Patents

Literature

34 results about "Lactose free milk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

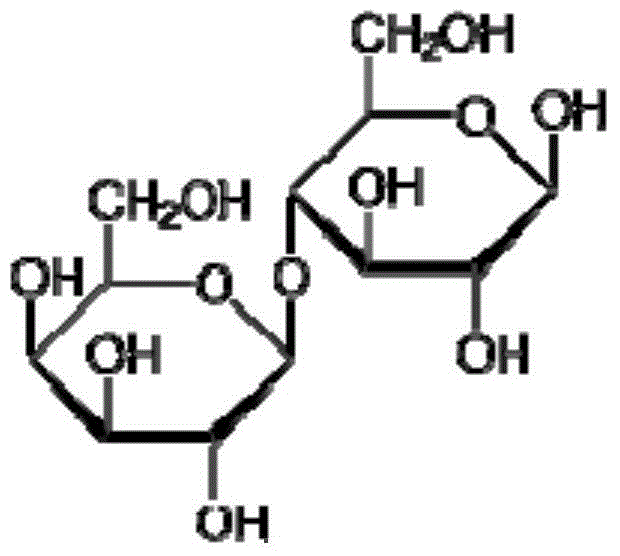

Lactose-free milk is a commercial milk product that is free of lactose. Lactose is a type of sugar found in milk products that can be difficult for some people to digest (1).

Process for producing a lactose-free milk product

ActiveUS20050214409A1Easy to processRetention characteristicMilk preparationOther dairy technologyLactose free milkUltrafiltration

