Patents

Literature

121 results about "Milk protein concentrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Milk protein concentrate (MPC) is any type of concentrated milk product that contains 40–90% milk protein. The United States officially defines MPC as "any complete milk protein (casein plus lactalbumin) concentrate that is 40 percent or more protein by weight." In addition to ultrafiltered milk products, the MPC classification includes concentrates made through other processes, such as blending nonfat dry milk with highly concentrated proteins, such as casein.

Method for producing nutritionally balanced food compositions

InactiveUS20050003054A1High activityExtended shelf lifeFruit and vegetables preservationMilk preservationEmulsionSoya bean

This invention relates to a process for manufacturing nutritionally balanced food compositions suitable for retort sterilization which have a low pH, extended shelf life, high antimicrobial activity, and which include protein in a stable emulsion. The primary protein source for the food composition is caseinates or milk protein concentrates and isolates comprised mostly of casein. Alternately, milk protein concentrates, milk protein isolates, milk protein hydrolystates, soy protein isolates or soy protein concentrates may also be used. The process includes two homogenization steps.

Owner:ENTRA SAFE

Pre-mix formulations comprising ingredients for dairy products

InactiveUS20060134297A1Avoid disadvantagesMilk preparationCheese manufacturePreservativeAdditive ingredient

Ingredients and methods of using ingredients to produce dairy based food products. The ingredients may include milk protein concentrate, fat containing powders and other compounds including sweetening agents, flavours, preservatives, salts and emulsifiers. Food products that can be made according to the invention include yoghurt, cheese, cheese spreads, sweet spreads, nutrition bars, cream cheese, dairy desserts and sour cream.

Owner:FONTERRA COOP GRP LTD

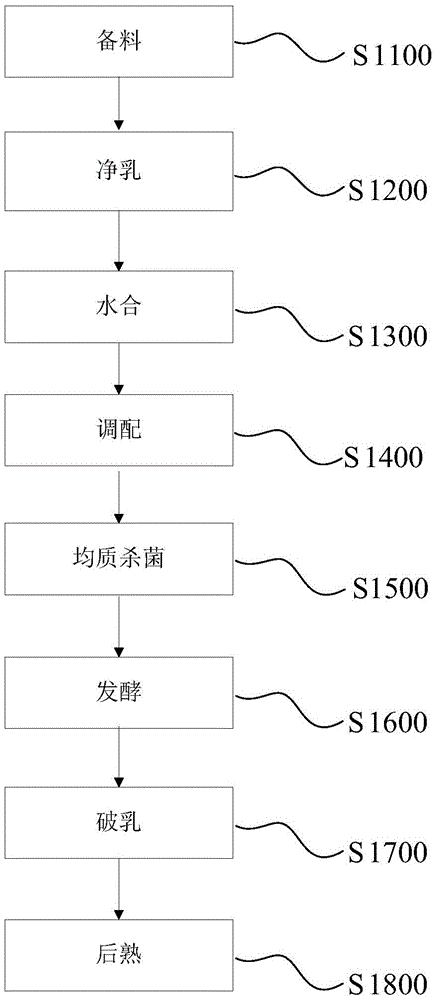

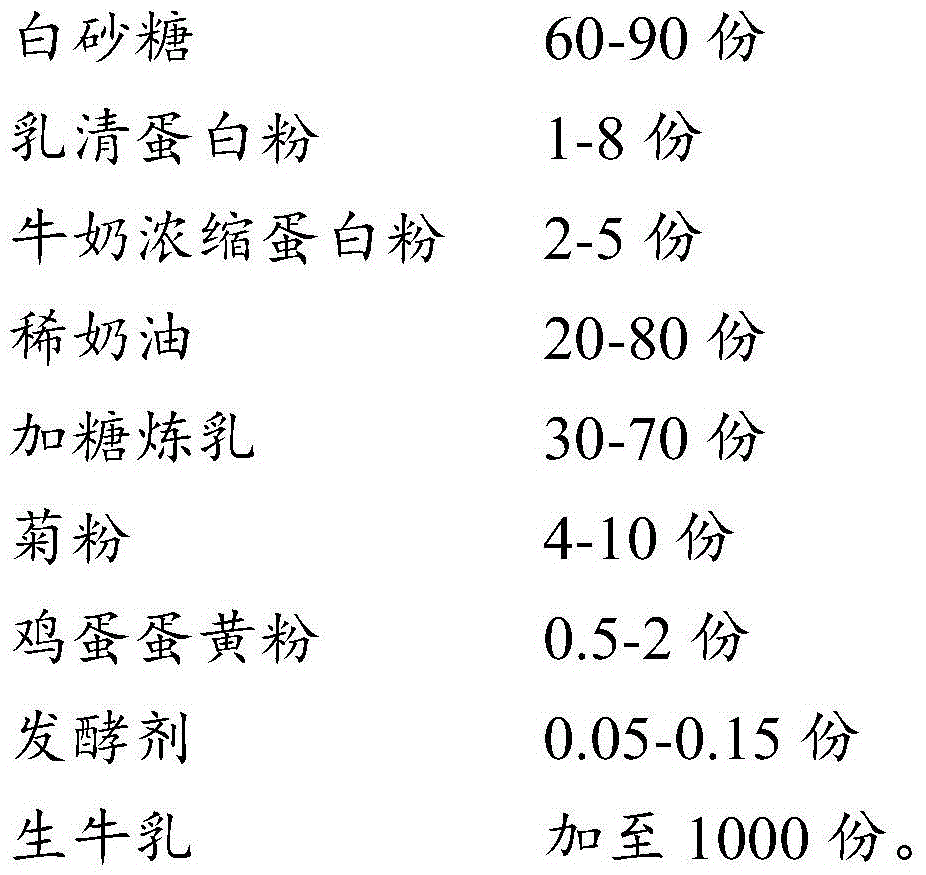

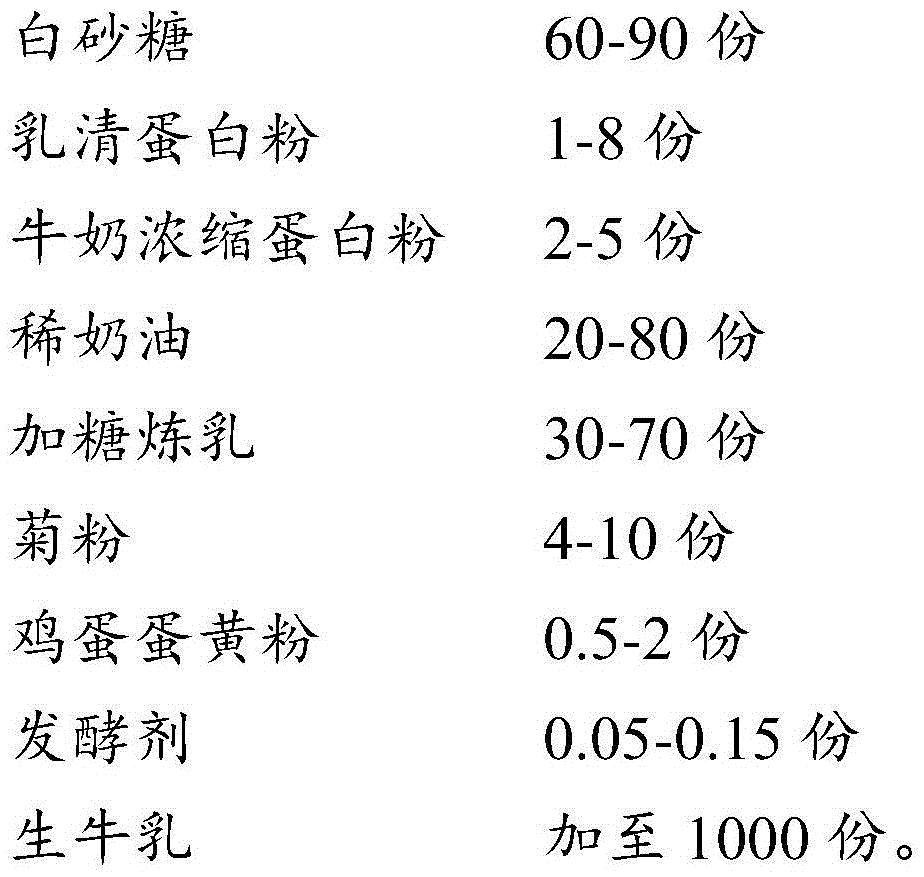

Stirring-type flavored fermented milk and preparation method thereof

The invention discloses stirring-type flavored fermented milk, which is prepared from the following raw materials in parts by weight: 60-90 parts of white granulated sugar, 1-8 parts of whey protein powder, 2-5 parts of milk protein concentrate powder, 20-80 parts of single cream, 30-70 parts of sweetened condensed milk, 4-10 parts of inulin, 0.5-2 parts of egg yolk powder, 0.05-0.15 part of leavening agent and the balance of raw milk ( 1,000 parts in total). The invention further discloses a preparation method of the stirring-type flavored fermented milk. The stirring-type flavored fermented milk is delicate in taste, good in flavor, stable in quality in shelf life; the raw materials also contain the inulin and the egg yolk powder with nutrient health effects; and the prepared product is abundant in nutrient and suitable for people of all ages to eat.

Owner:KUNMING XUELAN MILK

Milk protein products and processes

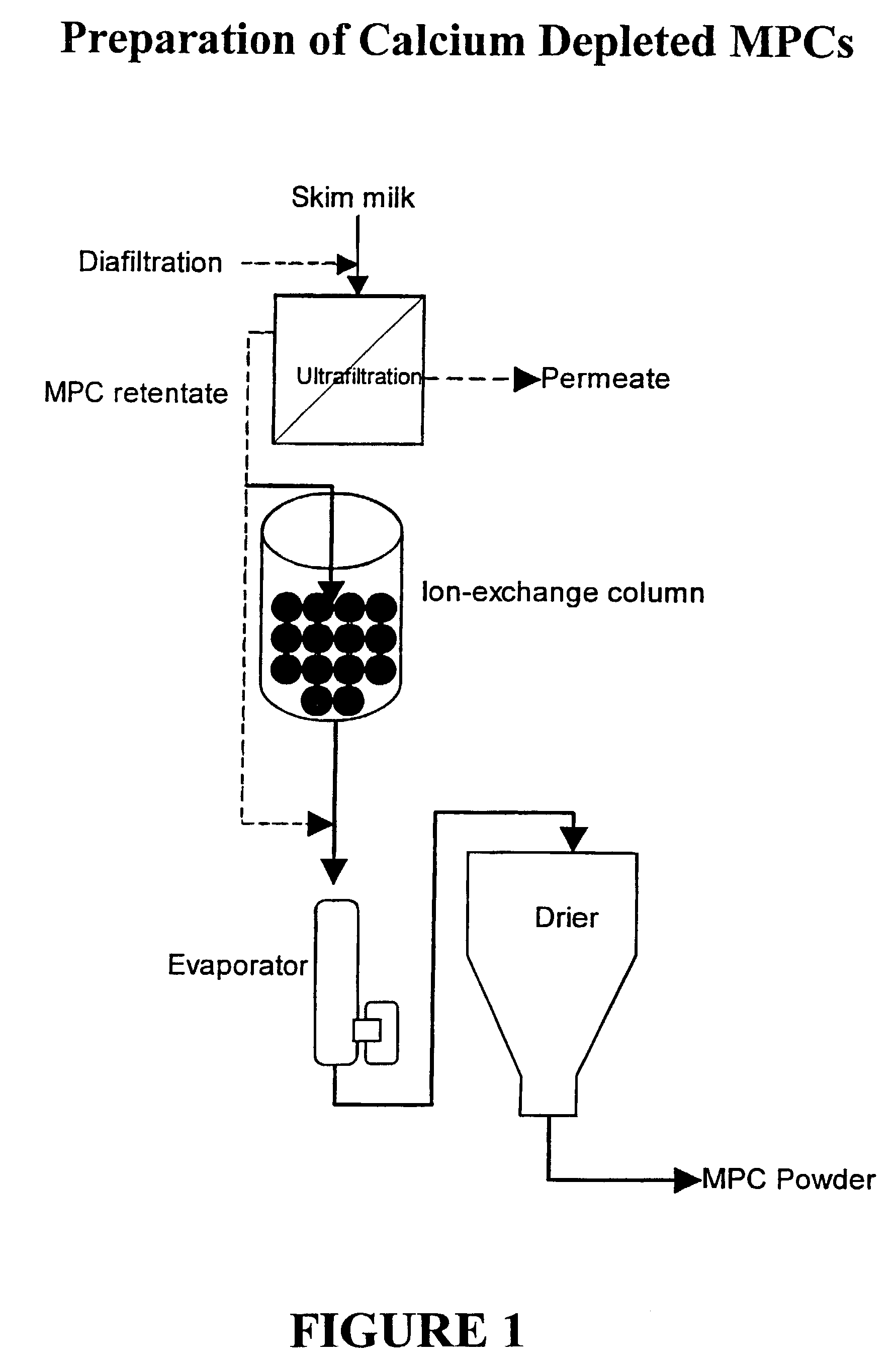

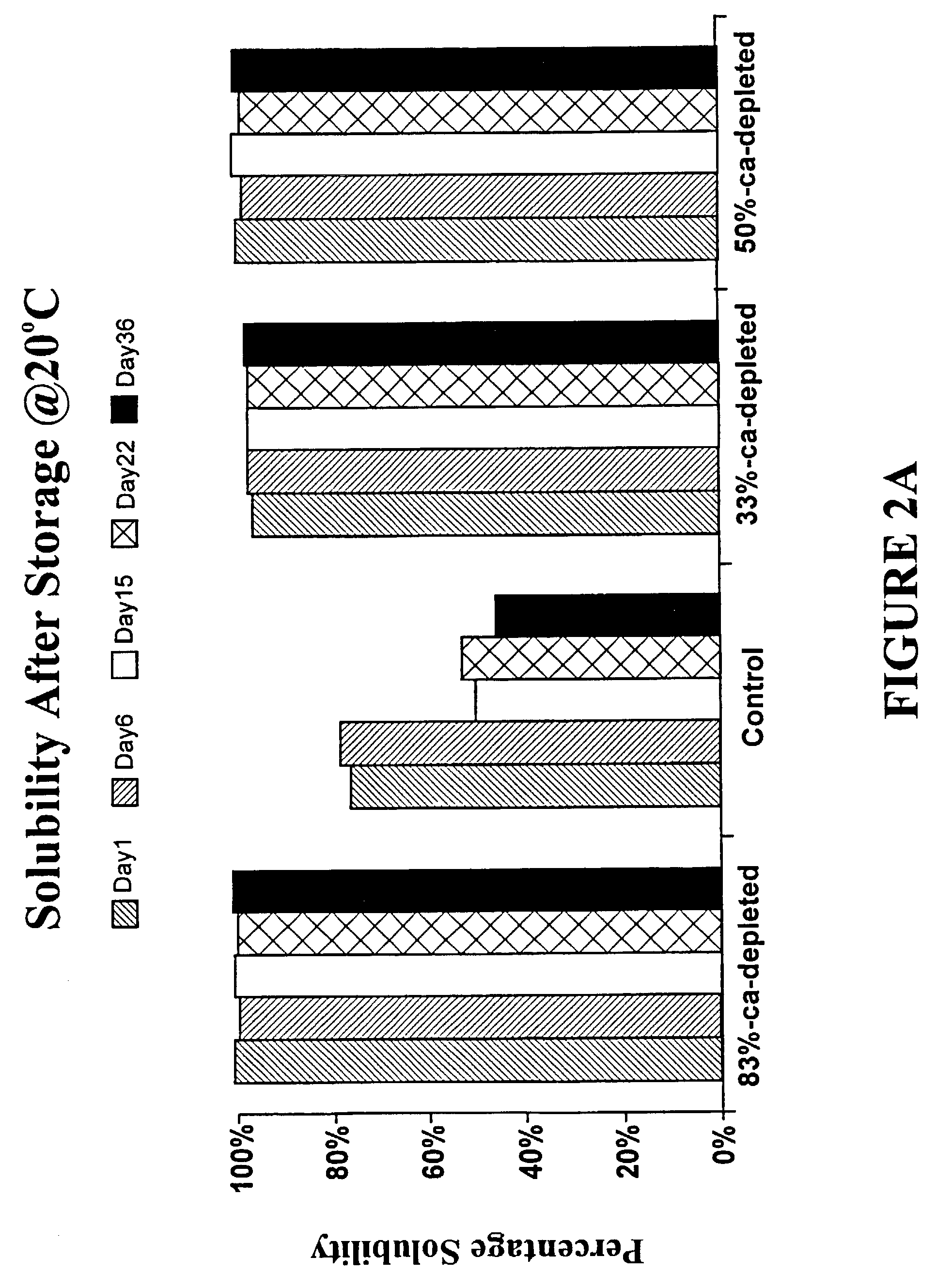

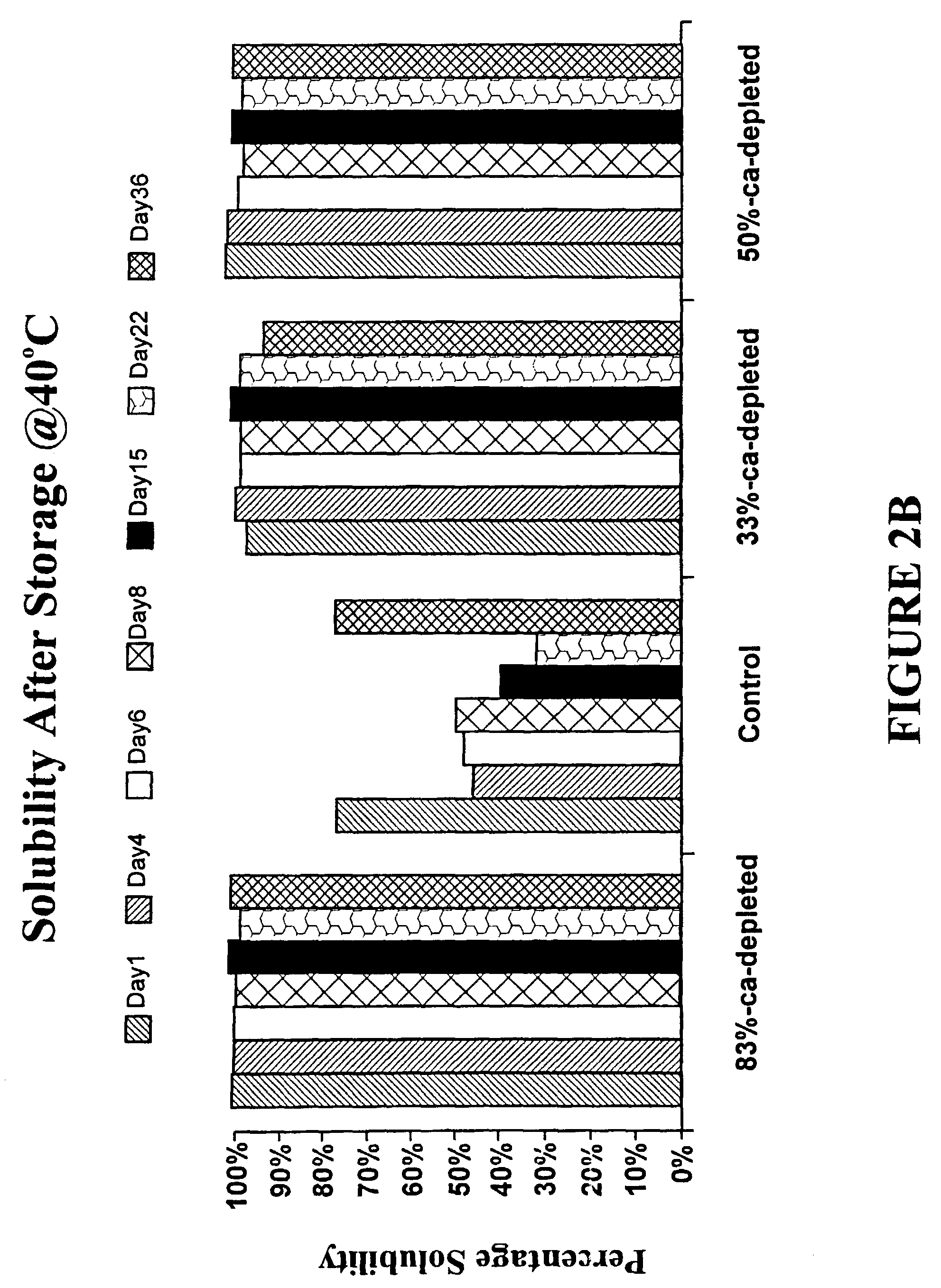

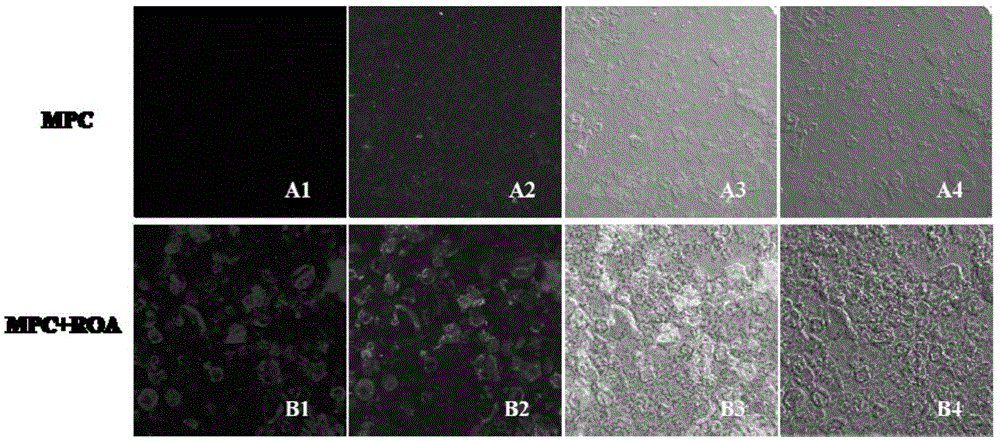

InactiveUS7157108B2Improve solubilityReduced nutritional valueProtein composition from fishMilk preparationCalcium depletionsCow milk

The invention relates to dried milk protein concentrates and their use. In particular the invention relates to such dried concentrates which have been calcium-depleted to an extent which allows improvements in the use of dried milk protein concentrates in cheese manufacture. The invention includes a method of cheese manufacture comprising: (a) dispersing in milk a dried MPC or MPI having at least 70% dry matter as milk protein; (b) treating the resulting mixture with one or more coagulating enzymes to produce a curd; and (c) processing the curd to make cheese; wherein the dried MPC or MPI is a calcium-depleted MPCF or MPI and the extend of calcium depletion is sufficient to allow manufacture of substantially nugget-free cheese.

