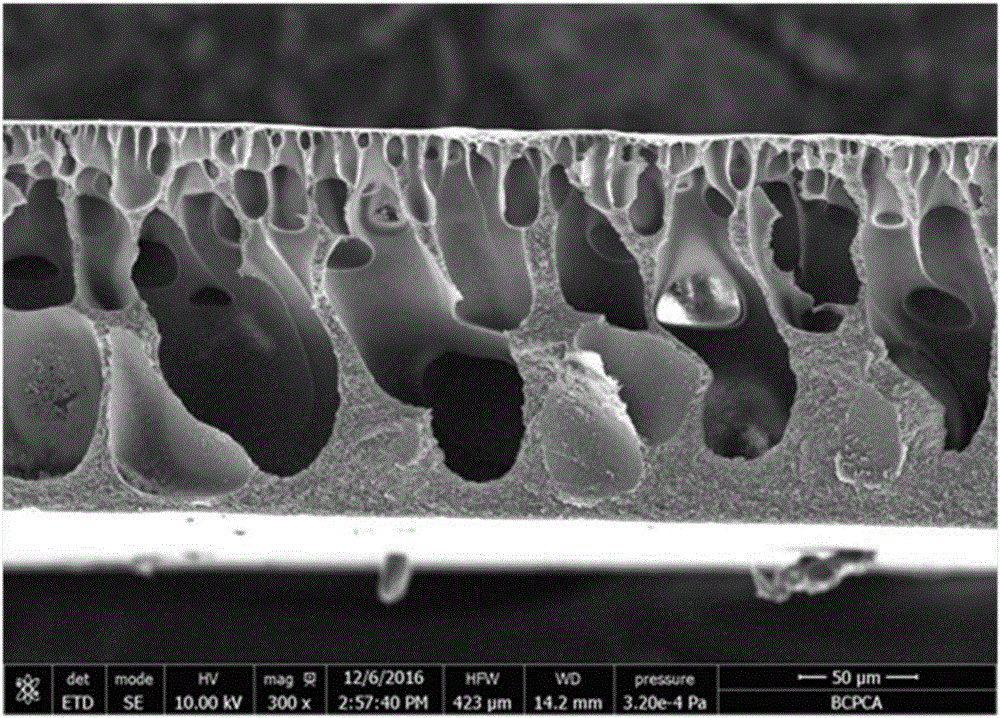

[0031]Weigh 0.03g of prepared LPDHNTS and dissolve in 16.40g of dimethylacetamide (i.e. DMAC), ultrasonically treat for 30min-45min to disperse LPDHNTS evenly, then add 3.00g of cellulose a...

Embodiment 2

[0036] The halloysite nanotubes weighing 1.0g are dissolved in the Tris-HCl buffer solution of 200ml PH=8.8, ultrasonically dispersed for 0.5-1h, so that the halloysite nanotubes are uniformly dispersed; the dispersed halloysite nanotubes (i.e. HNTS) is put into a constant temperature water bath with magnetic stirring, the temperature of the water bath is 25-30°C, and the rotating speed is 250r / min-300r / min, slowly add 0.4g of levodopa (ie L -DOPA), the stirring time is 12-14h; after the reaction is completed, the halloysite of the load levodopa is centrifuged with a centrifuge, the rotating speed of the centrifuge is 10000r / min, and the centrifugation time is 45-60min; after the centrifugation, use a freeze dryer Removal of water yields levodopa-loaded halloysite nanotubes (ie, LPDHNTS).