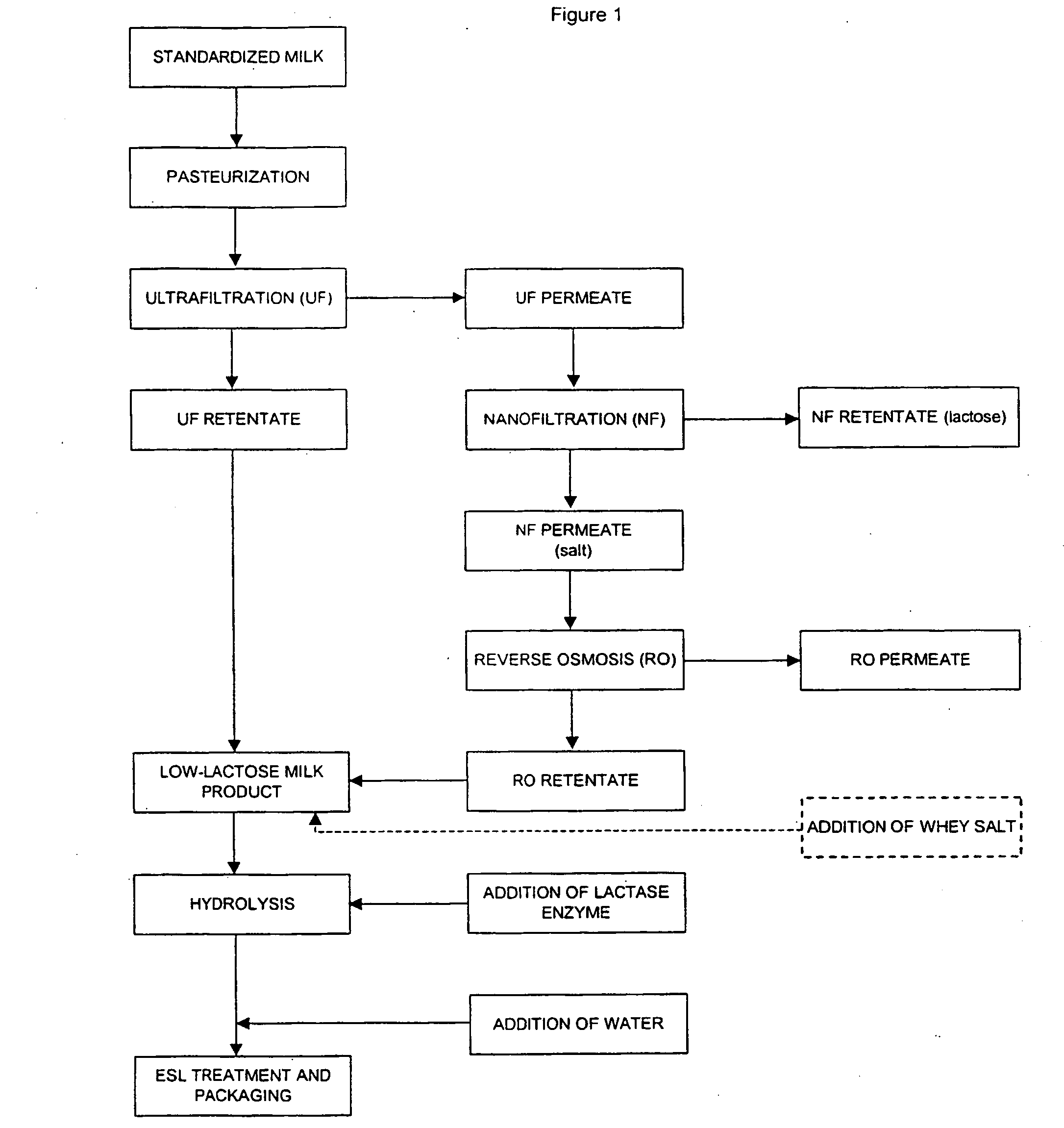

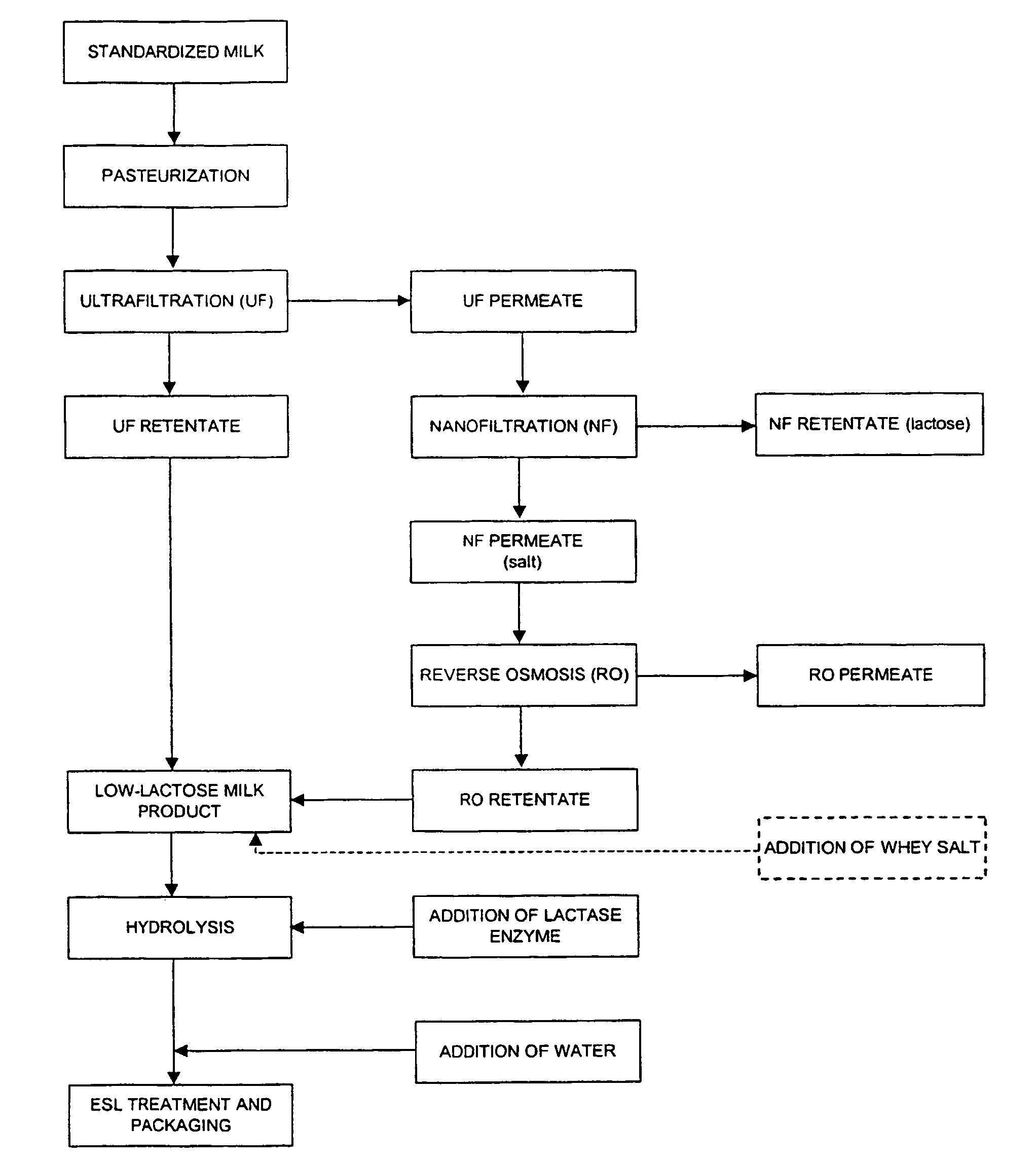

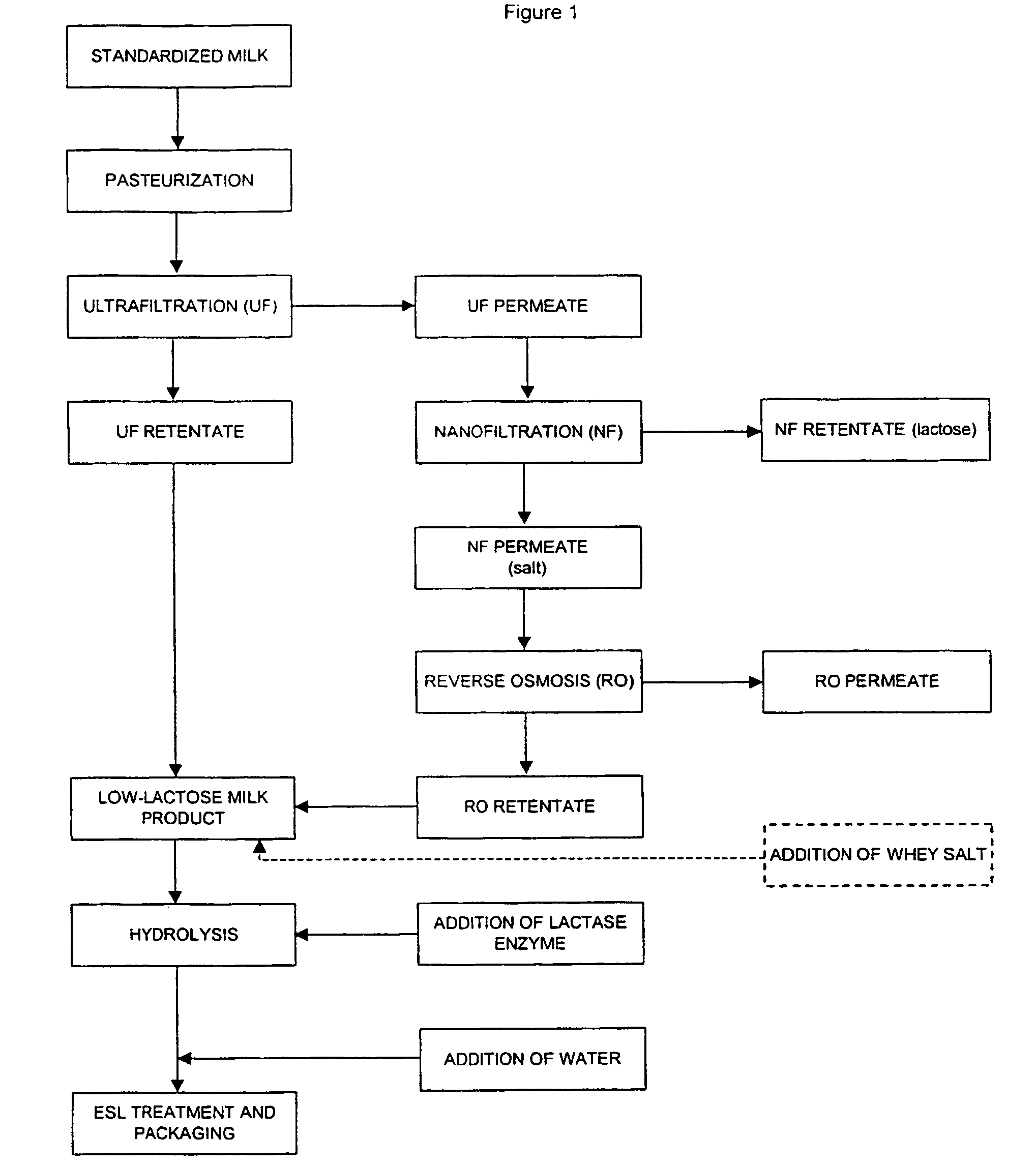

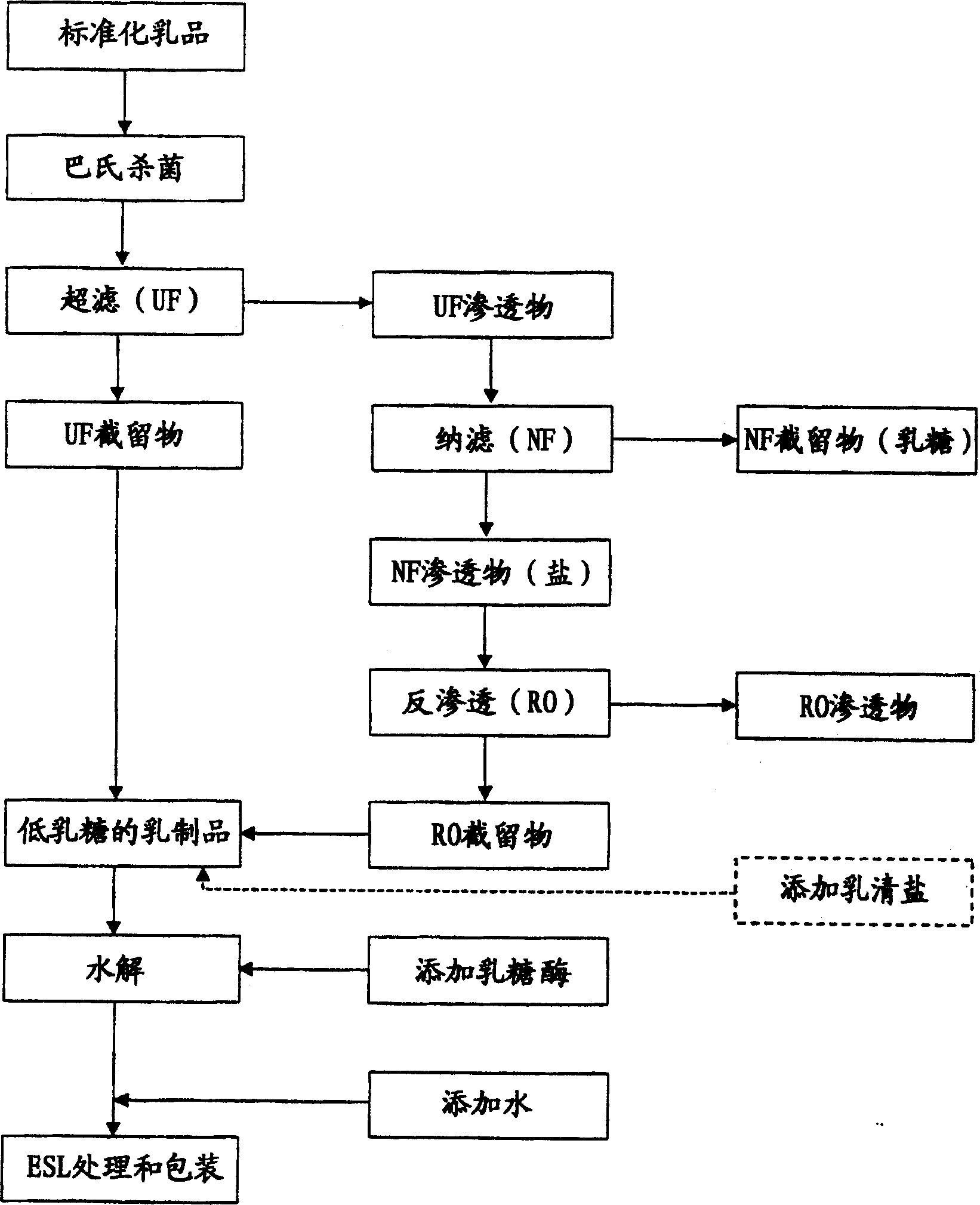

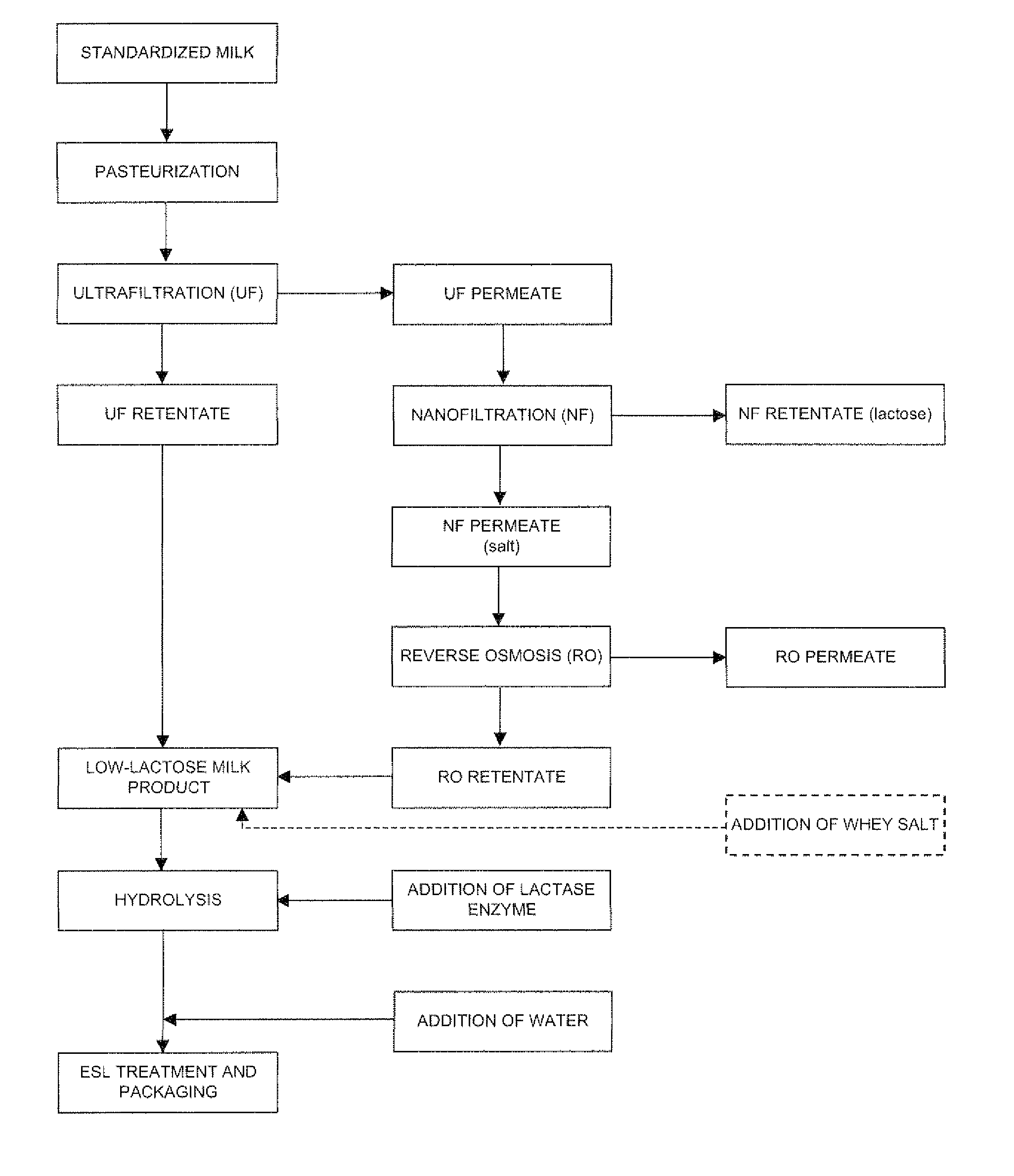

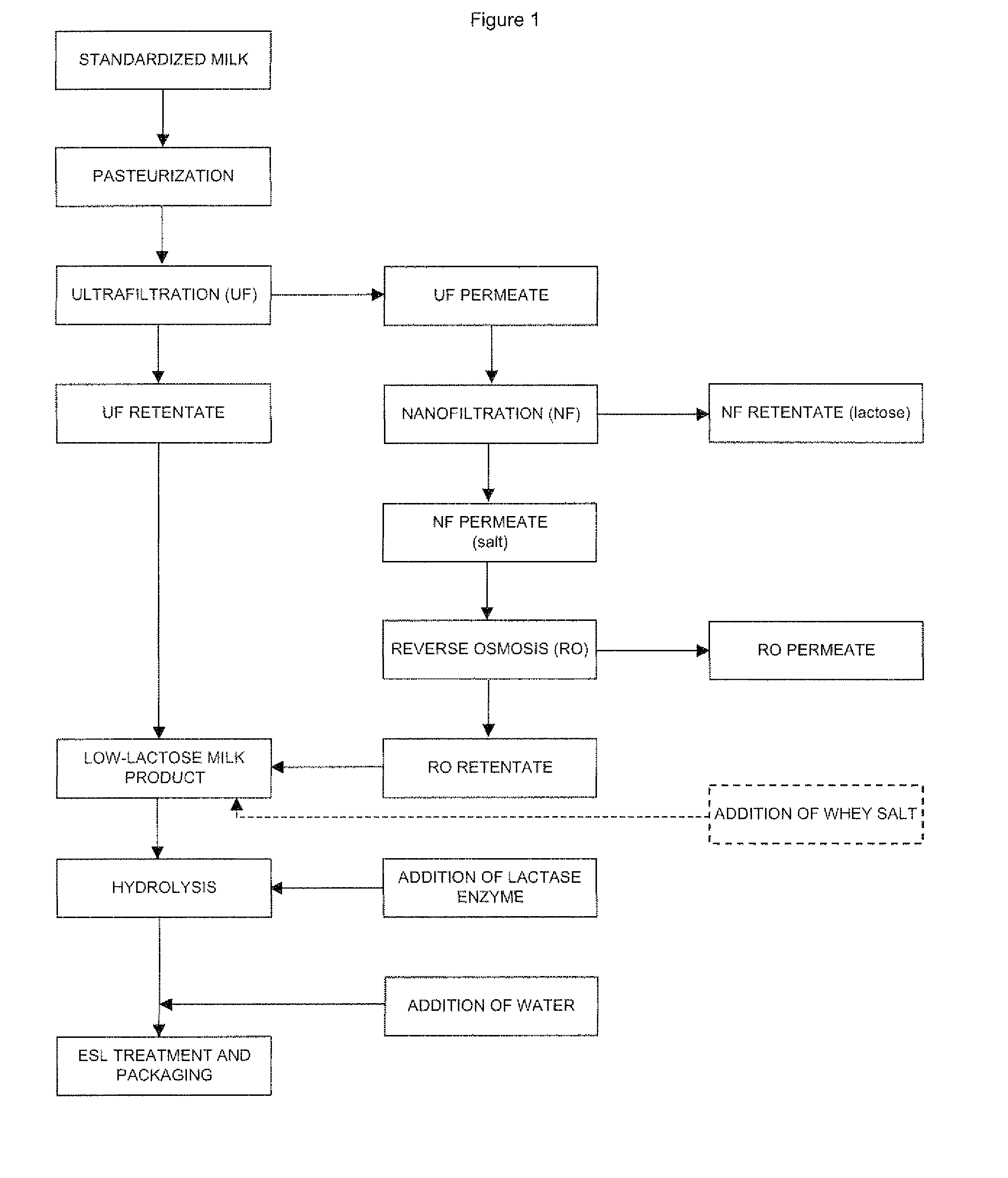

The invention relates to a process for producing lactose-free milk products. The process of the invention is characterized by the steps of subjecting a milk product to ultrafiltration (UF), nonfiltration (NF) and concentration by reverse osmosis, followed by the addition of salt to the UF retentate.

Owner:FAIRLIFE LLC

Process for making a lactose-free milk and milk so processed

InactiveUS6881428B2Affecting tasteLactose is reduced or substantially eliminated from milkMilk preparationWort preparationBiotechnologyLactose free milk

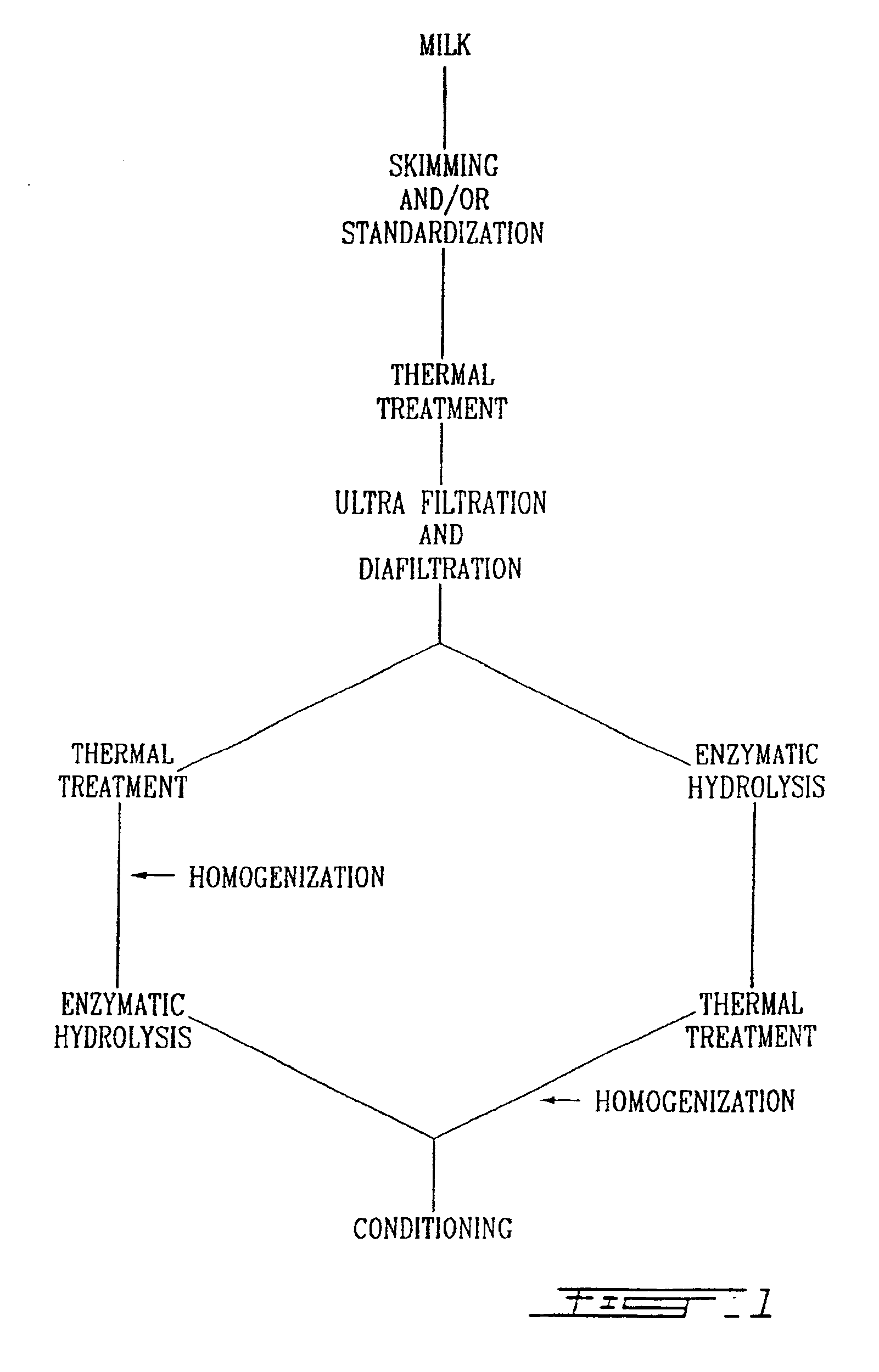

This invention relates to a process for producing a lactose-free milk which does not confer a sweet taste to the milk normally resulting from the hydrolysis of lactose into monosaccharides. The process comprises the step of reducing the lactose content of the milk to about 3% prior to hydrolysis with lactase. When the milk is skimmed milk, the protein content may be increased to about 3.8-4.0% or greater, which further improves the organoleptic properties of the milk. Milk so processed and dairy products derived therefrom are also disclosed and claimed.

Owner:AGROPUR COOP

Process for producing a lactose-free milk product

ActiveUS7829130B2Organoleptic characteristics of the milk product are retainedEasy to processMilk preparationOther dairy technologyLactose free milkUltrafiltration

Owner:FAIRLIFE LLC

Low-lactose and lactose-free milk product and process for production thereof

ActiveUS20100055286A1Need becomes problemNeed can be separatedMilk preparationOther dairy technologyLactose free milkSugar