Owner:FONTERRA COOP GRP LTD

Pre-mix formulations comprising ingredients for dairy products

Compositions and methods of using the compositions to prepare dairy food products are disclosed. The ingredients may include milk protein concentrates, fat containing powders and other mixtures including sweeteners, flavorings, preservatives, salt and emulsifiers. Food products prepared according to the invention include yogurt, cheese, soft cheese, spreads, nutritional bars, cream cheese, dairy desserts and yoghurt.

Owner:FONTERRA COOP GRP LTD

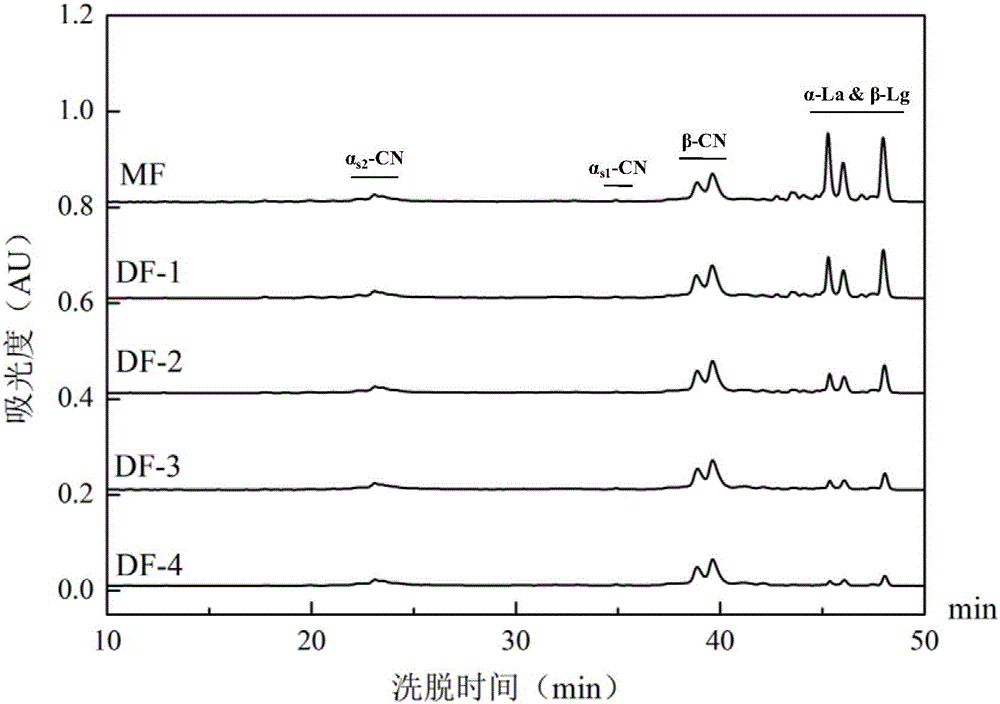

Method for separating cow milk beta-casein and whey protein at low temperature through microfiltration to simulate composition of human lactoprotein

ActiveCN106417888ARealize targeted regulationEfficient separationMilk preparationProtein composition from milkGlucono delta-lactoneAdditive ingredient

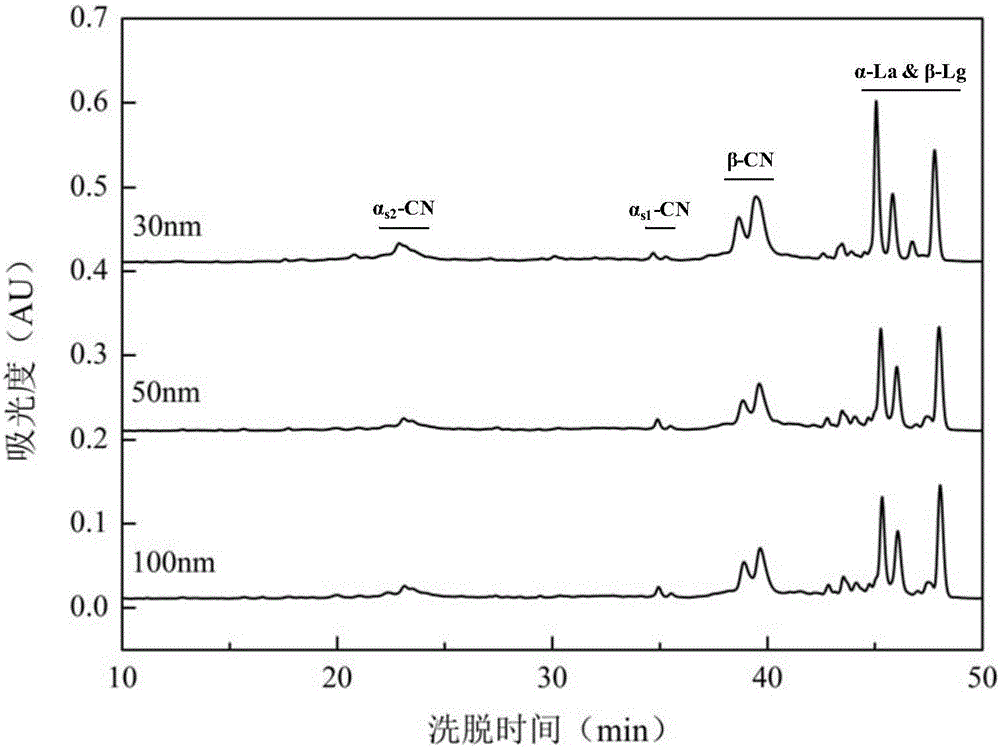

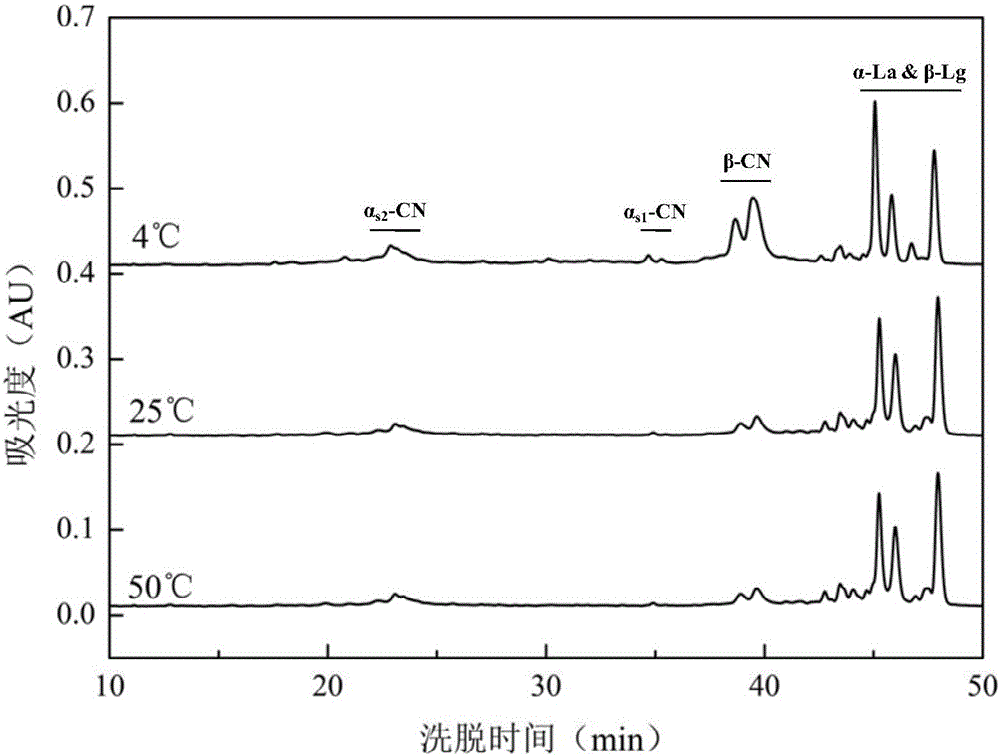

The invention relates to a method for separating cow milk beta-casein and whey protein at the low temperature through microfiltration to simulate composition of human lactoprotein. Skim milk, whole milk, dried skim milk, concentrated milk protein powder and the like are taken as raw materials, decalcification pretreatment is performed with the adoption of citrate, glucono-delta-lactone and other chelating agents or an acidifier, microfiltration and filter wash are performed with the adoption of a ceramic membrane or a polyethersulfone membrane and the like under the low-temperature (0-15 DEG C) condition, beta-casein and whey protein are selectively enriched into a permeating liquid, the permeating liquid is subjected to spray drying and dewatering after lactose and mineral substances are removed through ultrafiltration and concentration, and high-protein powder containing rich beta-casein and whey protein is prepared. An adopted technical process has the characteristics of being environment-friendly, efficient, high in operability, good in safety and the like and is suitable for large-scale industrial production. The obtained compound protein powder can serve a novel functional lactoprotein ingredient to replace whey protein and is used for research and development of infant food such as formula milk powder and the like, so that the protein molecule composition of the compound protein powder is closer to that of human lactoprotein.

Owner:JIANGNAN UNIV

Milk protein concentrates

InactiveUS20130011515A1Reduce the amount requiredMilk preparationProtein composition from milkFiltrationWhey protein

A method for making a milk protein concentrate can comprise heating a liquid milk composition at near its natural pH to a temperature that causes the whey protein in the milk to bind to the casein in the milk to form protein aggregates. After cooling, the liquid milk composition can be subjected to membrane filtration using a membrane filter having a large pore size. The protein aggregates are retained to yield a milk protein concentrate. The concentrate can be further treated to provide a concentrate having a lowered lactose content.

Owner:HORMEL FOODS

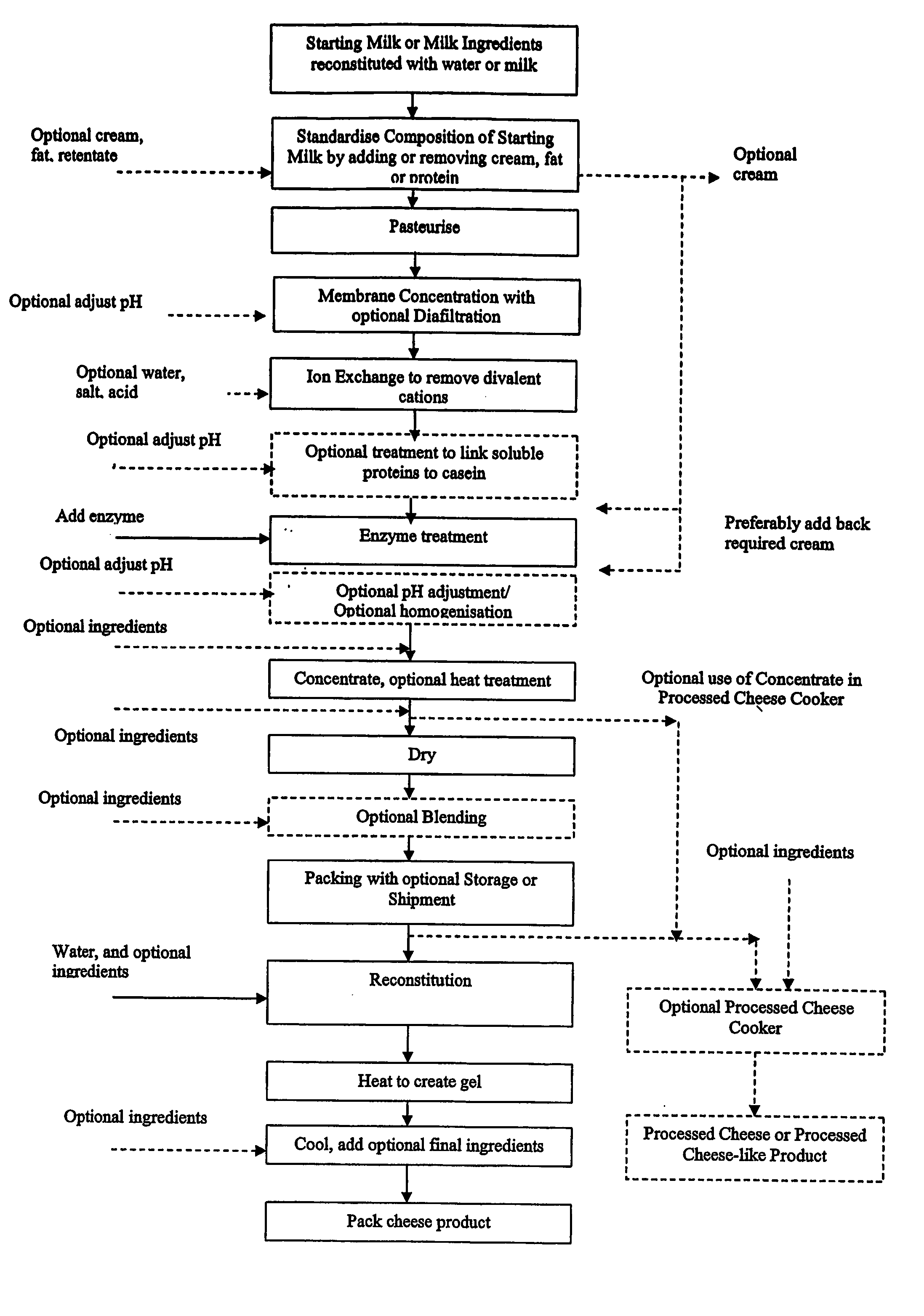

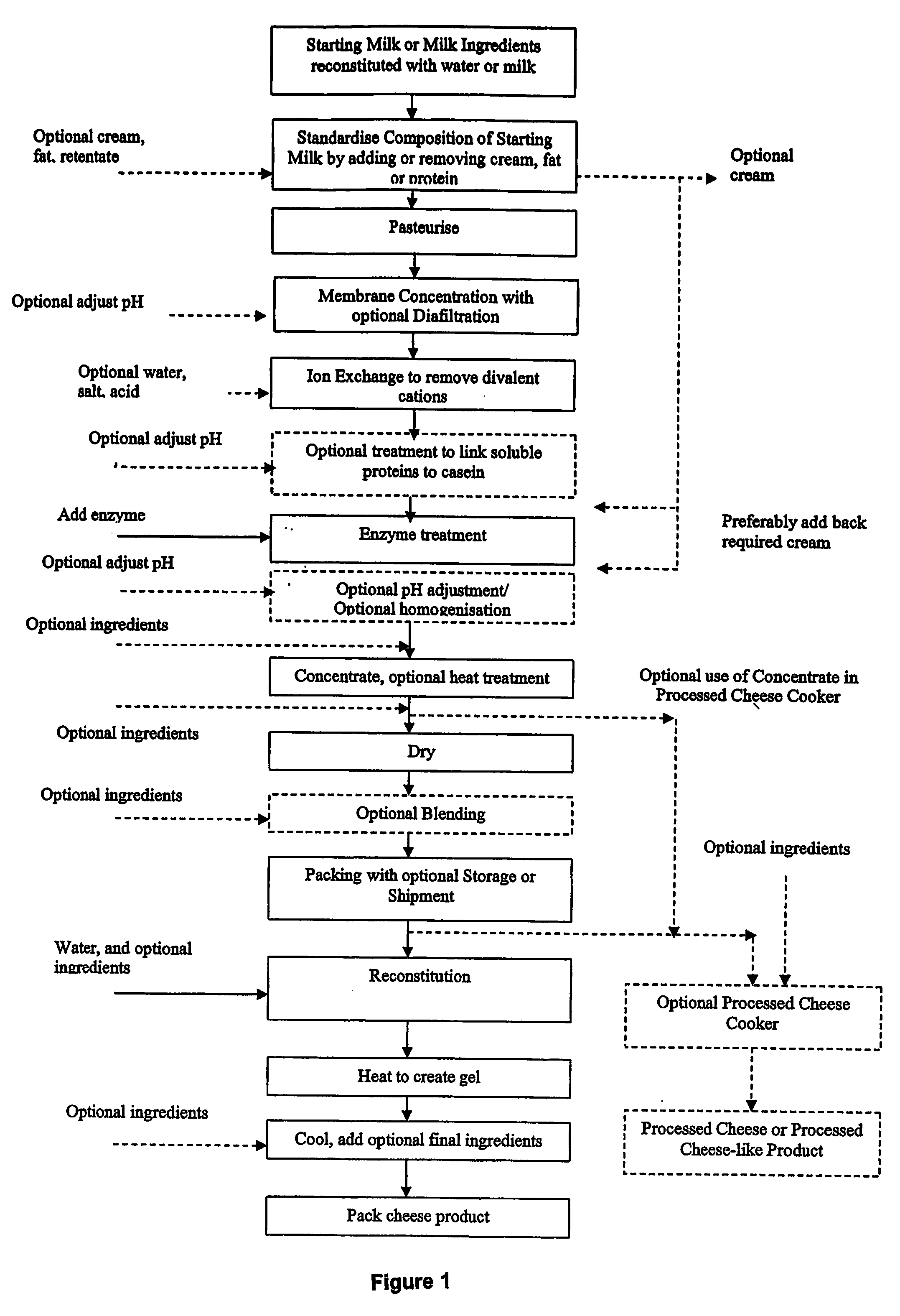

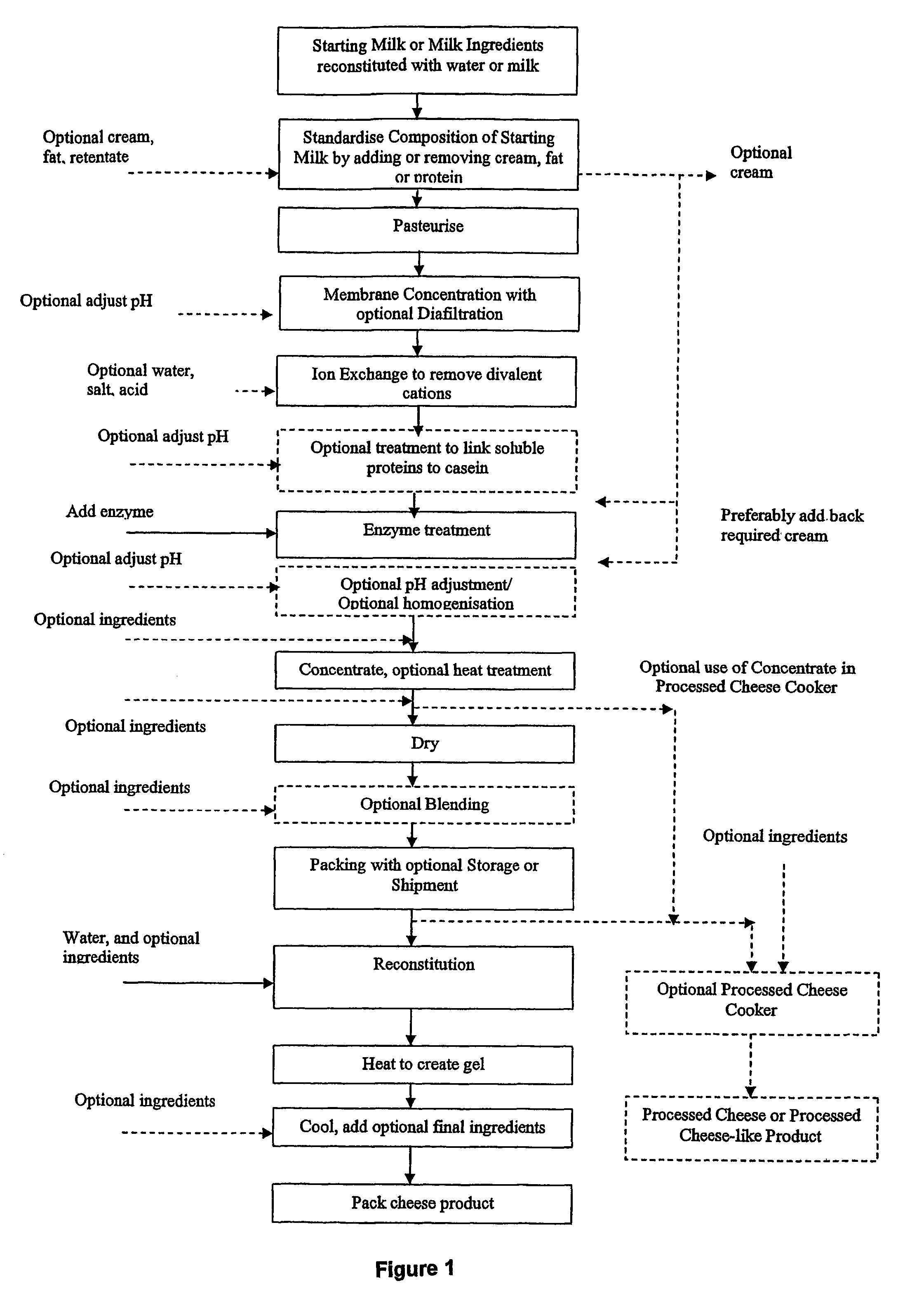

Process for preparing concentrated milk protein ingredient and processed cheese made thererfrom

Process for preparing a concentrated milk protein ingredient comprising the steps of: providing a membrane retentate solution having kappa-casein milk protein, adjusting the divalent ion content of said protein solution to a predetermined level at which no gel is formed after treatment with milk clotting enzyme, adding a food grade milk clotting enzyme under conditions where kappa-casein is converted to para-kappa casein while remaining in solution, terminating the conversion by removal or inactivation of the enzyme and concentrating said solution. The resultant milk protein concentrate ingredient is used in the production of cheese.

