Process for removing lactose in milk

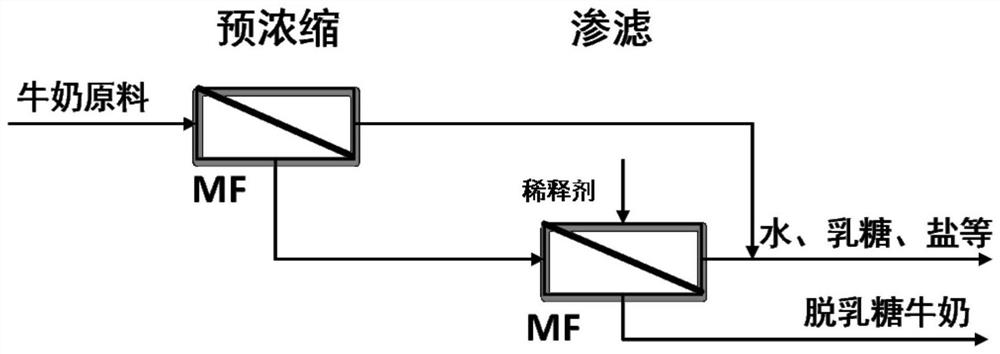

A technology for delactose and milk, applied in the field of membrane separation, can solve the problems of low protein/lactose separation factor and low flux, and achieve the effects of strong anti-biological pollution, high nutritional value, and high-temperature disinfection alleviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

