Patents

Literature

35results about How to "Guaranteed no leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

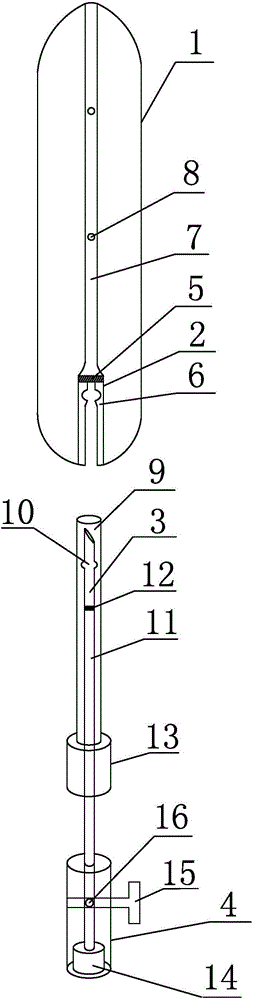

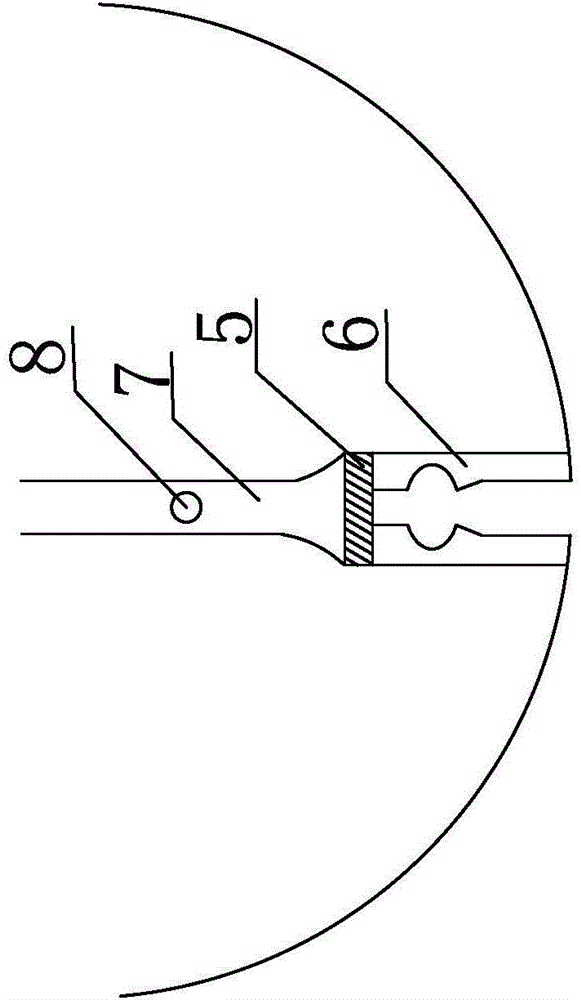

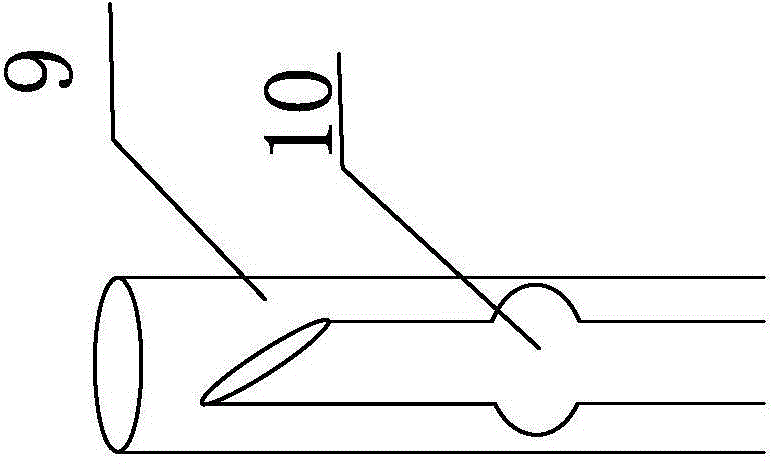

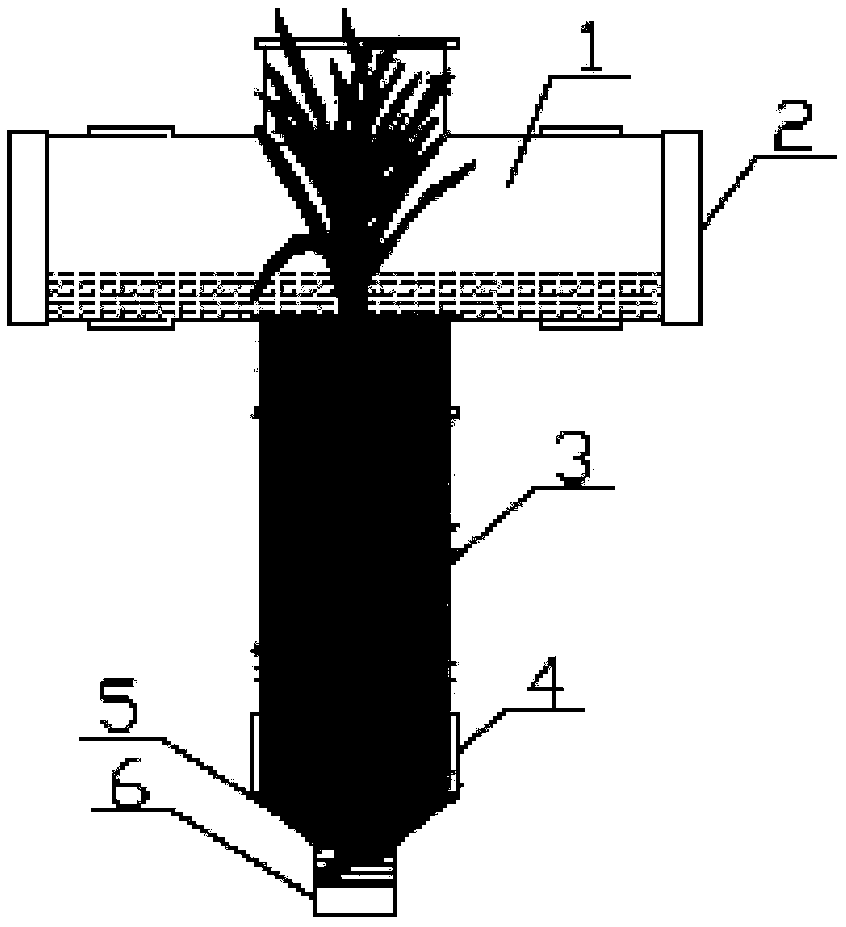

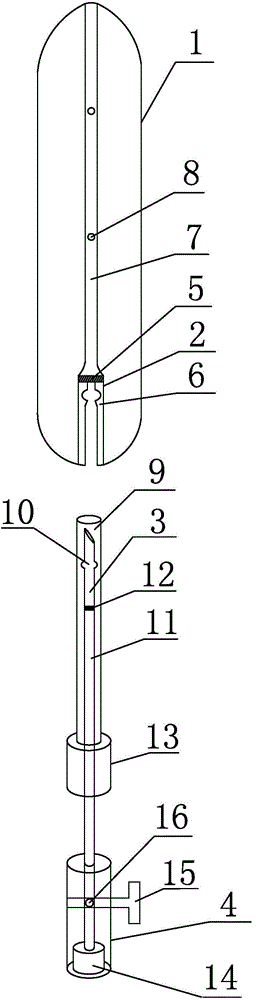

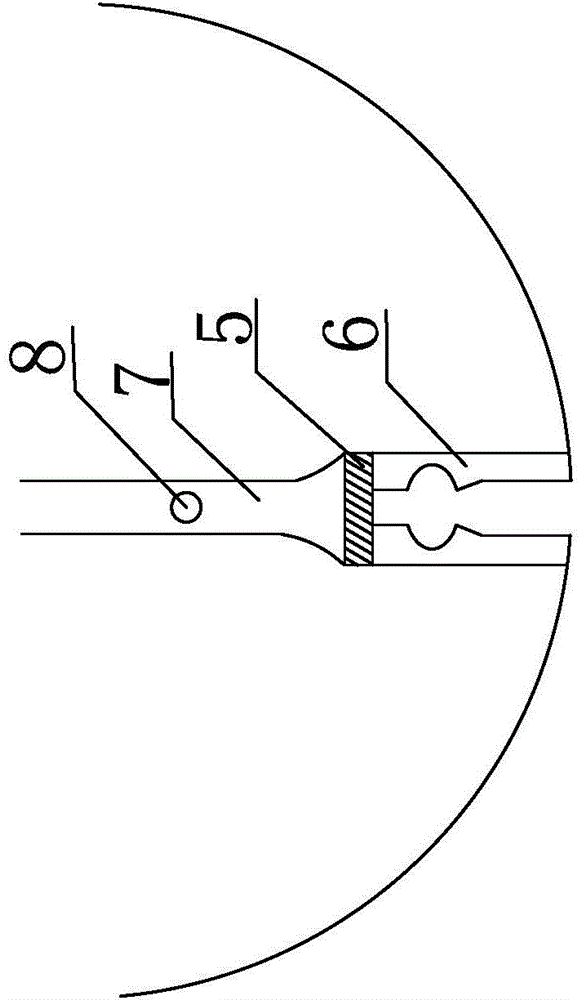

