Hemodialysis membrane and preparation method thereof

A technology for hemodialysis and bath solution, applied in the field of hemodialysis membrane and its preparation, can solve the problems of complex process, performance degradation, loss of additives, etc., and achieve the effect of simple preparation method and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Hemodialysis membrane, which is prepared by the following method:

[0031] (1) Add 5g of bisphenol S-type polysulfate (molecular weight: 50kDa) into 28.3g of N-methylpyrrolidone solution, heat and stir at 80°C to dissolve, then let it stand in a drying oven at 60°C for defoaming to obtain a uniform and a casting solution with a solid content of 15%;

[0032] (2) Pour the film-casting liquid onto a clean and smooth glass plate, scrape the film with a scraper to coat evenly, and after 30 seconds of natural volatilization, immerse the glass plate in methanol for a coagulation bath, and continue to place the film after the film falls off automatically. Soak it in deionized water for 24 hours.

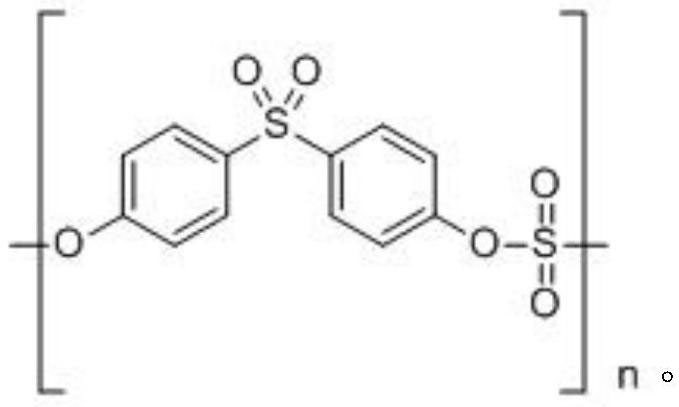

[0033] Wherein, the structural formula of bisphenol S type polysulfate is:

[0034]

[0035] After testing, the pure water flux of the hemodialysis membrane prepared in Example 1 is 232L m -2 h -1 · bar -1 , the contact angle is 52°, when separating and concentrating 1g / L bov...

Embodiment 2

[0037] Hemodialysis membrane, which is prepared by the following method:

[0038] (1) Add 5g of bisphenol S-type polysulfate (molecular weight: 70kDa) into 28.3g of N-methylpyrrolidone solution, heat and stir at 80°C to dissolve, then let it stand in a drying oven at 60°C for defoaming, and obtain a uniform and a casting solution with a solid content of 15%;

[0039] (2) Pour the film-casting liquid onto a clean and smooth glass plate, scrape the film with a scraper to coat evenly, and after 30 seconds of natural volatilization, immerse the glass plate in methanol for a coagulation bath, and continue to place the film after the film falls off automatically. Soak it in deionized water for 24 hours.

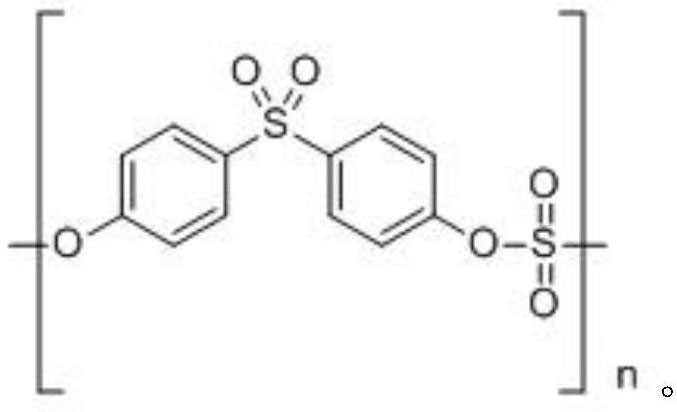

[0040] Wherein, the structural formula of bisphenol S type polysulfate is:

[0041]

[0042] After testing, the pure water flux of the hemodialysis membrane prepared in Example 2 is 262L m -2 h -1 · bar -1 , the contact angle is 54°, when separating and concentrating 1g / L b...

Embodiment 3

[0044] Hemodialysis membrane, which is prepared by the following method:

[0045] (1) Add 5g of bisphenol S-type polysulfate (molecular weight: 100kDa) into 28.3g of N-methylpyrrolidone solution, heat and stir at 80°C to dissolve, then let it stand in a drying oven at 60°C for defoaming to obtain a uniform and a casting solution with a solid content of 15%;

[0046] (2) Pour the film-casting liquid onto a clean and smooth glass plate, scrape the film evenly with a scraper, and after 30 seconds of natural volatilization, immerse the glass plate in methanol for a coagulation bath, and continue to place the film after the film falls off automatically. Soak it in deionized water for 24 hours.

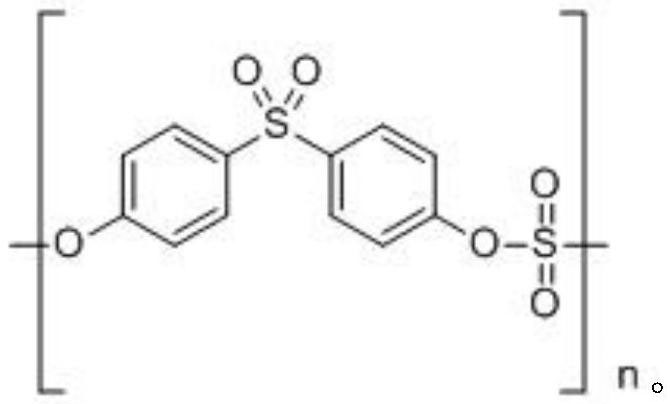

[0047] Wherein, the structural formula of bisphenol S type polysulfate is:

[0048]

[0049] After testing, the hemodialysis membrane membrane pure water flux that embodiment 3 makes is 285L m -2 h -1 · bar -1 , the contact angle is 58°, when separating and concentrating 1g / L bovine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com