Owner:FONTERRA COOP GRP LTD

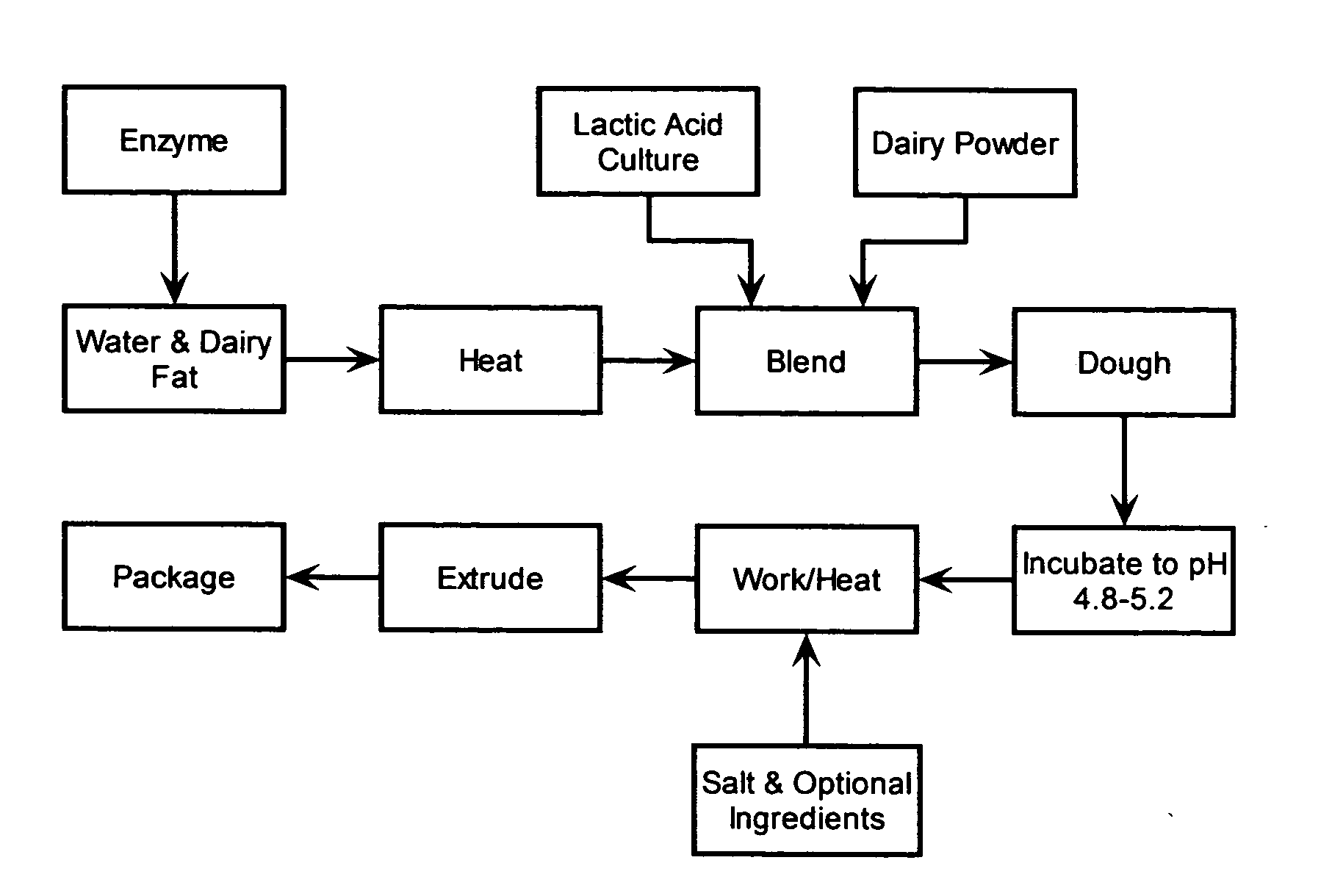

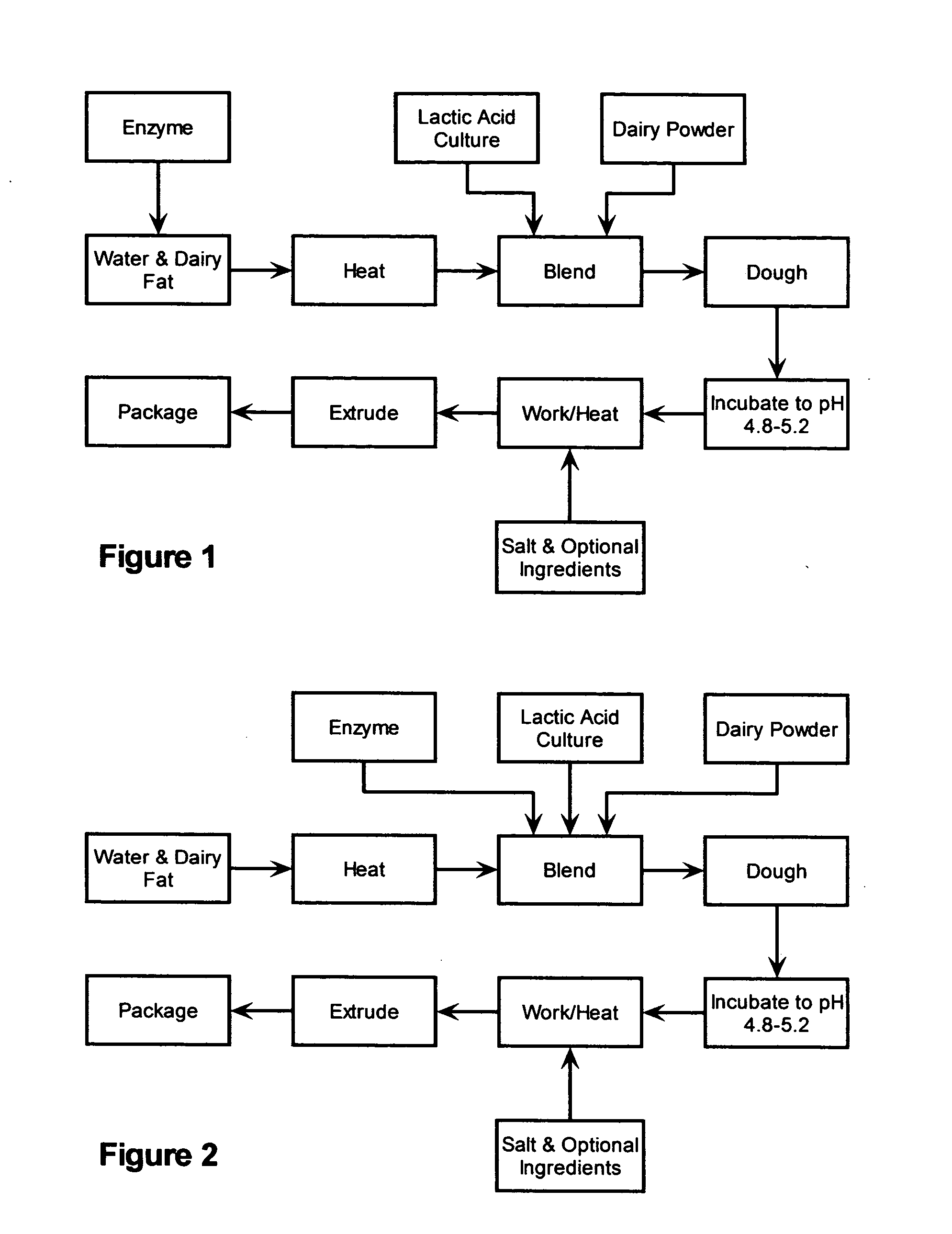

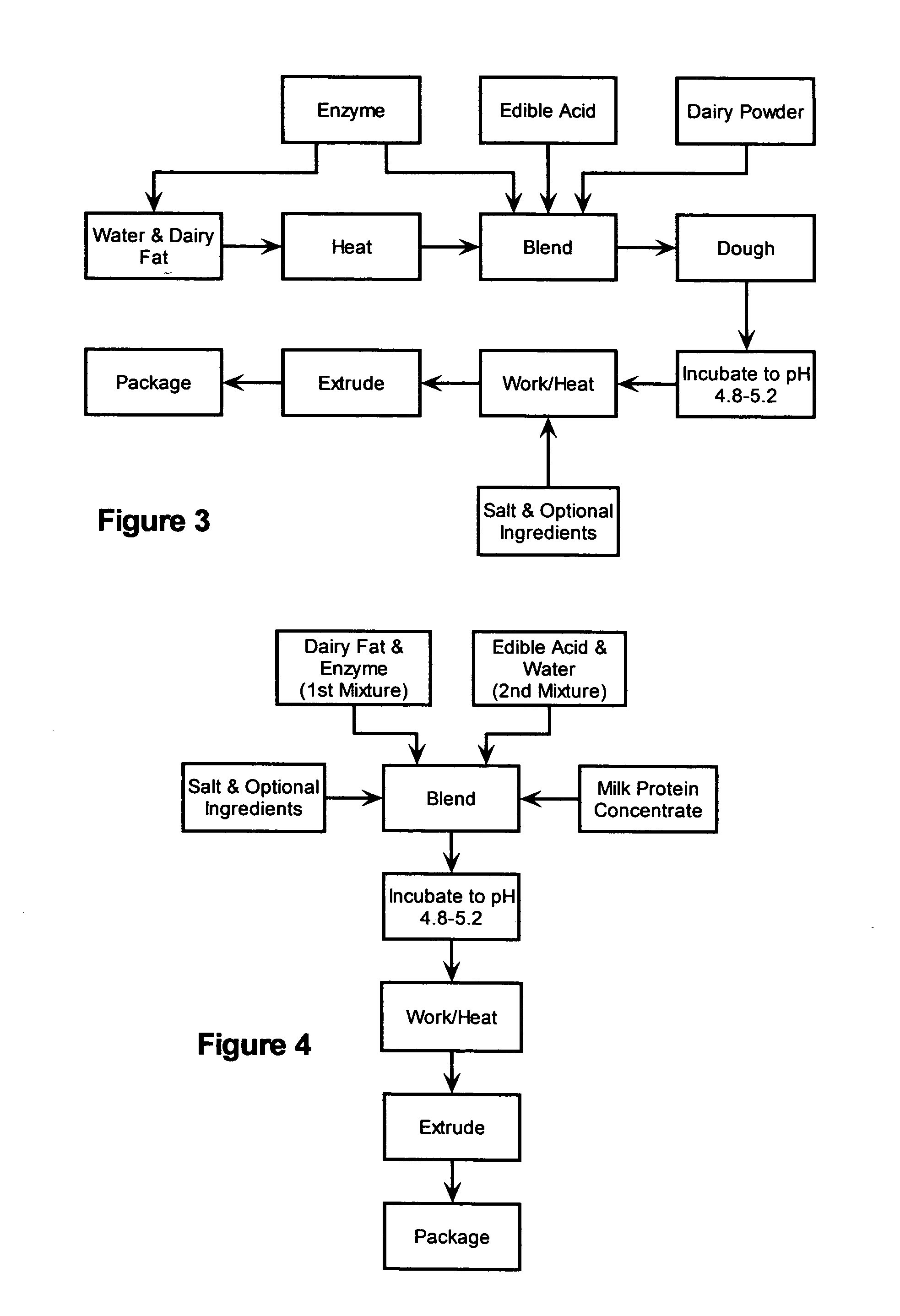

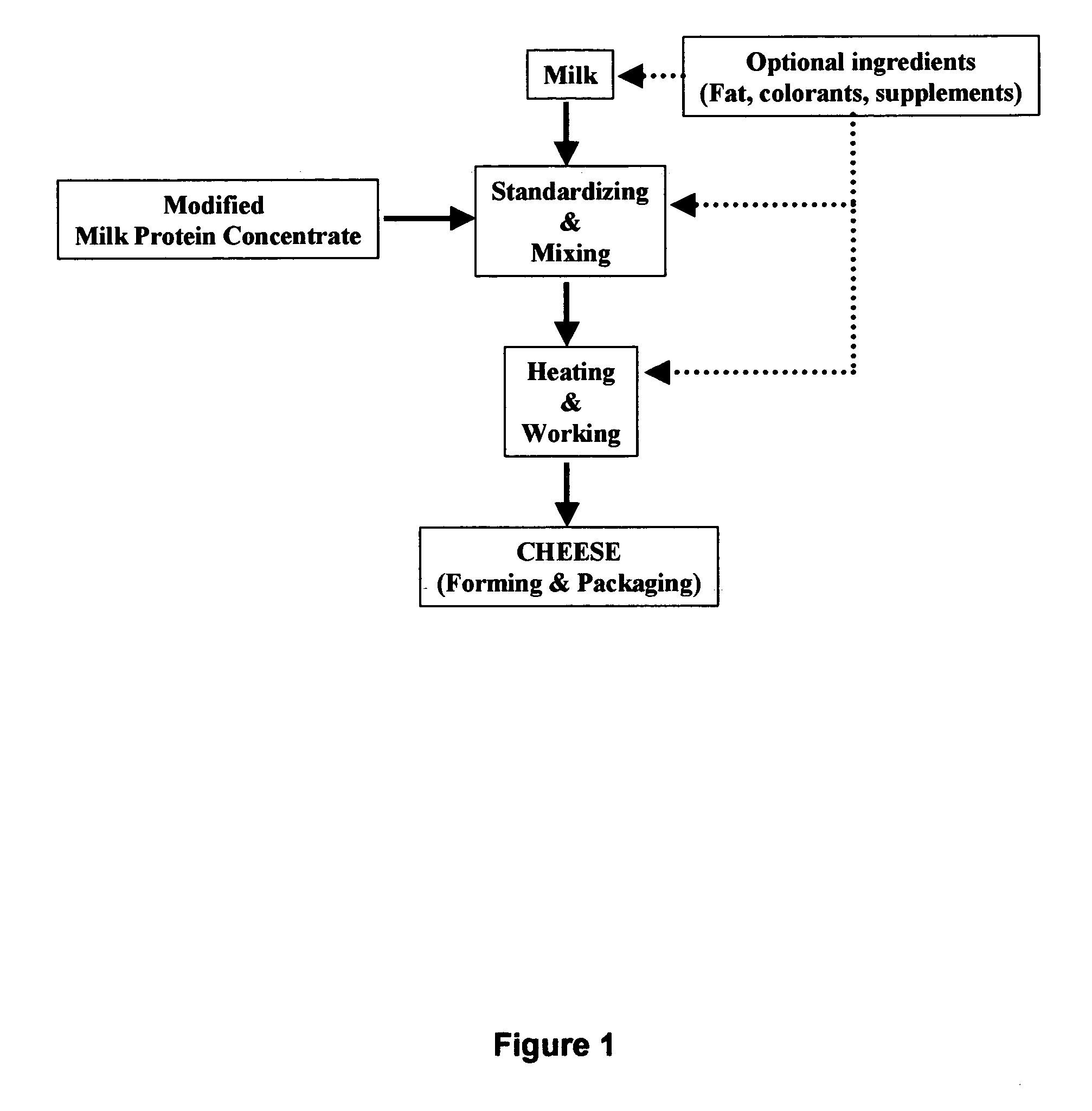

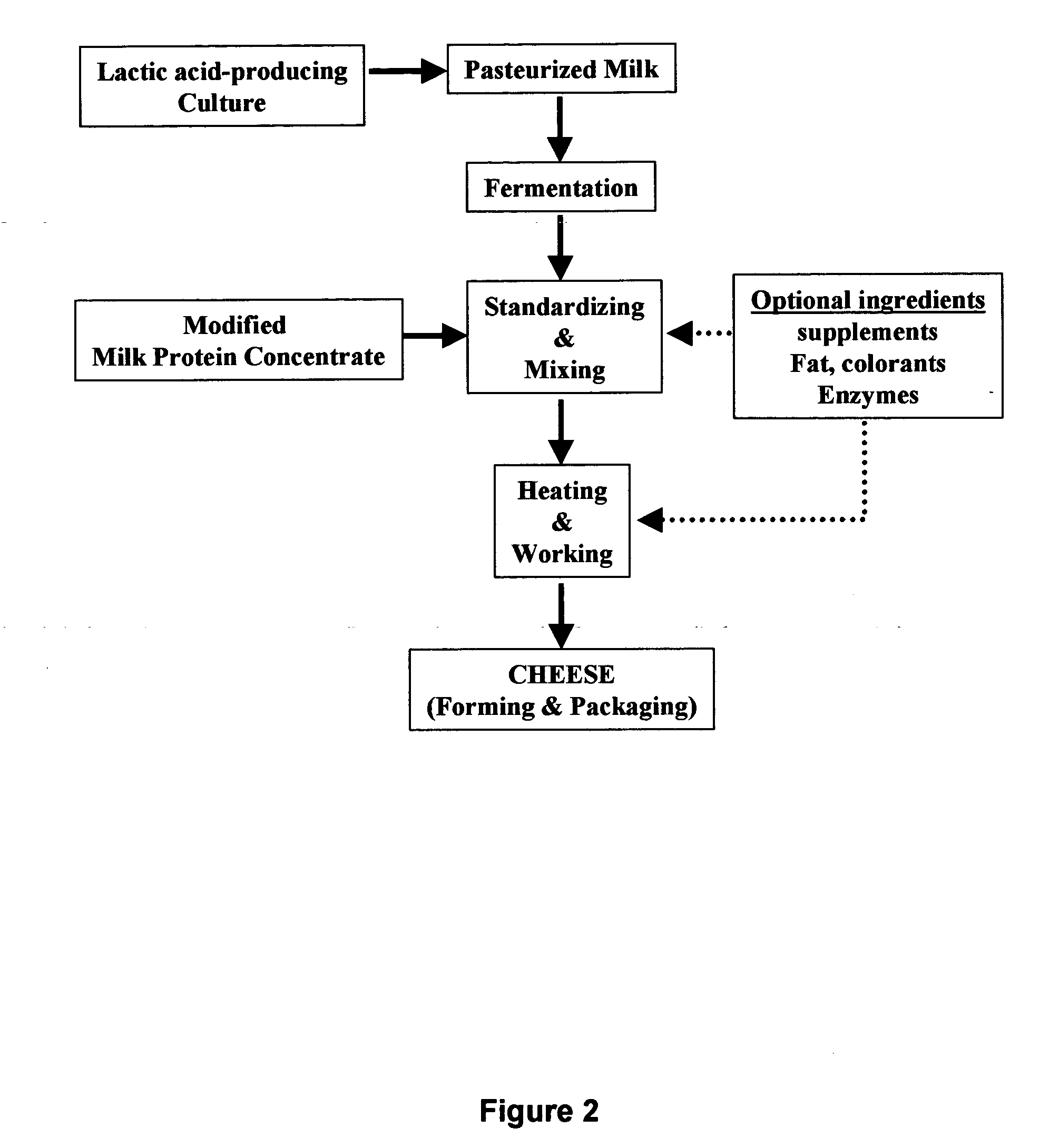

Wheyless process for the production of string cheese

InactiveUS20060057248A1Reduce lactoseReduce salt levelMilk preparationCheese manufactureAdditive ingredientMilk protein concentrate

The present invention provides a wheyless process for preparing natural mozzarella string cheese using dry dairy ingredients. This process enables the manufacture of string cheese from non-perishable or shelf-stable ingredients such as dried milk protein concentrate and anhydrous milkfat.