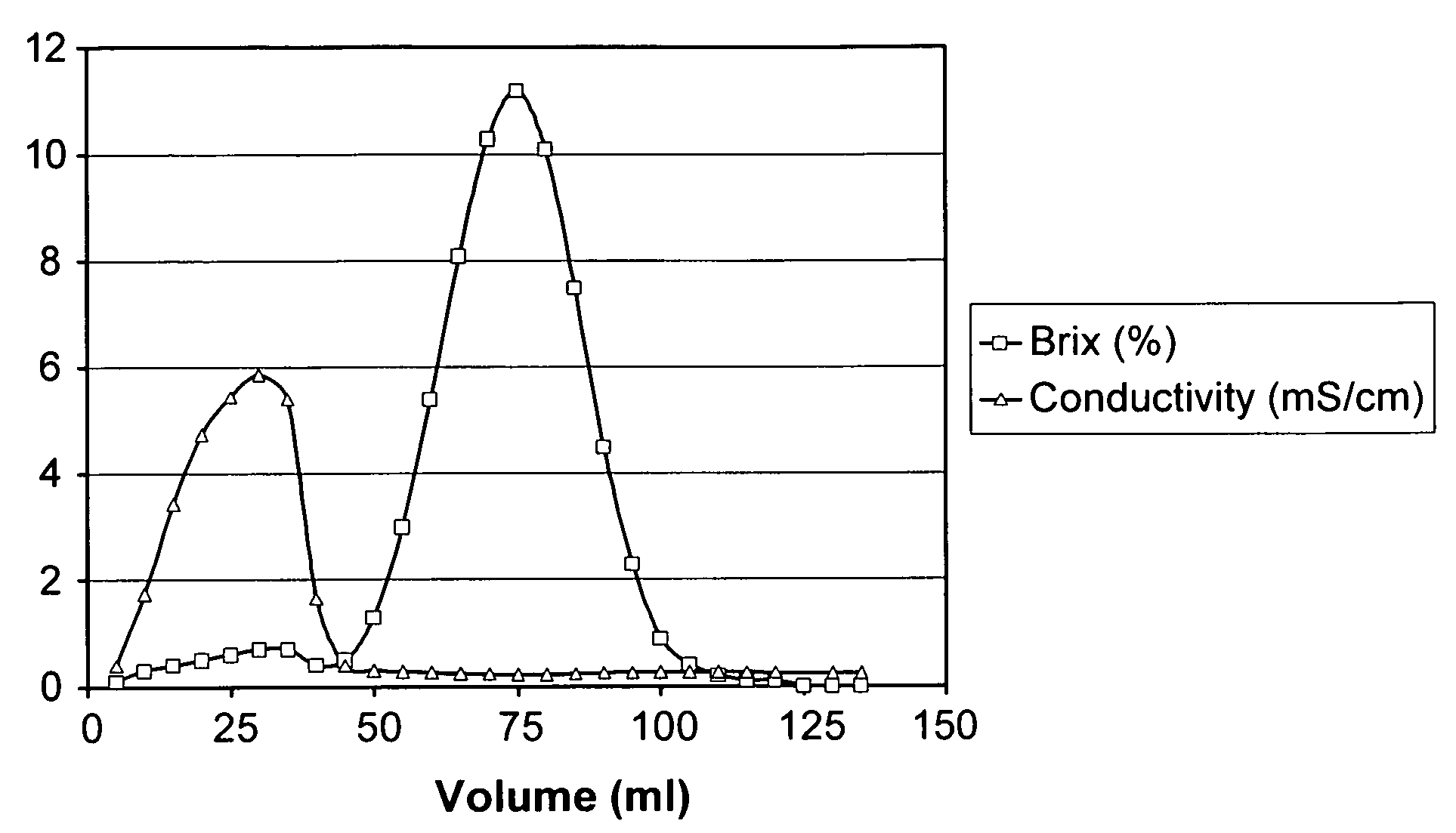

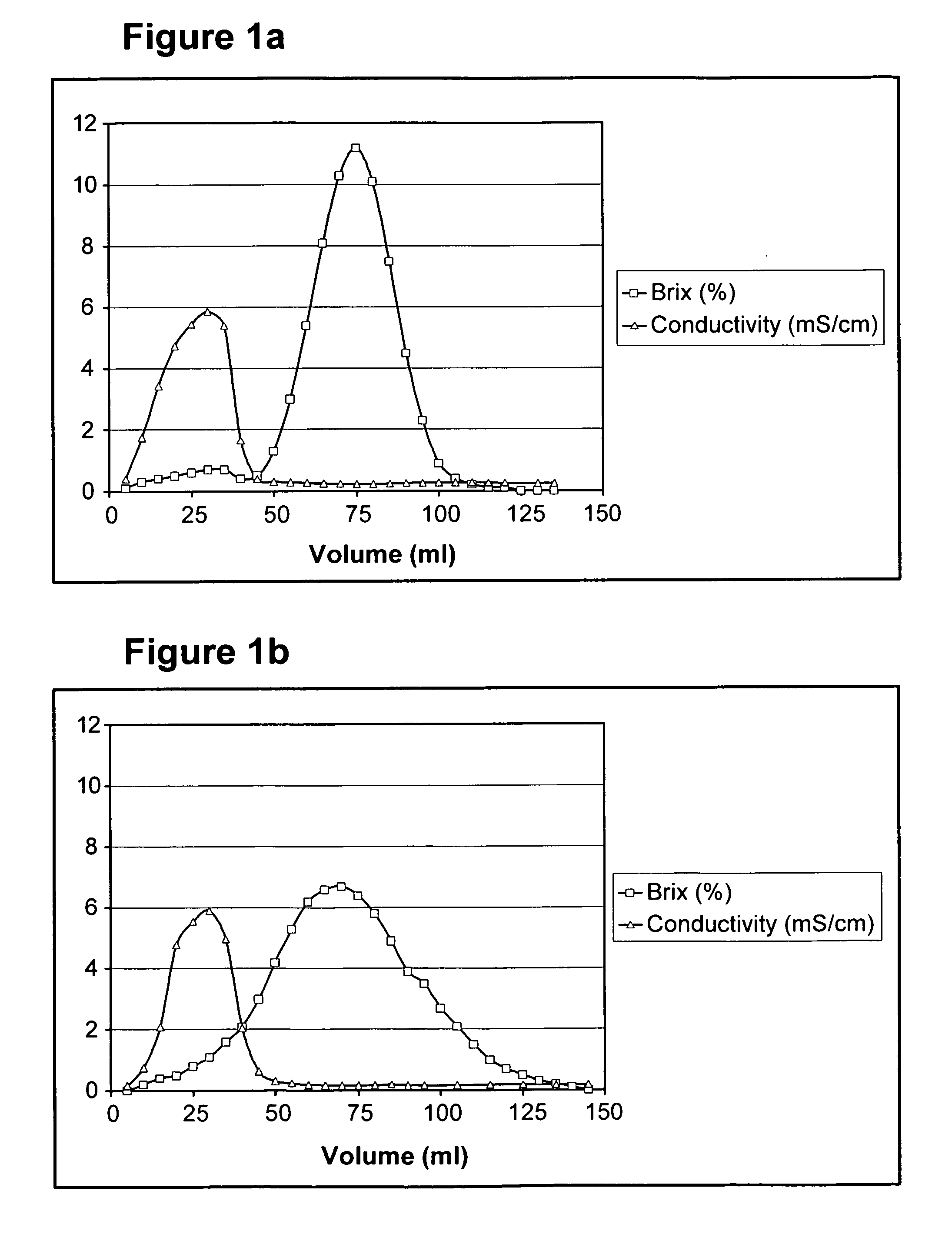

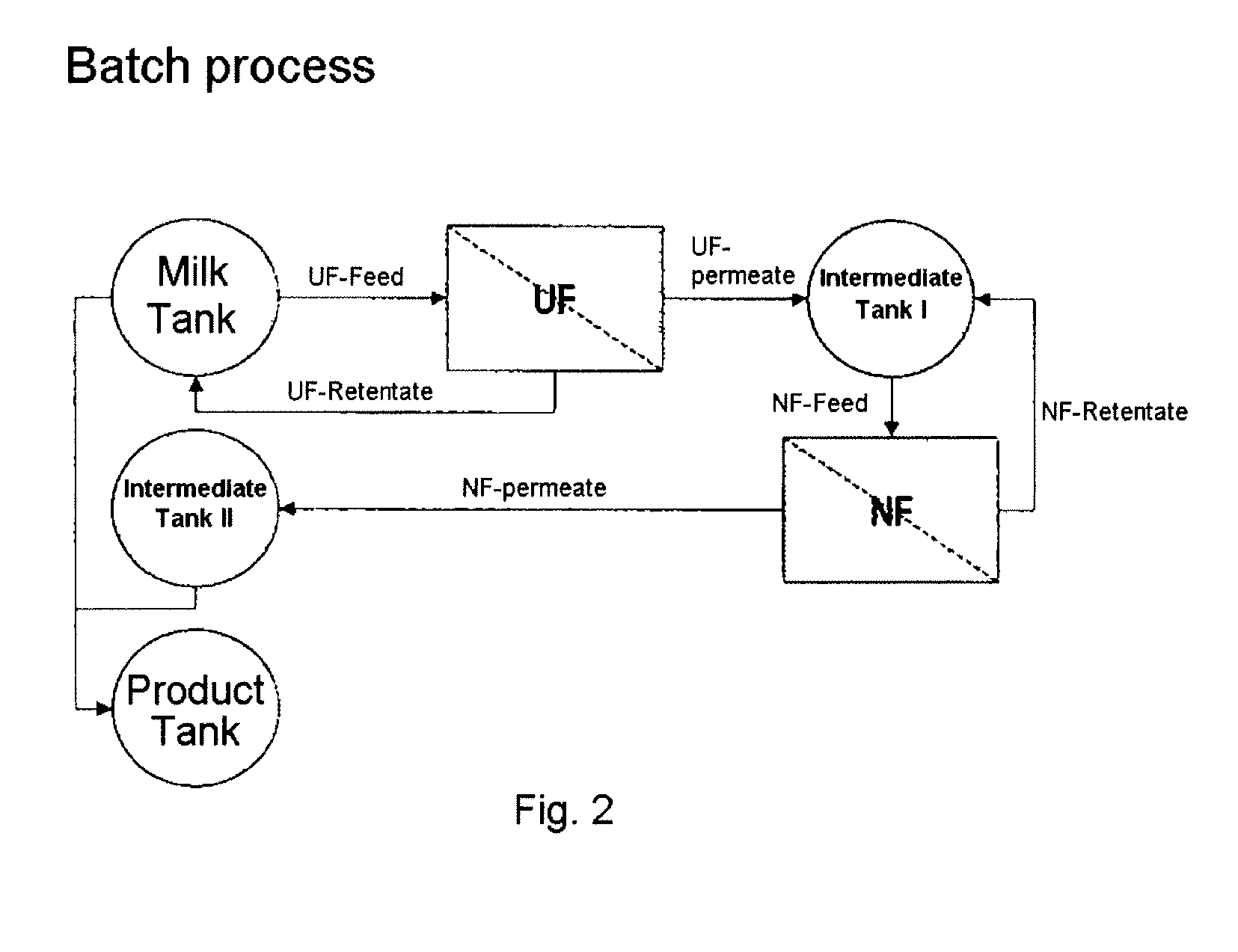

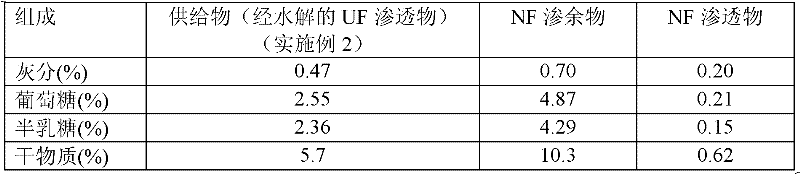

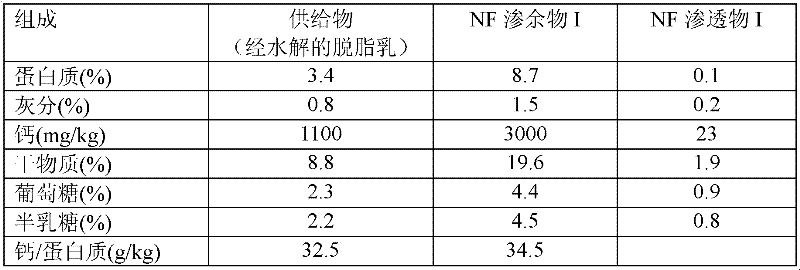

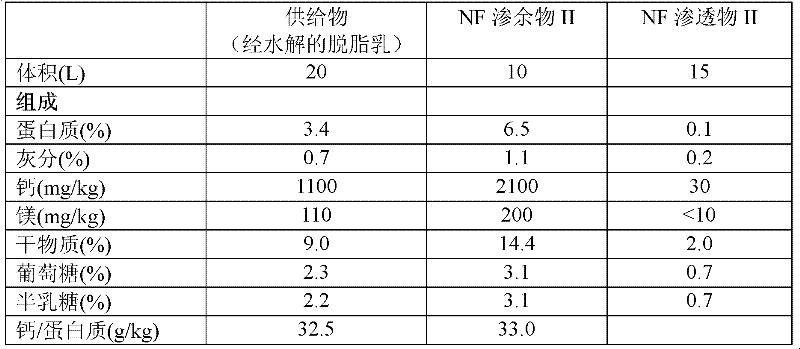

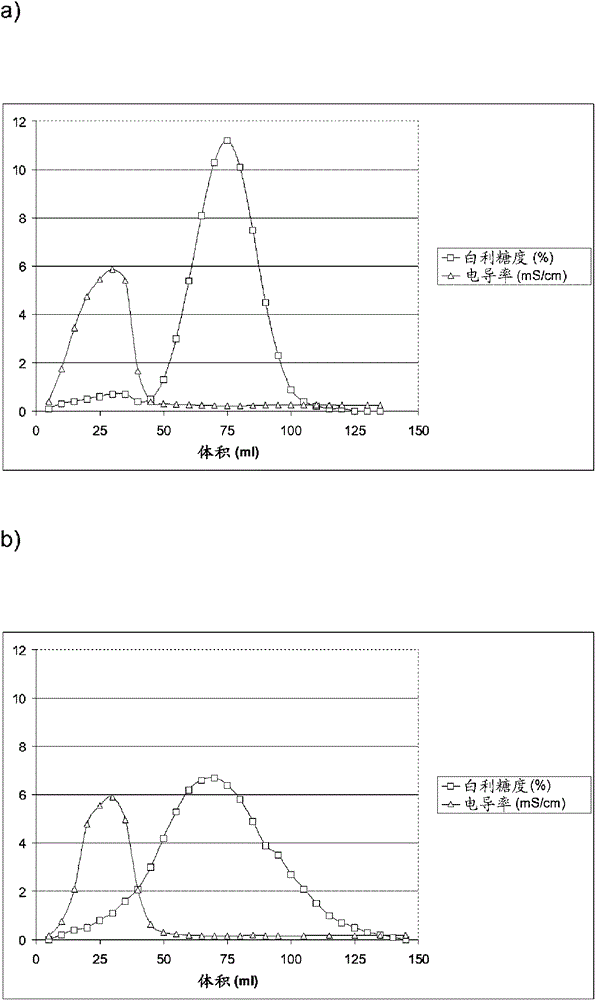

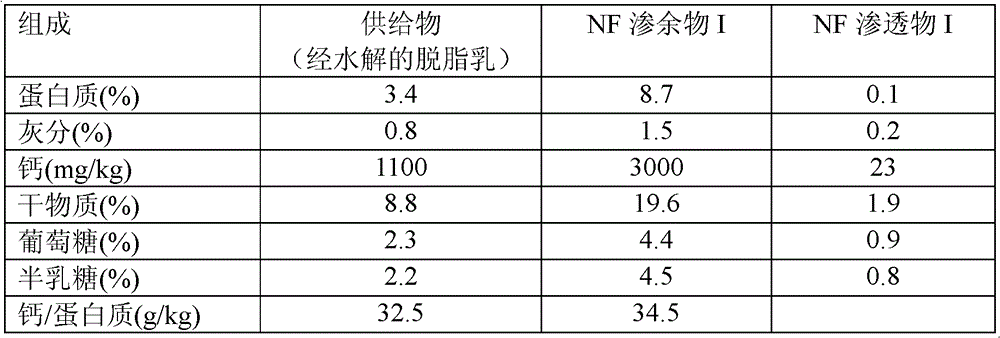

The invention relates to a low-lactose and a lactose-free milk product and to a process for the production thereof. The lactose in the milk raw material is hydrolyzed, proteins, minerals and sugars are separated into different fractions by the membrane technique, and a low-lactose or a lactose-free milk product is composed from the fractions. The invention provides a milk product, the water therein originating from the original milk raw material. In addition, useful by-products are produced in the process.

Owner:VALIO LTD

Low-lactose and lactose-free milk product and process for production thereof

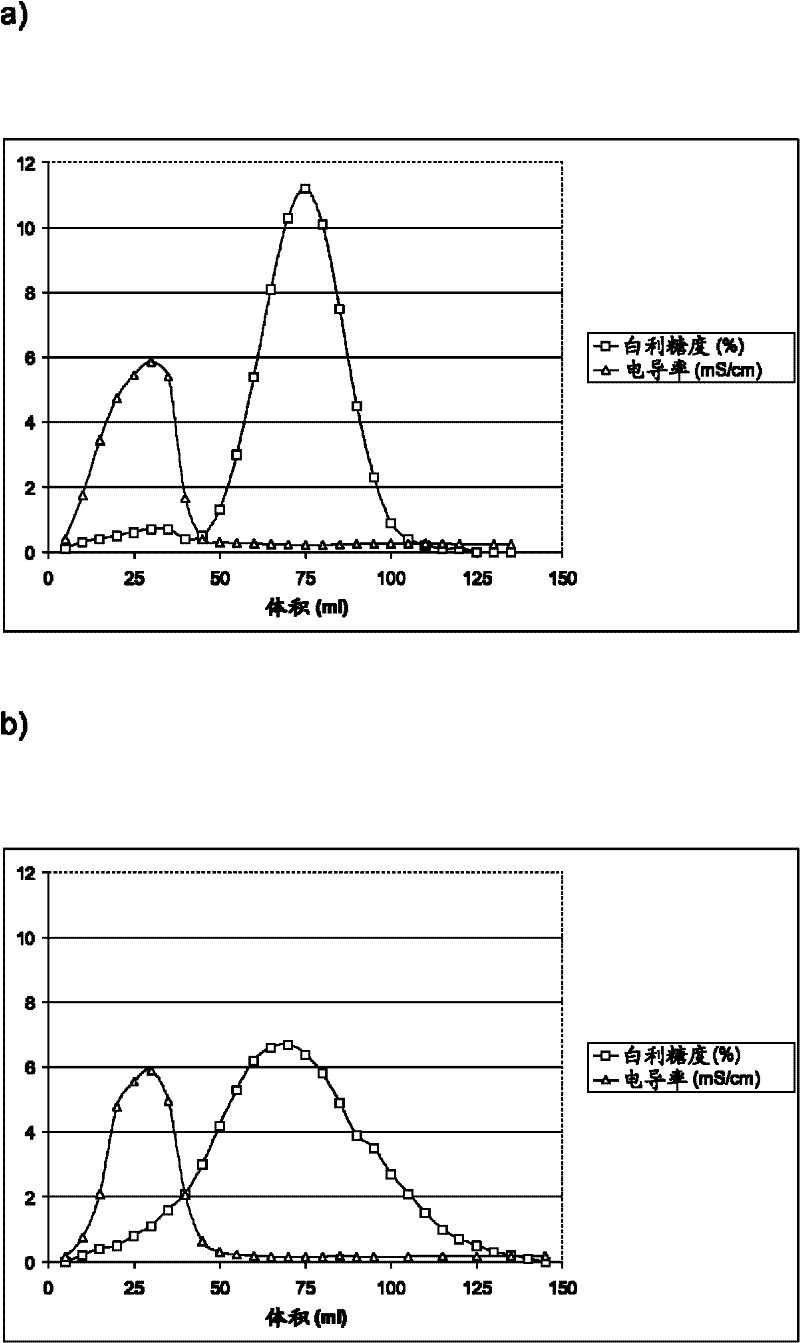

The invention relates to a process for separating milk components, wherein proteins, sugars and minerals are separated into different fractions. The lactose of milk is first hydrolyzed completely or partially, after which proteins, minerals and sugars are separated into fractions in a phased nanofiltration. The obtained fractions may also be further processed by chromatography, membrane techniques, and / or evaporation to further improve the separation of said components. The invention also relates to a low-lactose or lactose-free milk composed of these fractions. By means of the invention, calcium and protein losses can be minimized. Also, the energy content of the product can be reduced.

Owner:VALIO LTD

Process for producing a lactose-free milk product

InactiveCN1652690ACan maintain sensory propertiesEasy to processMilk preparationLactose free milkUltrafiltration

The invention relates to a process for producing lactose-free milk products. The process of the invention is characterized by the steps of subjecting a milk product to ultrafiltration (UF), nonfiltration (NF) and concentration by reverse osmosis, followed by the addition of salt to the UF retentate.

Owner:VALIO LTD

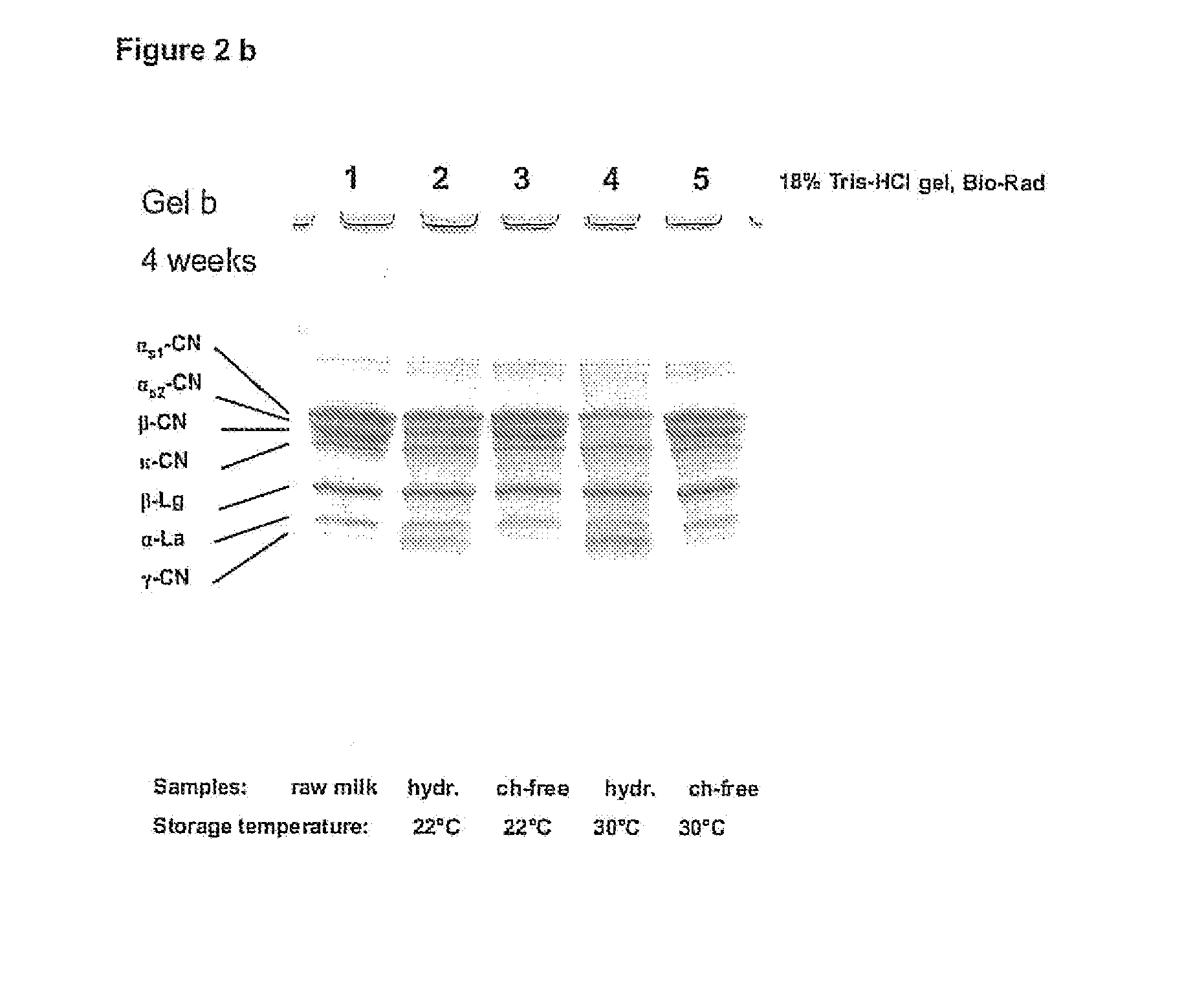

Process for producing well-preserving low-lactose or lactose-free milk product

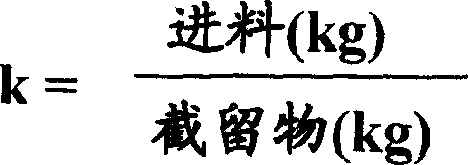

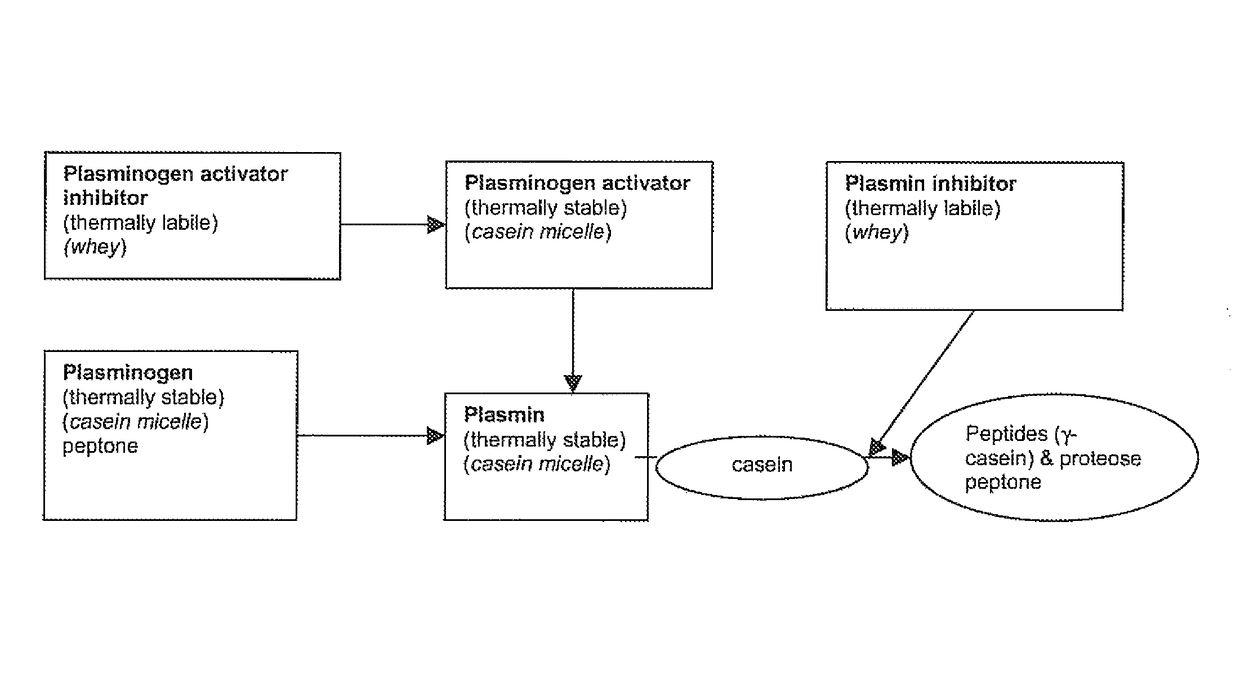

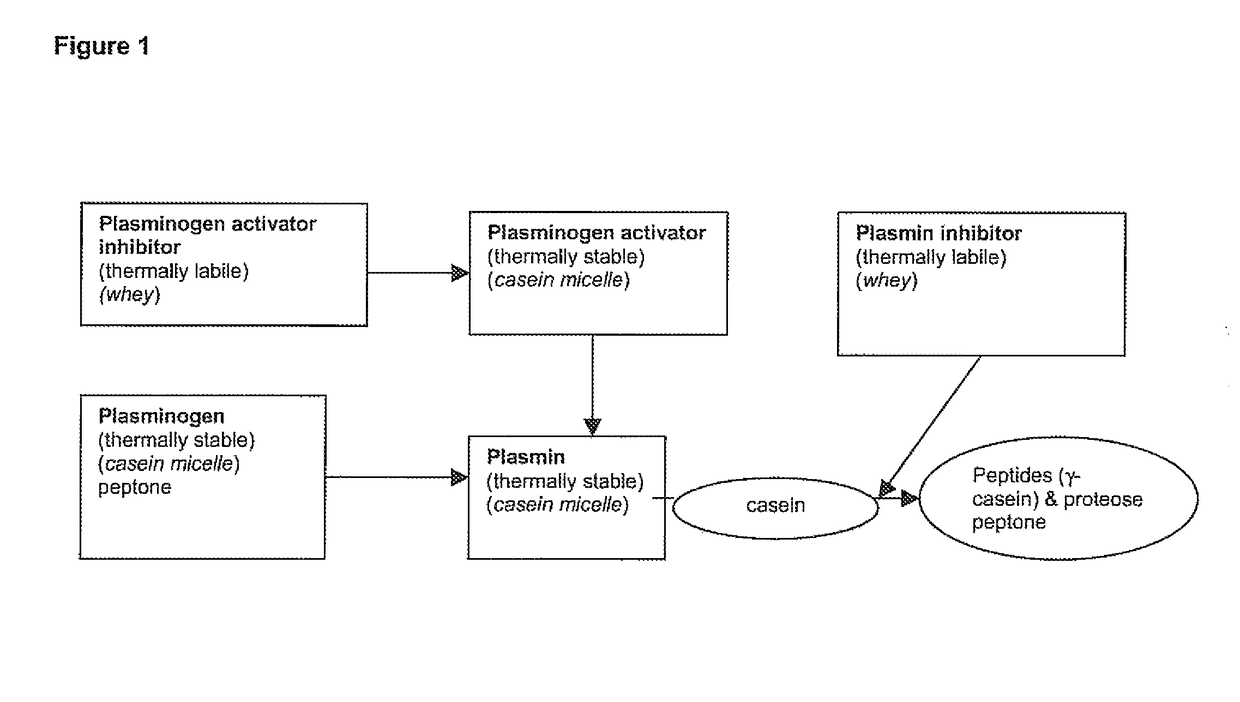

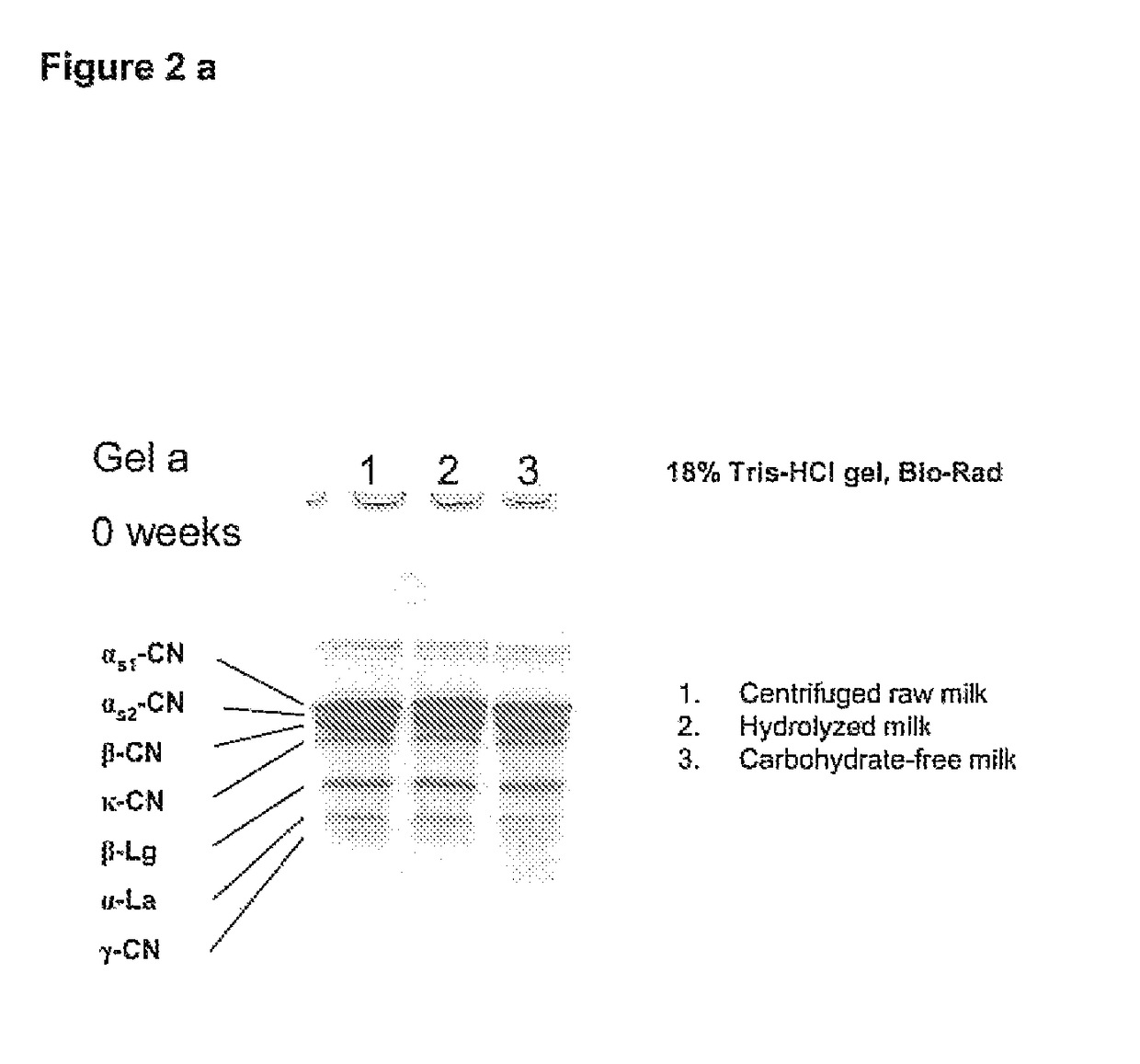

InactiveUS20100215828A1Extension of timeWeakening of nutritional valueMilk preparationMilk preservationLactose free milkEnzyme system

The invention relates to a process for the production of well-preserving lactose-free and low-lactose milk products. The process of the invention is characterized by separating the sugars and proteins in a raw material, thermally treating them in such a manner that the plasmin enzyme system and other proteolytic enzymes are inactivated, and combining the fractions and other preparation agents into a drink with a required composition and properties.

