Lactose free milk products

A technology for dairy products and products, applied in the field of lactose-free dairy products, can solve the problems of reduced production efficiency, loss of nutritional balance, and unrecovered carbohydrate content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] Preparation of lactose-free skimmed milk products

[0080] Lactose-free skim milk products are prepared as ready-to-mix liquids, liquid concentrates or dry powders. To prepare such lactose-free skim milk powder products (LF-SMP), the ratio of total digestible carbohydrates to milk protein is preferably comparable to that in whole lactose skim milk powder (SMP) to provide suitable nutrition for the adult consumer balance. When reconstituted from a lactose-free milk powder product, the viscosity of such skim milk products is such that it is comparable to skim milk at the same temperature and solids content.

[0081] An amount of lactose-free milk protein concentrate as milk protein concentrate (MPC), microfiltered milk protein concentrate (MMPC) or milk protein isolate (MPI) is added to one or more digestible polysaccharide hydrolysates and certain amount of minerals. The milk protein concentrate may be produced by filtration techniques to provide a milk protein concen...

Embodiment 1

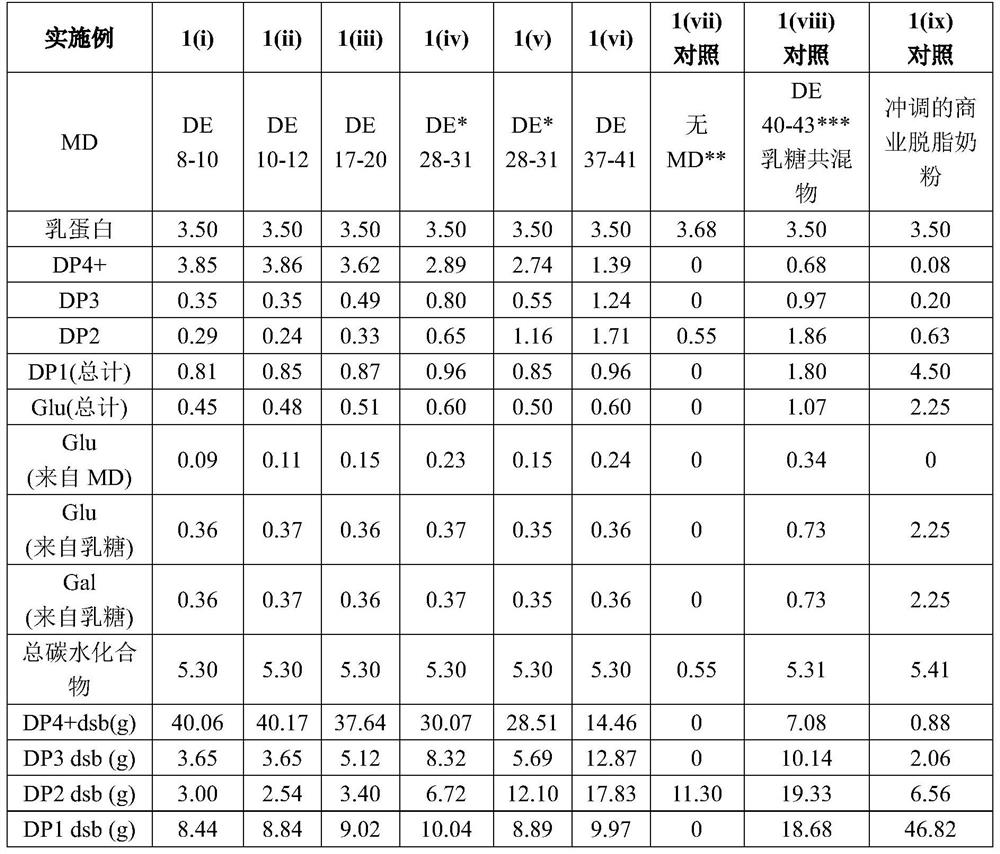

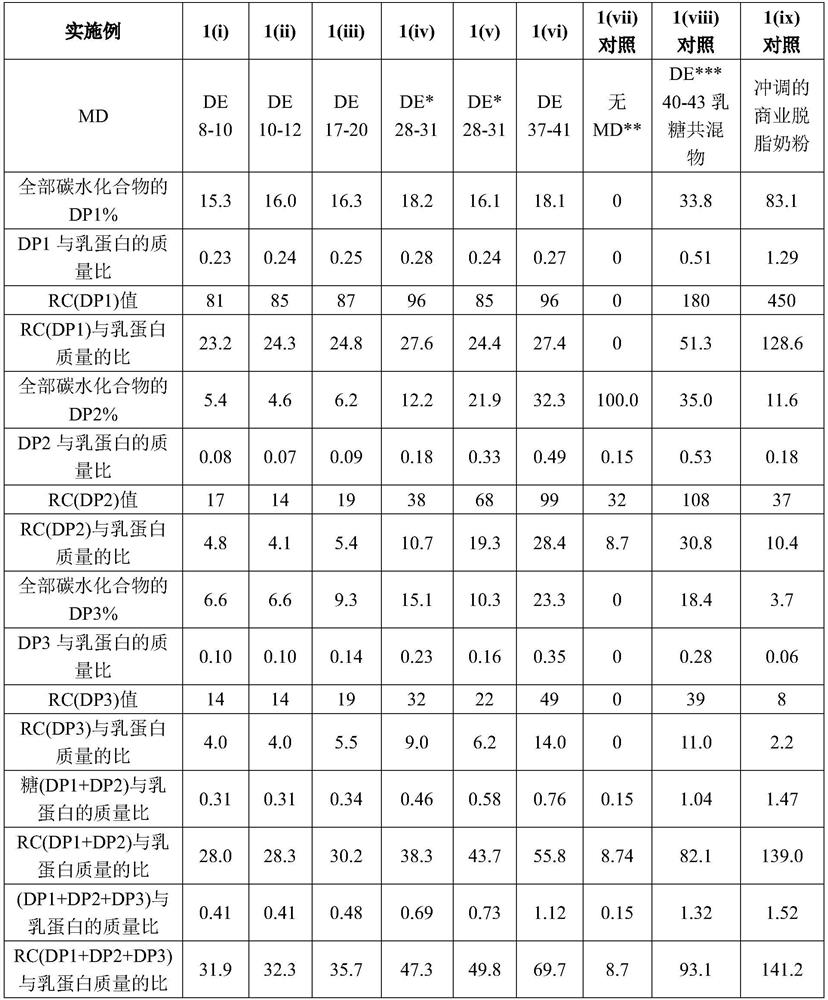

[0109] Example 1 - Laboratory-scale preparation of a liquid lactose-free skim milk product with a nutritional balance comparable to skim milk to identify suitable digestible polysaccharide hydrolysates to replace lactose when milk-derived minerals are included.