Owner:KRAFT FOODS INC

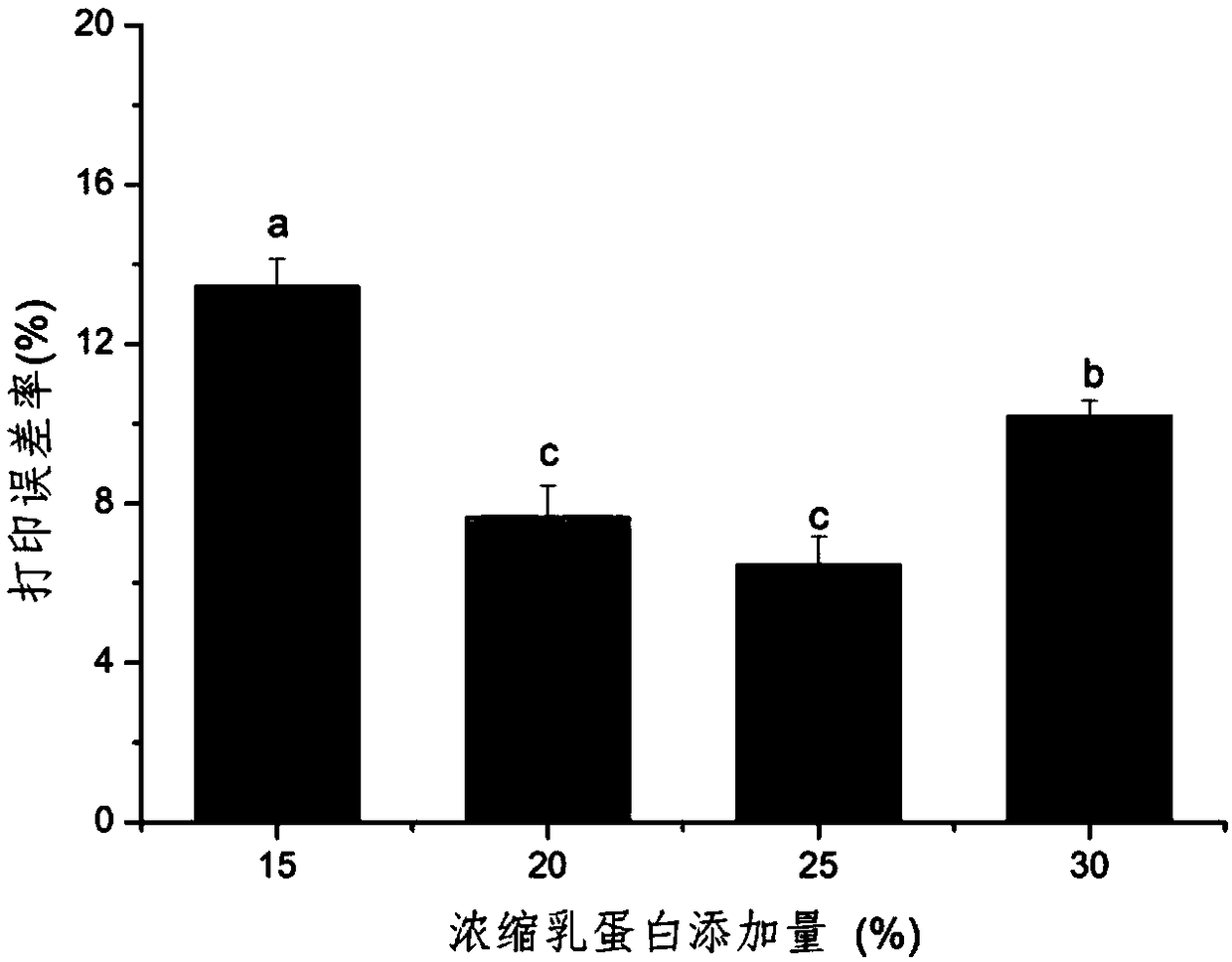

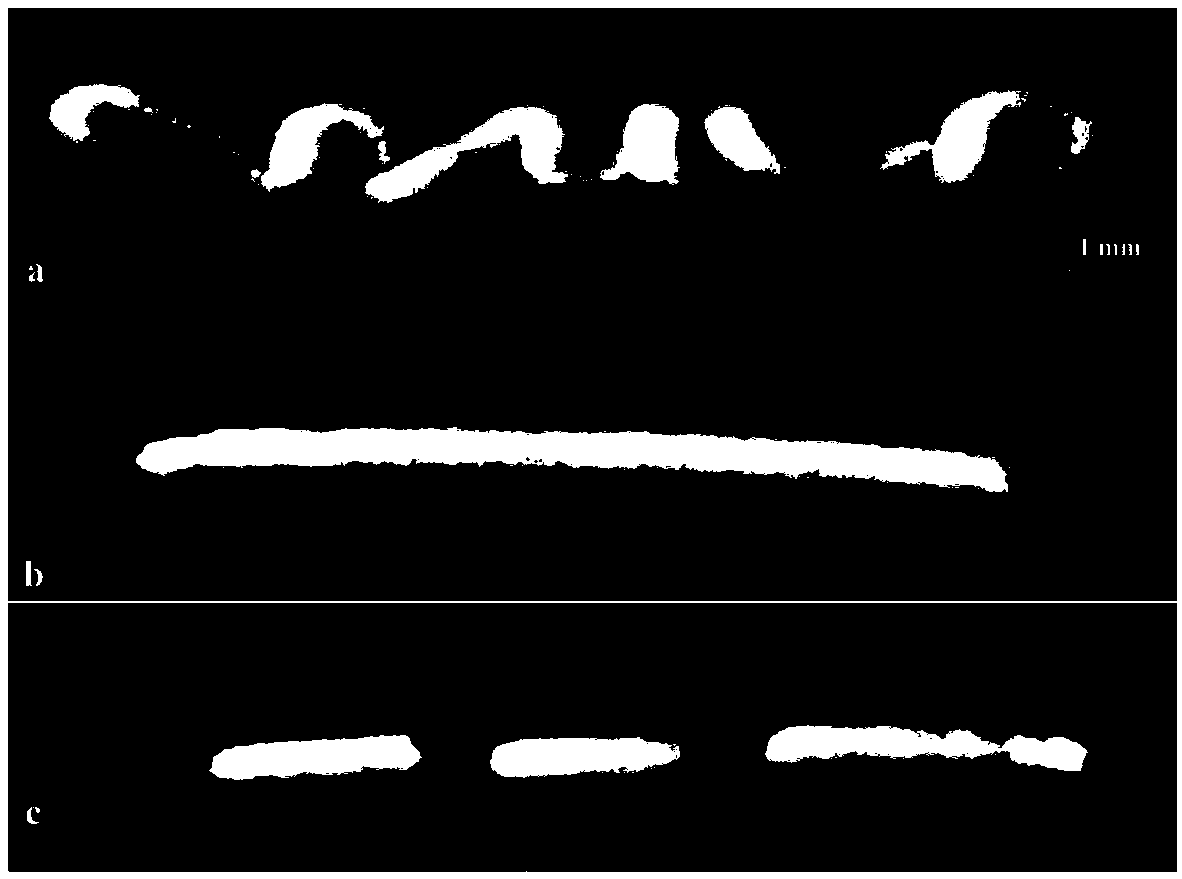

Accurate 3D printing method for high-protein semifluid instant food

The invention discloses an accurate 3D printing method for high-protein semifluid instant food, and belongs to the technical field of novel food processing. High-quality concentrated lactoprotein is taken as a primary raw material, and the accurate 3D printing method for high-protein semifluid instant food is established by adding a proper amount of proper polysaccharide colloid. The method is simple and practical and high in printing accuracy, products are nutritious and healthy, and the 3D printing of high-protein food is achieved. Products can be accepted by consumers as low-calorie high-nutrient healthy food, the products are semifluid food, the products are soft and easy to be chewed and swallowed, and the products are also suitable for children and elderly people to eat.

Owner:JIANGNAN UNIV

No-whey process for production of low fat hard cheese

InactiveUS20050238783A1Eliminates costly processing requirementSolve the real problemCheese manufactureMilk SerumWhey protein

The present invention provides a no-whey process for preparing a low-fat hard cheese product with completed capture of whey proteins using a modified milk protein concentrate. The modified milk protein concentrate comprises about 82 to about 96 percent milk protein concentrate and about 4 to about 18 percent multifunctional enzyme, wherein the multifunctional enzyme modifies the function of dairy proteins so that the completed capture of whey proteins into a cheese product will not interfere with the alignment of casein molecules into the fibers structure required for a good texture of hard cheeses such as mozzarella. The present invention solves problems associated with the whey generated from conventional making cheese plant and creates a new way of making low-fat hard cheese products.

Owner:HAN XIAO QING +1

Low pH food composition stabilization process

InactiveUS6921548B2Extended shelf lifeHigher antimicrobial activity towardsDough treatmentAlcoholic beverage preparationEmulsionAdditive ingredient

This invention relates to a process for manufacturing nutritionally balanced food compositions suitable for retort sterilization which have a low pH, extended shelf life, high antimicrobial activity, and which include protein in a stable emulsion. The primary protein source for the food composition is caseinates or milk protein concentrates and isolates comprised mostly of casein. The process includes two homogenization steps.

Owner:ENTRA SAFE

High-protein meal-replacement milk shake solid drink with full-stomach fat reducing effect

InactiveCN109673747ASuitable for meal replacementGood weight controlMilk preparationSkimmed milk powderConjugated linoleic acid

The invention discloses high-protein meal-replacement milk shake solid drink with full-stomach fat reducing effect. The high-protein meal-replacement milk shake solid drink is prepared from the following components: 15-70 parts of soybean protein isolate, 5-30 parts of maltodextrin, 1-10 parts of skimmed milk powder, 2-25 parts of inulin, 2-20 parts of chia seed powder, 2-20 parts of konjaku flour, 1-15 parts of conjugated linoleic acid glyceride, 0.5-10 parts of whey protein concentrate, 0.5-10 parts of membrane separation casein, 0.5-10 parts of milk protein concentrate, 0.5-10 parts of wheyprotein isolate, 1-36 parts of vitamin, 0.3-9 parts of mineral substances, and the like. The invention further discloses a preparation method for the meal-replacement milk shake solid drink. The meal-replacement food disclosed by the invention supplements nutrient by various beneficial proteins, vitamins and mineral substances, contains especially added weight-reducing substances such as conjugated linoleic acid, and added green tea, chocolate, coffee, vanilla and the like to form different tastes, is suitable for meal-replacement use of fat-reducing weight-reducing people, and has a good effect on controlling body weight.

Owner:天津活力达生物科技有限公司

High protein, fatigue reducing powder

A powdered composition which provides improved muscle growth and helps reduce fatigue, comprising a combination of edible nutritional whey protein, citrulline malate, and at least one branched chain amino acids. The branched chain amino acids are L-isoleucine, L-leucine, and L-valine. The concentration of nutritional protein present in the composition ranges from about 10% by weight to about 96% by weight, and may be about 20% by weight to about 90% by weight. The composition may contain additional ingredients such as polypeptides, a hyper-immune milk protein concentrate, amino acids, antioxidants and various flavorings and sweeteners. A method of use of the composition is also disclosed.

Owner:NEXTPROTEINS INC

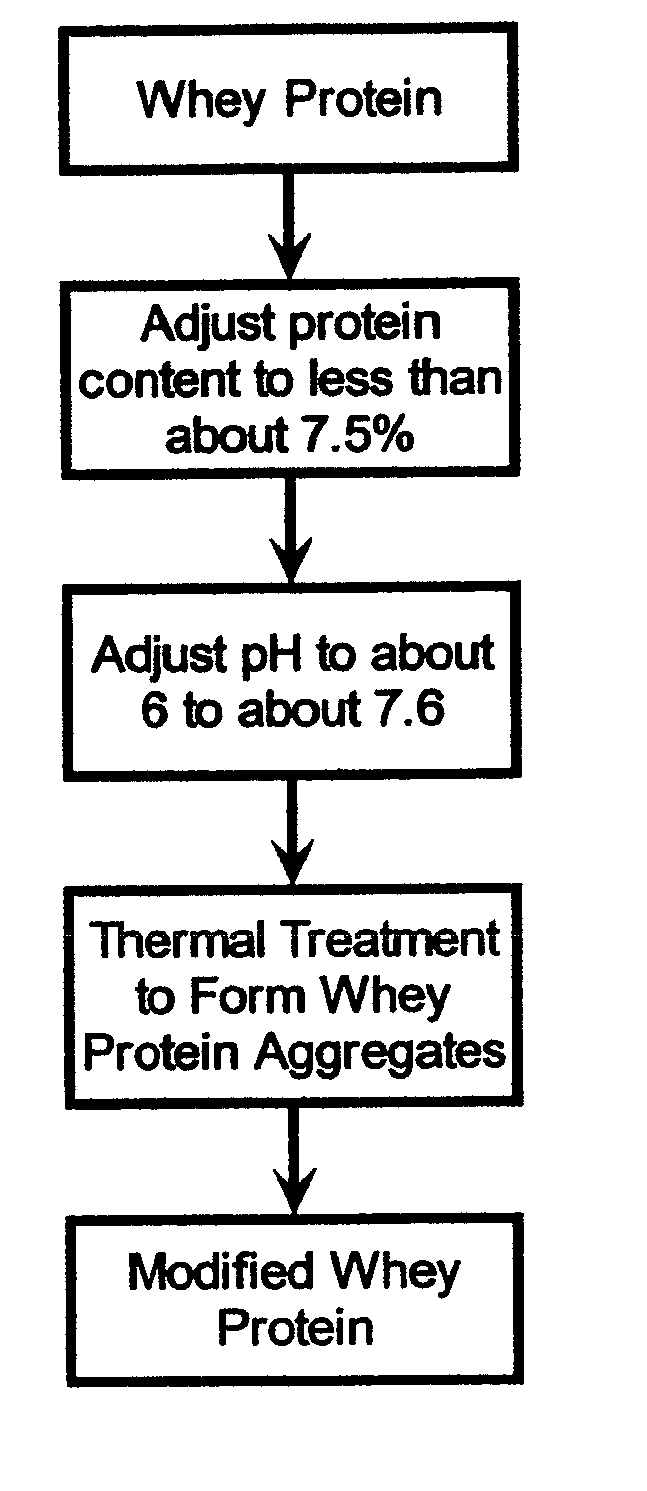

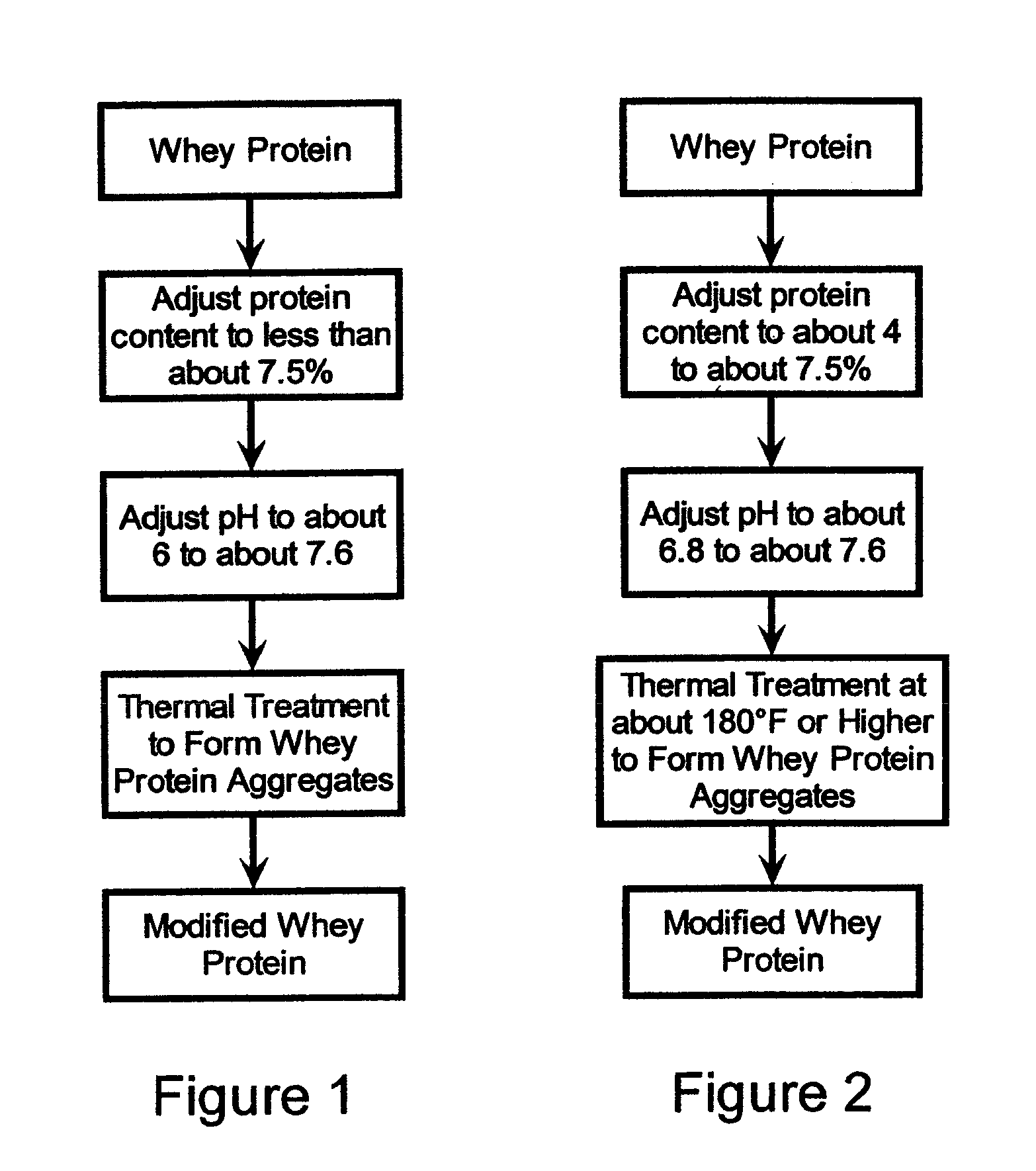

Modified Whey Protein For Low Casein Processed Cheese

InactiveUS20070134396A1Lower Level RequirementsIncreased level of moistureCheese manufactureAnimal proteins working-upWhey proteinSlurry

A processed cheese and method of forming the processed cheese are provided. The processed cheese generally includes between about 14 to about 16 protein, about 45 to about 50 percent moisture; and a ratio of casein protein to whey protein at least about 60:40. The method of forming the processed cheese includes thermally treating a whey protein at a protein concentration and pH sufficient to form whey protein aggregates, blending the thermally treated whey protein with a milk protein concentrate to form a slurry; and heating the slurry for a time and temperature sufficient to form the processed cheese. In one form, the processed cheese includes about 3 to about 6.3 percent modified whey protein.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Method for producing nutritionally balanced food compositions

InactiveUS7285301B2High activityExtended shelf lifeMilk preservationFruit and vegetables preservationEmulsionSoya bean

This invention relates to a process for manufacturing nutritionally balanced food compositions suitable for retort sterilization which have a low pH, extended shelf life, high antimicrobial activity, and which include protein in a stable emulsion. The primary protein source for the food composition is caseinates or milk protein concentrates and isolates comprised mostly of casein. Alternately, milk protein concentrates, milk protein isolates, milk protein hydrolystates, soy protein isolates or soy protein concentrates may also be used. The process includes two homogenization steps.

Owner:ENTRA SAFE

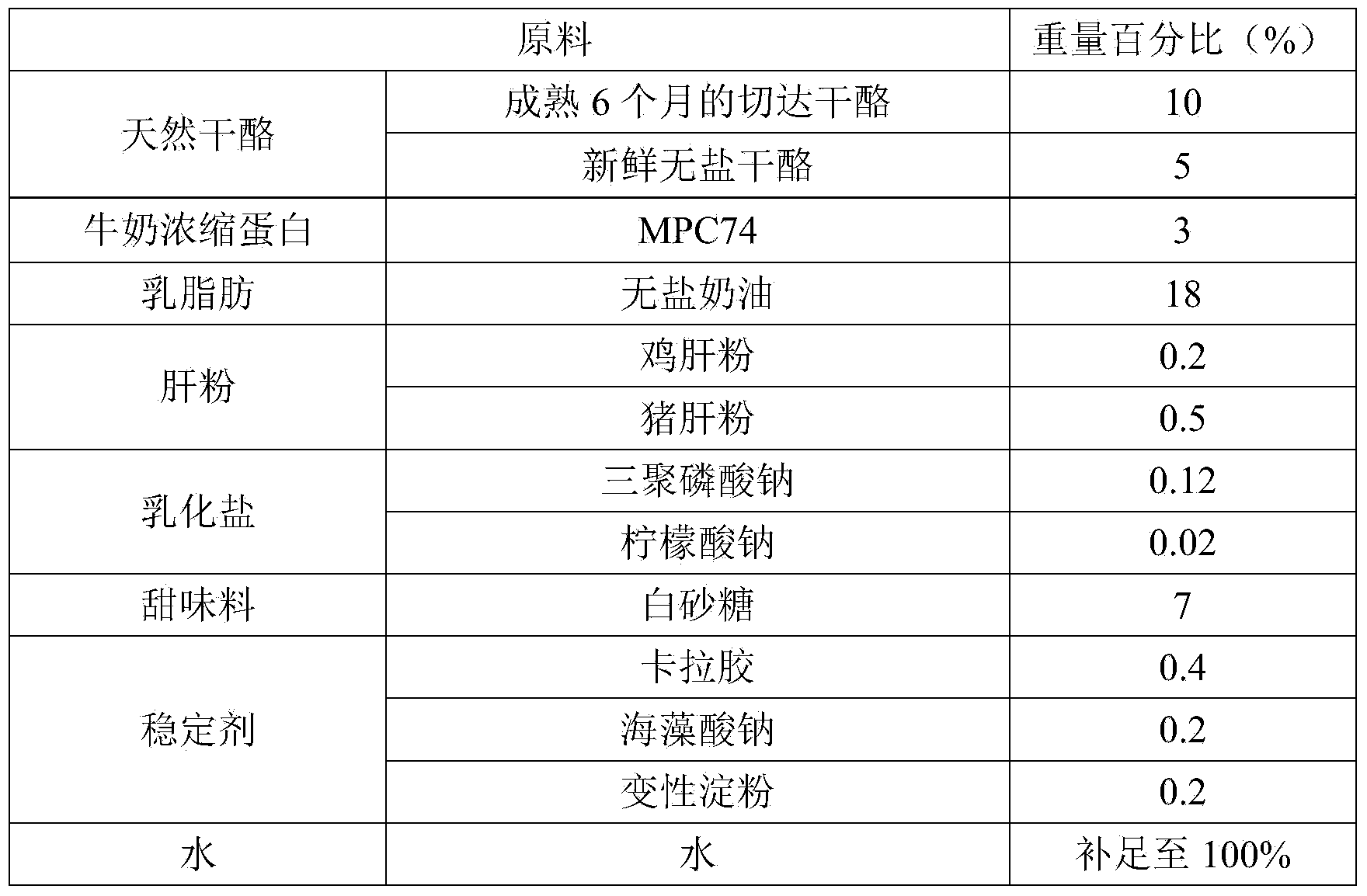

Method for processing meat paste product by utilizing livers of livestock and poultry

ActiveCN103340420ATo keep freshPlay a role in suppressing fishy smellFood preparationBiotechnologyEmulsion

The invention discloses a method for processing a meat paste product by utilizing livers of livestock and poultry. The method for processing the meat paste product by utilizing livers of livestock and poultry comprises the following steps of: with livers of livestock and poultry and fat and lean of the livestock and poultry as raw materials and milk protein, seasoners and blending materials as auxiliary materials, processing the livers, processing meat material, pickling, preparing concentrated milk protein, preparing liver emulsion, preparing meat paste, filling, carrying out two-stage hot processing and high temperature sterilization, and cooling. Therefore, the meat paste product with good slicing property, taste and flavour is processed, the utilization rate of the livers of the livestock and poultry is increased, content of vitamin A in the meat paste product is increased, ordinary people can take in required vitamin A while eating meat, and improvement on deficiency of the vitamin A in the ordinary people, especially children and the aged can be facilitated.