Owner:VALIO LTD

Lactose-free milk preparation method based on separation membrane technologies

The invention discloses a lactose-free milk preparation method based on separation membrane technologies, in which the four membrane technologies of microfiltration, ultrafiltration, electrodialysis and nanofiltration are coupled. The method includes the steps that firstly, most components in milk are intercepted through microfiltration and ultrafiltration, a penetrating solution is an aqueous solution containing lactose and inorganic salt, and after the inorganic salt is recovered by electrodialysis, desalinated liquid containing lactose and a small amount of inorganic salt is obtained; then,the desalinated liquid is subjected to nanofiltration separation to intercept lactose, and thus lactose removal is completed; components except lactose are recombined to obtain lactose-free milk powder through spray drying. By means of the method, the lactose interception rate reaches up to 95.85%; the production of the lactose-free milk powder is realized; meanwhile, water added in the production process can be effectively recovered and reused, lactose is also recovered by nanofiltration, and thus the method can guarantee that the whole process is environmentally friendly and free of by-product generation and raw material waste; besides, no chemical substance is added in the process, and thus the taste of milk will not be affected.

Owner:ZHEJIANG UNIV OF TECH

Process for producing lactose-free milk

ActiveUS20090092731A1Same propertySame sweetnessMilk preparationOther dairy technologyLactose free milkUltrafiltration