[0110]For industrial relevance, commercial dairy material originates from modern dairy plants that routinely produce milk protein concentrate (MPC) isolates from milk using membrane technology and recover the mineral components using a range of technologies , lactose and other milk fractions. All dairy ingredients were obtained by composition analysis performed by the dairy factory laboratory. Analytical details are provided in Table 3.

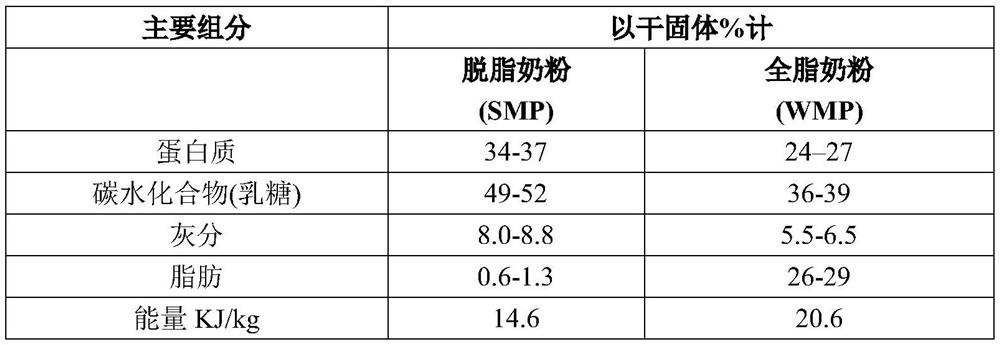

[0111] Table 3: Composition of Milk Components

[0112] milk ingredients Moisture % protein% Fat% carbohydrate% Ash% Total solids% MPC-85 4.8 85 1.2 3.5 6.8 95.2 mineral powder 4.5 15 3 44 33.5 96.5 mineral concentrate 63.1 6.5 0....

Embodiment 2

[0163] Example 2 - Lab-scale preparation of a liquid lactose-free skim milk product with a nutritional balance comparable to skim milk to identify suitable lactose substitutes for lactose when using non-dairy derived minerals supplied as food grade chemicals digestible polysaccharide hydrolyzate

[0164] The commercial milk protein concentrate such as MPC-85 is derived from a modern dairy factory as in Example 1, and its composition analysis is shown in Table 3.

[0165] As shown in Example 1, digestible starch hydrolysates covering a range of dextrose equivalents were obtained from commercial suppliers as maltodextrins.

[0166] In order to evaluate the suitability of each available maltodextrin product for replacing lactose in lactose-free non-fat milk products incorporating food-grade minerals, small batches of the product were prepared as shown in Example 1, in which mineral Substances are commercially available food grade chemicals, not milk derived minerals. As a resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com