Owner:CHENGDU UNIV +1

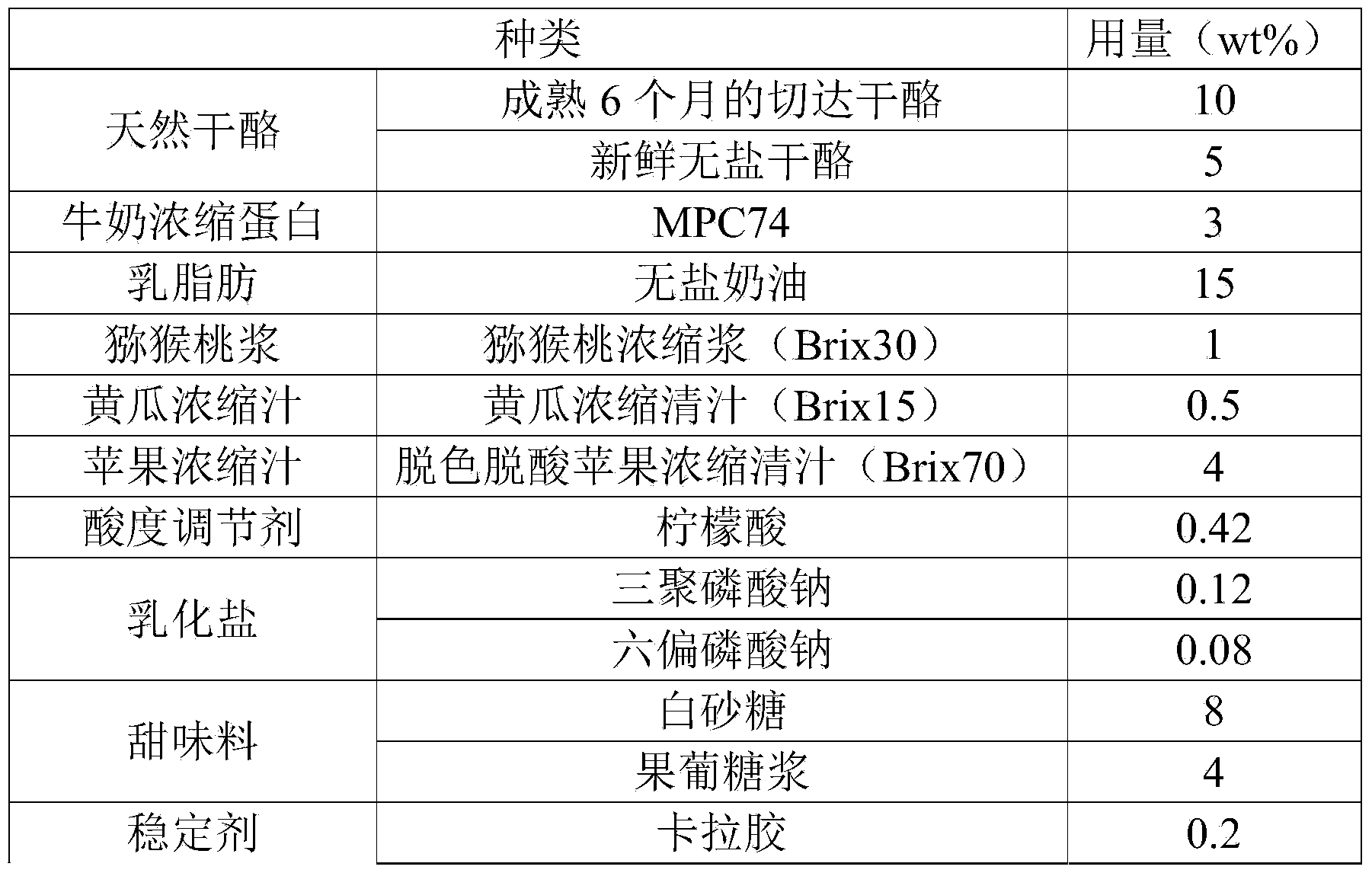

Processed cheese spread and preparation method thereof

The invention discloses a processed cheese spread and a preparation method thereof. The preparation method comprises the steps of (1) evenly mixing 15%-25% of natural cheese, 11%-30% of milk fat, 0.2%-0.5% of emulsifying salt, 1%-5% of milk protein concentrate, 8%-12% of a sweetener, and a stabilizer and water together, (2) further adding 1-15% of kiwi fruit pulp, 1-4% of apple concentrated juice, 0.5-1.2% of cucumber concentrated juice, 0.03-0.42% of an acidity regulator and 0.02%-0.04% of an antioxidant at a stirring speed ranging from 600rpm to 1200rpm, and stirring, (3) carrying out homogenizing at a temperature ranging from 82 DEG C to 90 DEG C and under pressure within the range from 15MPa to 20MPa, and pasteurizing, and (4) performing super-high pressure treatment on 0.05-0.2% of fresh vegetable juice, and then adding the fresh vegetable juice to the slurry obtained in the step (3), and carrying out hot filling and three-stage quick cooling and molding. The processed cheese prepared by the preparation method is high in nutritive value, naturally green, and good in sensory evaluation.

Owner:BRIGHT DAIRY & FOOD

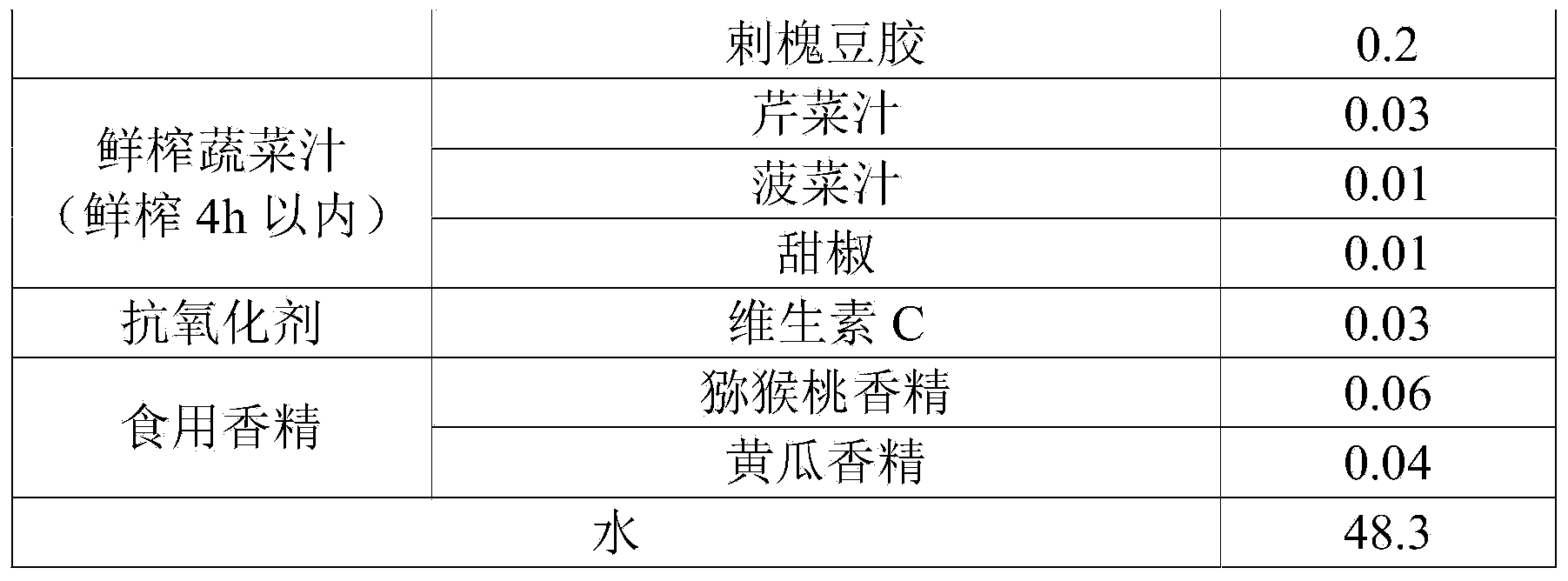

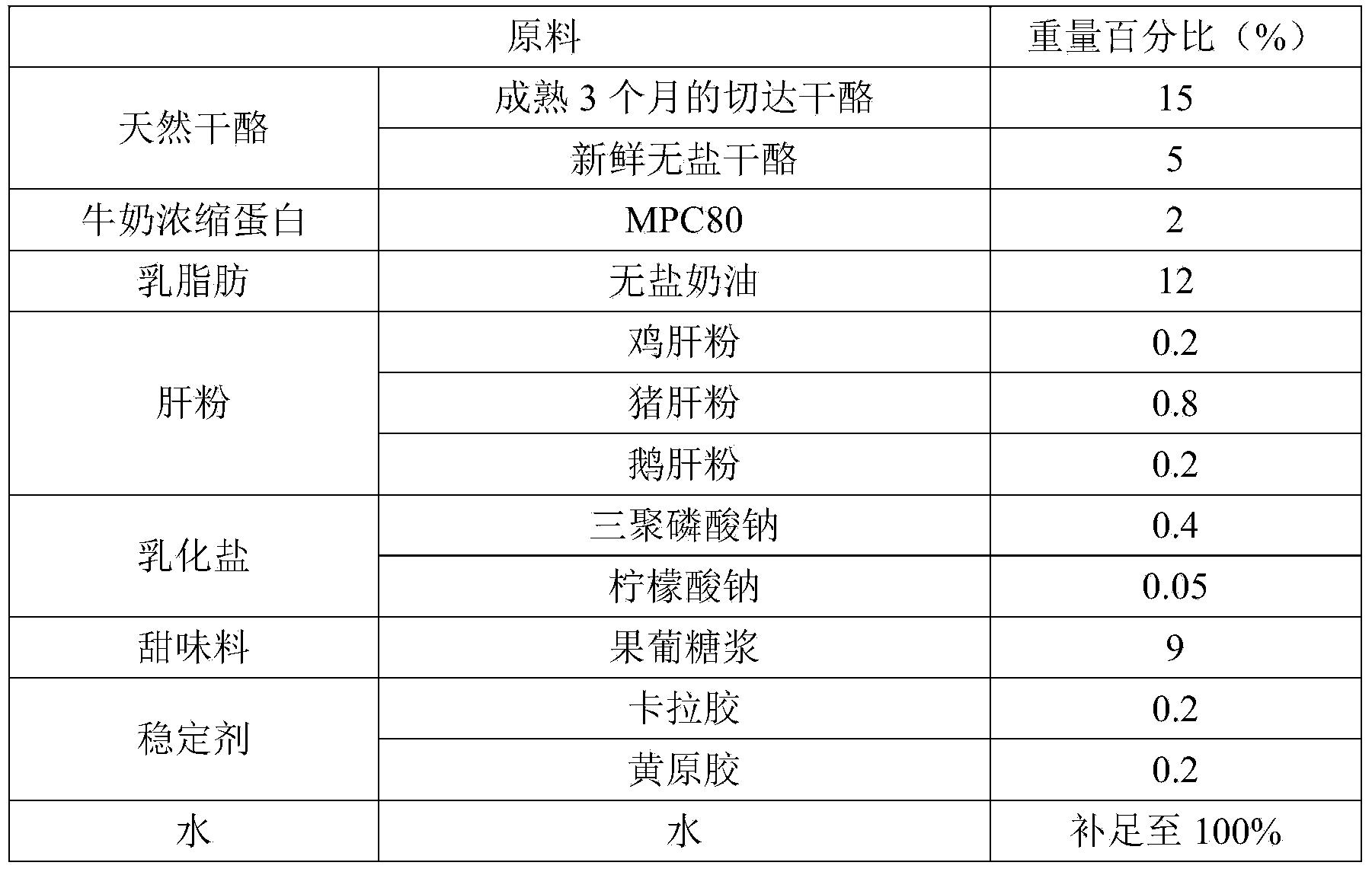

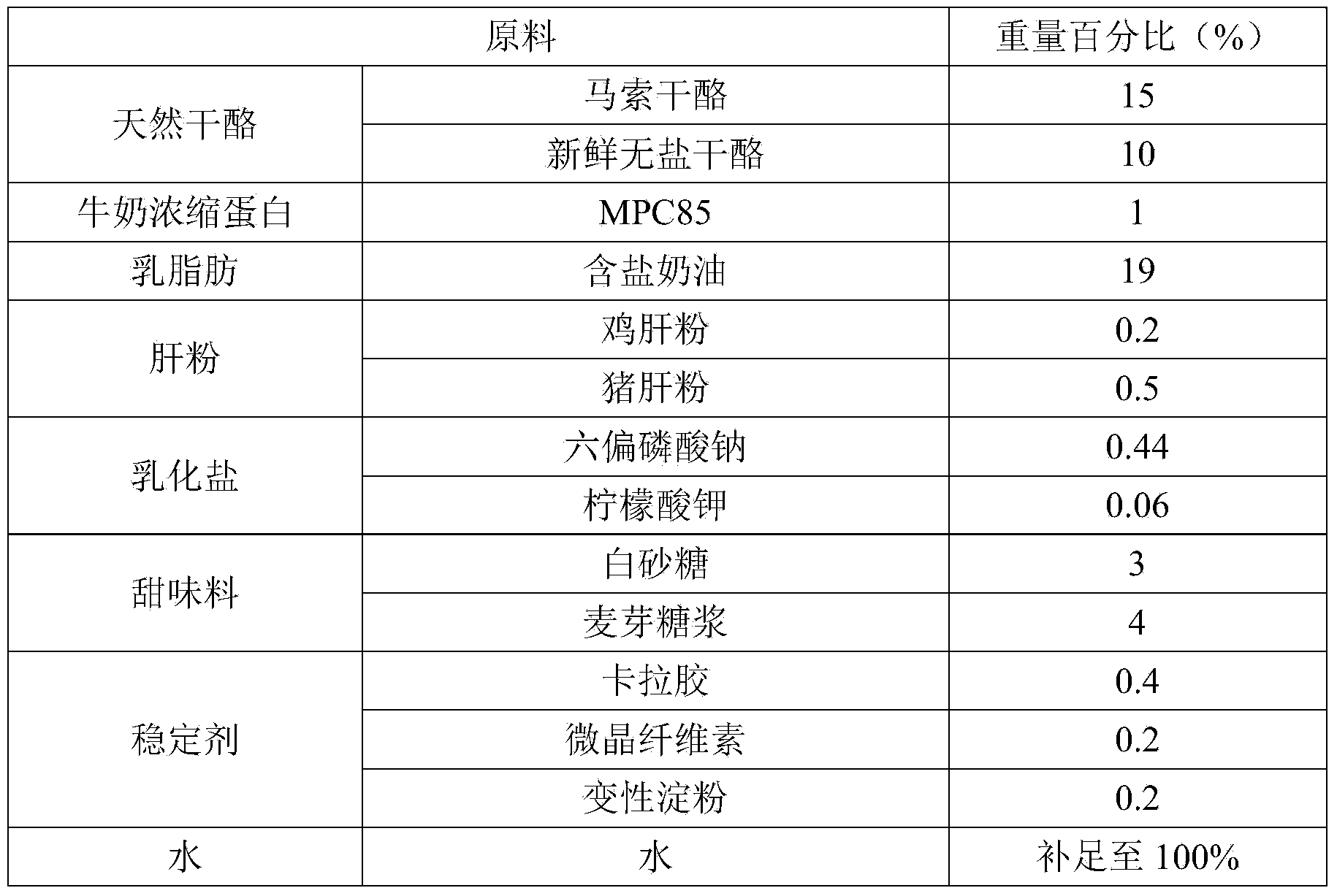

Preparation method of smearing type processed cheese and prepared smearing type processed cheese

The invention discloses a preparation method of a smearing type processed cheese and the prepared smearing type processed cheese. The processed cheese comprises raw materials including natural cheese, milk protein concentrate, butter oil, liver meal, emulsifying salt, a sweetener, a stabilizer and water, wherein the content of the natural cheese is 15-25 percent, the content of the milk protein concentrate is 1-5 percent, and the content of the liver meal is 0.5-1.5 percent; the natural cheese is a mixture of ripen cheese with 3-6 month ripeness and fresh salt-free cheese; and the stabilizer comprises carrageenan. The preparation method comprises the following steps: 1, pre-mixing the natural cheese, the butter oil, the emulsifying salt, the milk protein concentrate, the liver meal and the stabilizer to obtain a material A; 2, mixing the material A, the sweetener, and the water, melting, degassing at pressure of 750-850 mbar for 15-30 seconds; 3, performing super-pasteurization; 4, sterilely homogenizing; 5, emulsifying; and 6, thermally canning, cooling and forming. The smearing type processed cheese contains animal liver, and is good in flavor, thin in texture, stable in shelf life, and suitable for being eaten by a baby.