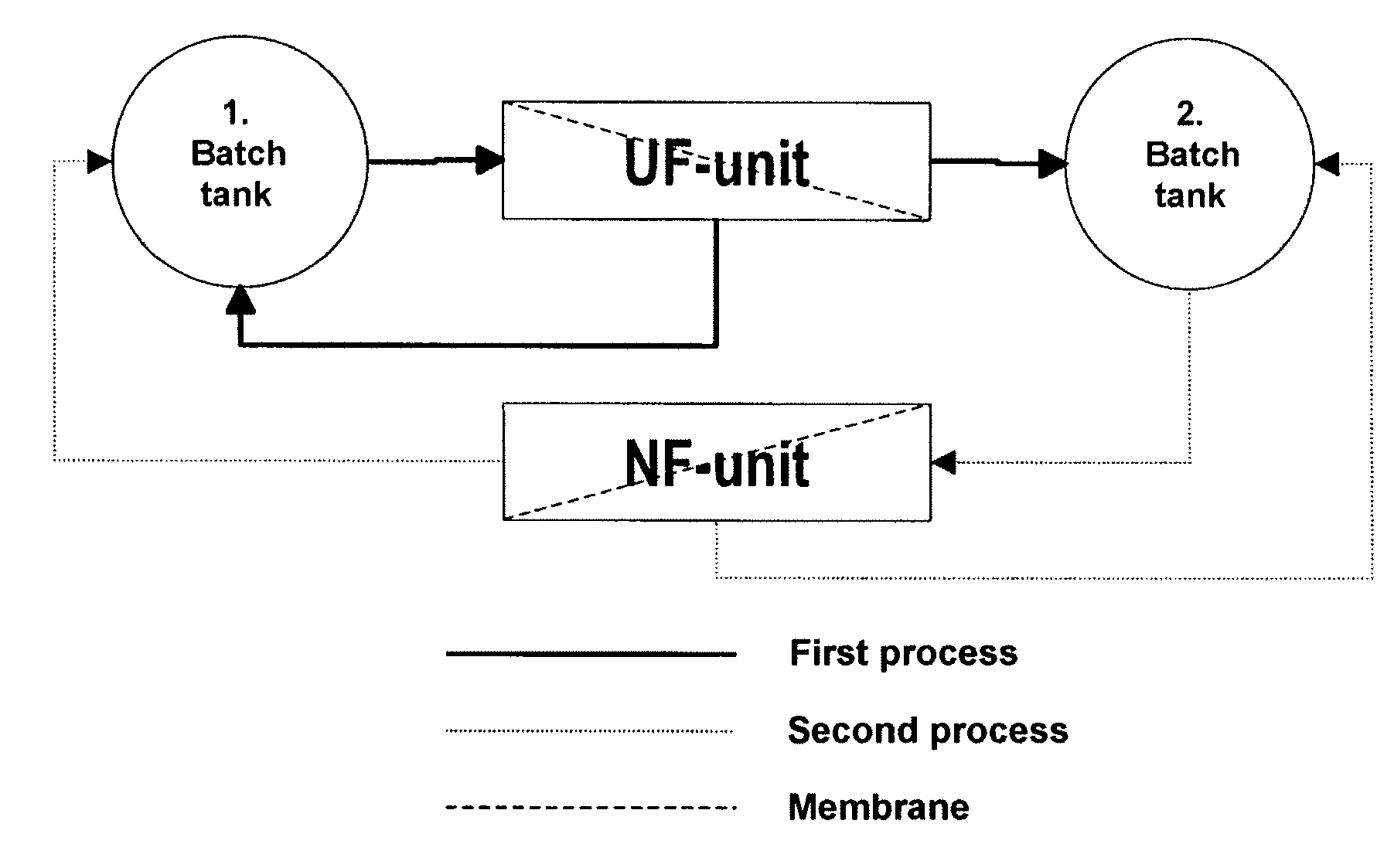

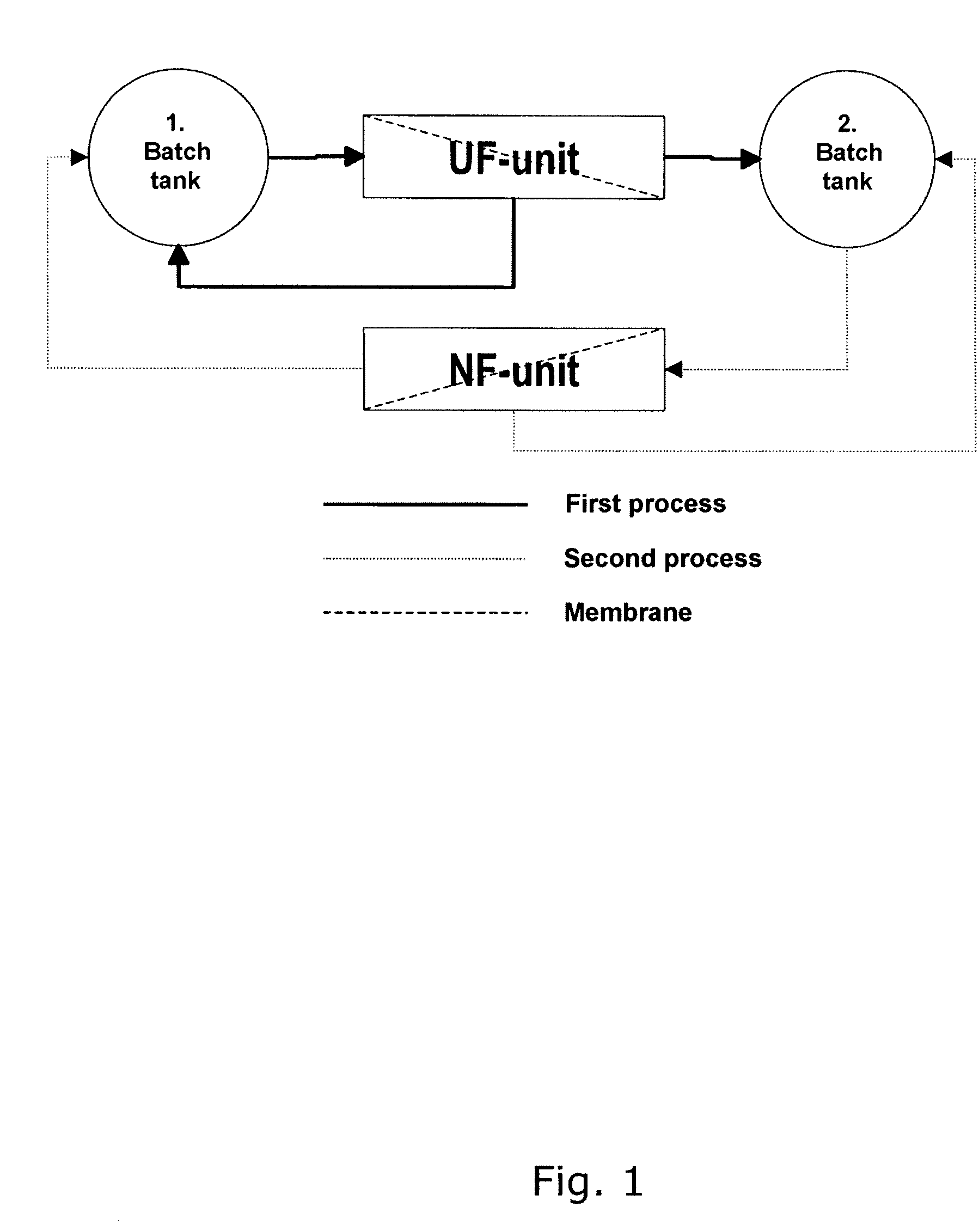

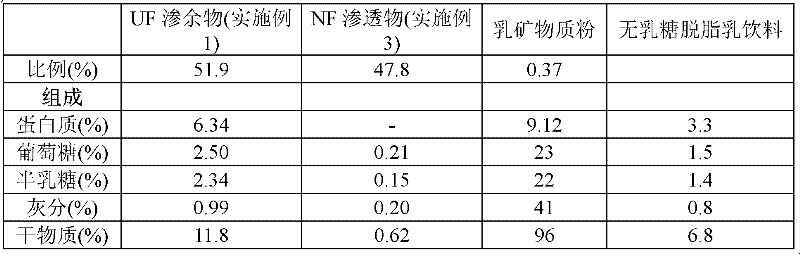

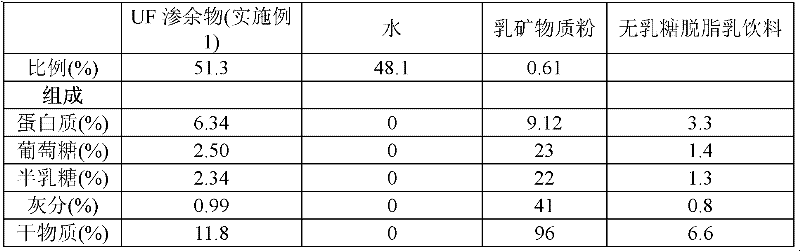

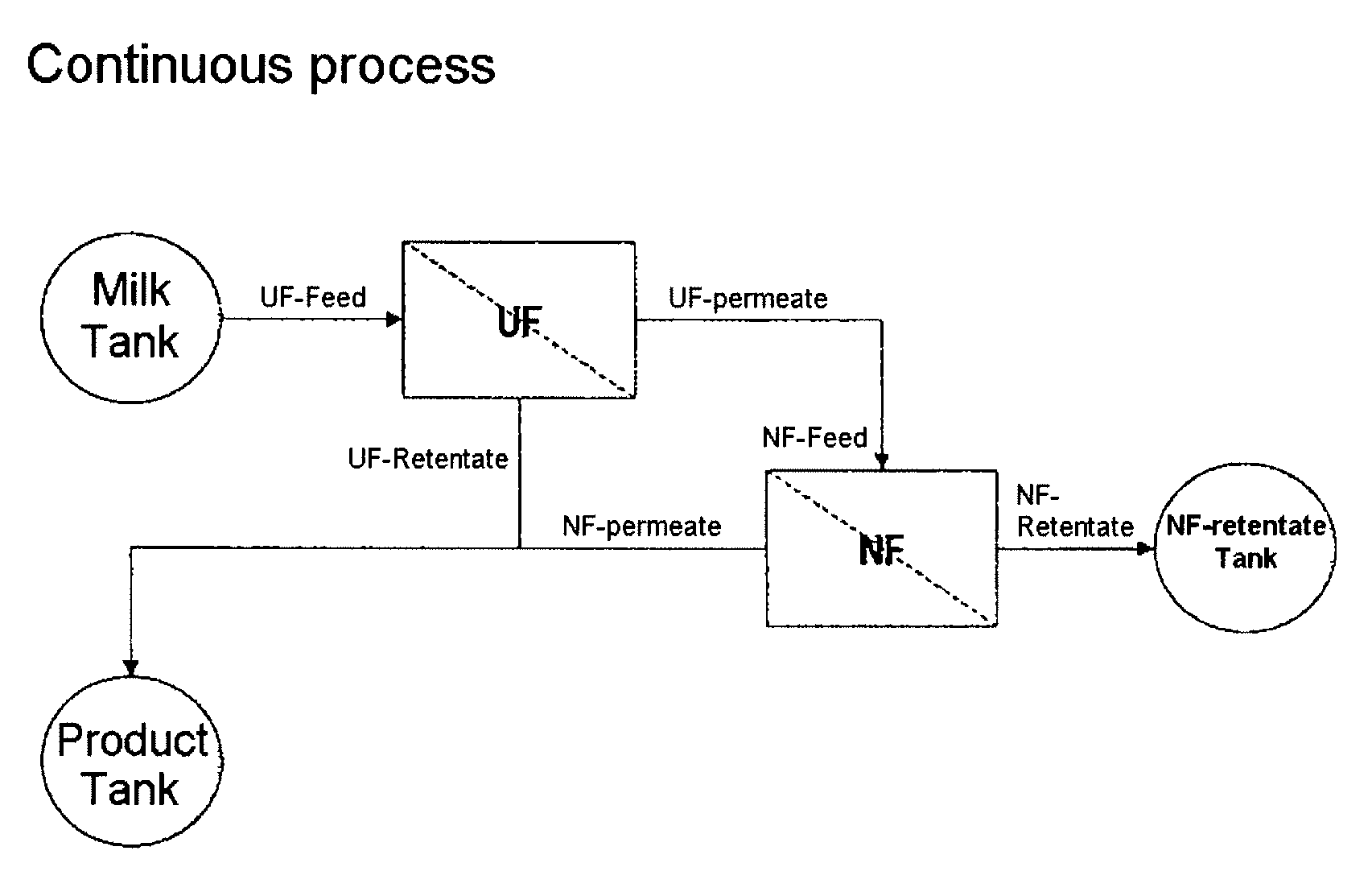

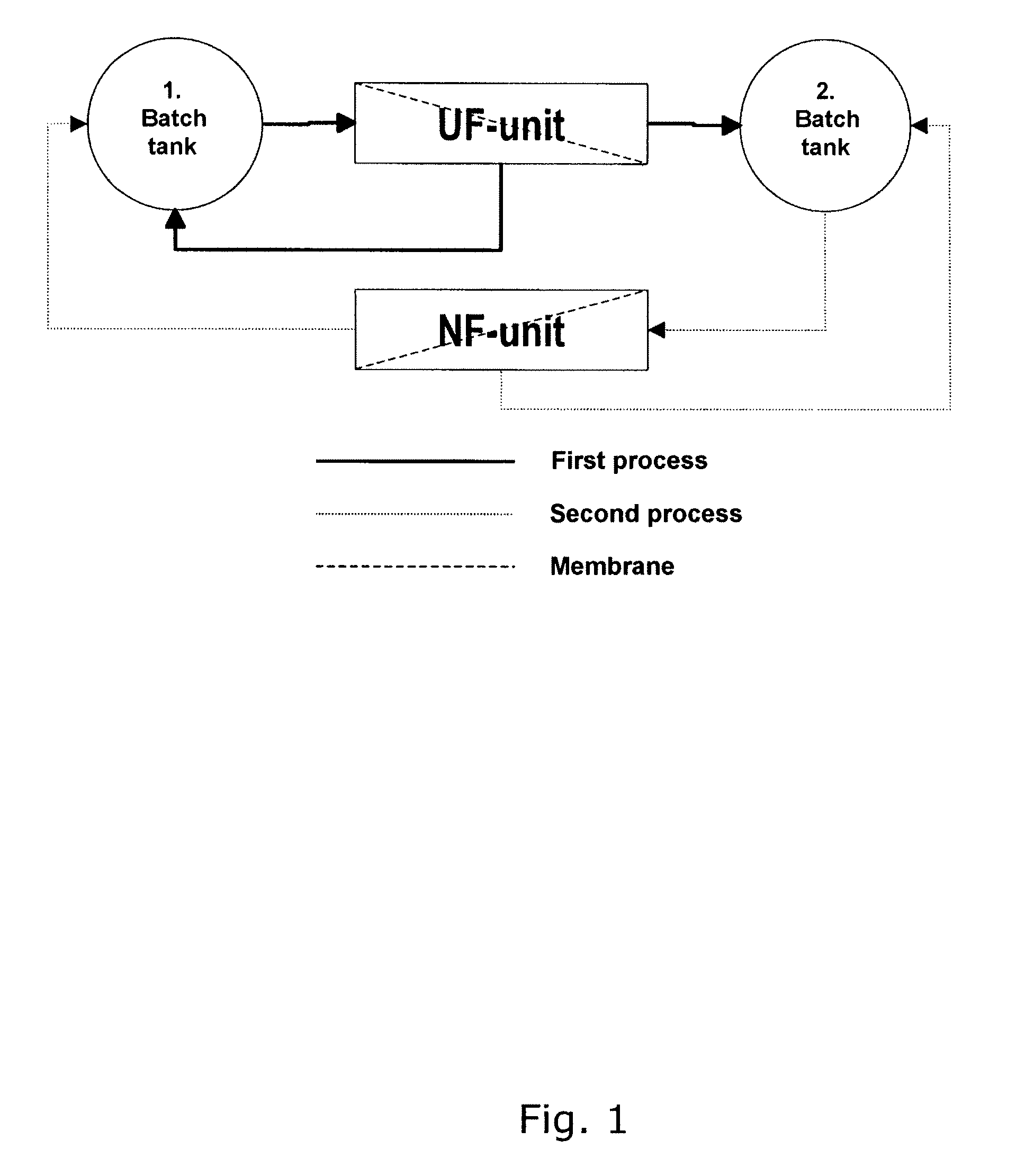

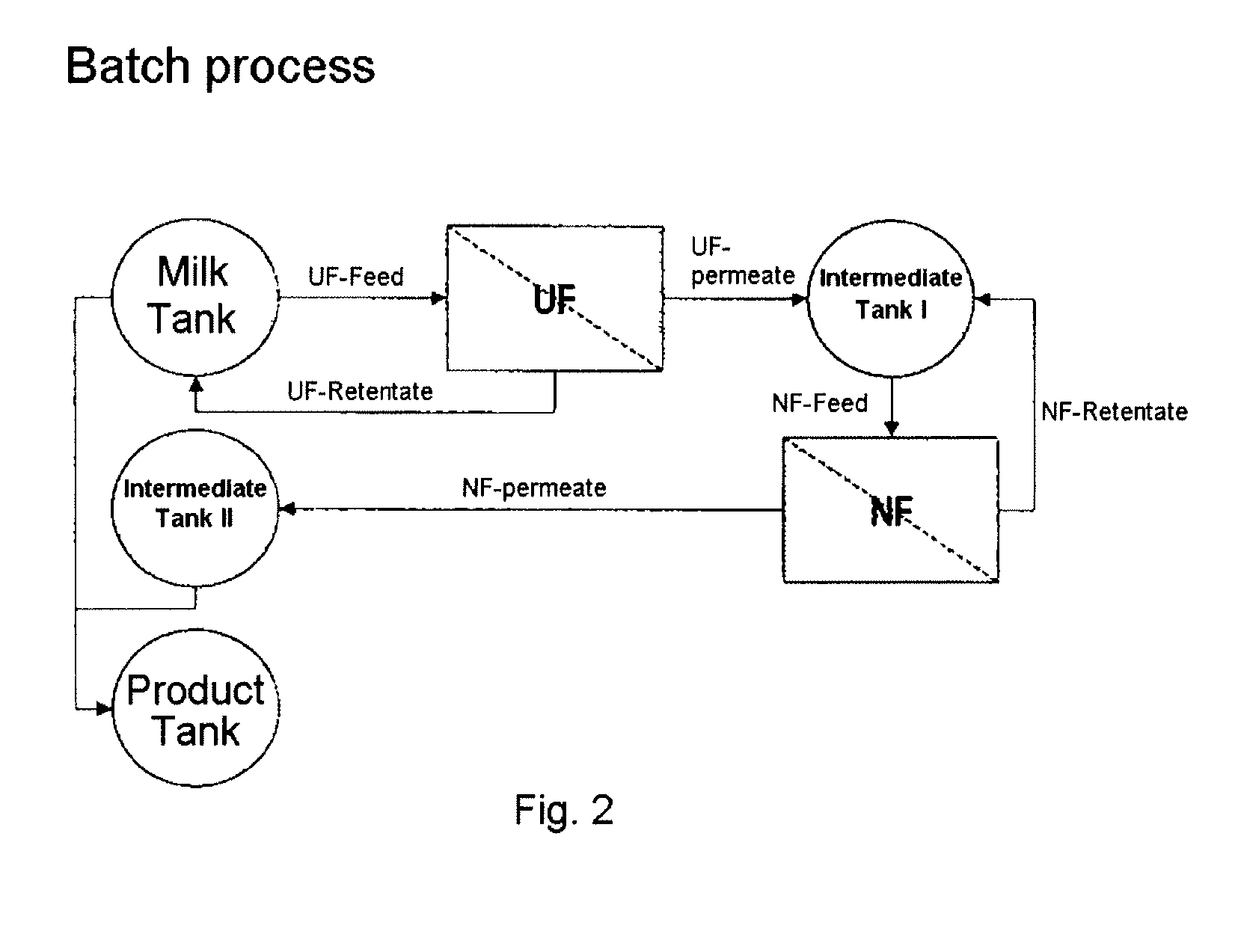

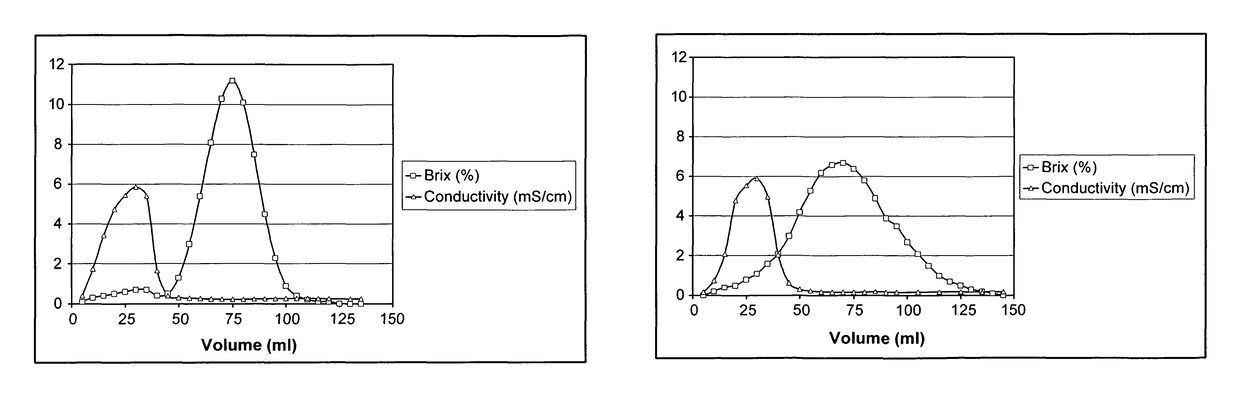

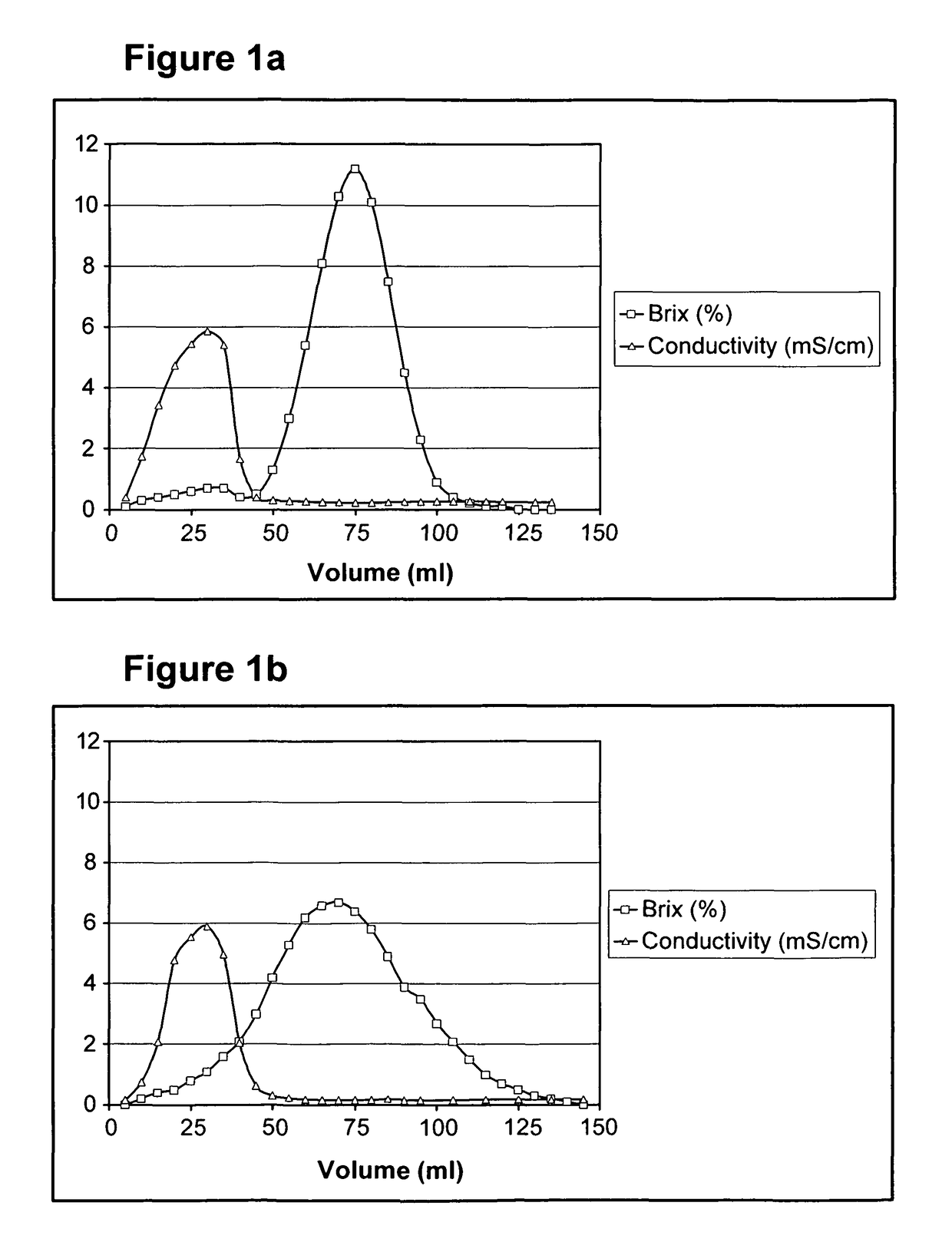

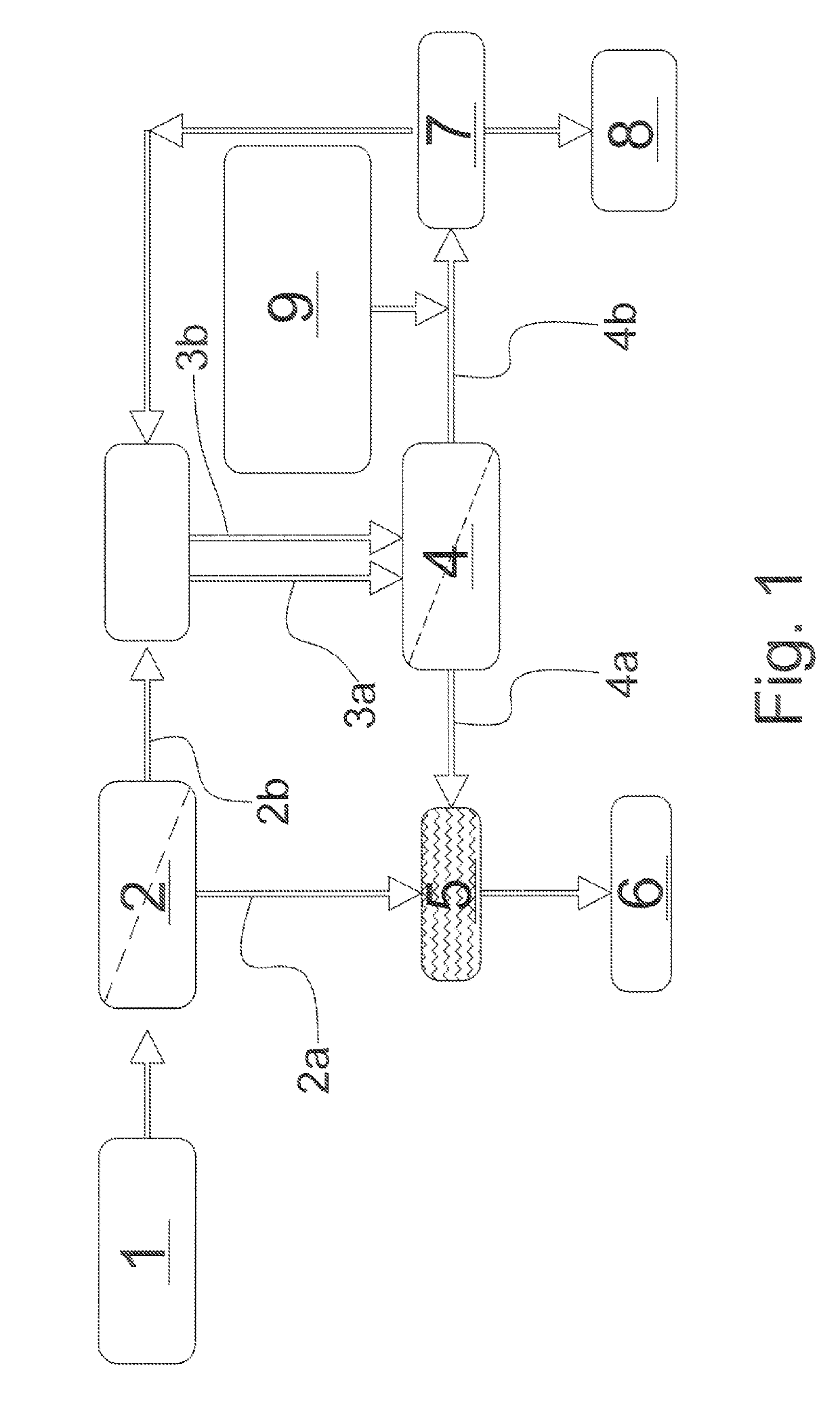

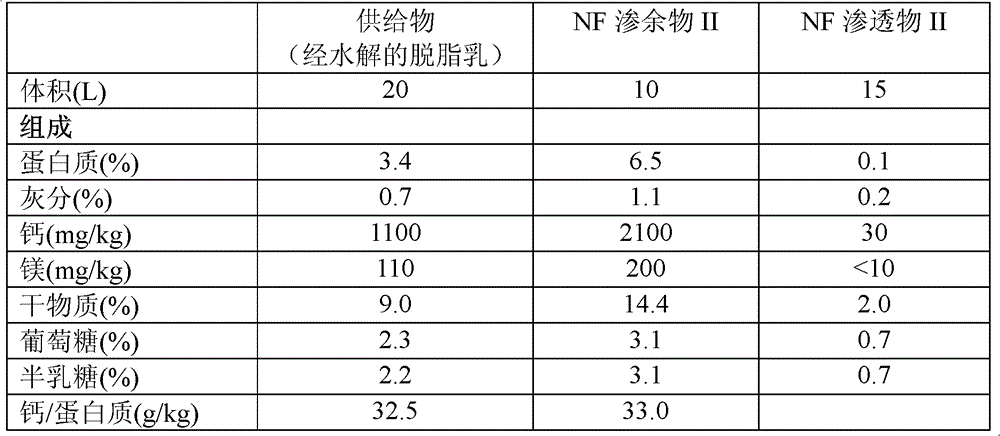

The invention concerns a process for producing lactose-free or substantially lactose-free milk, preferably without addition of water, and the product obtainable by the process. The process comprises the steps of:a) Ultrafiltration of original milk to obtain a first permeate and a first retentate;b) Nanofiltration of said first permeate to obtain a second permeate and a second retentate;c) Mixing said first retentate with said second permeate to obtain a mixture; andd) Hydrolysing remaining lactose in said mixture to obtain a hydrolysed milk.The process provides a lactose-free product with the taste of the original milk.

Owner:ARLA FOODS AMBA

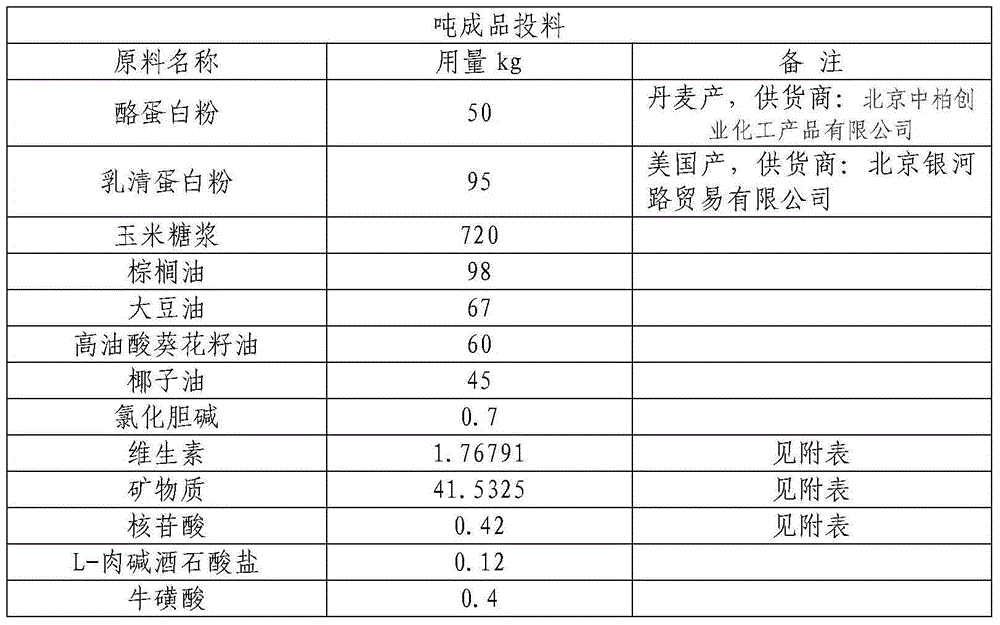

Formula milk powder for enhancing intestinal health of young pets and preparation method thereof

PendingCN106858117AAvoid damageReduce absorptionAnimal feeding stuffAccessory food factorsLactose free milkVegetable oil

The present invention discloses formula milk powder for enhancing intestinal health of young pets. The formula milk powder comprises the following components in parts by weight: 5-50 parts of skimmed and lactose-free milk powder, 1-40 parts of vegetable oil, 1-30 parts of hydrolyzed casein powder, 1-30 parts of hydrolyzed whey protein powder, 1-20 parts of glucose, 1-10 parts of yeast hydrolyzate, 0.5-5 parts of compound vitamins, 0.5-5 parts of compound minerals, 0.01-5 parts of mixed probiotics, 0.1-10 parts of compound prebiotics, 0.1-5 parts of arginine, 0.1-5 parts of methionine, 0.1-5 parts of choline chloride, 0.01-5 parts of taurine, 0.1-5 parts of immunoglobulin, and 0.01-2 parts of L-carnitine tartrate. The formula milk powder can enhance the intestinal health of the young pets.

Owner:上海依蕴宠物用品有限公司

Low-lactose and lactose-free milk product and process for production thereof

The invention relates to a low-lactose and a lactose-free milk product and to a process for the production thereof. The lactose in the milk raw material is hy- drolyzed, proteins, minerals and sugars are separated into different fractions by the membrane technique, and a low-lactose or a lactose-free milk product is composed from the fractions. The invention provides a milk product the water therein originating from the original milk raw material. In addition, useful by-products are produced in the process.

Owner:VALIO LTD

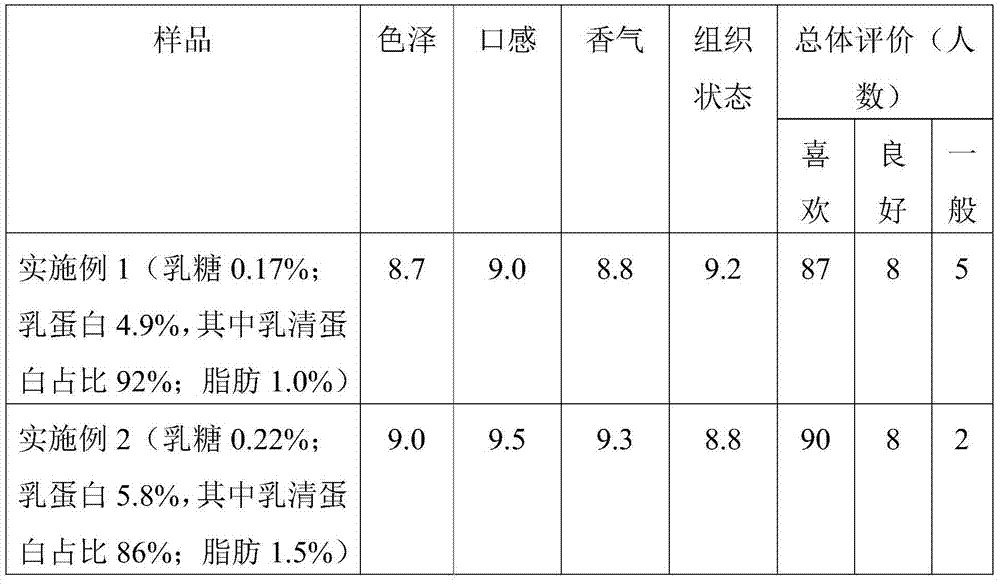

High-protein lactose-free milk and preparation method thereof

ActiveCN104489096ASolve problems that are not conducive to blood sugar stabilitySolve easy cokingMilk preparationLactose free milkSlurry

The invention provides high-protein lactose-free milk and a preparation method thereof. The raw materials of the high-protein lactose-free milk are prepared from the following components in percentage by weight: 0.5-1% of milk protein concentration, 5.0-5.5% of desalted separated whey proteins, 2.5-3.5% of watery cream and the balance of water, totaling 100%, wherein the percentage by weight is that relative to the total mass of the raw materials. The preparation method comprises the following steps: (1) mixing the milk protein concentration, the desalted separated whey proteins and water, standing and filtering by virtue of a ceramic membrane to obtain slurry A; (2) carrying out pasteurization on the watery cream to obtain slurry B; (3) mixing the slurry A and the slurry B; (4) homogenizing; and (5) cooling and filling. According to the ceramic membrane filtration process, the problem that a high-protein product is easily coked on tubular or platy sterilization equipment is solved, and the final product helps solve the problem that the common milk drank by the diabetic patient is adverse to glucostasis and has the function of controlling blood glucose of the type 2 diabetic patient in an assistant manner.