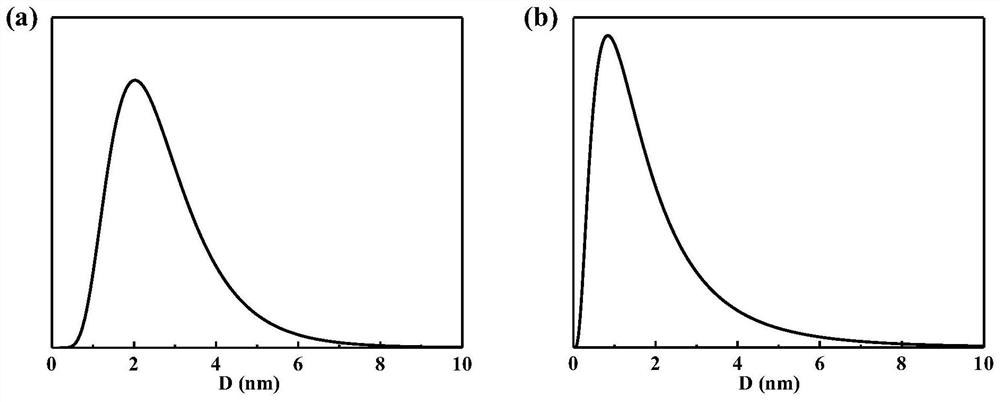

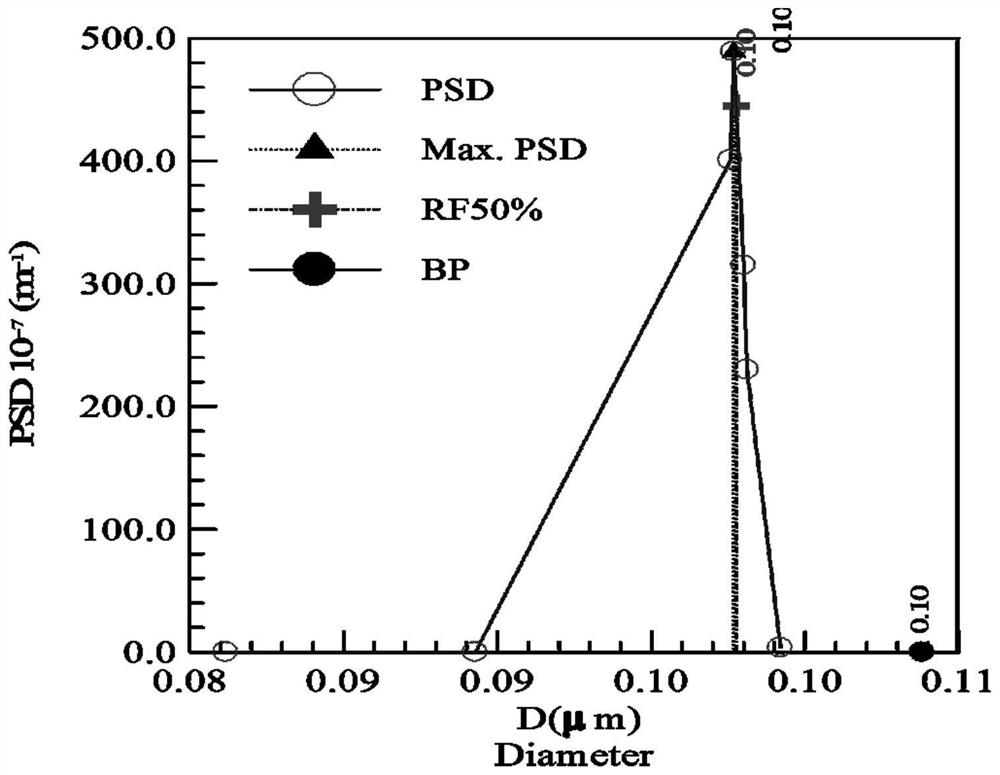

[0053] This example is used to compare the treatment effects of three different ceramic membranes on milk lactose. The three ceramic membranes used in this example are: Al with a pore size of ~5nm 2 o 3 and ZrO 2 Ultrafiltration membranes and Al with a pore size of ~100nm 2 o 3 microfiltration membrane.

[0054] Al in this patent 2 o 3 The number of pores in the ultrafiltration membrane within the pore diameter range of 1.3-4nm accounts for more than 80%.

[0055] ZrO in this patent 2 The number of pores in the ultrafiltration membrane in the range of 0.2-3nm pore diameter accounts for more than 80%.

[0056] The microfiltration membrane in this patent has more than 99% of the pores in the 94-104nm pore diameter range.

[0057] Put 10kg of skimmed milk raw material into the raw material tank, and use the above three ceramic membranes for pre-concentration, the pre-concentration factor is 2, the operating pressure is 2bar, the temperature is 30°C, and the membrane surf...

Embodiment 2

[0061] Add 10kg of skimmed milk raw material into the raw material tank, use 50nm ceramic microfiltration membrane for pre-concentration, the pre-concentration factor is 2, the operating pressure is 2bar, the temperature is 50°C, and the membrane surface flow rate is 6.5m·s -1 , to obtain 5kg of the first concentrated solution containing protein, calcium, part of lactose and 5kg of the first permeate containing lactose, small molecule vitamins, etc.; the first concentrated solution is carried out to constant volume intermittent feeding diafiltration, the operating pressure is 5bar, the temperature at 50°C, the flow velocity at the membrane surface is 6.5m·s -1 , first add 1 kg of water to the concentrated side, then concentrate the raw material side to 5 kg, perform the first diafiltration, repeat 9 times of diafiltration to obtain 5 kg of the second concentrate containing concentrated protein and calcium and 9 kg of lactose and small molecule vitamins The second permeate and ...

Embodiment 3

[0063] Add 10kg of skimmed milk raw material into the raw material tank, use 50nm ceramic microfiltration membrane for pre-concentration, the pre-concentration factor is 2, the operating pressure is 2bar, the temperature is 50°C, and the membrane surface flow rate is 6.5m·s -1 , to obtain 5kg of the first concentrated solution containing protein, calcium, part of lactose and 5kg of the first permeate containing lactose, small molecule vitamins, etc.; the first concentrated solution is carried out to constant volume intermittent feeding diafiltration, the operating pressure is 5bar, the temperature at 50°C, the flow velocity at the membrane surface is 6.5m·s -1 , first add 1 kg of water to the concentrated side, then concentrate the raw material side to 5 kg, perform the first diafiltration, and repeat the 2 times of diafiltration to obtain 5 kg of the second concentrate containing concentrated protein and calcium and 2 kg of lactose and small molecule vitamins. The second perm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size range | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com