Owner:BRIGHT DAIRY & FOOD

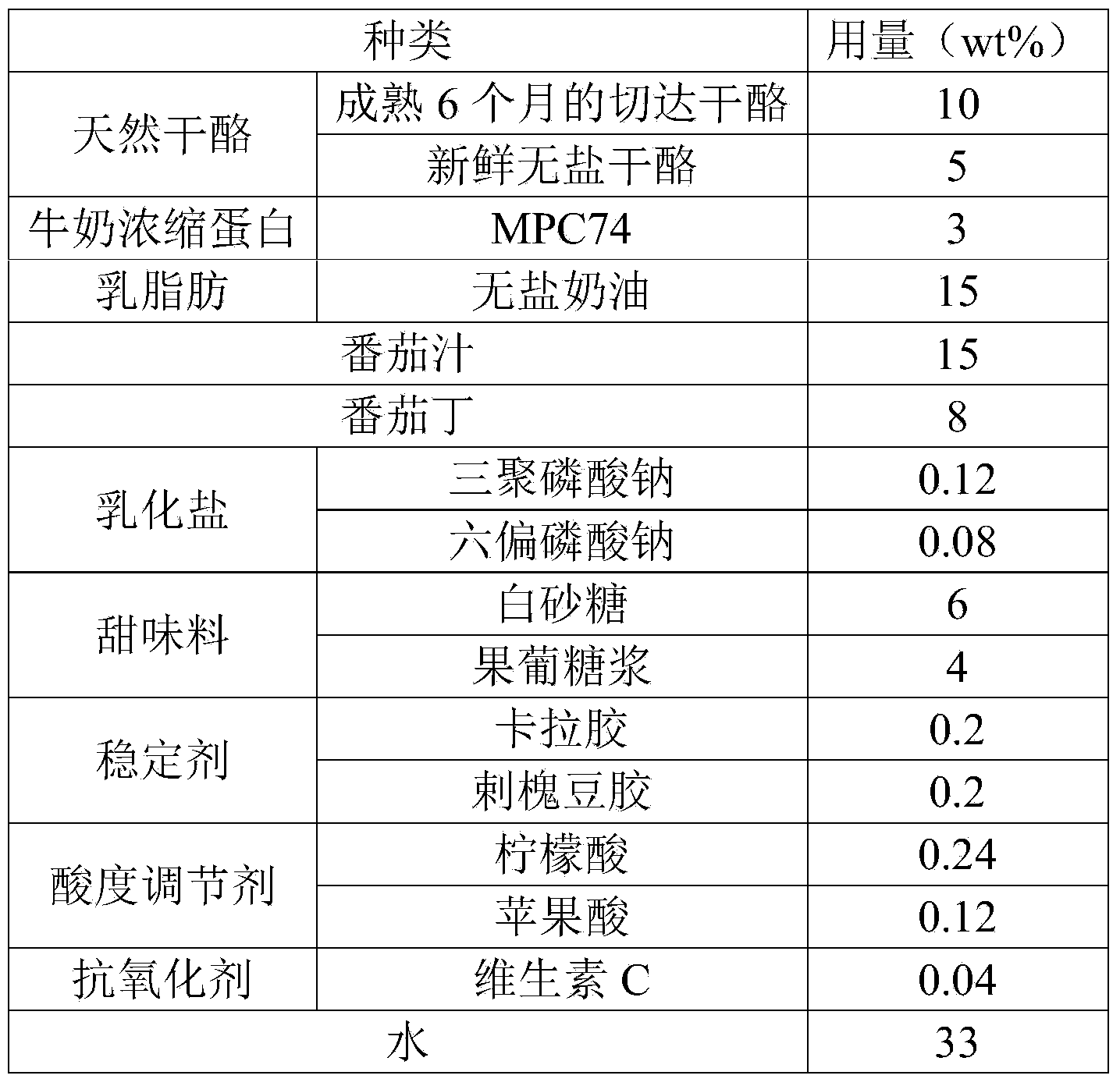

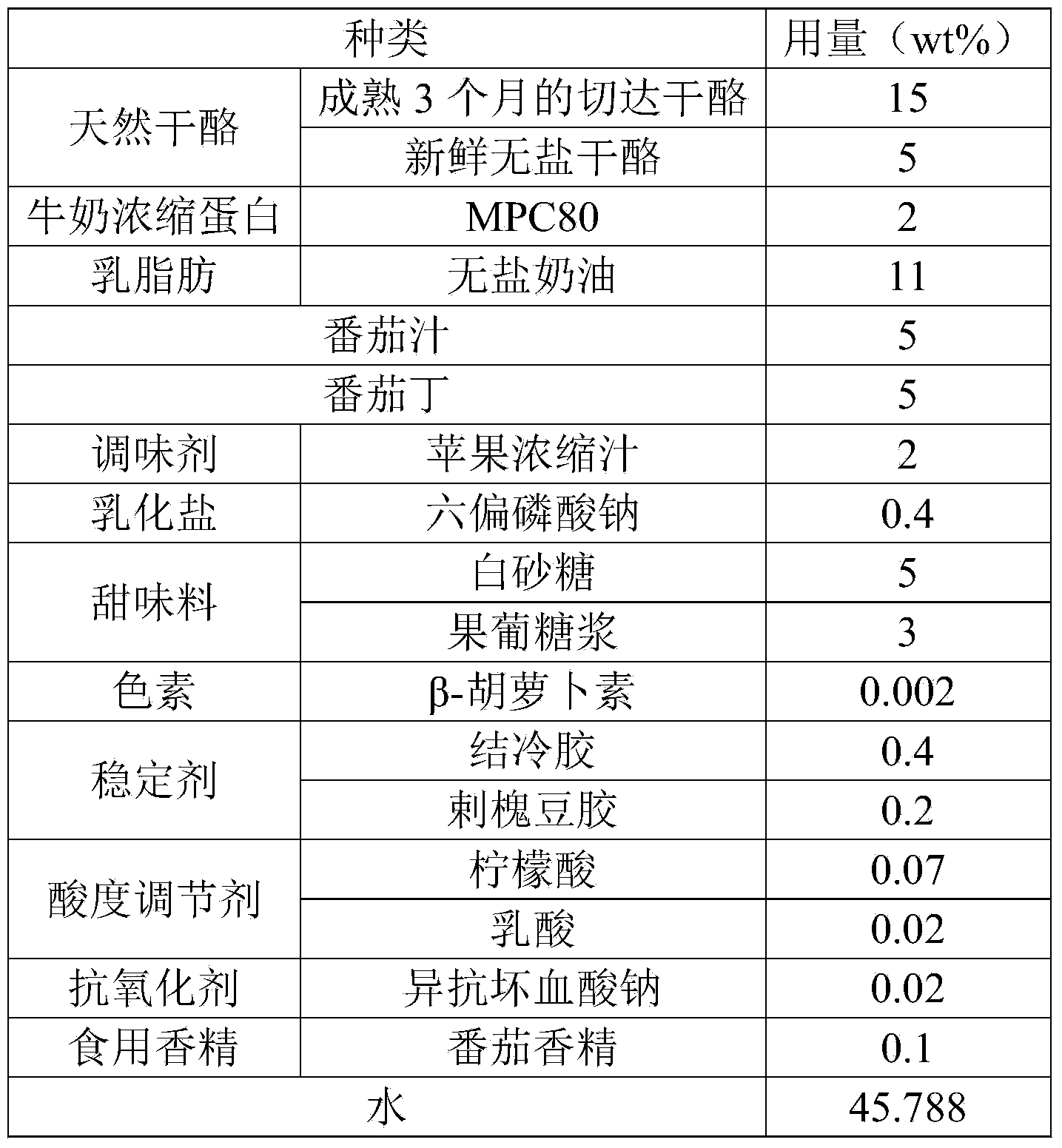

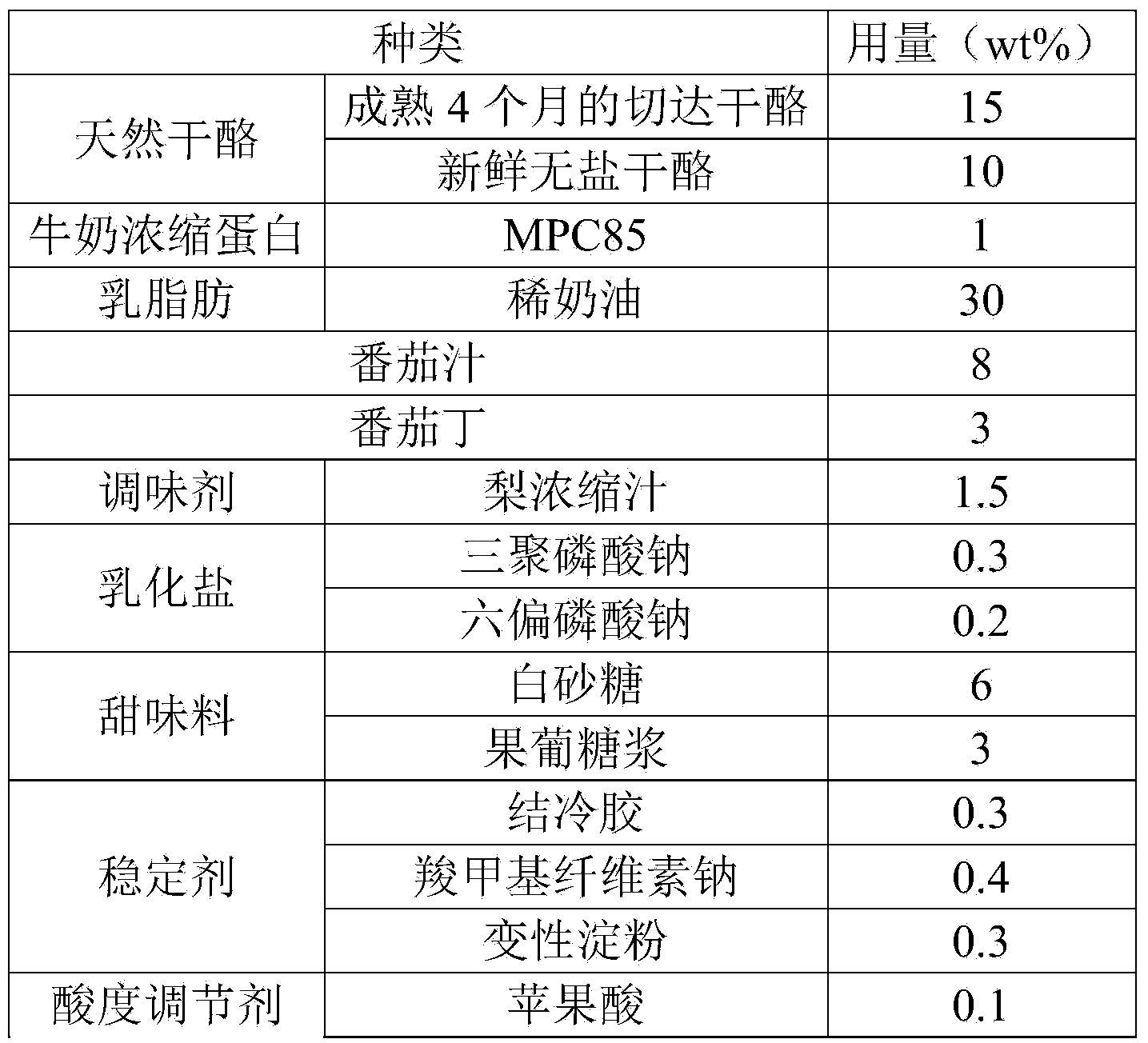

Fruit-vegetable processed cheese spread and preparation method thereof

ActiveCN103828934ARandom combinationAttractive appearanceCheese manufactureUltra high pressureAntioxidant

The invention discloses a preparation method of a processed cheese spread and the processed cheese spread obtained by the preparation method. The preparation method comprises the steps of (1) evenly mixing 15%-25% of natural cheese, 1%-5% of milk protein concentrate, 11%-30% of milk fat, 0.2%-0.5% of emulsifying salt, 8%-11% of a sweetener, 0.4%-1.0% of a stabilizer and water together, (2) adding an acidity regulator, carrying out homogenizing and pasteurizing to obtain a slurry B, (3) performing ultra-high pressure treatment on 5-15% of fresh tomato juice, 3-8% of diced tomatoes and 0.01-0.04% of an antioxidant within a range from 400MPa to 500MPa for 15-20 minutes, and mixing the mixture with the slurry B obtained in the step (2) evenly, and (4) carrying out hot filling and three-stage quick cooling and molding to obtain the product. The preparation method is simple; the processed cheese is comprehensive in nutrition, has the flavor of fresh tomato juice due to crisp diced tomatoes, and further has excellent appearance, color and luster and texture.

Owner:BRIGHT DAIRY & FOOD CO LTD

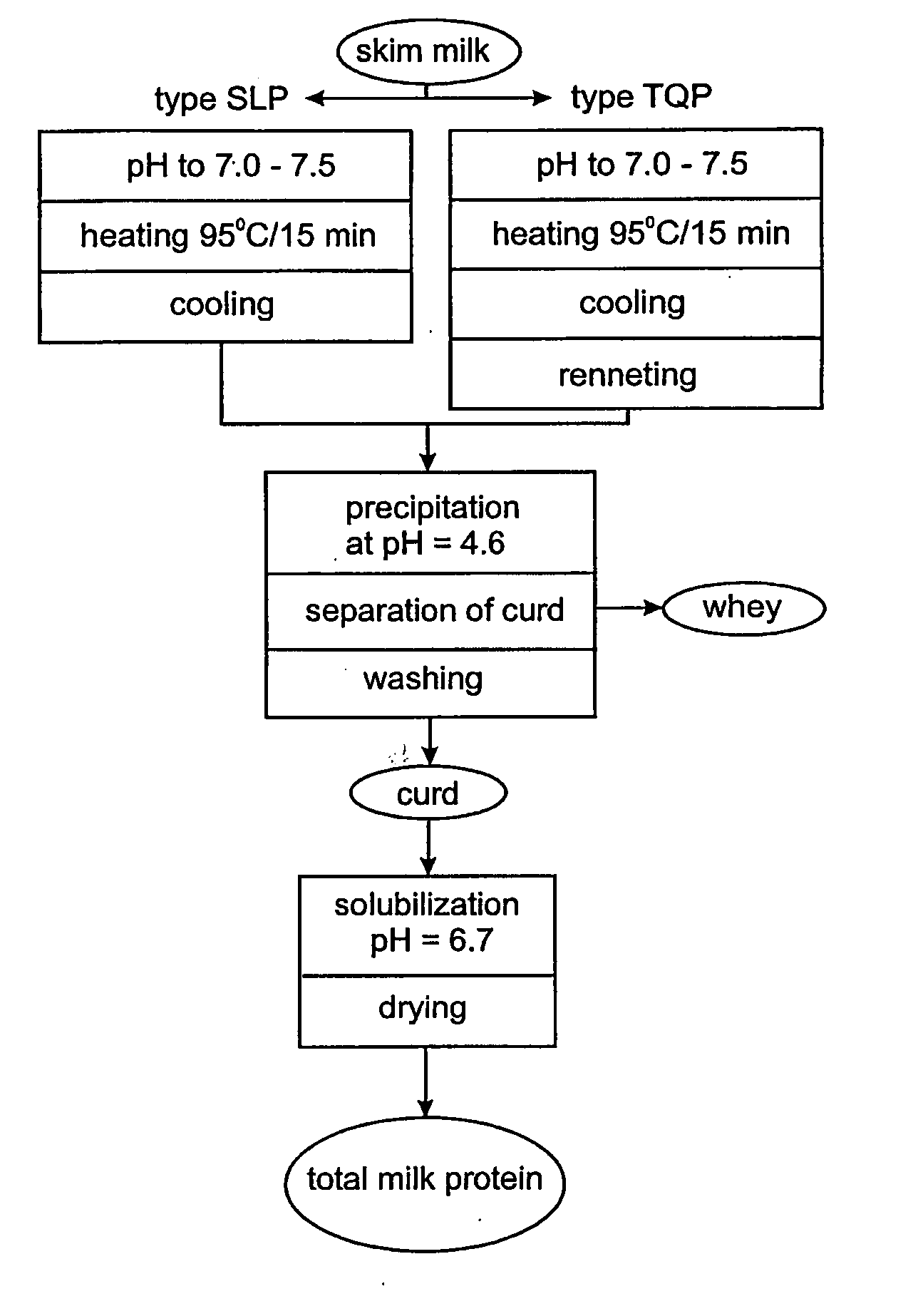

Dairy protein process and applications thereof

InactiveUS20060159804A1More palatableRaise the pHMilk preparationProtein composition from milkWhey proteinConcentration protein

The invention provides a dried milk protein concentrate which has high denatured whey protein content and is calcium depleted. Processes for preparing the product are also provided. The product is useful in preparing cheese, particularly for reducing the formation of nuggets (thin protein rich gels of a different colour) in the cheese. In one embodiment the calcium content of a milk protein concentrate is reduced and whey proteins are denatured using heat treatment, prior to drying, to obtain the product.