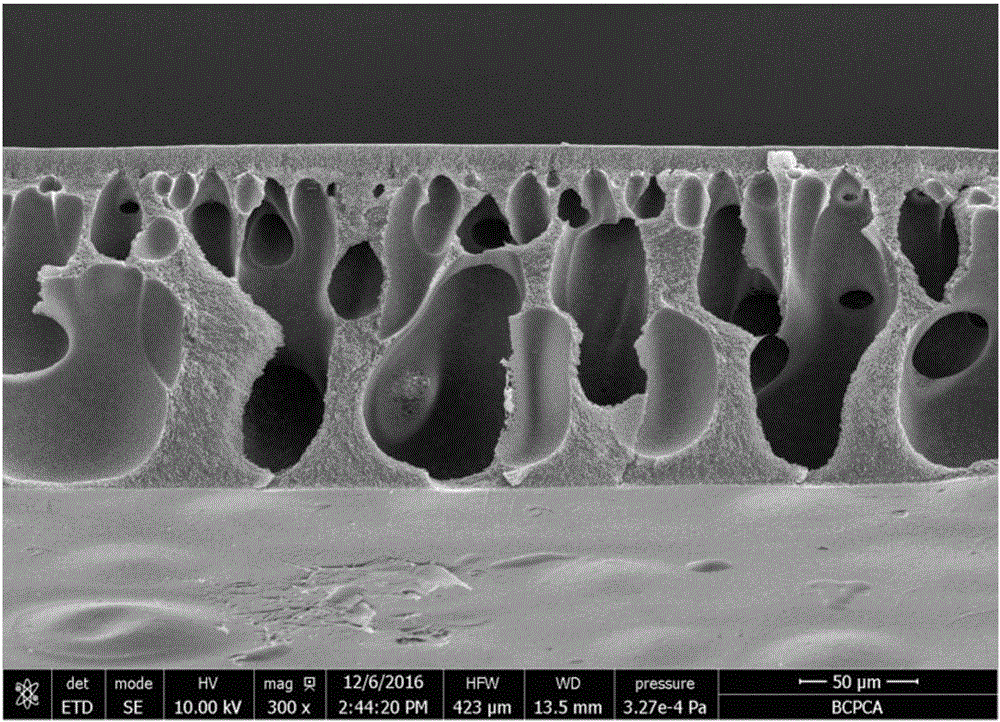

[0037] Weigh 0.06g of the prepared LPDHNTS and dissolve it in 16.40g of dimethylacetamide (i.e. DMAC), ultrasonically treat it for 30min-45min to disperse the LPDHNTS evenly, then add 3.00g...

Embodiment 3

[0042] The halloysite nanotubes weighing 1.0g are dissolved in the Tris-HCl buffer solution of 200ml PH=8.8, ultrasonically dispersed for 0.5-1h, so that the halloysite nanotubes are uniformly dispersed; the dispersed halloysite nanotubes (i.e. HNTS) is put into a constant temperature water bath with magnetic stirring, the temperature of the water bath is 25-30°C, and the rotating speed is 250r / min-300r / min, slowly add 0.4g of levodopa (ie L -DOPA), the stirring time is 12-14h; after the reaction is completed, the halloysite of the load levodopa is centrifuged with a centrifuge, the rotating speed of the centrifuge is 10000r / min, and the centrifugation time is 45-60min; after the centrifugation, use a freeze dryer Removal of water yields levodopa-loaded halloysite nanotubes (ie, LPDHNTS).

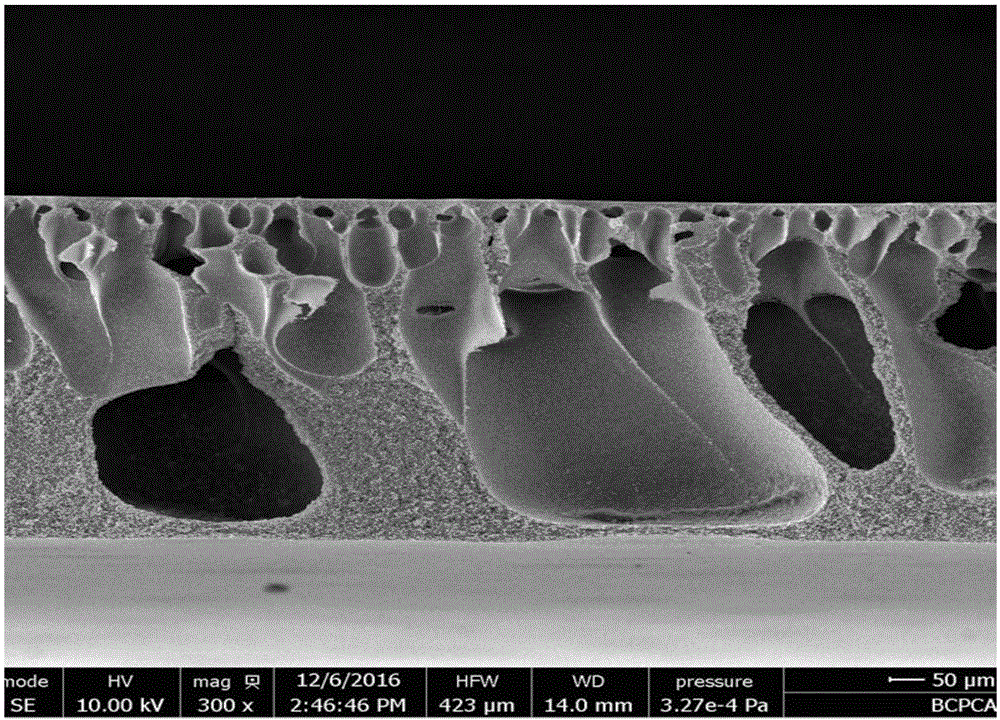

[0043] Weigh 0.09g of the prepared LPDHNTS and dissolve it in 16.40g of dimethylacetamide (i.e. DMAC), ultrasonically treat it for 30min-45min to disperse the LPDHNTS evenly, then add 3.00g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com