Owner:BRIGHT DAIRY & FOOD CO LTD

Low-lactose and lactose-free milk product and process for production thereof

ActiveUS8986768B2Need can be separatedWaste water loadMilk preparationOther dairy technologyLactose free milkSugar

Owner:VALIO LTD

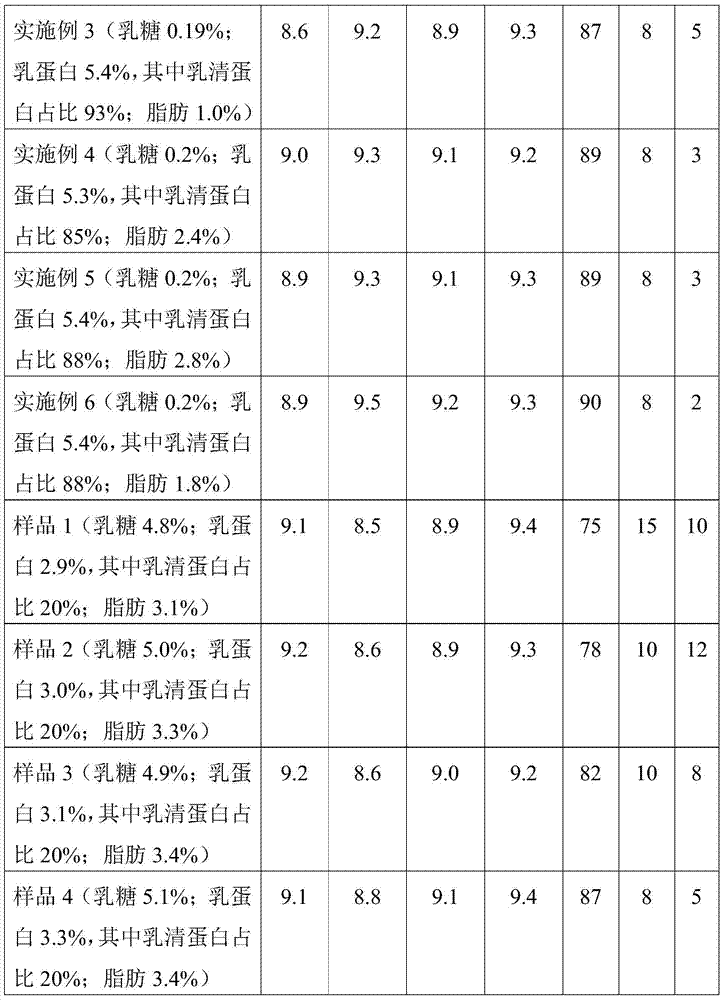

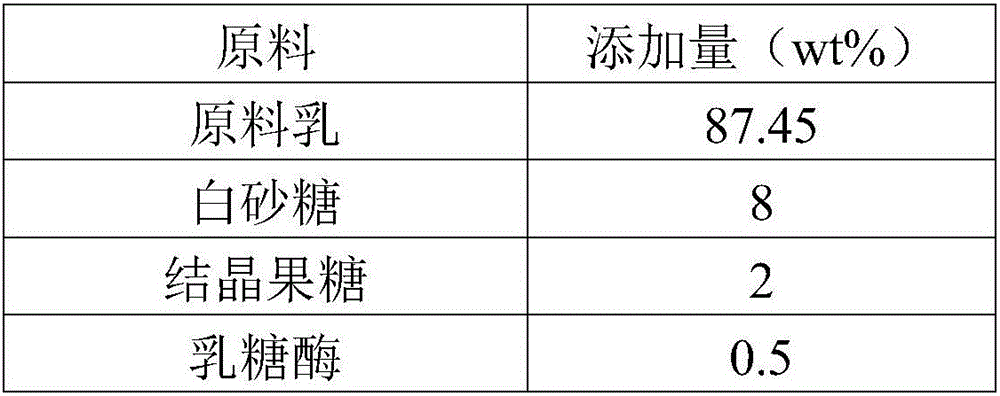

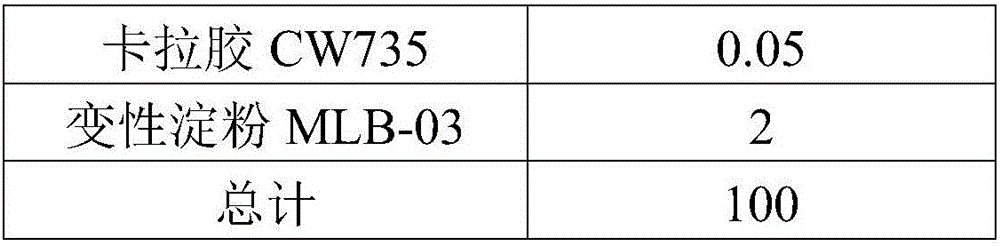

Puddings and preparation method of puddings

InactiveCN106819856ASugar food ingredientsFood ingredient as thickening agentLactose free milkFlavor

The invention belongs to the field of puddings and in particular discloses a preparation method of the puddings. The preparation method is prepared from the following raw materials in percentage by mass: 87.3 percent to 94.65 percent of raw milk, 0.2 percent to 0.5 percent of lactase, 5 percent to 10 percent of a sweetener and 0.15 percent to 2.2 percent of a stabilizer; the preparation method comprises the following steps: (1) degreasing the raw milk, concentrating, carrying out pre-pasteurization and cooling; adding the lactase and hydrolyzing to obtain lactose-free milk; (2) uniformly mixing the lactose-free milk, the sweetener and the stabilizer to obtain material liquid; (3) homogenizing the material liquid, sterilizing and cooling. The puddings prepared by the preparation method provided by the invention have the characteristics of low lipid, low lactose, high protein and high calcium and have a good flavor and a fine, smooth and elastic taste; the preparation method is simple and feasible and is suitable for large-scale continuous production.

Owner:BRIGHT DAIRY & FOOD CO LTD

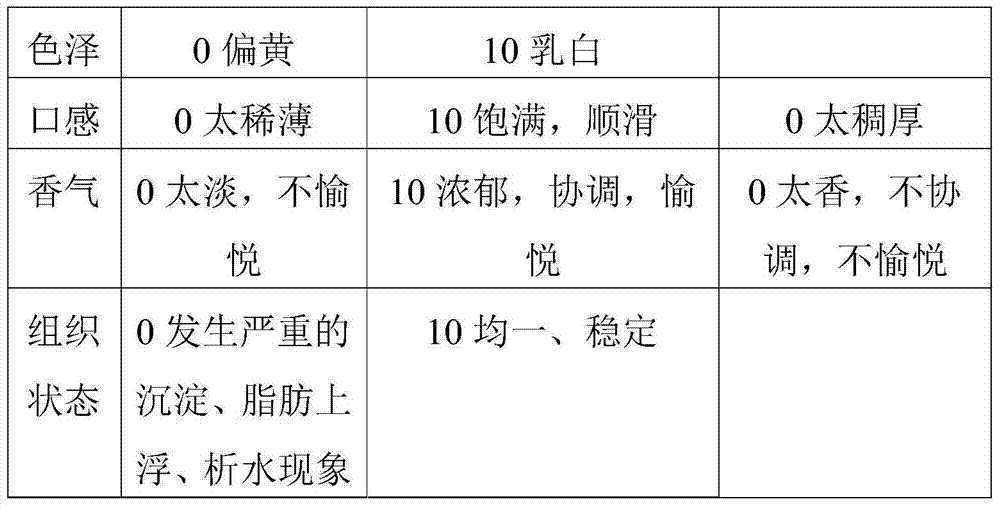

Lactose-removing milk process for lactose-free milk production and byproduct use

ActiveUS20160174586A1Low production costMilk preparationOther dairy technologyLactose free milkNanofiltration

The present invention relates to dairy and milk treatment industries for obtaining lactose-free milk and assessment of byproduct in particular, particularly to milk treatment industry through different separation means such as micro and nanofiltration equipment. One of the purposes of this invention is to provide a delactosed or lactose-free milk with sensory profile equivalent to a normal pasteurized milk using essential separation steps to reduce product costs. Another purpose of this invention is to determine the effect of milk natural components concentration on organoleptic properties to achieve the first purpose of this invention. Another purpose is to determine percentage between retentate and permeate to get a sensory profile equivalent to a normal pasteurized milk.

Owner:COMERCIALIZADORA DE LACTEOS Y DERIVADOS SA DE CV

Process for producing lactose-free milk

ActiveUS8445052B2Cost advantageLoss of original milk is limitedMilk preparationOther dairy technologyLactose free milkUltrafiltration

The invention concerns a process for producing lactose-free or substantially lactose-free milk, preferably without addition of water, and the product obtainable by the process. The process comprises the steps of:a) Ultrafiltration of original milk to obtain a first permeate and a first retentate;b) Nanofiltration of said first permeate to obtain a second permeate and a second retentate;c) Mixing said first retentate with said second permeate to obtain a mixture; andd) Hydrolysing remaining lactose in said mixture to obtain a hydrolysed milk.The process provides a lactose-free product with the taste of the original milk.

Owner:ARLA FOODS AMBA

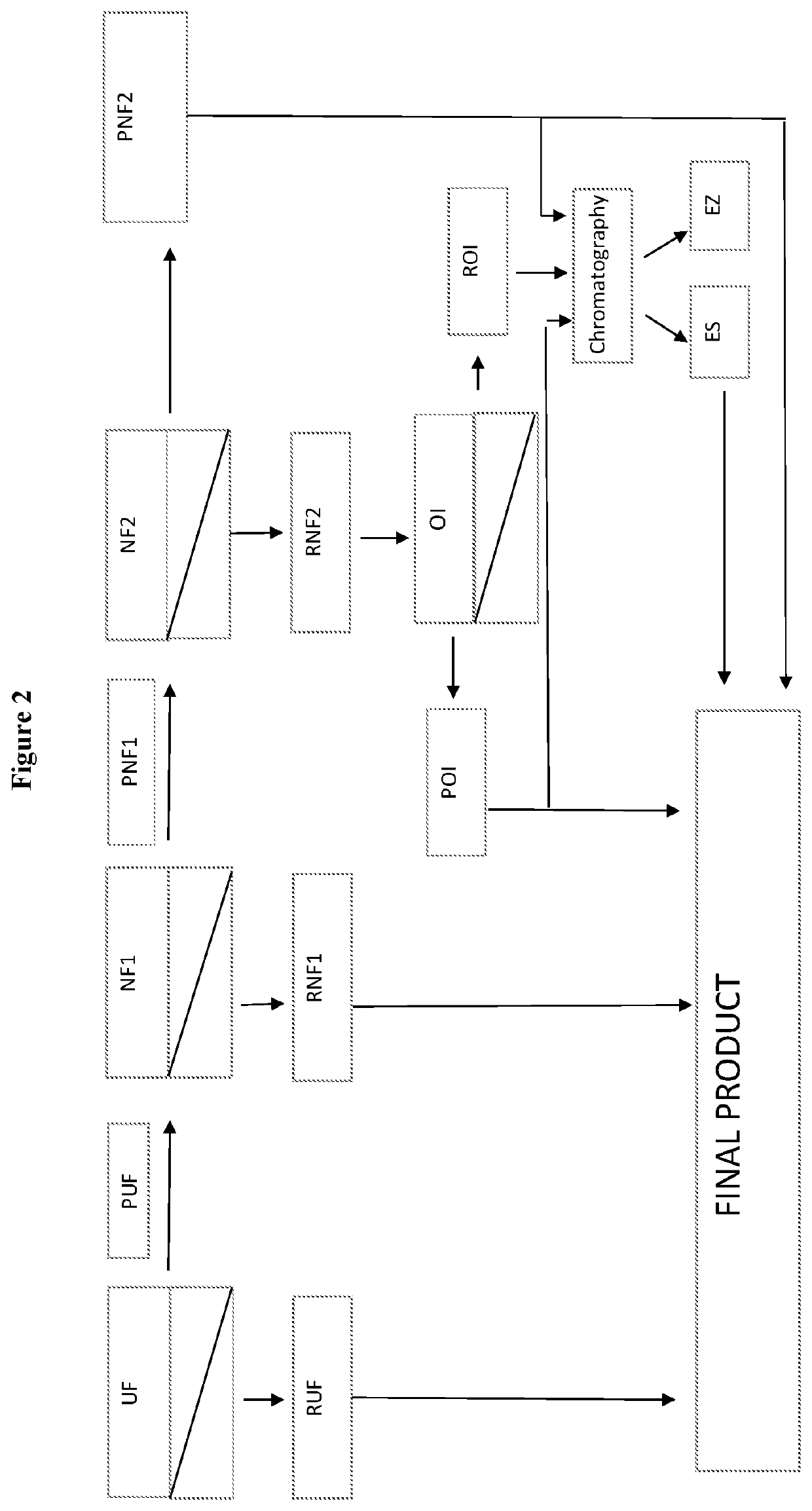

Low-lactose and lactose-free milk product and process for production thereof

InactiveUS10080372B2Avoiding calcium and protein lossesSimplify and enhance the production of low-lactose and lactose-free milk productsMilk preparationLactose free milkSugar

The invention relates to a process for separating milk components, wherein proteins, sugars and minerals are separated into different fractions. The lactose of milk is first hydrolyzed completely or partially, after which proteins, minerals and sugars are separated into fractions in a phased nanofiltration. The obtained fractions may also be further processed by chromatography, membrane techniques, and / or evaporation to further improve the separation of said components. The invention also relates to a low-lactose or lactose-free milk composed of these fractions. By means of the invention, calcium and protein losses can be minimized. Also, the energy content of the product can be reduced.

Owner:VALIO LTD

Lactose-Free Milk Products

InactiveUS20150230484A1Improve throughputIncrease profitabilityMilk preparationMilk treatmentLactose free milkLactase