Owner:FONTERRA COOP GRP LTD

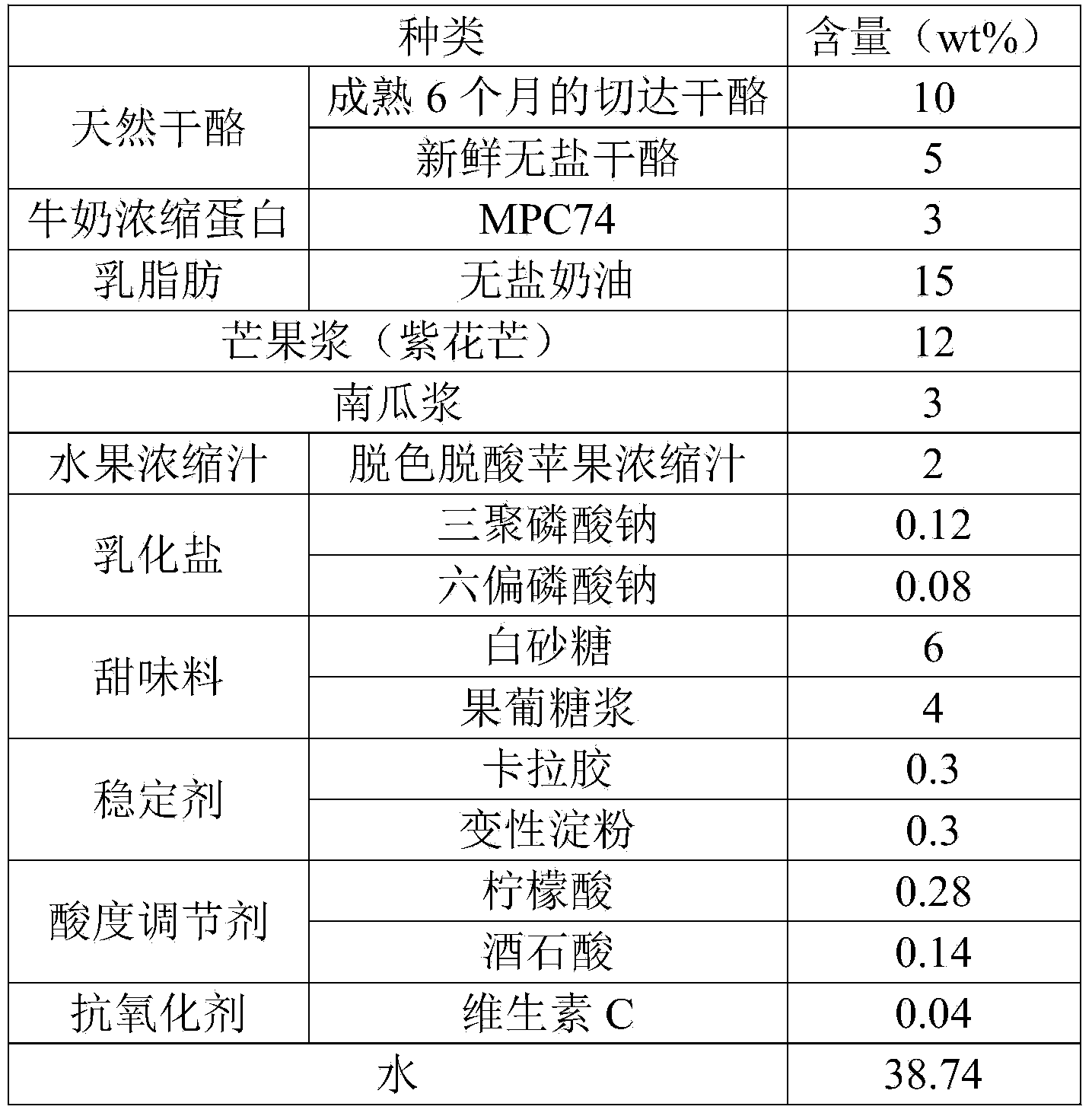

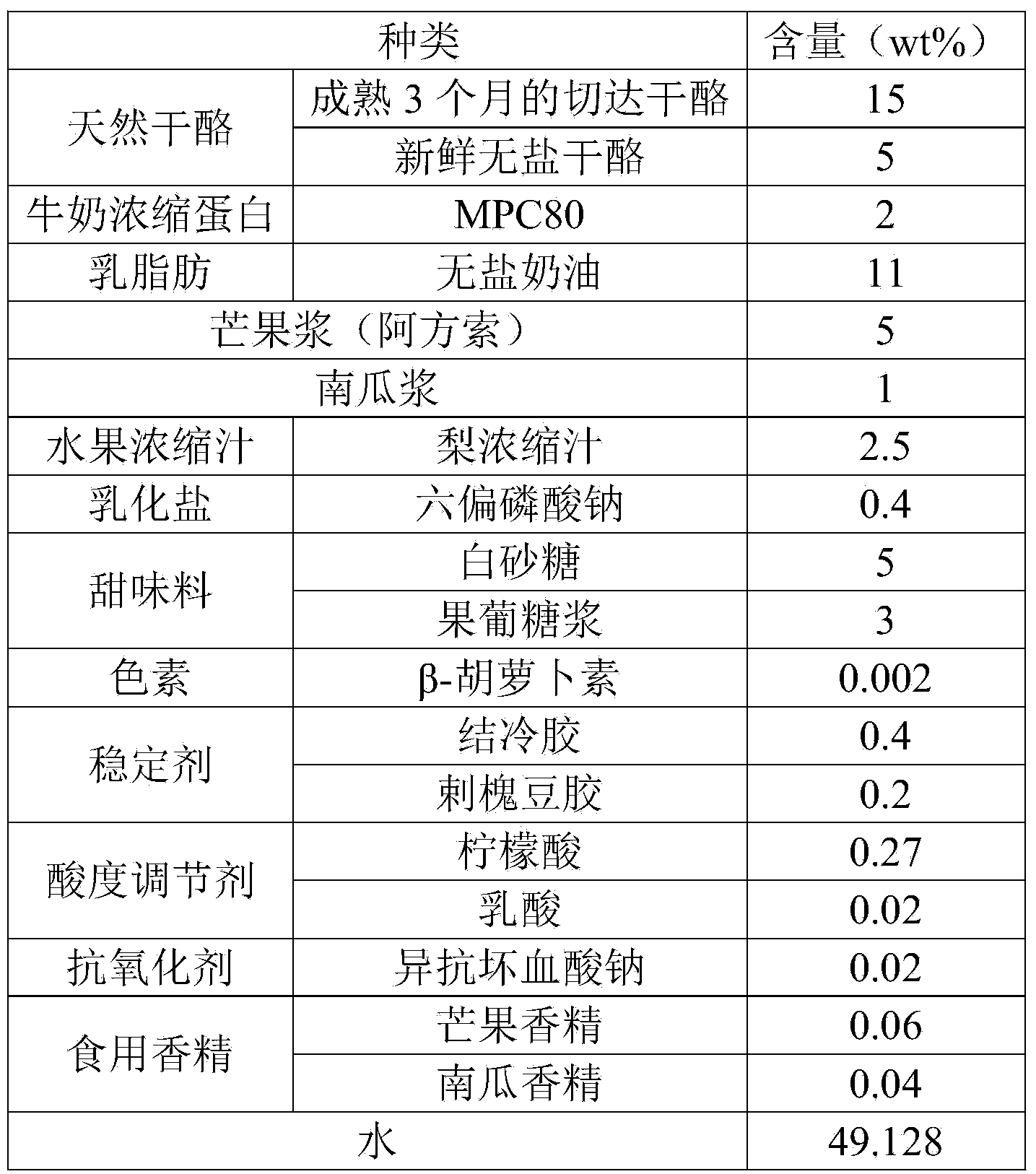

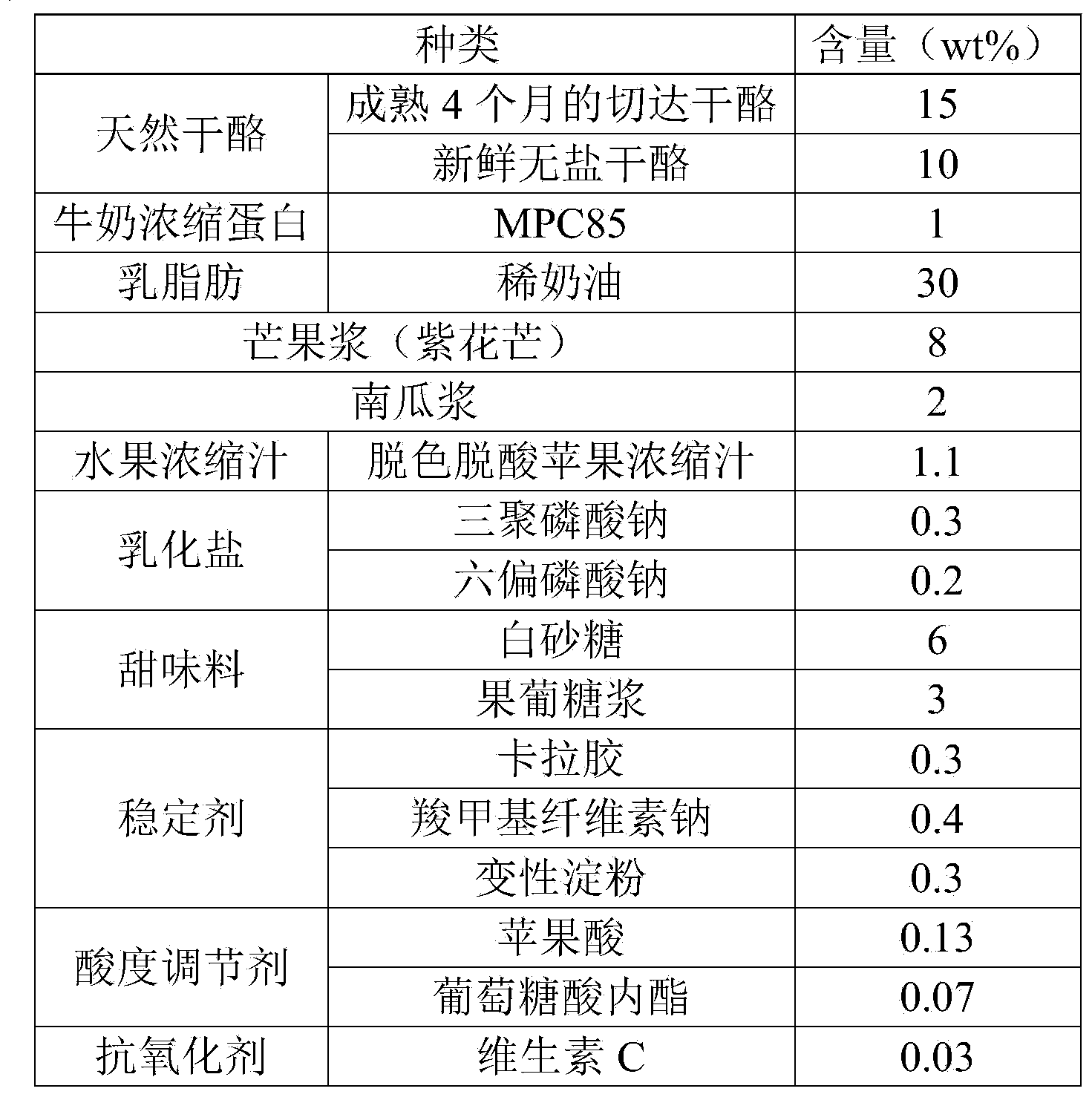

Fruit-vegetable processed cheese spread and preparation method thereof

The invention discloses a preparation method of a processed cheese spread and the processed cheese spread obtained by the preparation method. The preparation method comprises the steps of (1) evenly mixing 15%-25% of natural cheese, 1%-5% of milk protein concentrate, 11%-30% of milk fat, 0.2%-0.5% of emulsifying salt, 8%-11% of a sweetener, 0.4%-1.0% of a stabilizer and water together, (2) evenly mixing the mixture obtained in the step (1) with 5%-12% of mango pulp, 1%-3% of pumpkin pulp, 0.5%-2.5% of fruit concentrated juice, 0.2%-0.42% of an acidity regulator and 0.01%-0.04% of an antioxidant, (3) carrying out homogenizing at a temperature ranging from 82 DEG C to 90 DEG C and under pressure within the range from 15MPa to 20MPa, and pasteurizing, and (4) carrying out hot filling and three-stage quick cooling and molding. The preparation method is simple in process; the processed cheese is comprehensive in nutrition, excellent in flavor, fused in taste, and also has excellent appearance, color and luster and texture, and the quality guarantee period of the product is 4 months.

Owner:BRIGHT DAIRY & FOOD

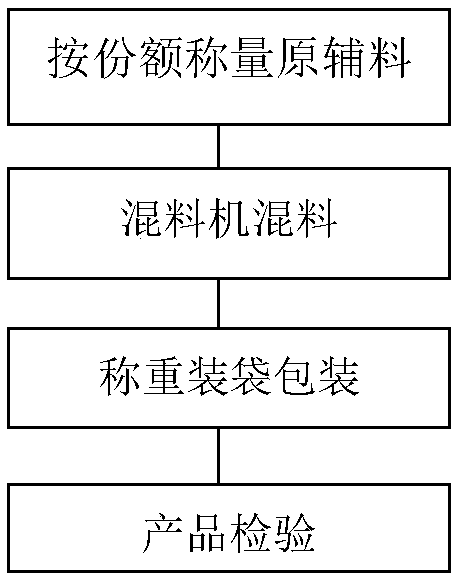

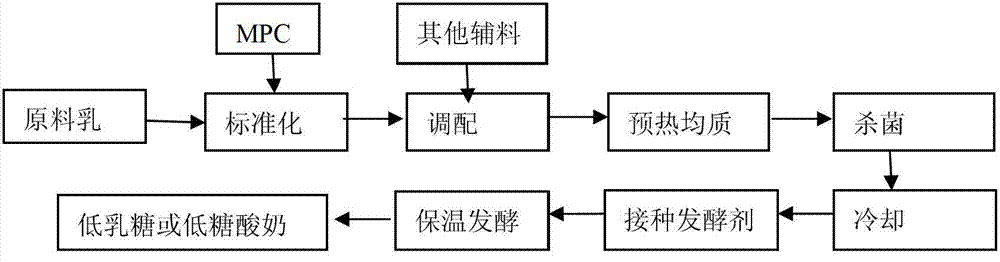

Method for producing low-lactose or low-sugar yogurt by using milk protein concentrates (MPC)

The invention discloses a method for producing low-lactose or low-sugar yogurt by using milk protein concentrates (MPC), belonging to the technical field of milk product processing. The method provided by the invention comprises the following steps of: selectively adding other additives into the standardized raw milk of the MPC, and then, preheating, homogenizing, sterilizing and carrying out inoculated fermentation to prepare the low-lactose or low-sugar yogurt. According to the method, the MPC is used for standardizing the raw milk of the yogurt to reduce the content of lactose in the yogurt by utilizing the characteristic of low lactose of the MPC, so that low-lactose yogurt which has the lactose content reduced to below 0.1% after being fermented is obtained to meet the requirements of the crowd sensitive to lactose. Through controlling fat in yogurt materials in the standardizing process and the cane sugar addition amount in the formula design, high-protein, low-fat and low-sugar yogurt can be obtained to meet the requirements of the crowd requiring low-calorie food.

Owner:CHINA AGRI UNIV

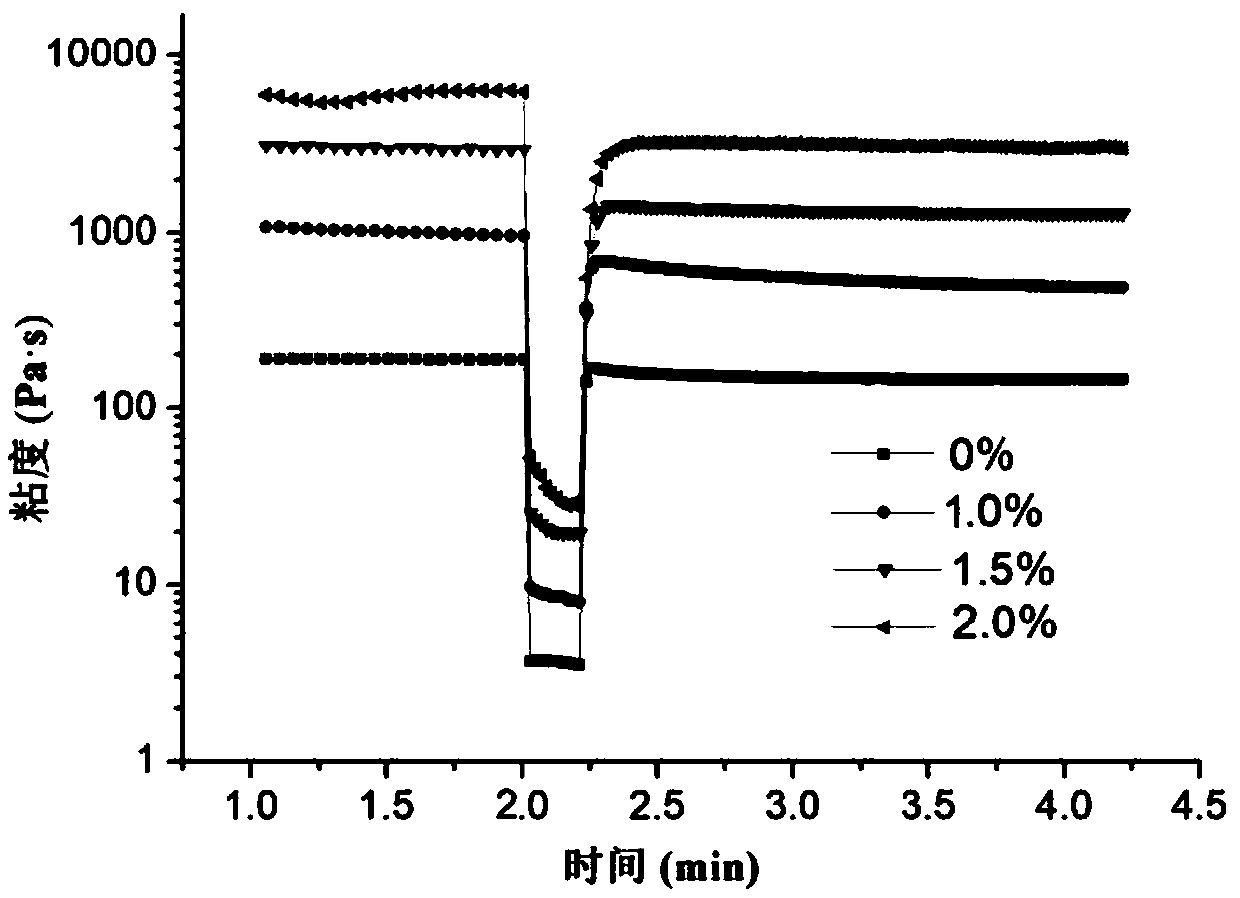

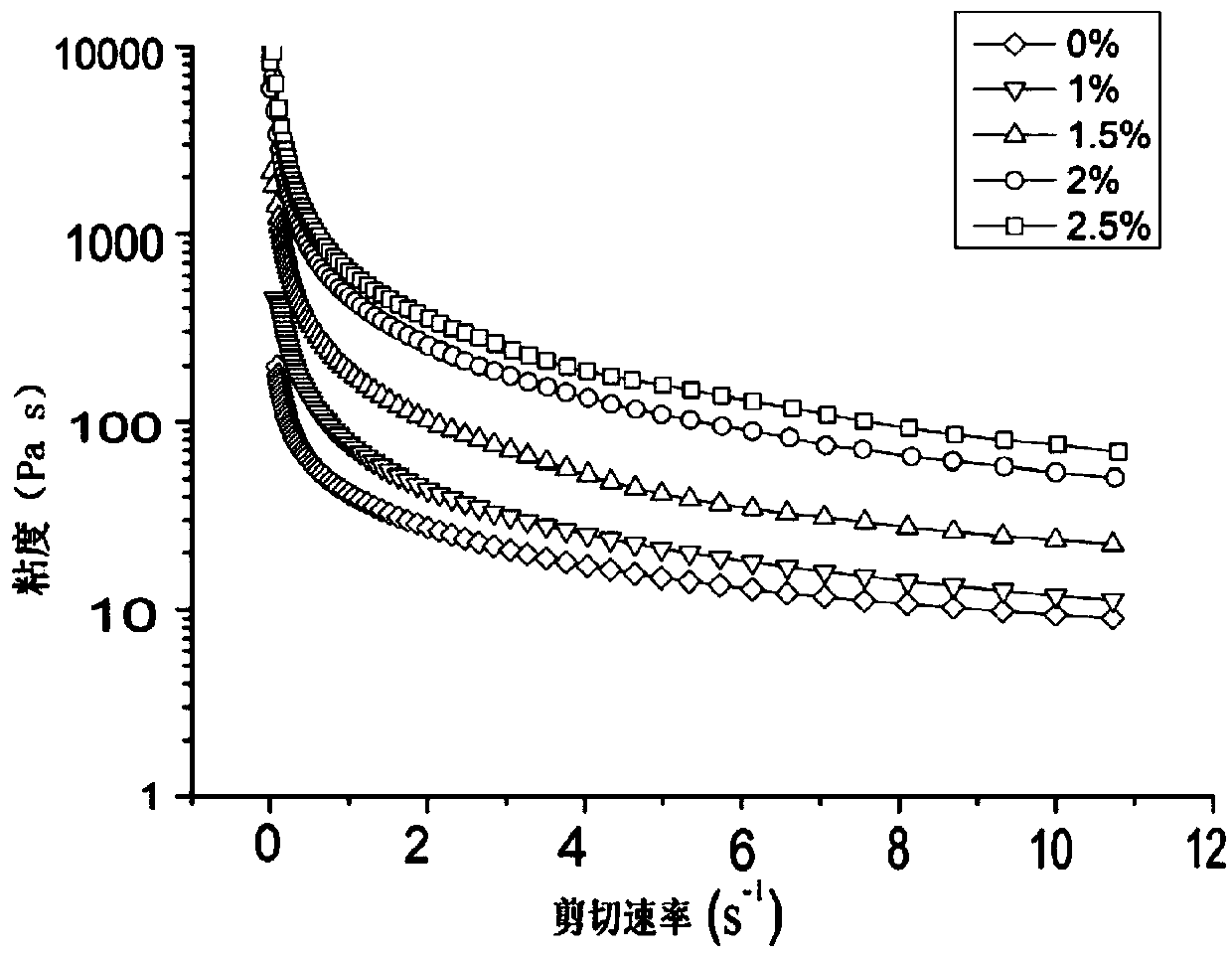

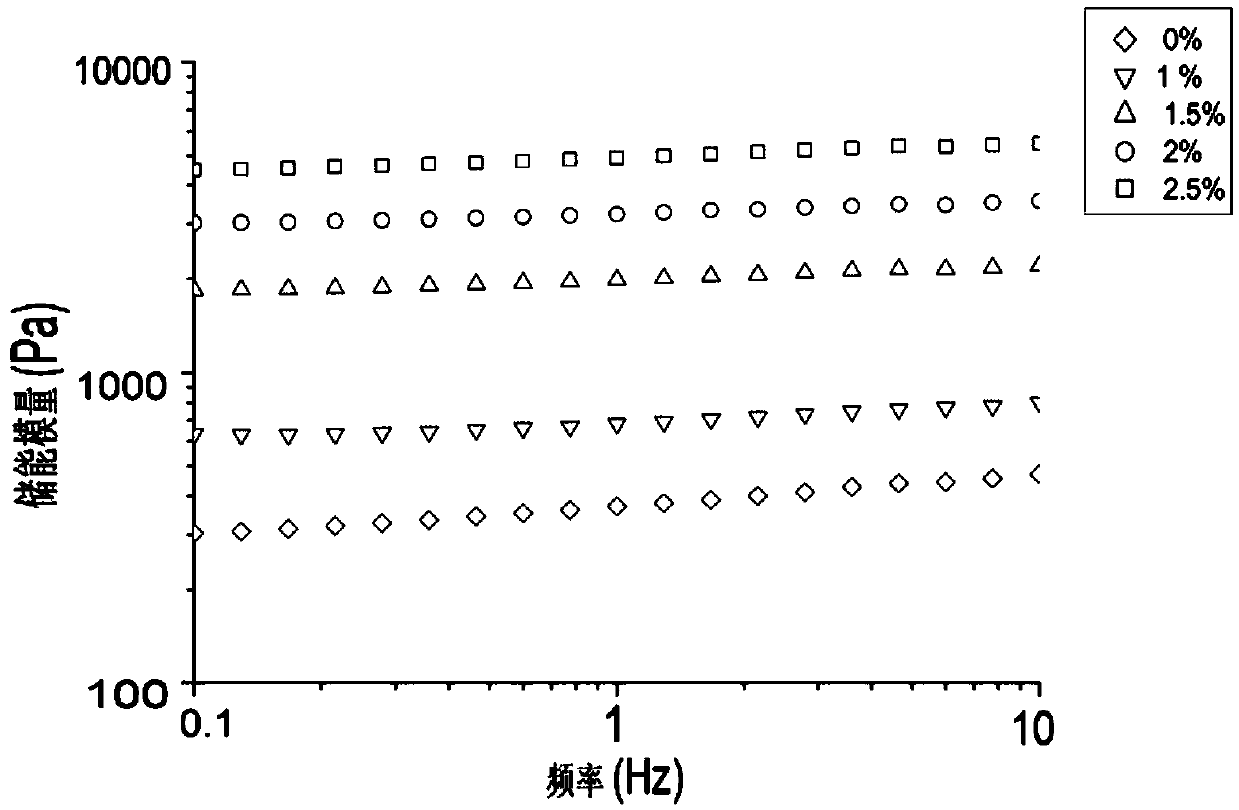

Preparation of instant milk protein gel and application thereof in 3D printing

ActiveCN108740284A3D printing realizedImprove adaptabilityAdditive manufacturing apparatusAnimal proteins working-upFood additiveSodium Caseinate

The invention discloses preparation of instant milk protein gel and application thereof in 3D printing and belongs to the technical field of 3D printing food material preparation. The preparation disclosed by the invention comprises the steps: firstly, preparing protein suspension of sodium caseinate; then adding milk protein concentrate (MPC) into the protein suspension to prepare milk protein plural gel. According to the preparation disclosed by the invention, a high-quality milk protein ingredient is utilized as a printing food material, and no other food additive is added; thus, the instant milk protein gel has the advantages of high nutritional value, easiness in absorption, good taste, favorability in being swallowed and the like; meanwhile, the instant milk protein gel can meet natural, healthy and zero-addition diet requirements of modern people. According to the preparation disclosed by the invention, when the instant milk protein gel is prepared, accurate temperature controlis avoided, a printing technology is simplified, convenience in operation is achieved, a strict requirement to the environment is avoided, and adaptability and operability of the 3D printing are improved.

