Spread processed cheese and preparing method thereof

A technology of processed cheese and cheese, which is applied in the field of smeared processed cheese and its preparation, can solve the problems that need to be improved, and achieve the effect of excellent flavor and taste, long shelf life and good flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

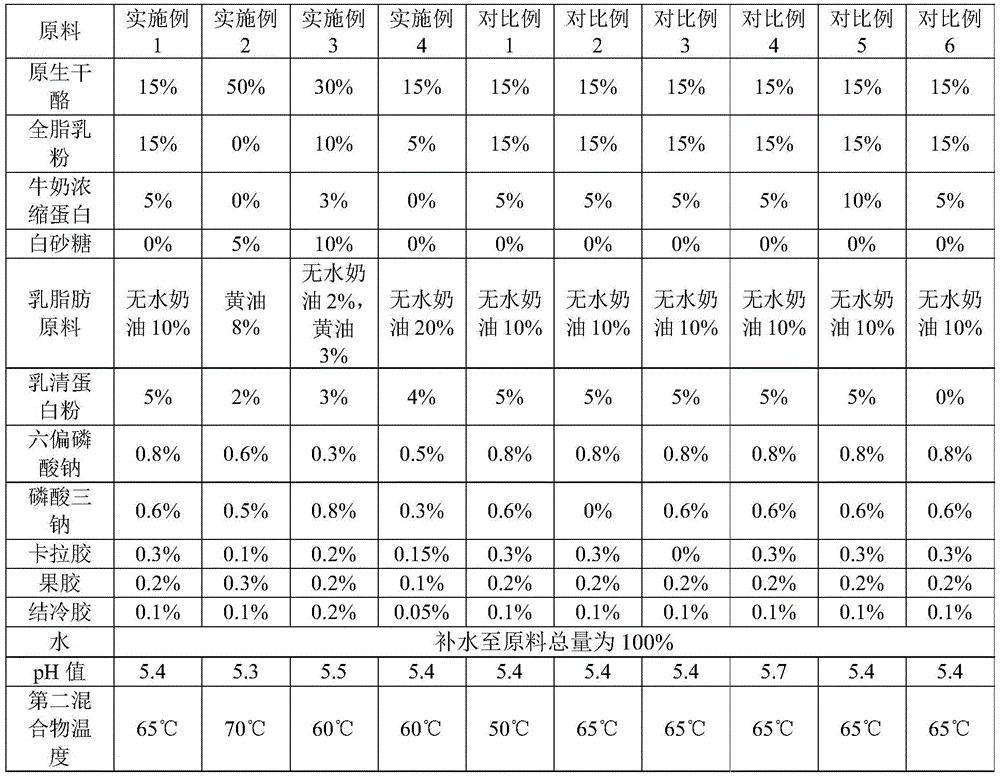

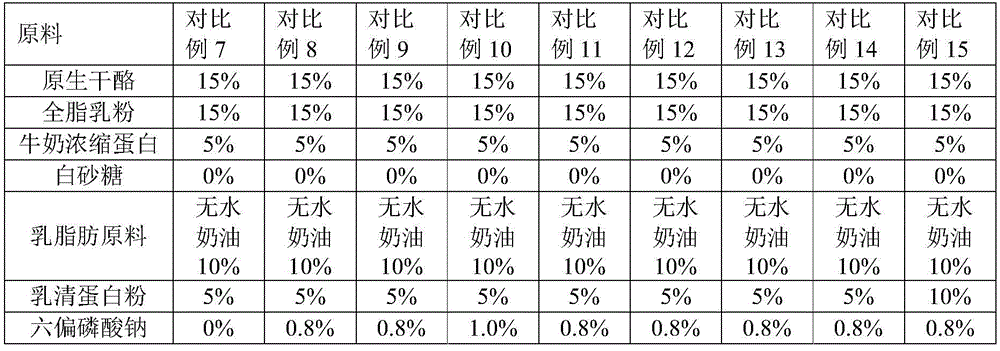

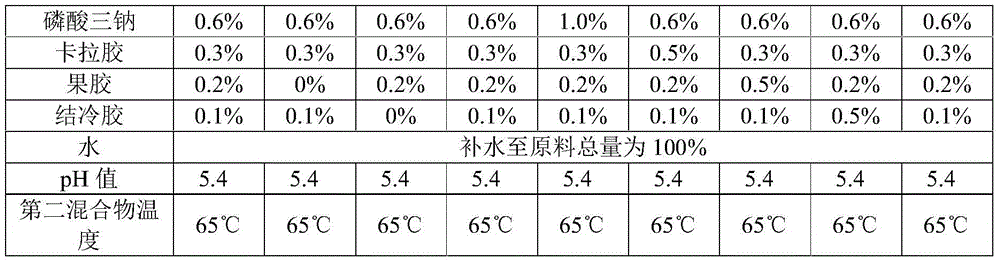

Embodiment 1~4 and comparative example 1~15

[0051] In Examples 1-4 and Comparative Examples 1-15, spread processed cheese was prepared according to the following process:

[0052] (1) Weigh the raw materials according to the ingredients and dosage listed in Table 1, cut the original cheese into small pieces and add them into the melting pot to grind and mix with other raw materials to obtain the first mixture, and the first mixture The pH value is adjusted to the pH value listed in Table 1;

[0053] (2) heat the mixture obtained in step (1) at 85-90 degrees Celsius for 10 minutes to carry out emulsification treatment, and then lower the temperature of the obtained emulsified product to obtain a second mixture, wherein the temperature of the second mixture As shown in Table 1;

[0054] (3) The second mixture is input into the filling buffer tank, the temperature of the second mixture shown in Table 1 is maintained and stirred at a speed of 20rpm, while stirring, the filling machine is fed to the filling machine for fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com