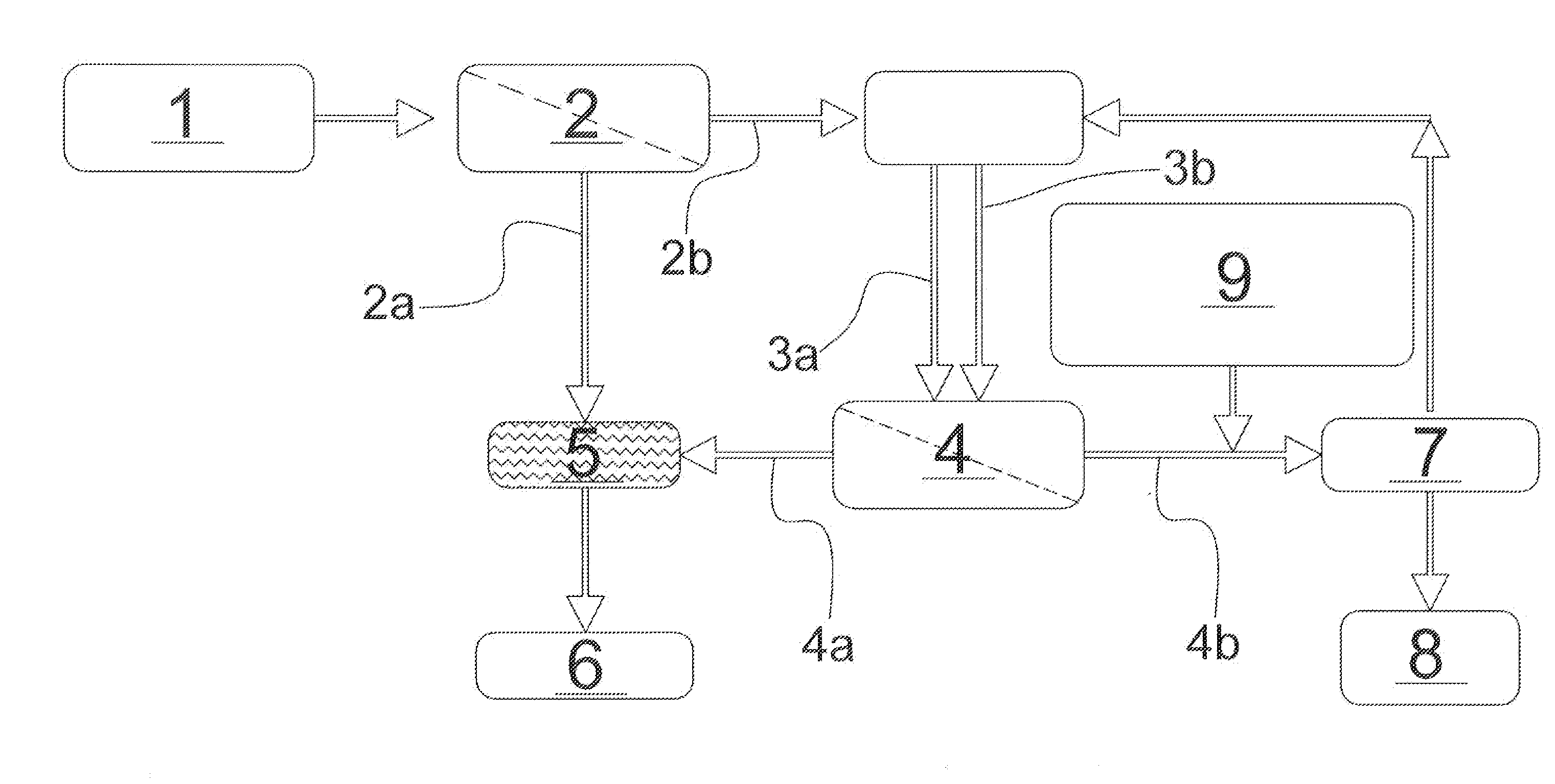

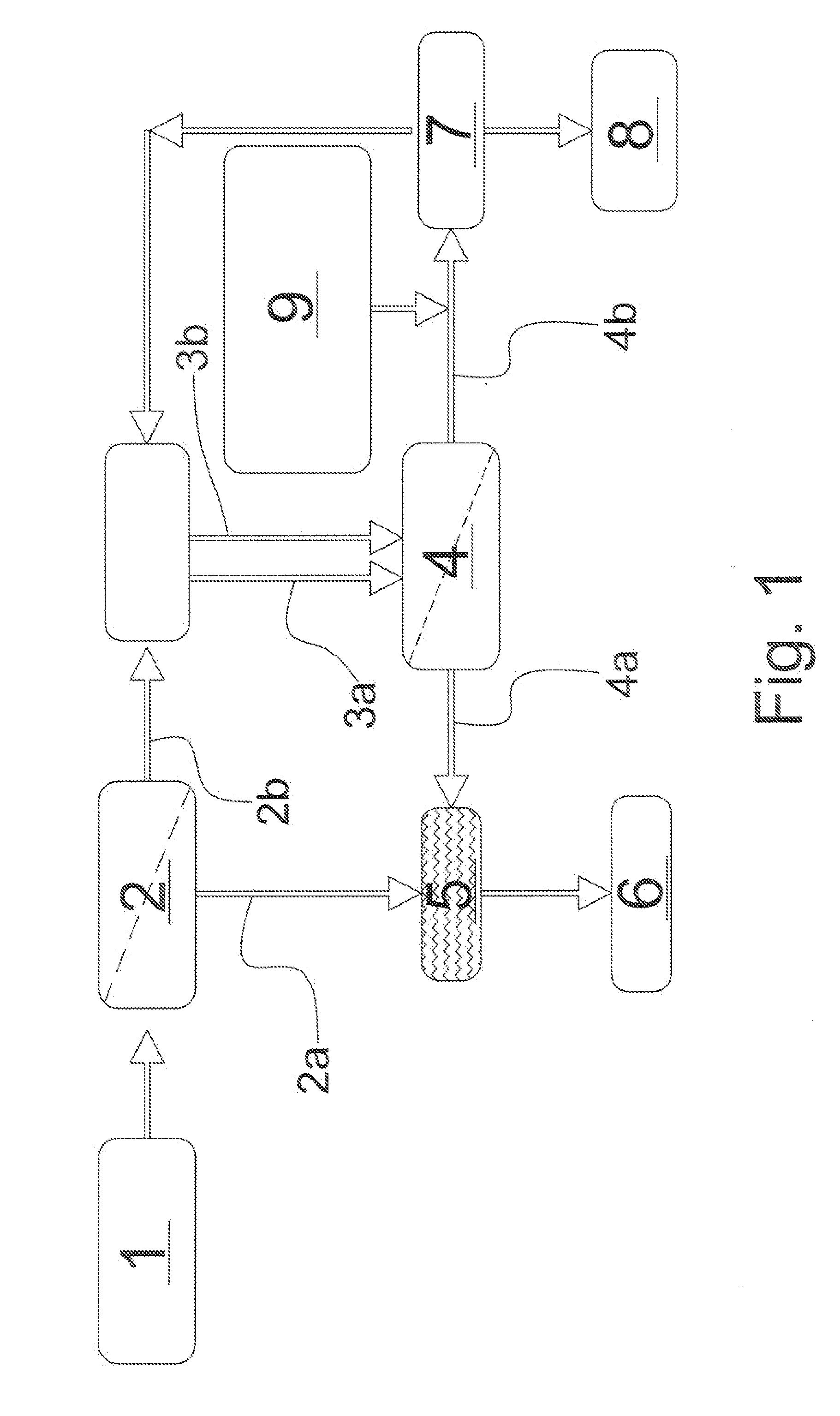

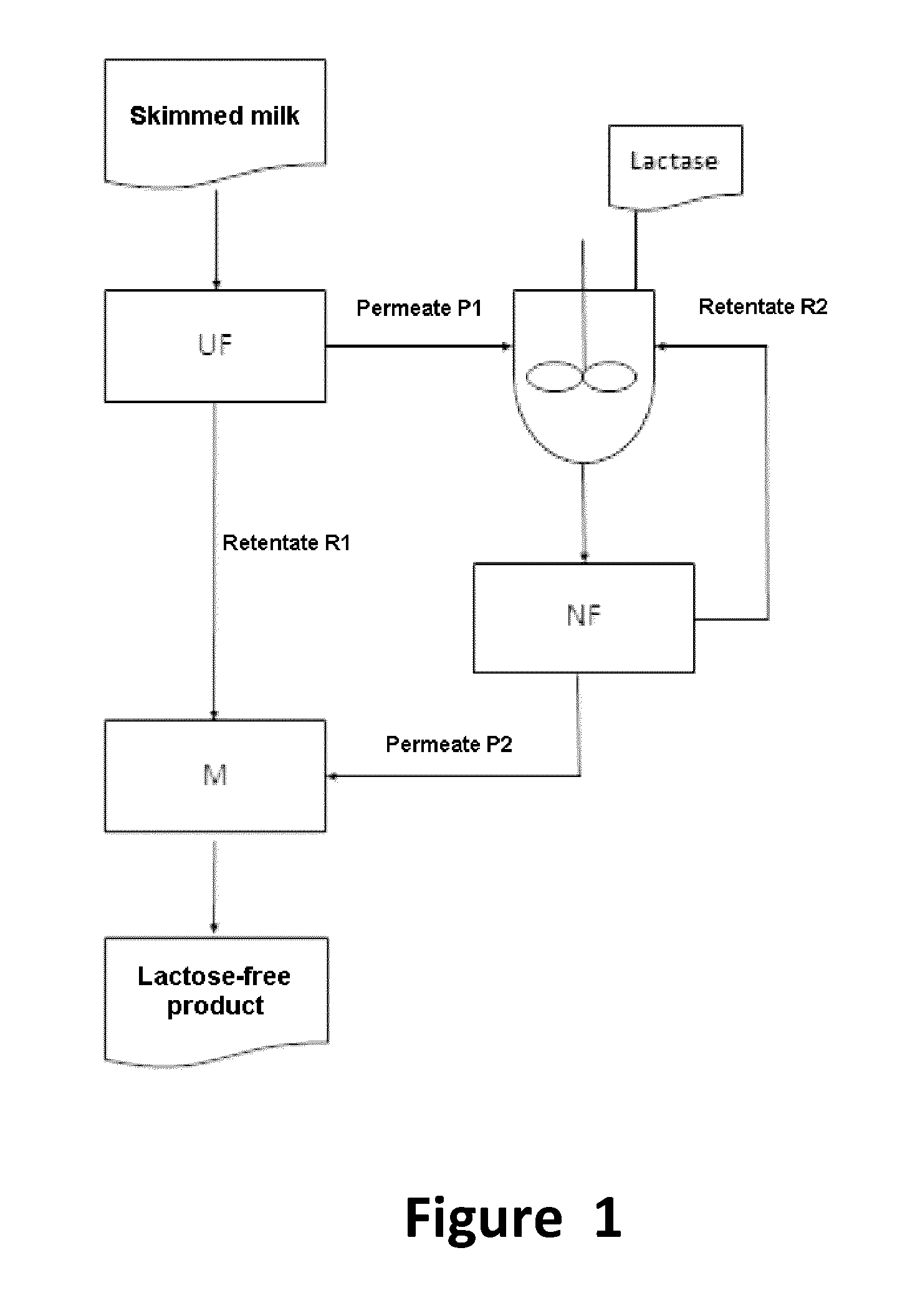

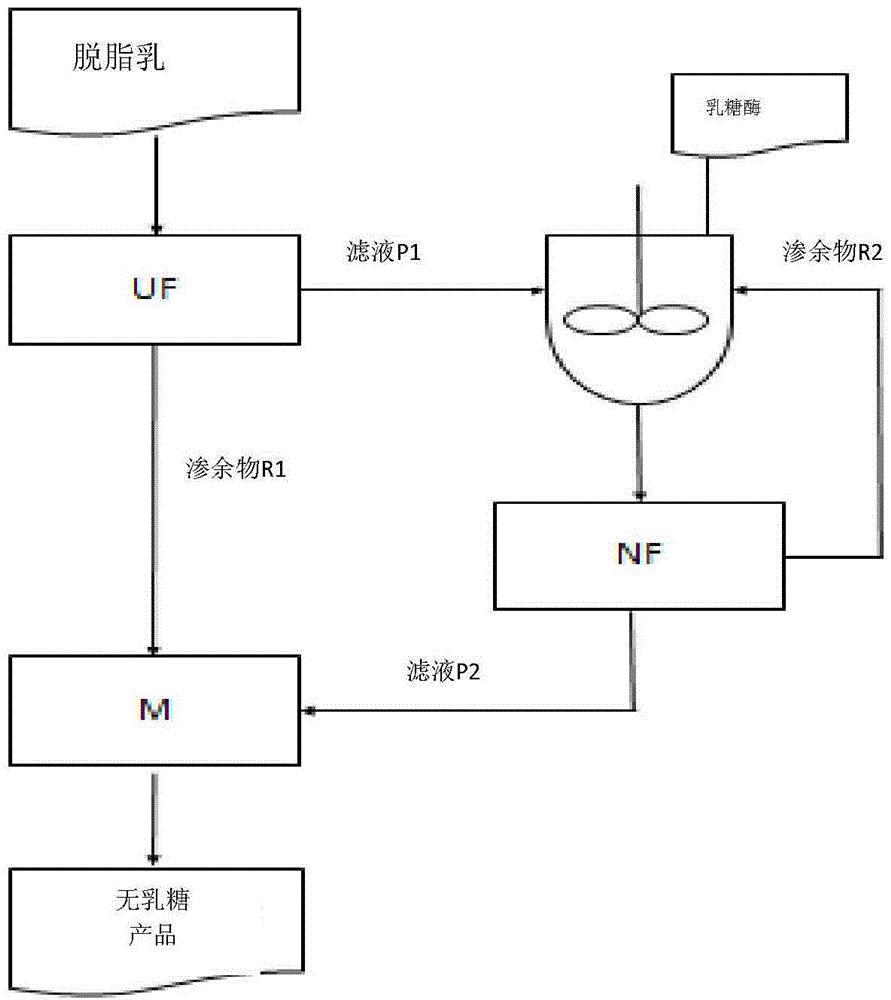

A process for producing lactose-free milk products is proposed in which(a) skimmed milk is subjected to an ultrafiltration or to a combination of dia- and ultrafiltration,(b) the lactose-free retentate R1 is fed to a storage container and the lactose-containing permeate P1 is fed to an enzyme reactor,(c) an amount of lactase sufficient for the enzymatic degradation of the lactose present therein is added to the permeate P1,(d) the reaction mixture obtained in this way is subjected to a nanofiltration,(e) the lactose-free permeate P2 is conveyed to the storage container and mixed with the lactose-free retentate R2, and(f) the retentate R2, which still comprises unreacted lactose and enzyme, is returned again to the enzyme reactor.

Owner:DMK DEUT MILCHKONTOR

Low-lactose and lactose-free milk product and process for production thereof

InactiveCN102131397ASimplify and improve productionReduce lossesMilk preparationLactose free milkSugar

The invention relates to a process for separating milk components, wherein proteins, sugars and minerals are separated into different fractions. The lactose of milk is first hydrolyzed completely or partially, after which proteins, minerals and sugars are separated into fractions in a grading nanofiltration. The obtained fractions may also be further processed by chromatography, membrane techniques, and / or evaporation to further improve the separation of said components. The invention aiso relates to a low-lactose or lactose-free miik composed of these fractions. By means of the invention, calcium and protein fosses can be minimized. Also, the energy content of the product can be reduced.

Owner:VALIO LTD

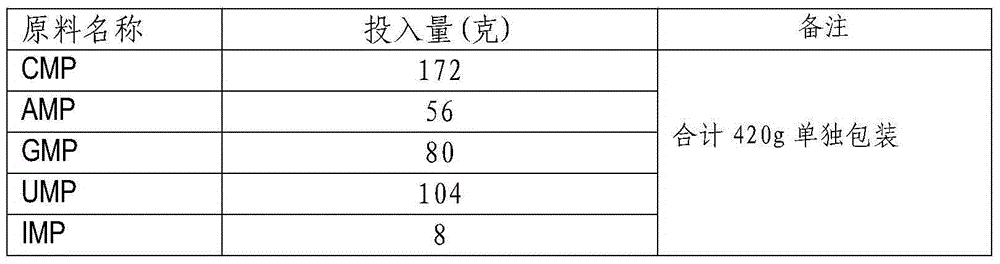

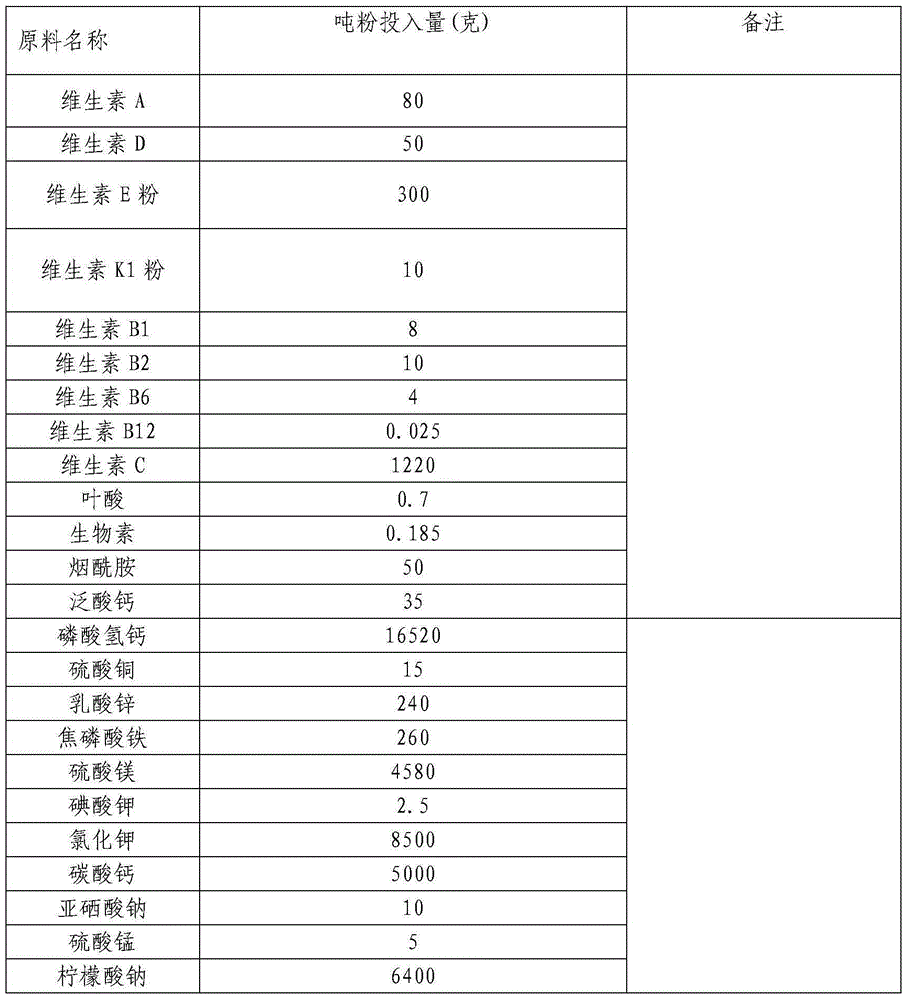

Special medical use infant formula milk powder

InactiveCN110419579AAvoid intoleranceEase the burden on digestionMilk preparationLactose free milkLactose maldigestion

The present invention relates to special medical use infant formula milk powder. The special medical use infant formula milk powder comprises the following raw materials in weight percentages: lactose-free whole milk powder, isolated whey protein WPI, solid corn syrup, plant fat powder, nucleotide, arachidonic acid, docosahexaenoic acid, vitamins and a mineral premix. A formula is as follows: producing 1 ton of the product requires the following accessory materials: 150 kg of lactose-free whole milk powder, 70 kg of isolated whey protein WPI, 326 kg of solid corn syrup, 400 kg of plant fat powder, 1.2 kg of nucleotides, 8.6 kg of arachidonic acid, docosahexaenoic acid, 36 kg of vitamins and a mineral premix. The special medical use infant formula milk powder uses a lactose-free formula andhas a lactose content less than 0.5%, lactose indigestion may cause diarrhea, flatulence, crying and screaming, etc., the lactose-free formula can reduce the diarrhea, flatulence, crying and screaming, etc. caused by lactose intolerance, and the lactose-free milk powder can reduce intestinal digestive burden, is conducive to diarrhea recovery and can avoid the lactose intolerance.

Owner:湖南欧比佳营养食品有限公司

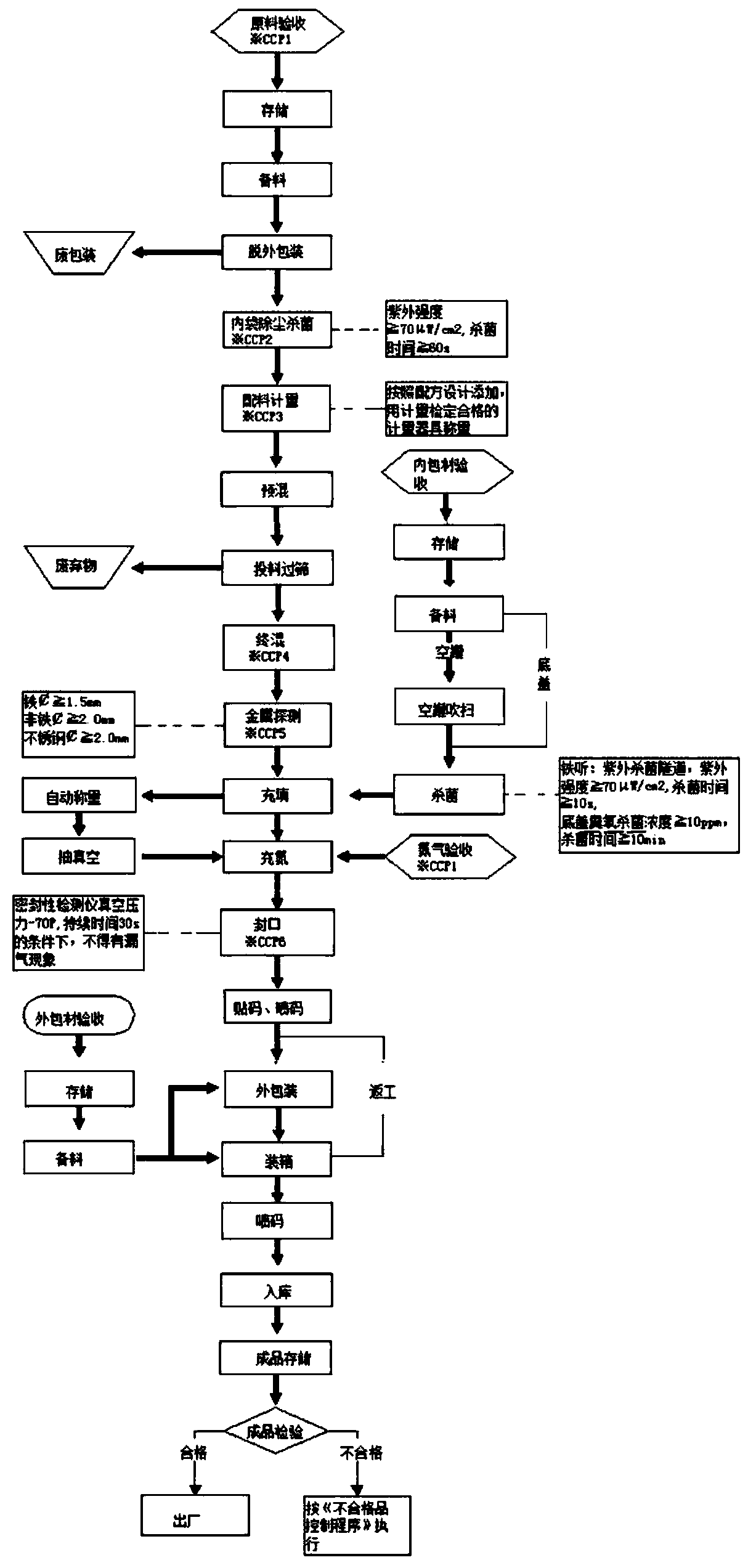

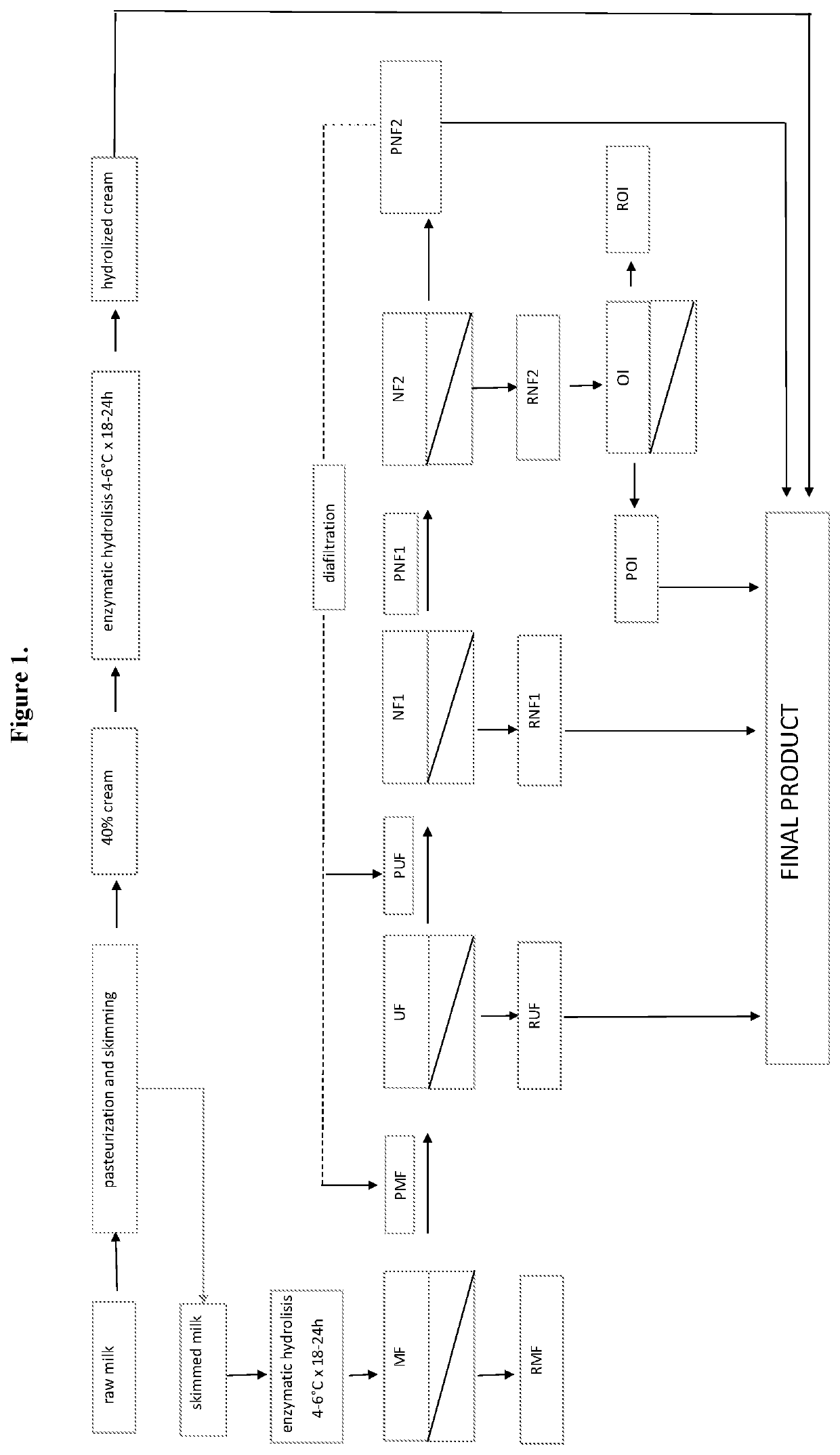

Process for preparing a lactose-free milk

ActiveUS20190335779A1Reduce scrap rateMilk preparationOther dairy technologyLactose free milkEnzymatic hydrolysis

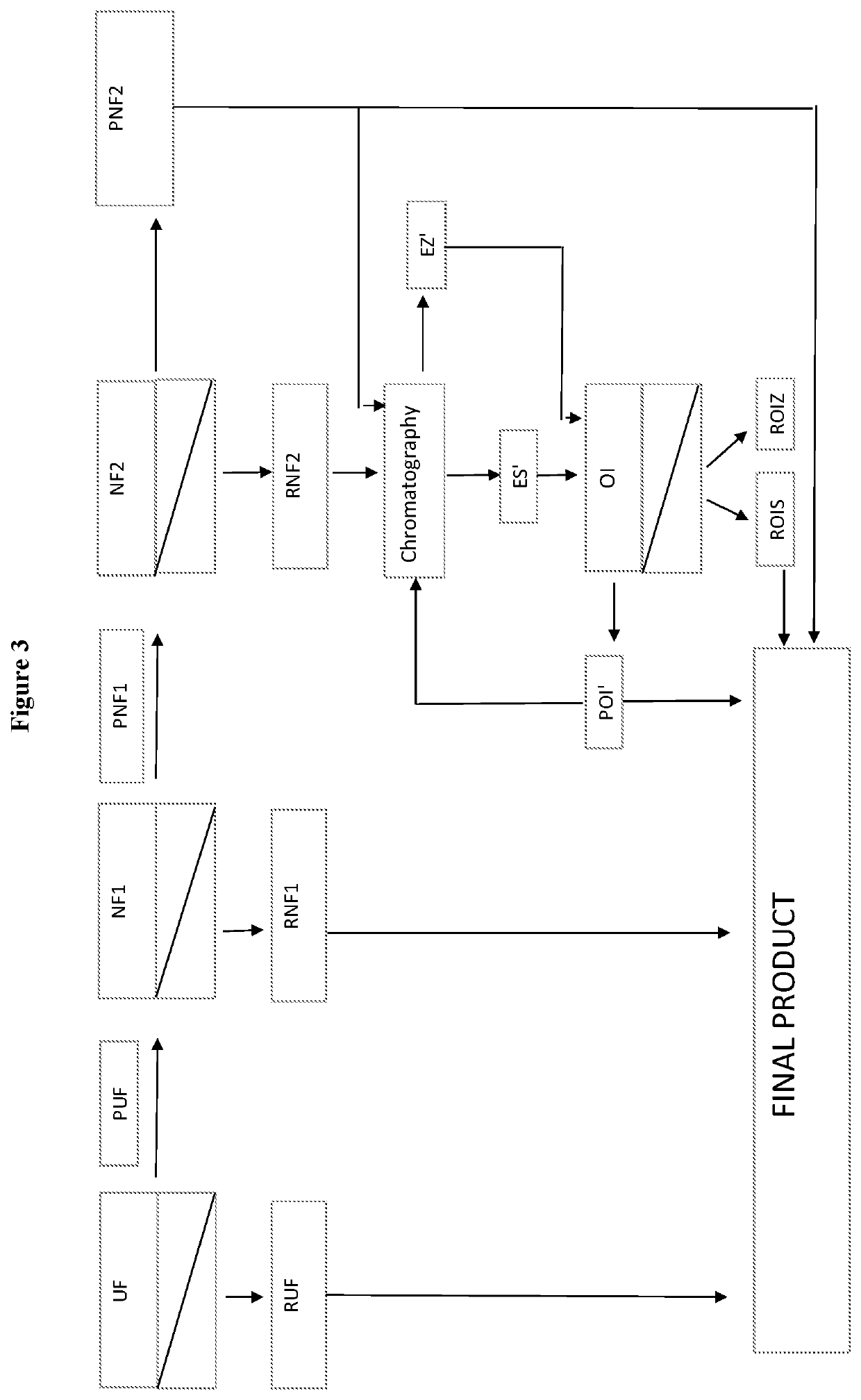

Process for preparing lactose-free skimmed, partially skimmed and whole milk, comprising the following steps: 1) pasteurization and skimming, 2) enzymatic hydrolysis of the skimmed milk by lactase enzyme, 3) microfiltration of the hydrolysed skimmed milk and obtainment of a microfiltration retentate (RMF) and of a microfiltration permeate (PMF), 4) PMF ultrafiltration and obtainment of an ultrafiltration retentate (RUF) and of an ultrafiltration permeate (PUF), 5) first PUF nanofiltration and obtainment of the first nanofiltration retentate (RNF 1) and of a first nanofiltration permeate (PNF 1), 6) second PNF 1 nanofiltration and obtainment of a second nanofiltration retentate (RNF2) and of a second nanofiltration permeate (PNF2), and 7) final step: obtainment of lactose-free milk by mixing one or more of the fractions deriving from one or more of the previous steps, which is characterized in that: (I) the first nanofiltration of step 5) is carried out with membranes having a molecular weight cut-off ranging from 400 to 600 Da and the second nanofiltration is carried out with membranes having a molecular weight cut-off ranging from 150 to 250 Da, and (II) the final step 7) is carried out by mixing a composition comprising at least RUF, RNF1 and PNF2.