Owner:JIANGNAN UNIV

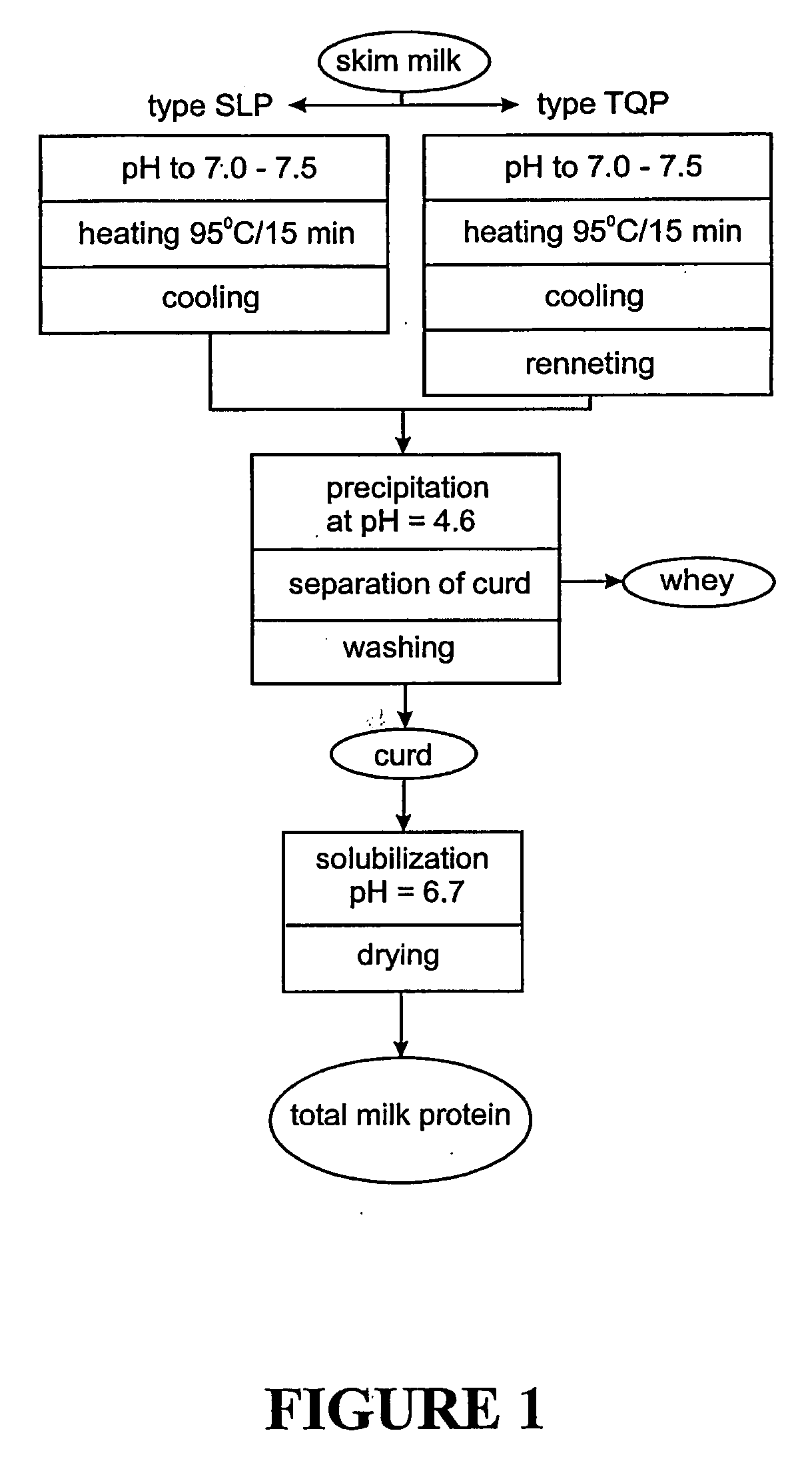

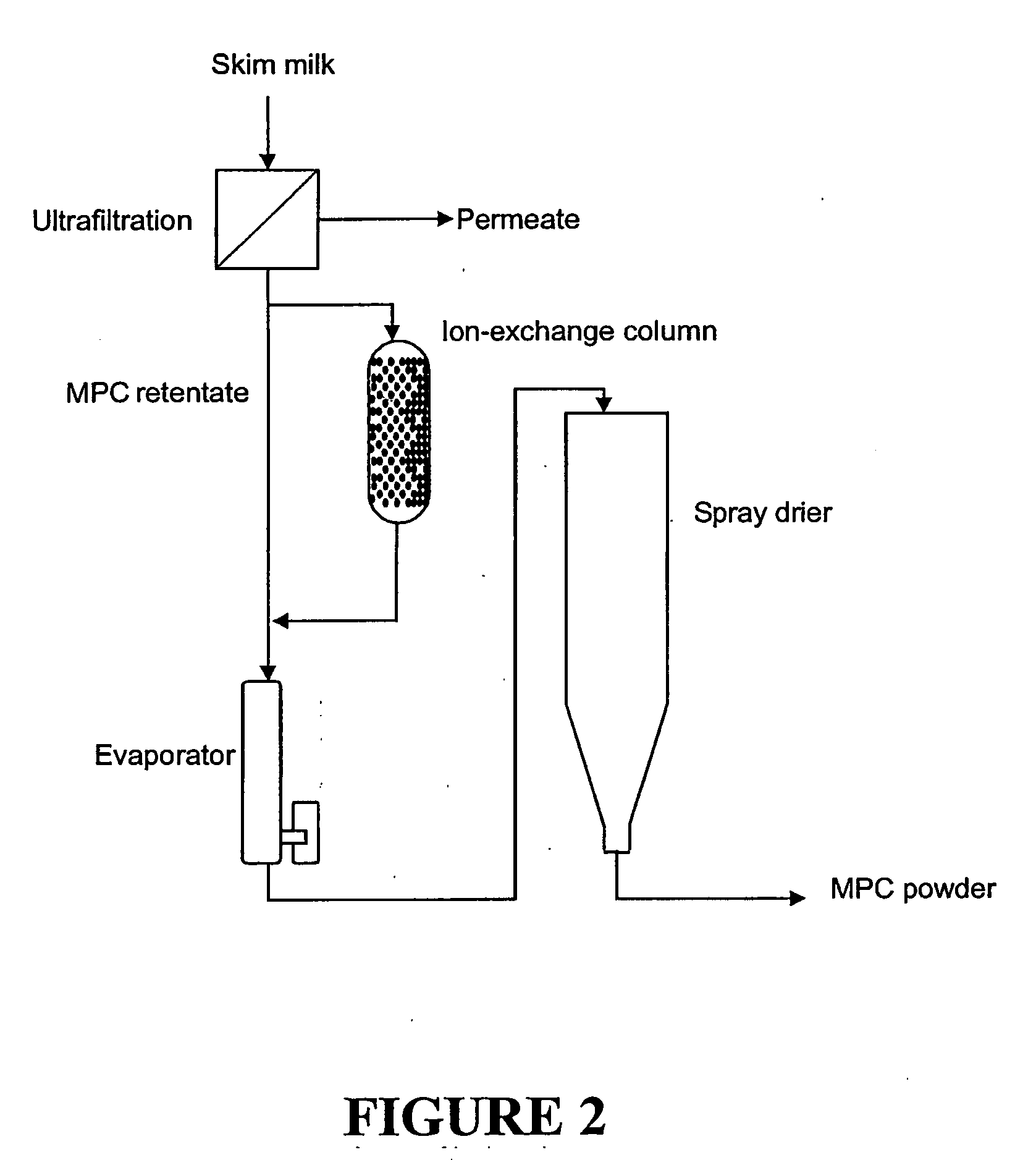

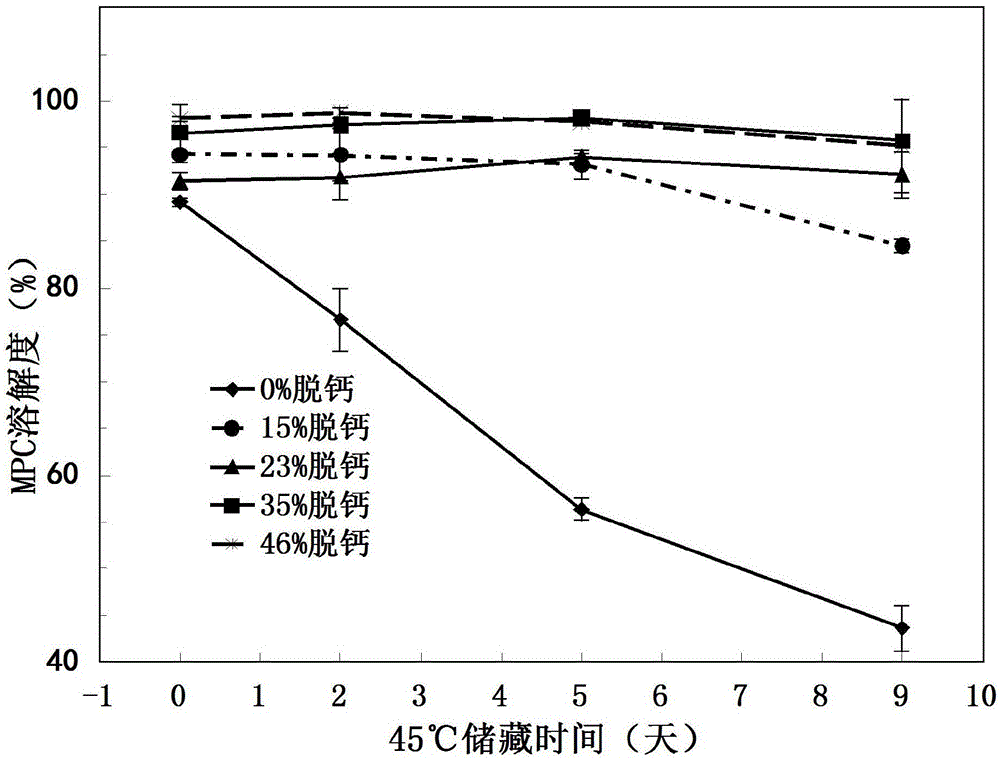

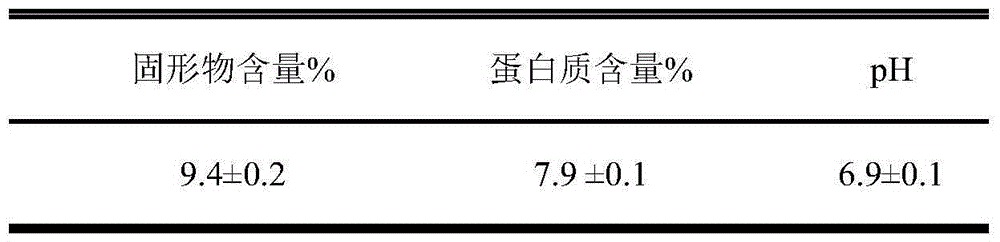

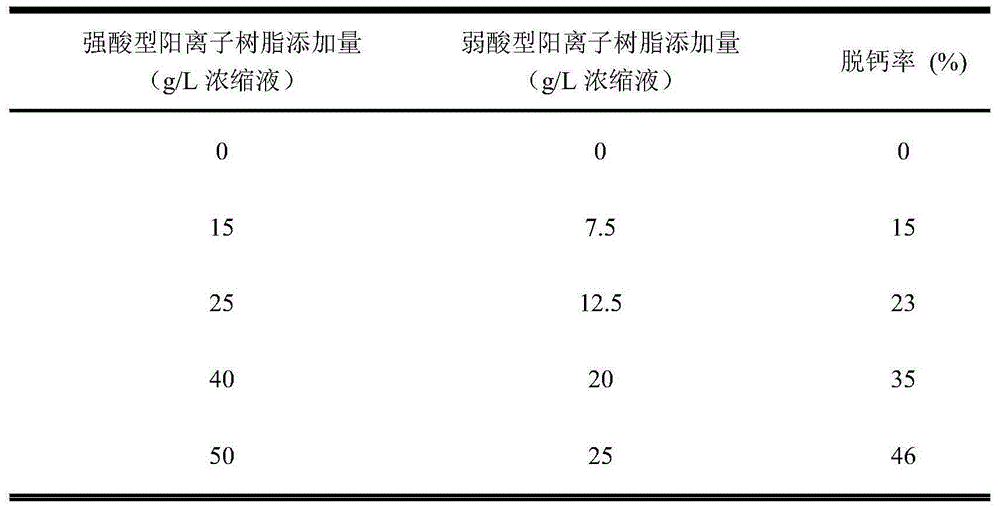

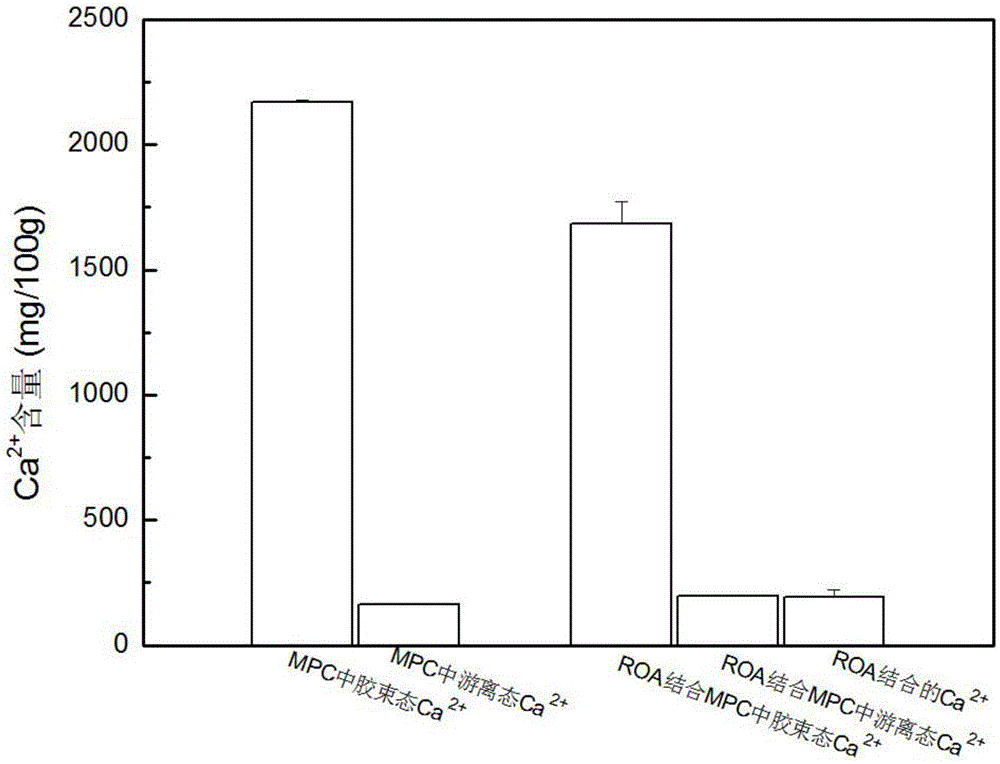

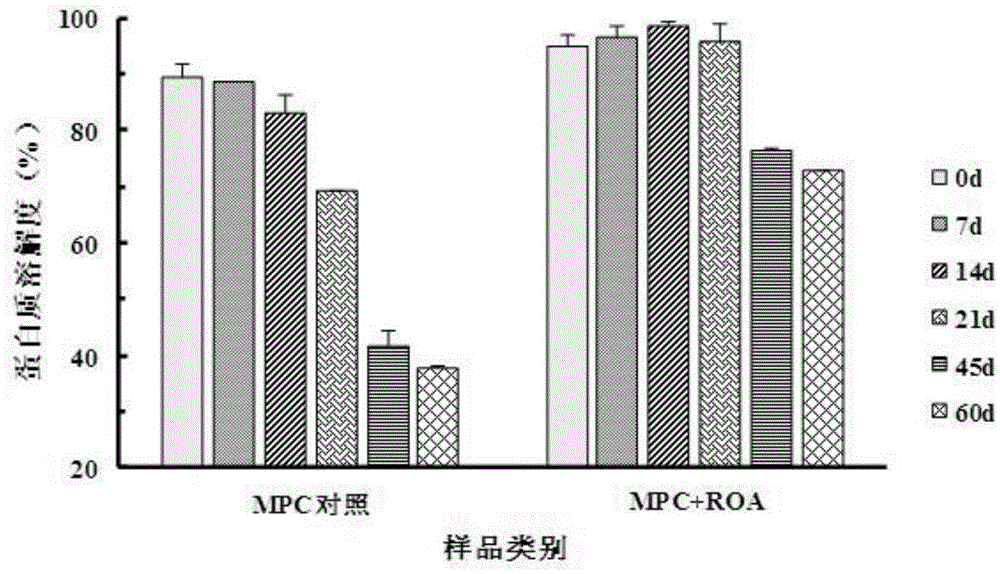

Method for improving concentrated milk protein powder solubility through ion exchange decalcification

InactiveCN105104704AGuaranteed functionalityHigh protein contentMilk preparationProtein composition from milkSolubilityNutritive values

The invention relates to a method for improving concentrated milk protein powder solubility through ion exchange decalcification. Concentrated milk protein trapped fluid is obtained from raw material milk through ultrafiltration or milk protein concentrated liquid is obtained by directly dissolving concentrated milk protein powder sold in the market again, and ion exchange decalcification is carried out by adding cation exchange resin. The obtained decalcified milk protein concentrated liquid is sprayed and dried to obtain the decalcified concentrated milk protein powder. The decalcified concentrated milk protein powder has the advantages of being good in solubility and high in storage stability. Besides, 10-30% of the concentrated milk protein powder is decalcified, the solubility of the concentrated milk protein powder is greatly improved, and meanwhile certain nutrient value and functional properties such as gel property, emulsibility and foamability of the concentrated milk protein powder can be guaranteed. The concentrated milk protein powder decalcified partly can be used for producing high-quality cheese, high-protein yoghurt, protein nourishment and the like.

Owner:JIANGNAN UNIV

Process for preparing concentrated milk protein ingredient and processed cheese made therefrom

Owner:FONTERRA COOP GRP LTD

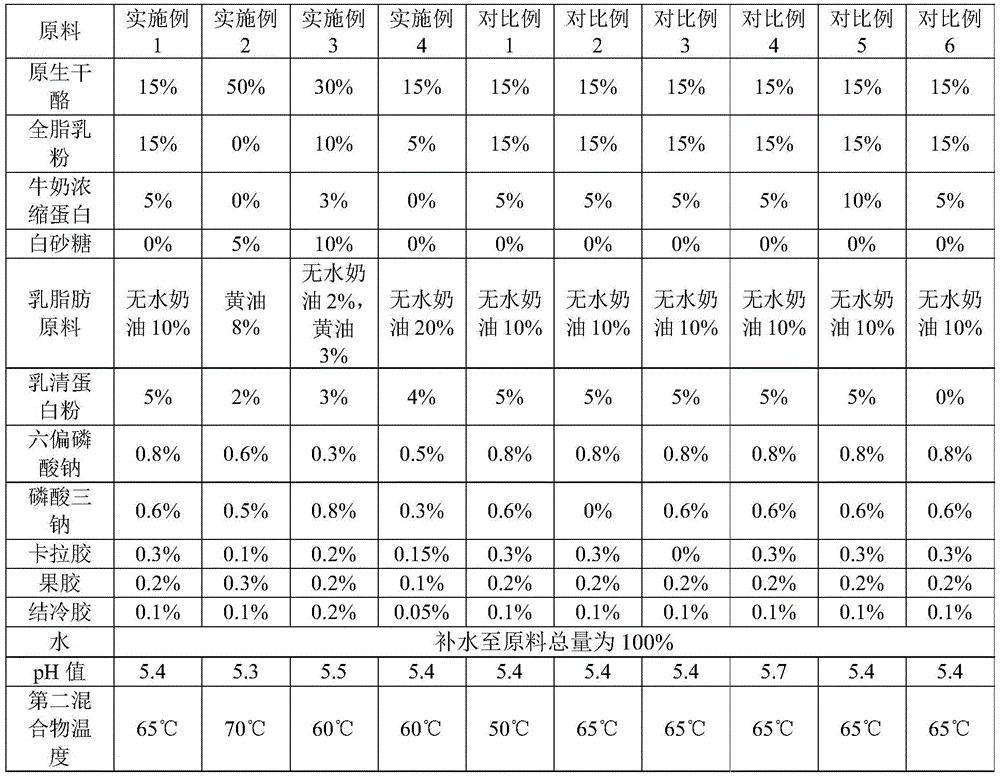

Spread processed cheese and preparing method thereof

ActiveCN105454444AThere will be no material leakageImprove stabilityCheese manufactureWhey protein powderSugar

The invention discloses a spread processed cheese and a preparing method thereof. The spread processed cheese is prepared from, by weight, 15-50 parts of primary cheese, 0-15 parts of whole milk powder, 0-5 parts of milk protein concentrate, 0-10 parts of white granulated sugar, 5-20 parts of milk fat raw materials, 2-5 parts of whey protein powder, 0.6-1.6 parts of emulsifying salt and 0.25-0.8 part of stabilizing agent. Filling of the spread processed cheese can be carried out at the low temperature, material leaking can be avoided, stability is high, and relish and taste are excellent.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Milk powder and method of manufacture

InactiveUS20090252849A1Affecting quality of powderImprove functionalityMilk preparationDough treatmentWhey proteinUltrafiltration

A method for the processing of milk ultrafiltration permeate created during the manufacture of milk protein concentrate (MPC) and / or whey protein concentrate (WPC) to produce a reduced-protein milk powder, which nevertheless has useful functional and sensory properties.

Owner:MURRAY GOULBURN COOP CO LTD

Method for improving solubility of concentrated protein powder by means of fatty acid combination or by removing calcium in casein micelle

InactiveCN105594867AImprove functional nutritional valueHigh sphericityMilk preparationLipidic food ingredientsProtein solutionCasein micelles

The invention relates to a method for improving solubility of concentrated protein powder by means of the fatty acid combination or by removing calcium in casein micelle. Fatty acid is added into a raw material dairy product to reduce a pH value of protein, calcium in the casein micelle is combined or removed, and spray drying is carried out to obtain the concentrated protein powder rich in functional fatty acid; fatty acid calcium and a protein solution can also be separated by means of simple centrifugal operation, and the protein solution is dried in a spray mode to obtain the concentrated protein powder partially decalcified. The method has the advantages that the production process is simple and free of pollution; functional milk powder is rich in beneficial fatty acid, after being partially decalcified, the protein solubility is good, and storage stability is high; the concentrated milk protein powder is decalcified partially (10-30%), and nutritional value and functionality of milk protein are retained, and solubility is improved; the two products can be used for producing high-protein food such as liquid milk beverages, yoghourt, cheese and nutrition bars; fatty acid calcium obtained by means of centrifugal separation can be applied to feed processing.

Owner:JIANGNAN UNIV

Food products containing partially and/or totally denatured milk proteins

InactiveUS20050084579A1Reinforcing fiberProteins working-up by texturisingFood shapingFiberReady to eat

The present invention relates to a dietary composition produced by a process involving extruding a milk containing product (e.g., milk, milk concentrate, milk protein concentrate, whey, whey concentrate, whey protein isolate, whey protein concentrate) through an extruder at about 50-about 450 rpm and at a temperature of about 40° to about 120° C. to produce the dietary fiber composition (which contains partially or totally denatured milk containing product). The present invention also concerns a food product containing at least one food ingredient and the dietary composition described herein; for example the dietary composition containing partially denatured proteins may be used to create a fully cooked, totally expanded or puffed ready-to-eat snack food product (or pellets or half products). In addition, the present invention relates to a method of making a food product, involving adding the dietary composition described herein to one or more food ingredients or adding one or more food ingredients to the dietary composition described herein. Furthermore, the present invention concerns a method of increasing fiber in the diet of a mammal, involving feeding to the mammal the fiber enriched food product described herein.

Owner:US SEC AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com