Owner:GRANAROLO

Lactose-free lipid-lowering milk and production method thereof

InactiveCN106070636AFit for consumptionSatisfactionMilk preparationOther dairy technologyLactose free milkAnimal science

The invention provides lactose-free lipid-lowering milk and a production method thereof. The lactose-free lipid-lowering milk is prepared from a main material and auxiliary materials in the weight ratio being (90-98):(2-10), wherein the main material is lactose-free milk, the auxiliary materials comprise 50-80 parts by weight of hawthorn fruit powder, 10-30 parts by weight of cassia seed powder, 10-20 parts by weight of black fungus polysaccharides and 0.1-1 part by weight of phytosterol. During preparation, firstly, components of the auxiliary materials are mixed in proportion and then mixed with the lactose-free milk, the mixture is homogenized and sterilized, and the lactose-free lipid-lowering milk is obtained. According to the lactose-free lipid-lowering milk, various Chinese herbal medicine components perform a synergistic function and have a remarkable curative effect on hyperlipidemia; the content of lactose in the lactose-free milk is lower than 0.1%, and the lactose-free lipid-lowering milk is suitable for lactose-intolerant people; due to complete removal of lactose and monosaccharide, the lactose-free lipid-lowering milk is also suitable for people who have higher requirements for the content of sugar, such as people suffering from diabetes.

Owner:方雅悯 +1

Lactose-free milk product and processes for producing the same

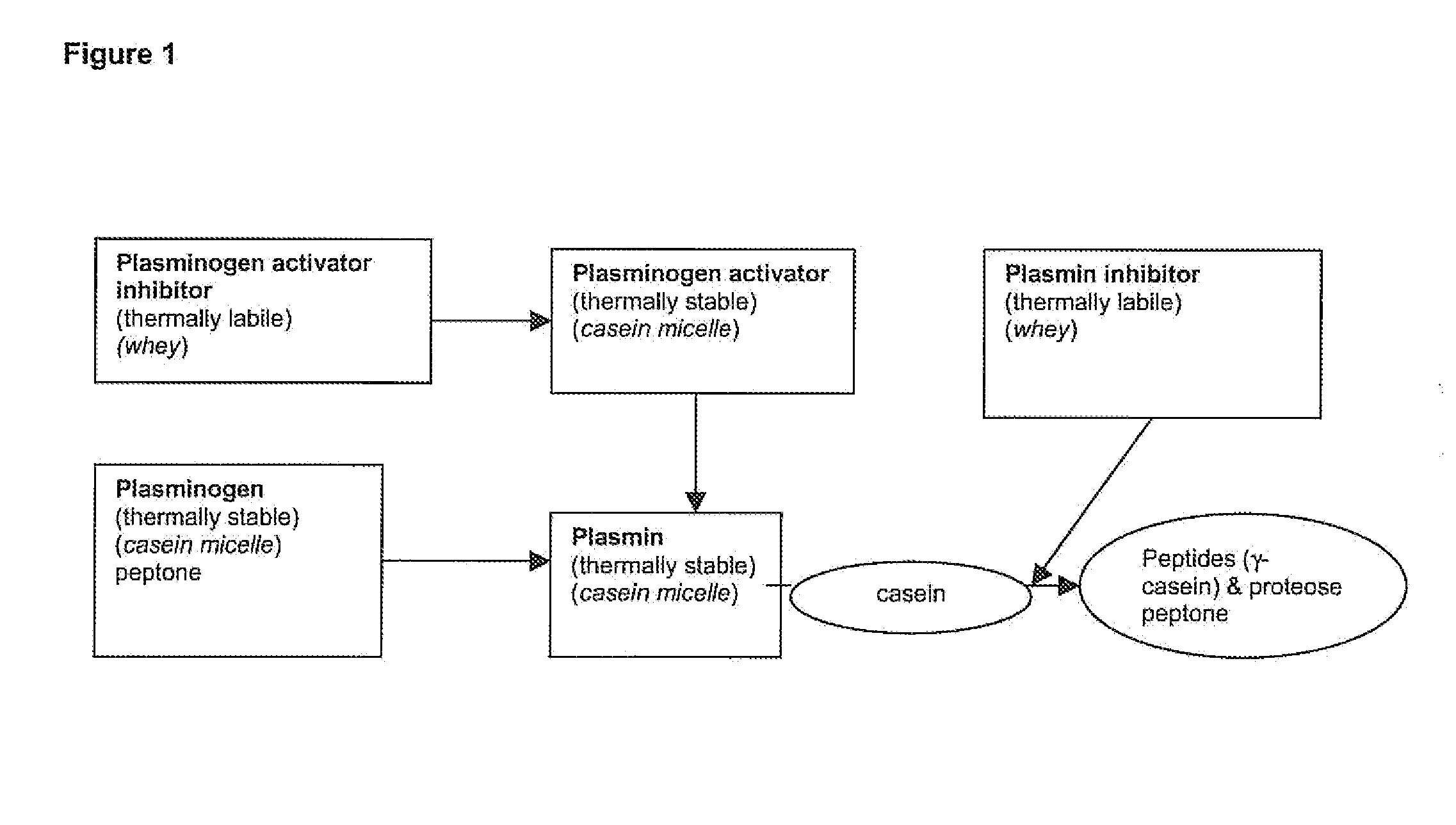

ActiveUS20120034367A9Organoleptic characteristics of the lactose-free milk product are retainedEasy to processMilk preparationOther dairy technologyLactose free milkMembrane configuration

The invention relates to processes for the separation of milk components by membrane-based processes. The invention also provides processes for producing lactose-free milk products from fractioned milk components, and lactose-free milk products that are prepared from fractionated milk components.

Owner:VALIO LTD

Lactose-Free Milk Products

A process for producing lactose-free milk products is proposed in which (a) skimmed milk is subjected to an ultrafiltration or to a combination of dia- and ultrafiltration, (b) the lactose-free retentate R1 is fed to a storage container and the lactose-containing permeate P1 is fed to an enzyme reactor, (c) an amount of lactase sufficient for the enzymatic degradation of the lactose present therein is added to the permeate P1, (d) the reaction mixture obtained in this way is subjected to a nanofiltration, (e) the lactose-free permeate P2 is conveyed to the storage container and mixed with the lactose-free retentate R2, and (f) the retentate R2, which still comprises unreacted lactose and enzyme, is returned again to the enzyme reactor.

Owner:DMK DEUT MILCHKONTOR

Lactose-removing milk process for lactose-free milk production

ActiveUS10743556B2Low production costMilk preparationOther dairy technologyBiotechnologyLactose free milk

The present invention relates to dairy and milk treatment industries for obtaining lactose-free milk and assessment of byproduct in particular, particularly to milk treatment industry through different separation means such as micro and nanofiltration equipment. One of the purposes of this invention is to provide a delactosed or lactose-free milk with sensory profile equivalent to a normal pasteurized milk using essential separation steps to reduce product costs. Another purpose of this invention is to determine the effect of milk natural components concentration on organoleptic properties to achieve the first purpose of this invention. Another purpose is to determine percentage between retentate and permeate to get a sensory profile equivalent to a normal pasteurized milk.

Owner:COMERCIALIZADORA DE LACTEOS Y DERIVADOS SA DE CV

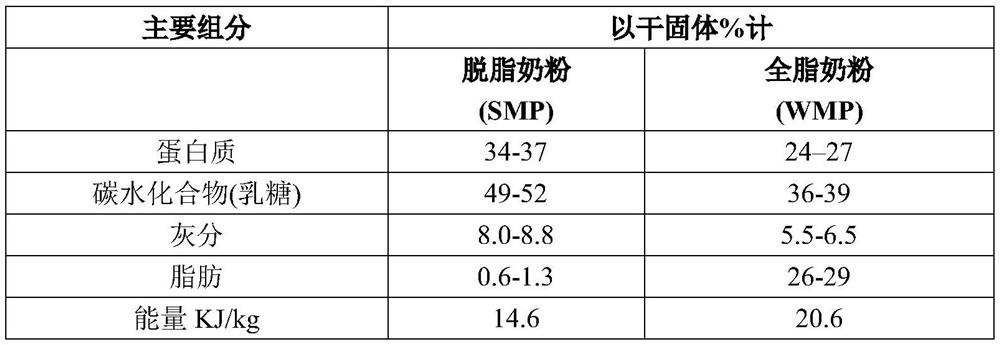

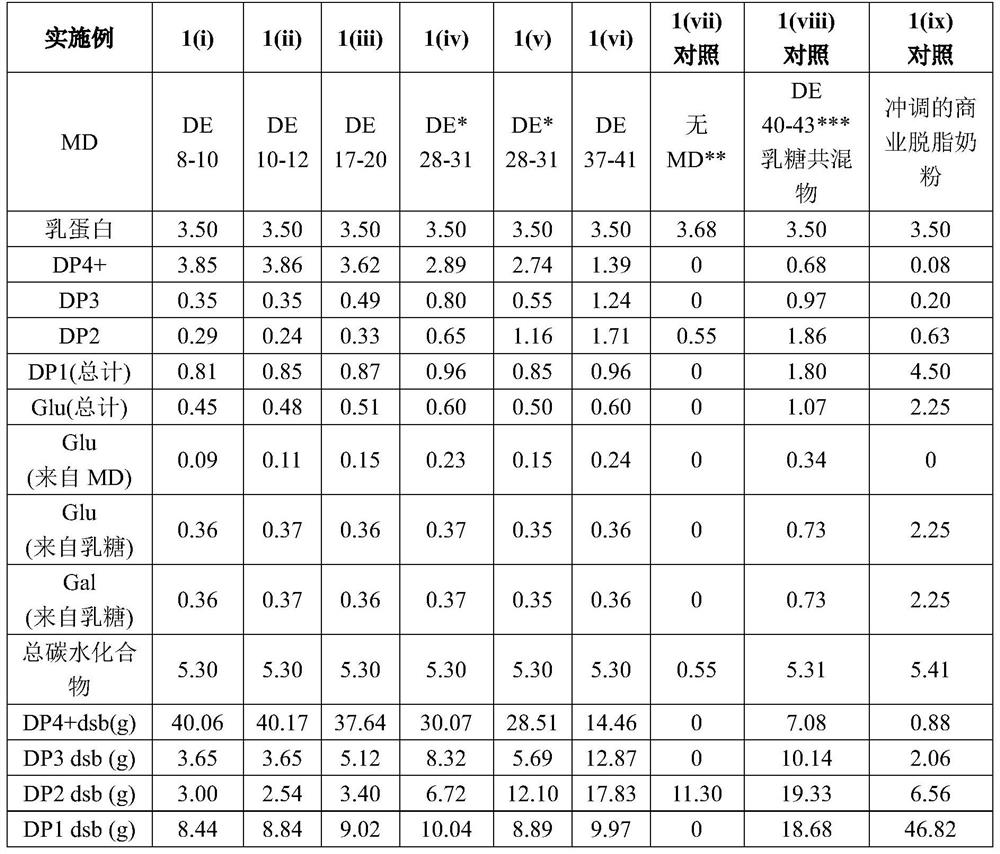

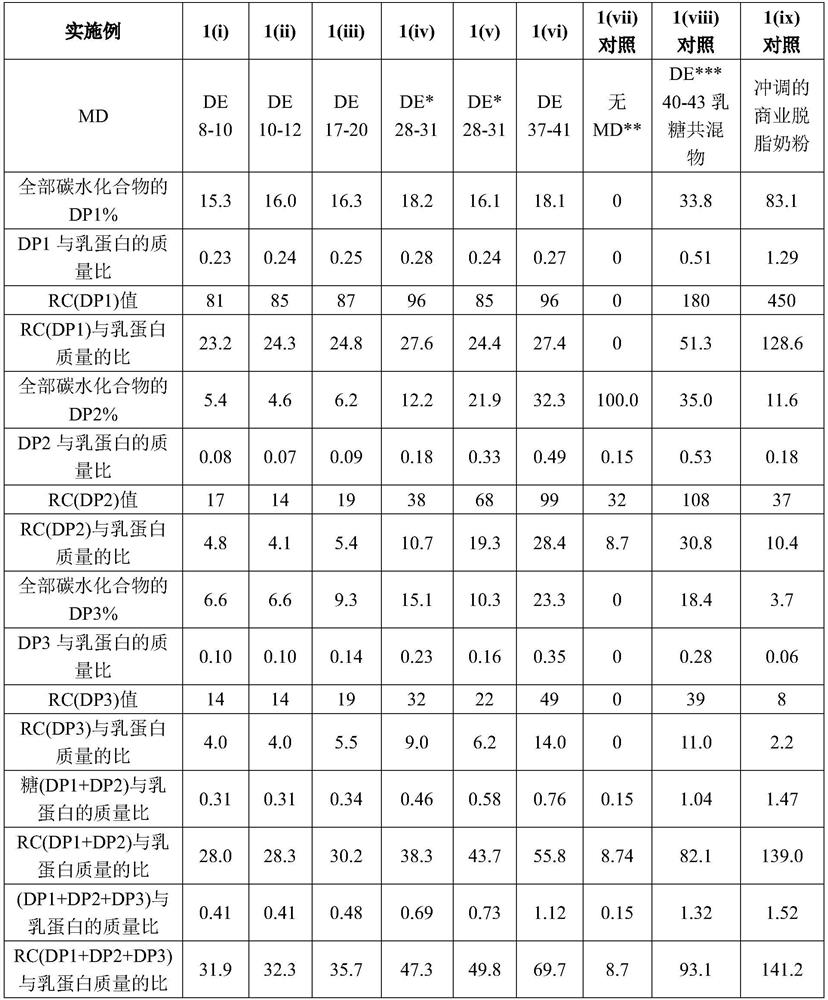

Lactose free milk products

Described herein are liquid, concentrated or dried lactose-free skim milk products or lactose- free, fat containing milk products that exhibit stability during thermal processing and storage as a result of the reductive carbohydrate to milk protein ratio of the milk products. The osmolality of the lactose-free milk products described herein also enable improved nutritional availability when compared to commercially available lactose hydrolysed milk products.

Owner:AGROTEKNIK +1

Low-lactose and lactose-free dairy products and methods for their manufacture

InactiveCN102131397BSimplify and improve productionReduce lossesMilk preparationLactose free milkMembrane technology

The present invention relates to a method for separating milk components, wherein proteins, sugars and minerals are separated into different fractions. The lactose in the milk is first fully or partially hydrolyzed, then proteins, minerals and sugars are separated into fractions in a staged nanofiltration. The fractions obtained can also be further processed by chromatography, membrane techniques and / or evaporation in order to further improve the separation of the components. The invention also relates to lactose-reduced or lactose-free milk consisting of these fractions. Through the present invention, the loss of calcium and protein can be minimized. Also, the energy content of the product can be reduced.

Owner:VALIO LTD

Process for preserving low-lactose or lactose-free milk product

InactiveUS10085462B2Improve propertiesImprove stabilityMilk preparationMilk preservationLactose free milkEnzyme system

The invention relates to a process for the production of well-preserving lactose-free and low-lactose milk products. The process of the invention is characterized by separating the sugars and proteins in a raw material, thermally treating them in such a manner that the plasmin enzyme system and other proteolytic enzymes are inactivated, and combining the fractions and other preparation agents into a drink with a required composition and properties.

Owner:VALIO LTD

Dairy-based lactose-free infant formula

Owner:HEBEI SANYUAN FOOD

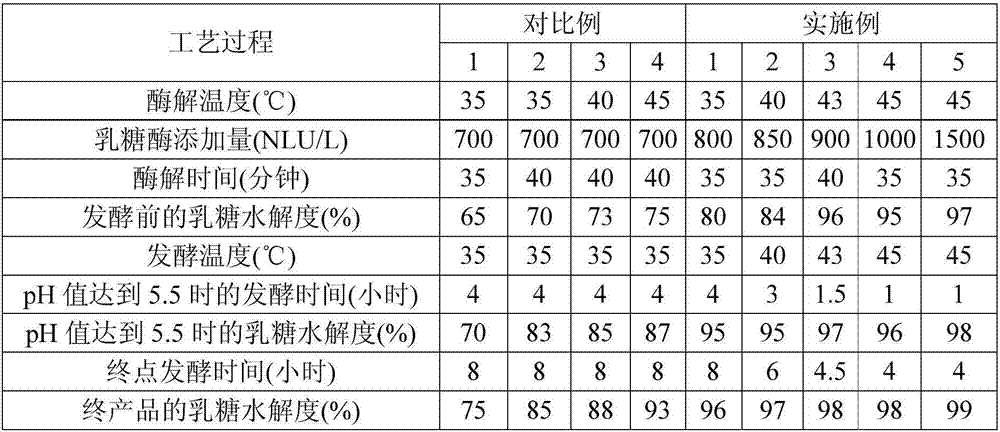

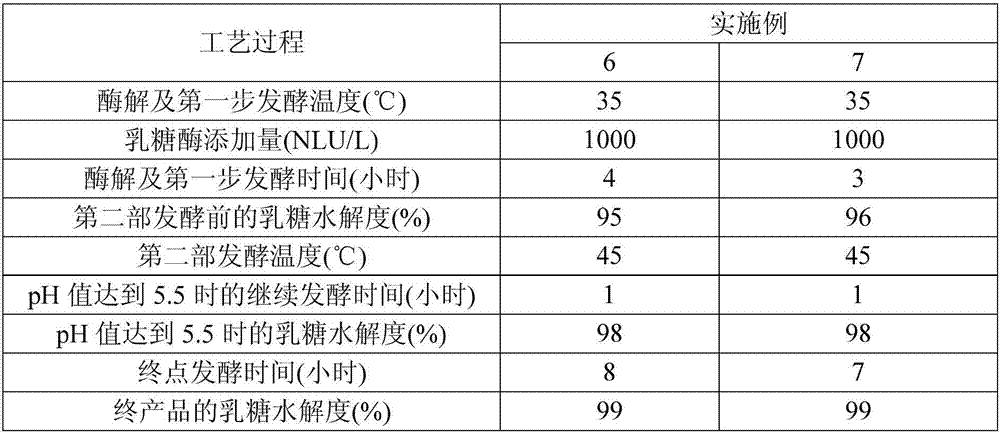

A kind of preparation method of lactose-free fermented milk product

The invention provides a method for preparing a lactose-free fermented milk product. The method comprises the following steps: the raw materials are mixed, homogenized, sterilized, enzymatically hydrolyzed and fermented, filled and refrigerated in order to obtain lactose-free fermented milk products, wherein the enzymolyzed and fermented steps include: When the hydrolysis degree is above 80% by adding lactase at low temperature, add bacteria, or add lactase at 41-45°C and add bacteria when the hydrolysis degree is above 95%, and the lactase will start to lose when the pH value of the feed liquid is 5.5. Live, when the pH value of the feed liquid is 4.3-4.5, the fermentation ends; or add lactase and mesophilic strains at 30-35°C, and when the pH value of the feed liquid is 5.5, heat up to 40-45°C to add thermophilic strains, feed liquid Fermentation ends at pH 4.3‑4.5. The invention can efficiently prepare lactose-free fermented milk products by adding lactase and improving the fermented milk preparation process.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com