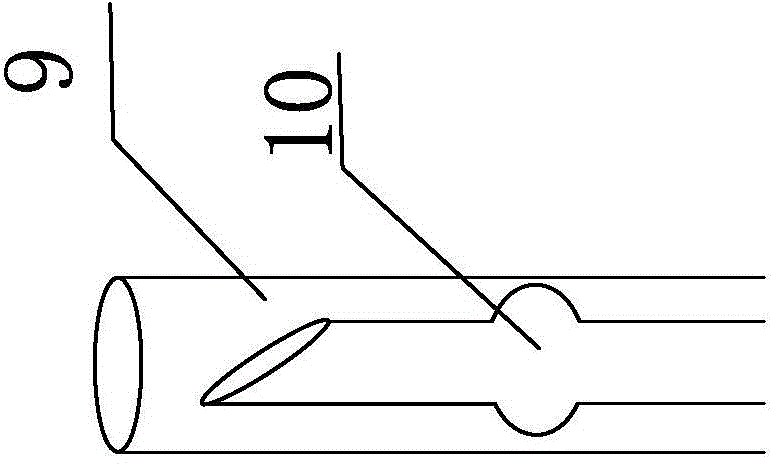

Separable air bag device for protecting intestinal tract surgery field

ActiveCN104083215AAvoid bacterial contaminationReduce use and hospital stayDiagnosticsSurgeryInjectorFull thickness resection

The invention relates to a separable air bag device for protecting an intestinal tract surgery field. An air bag core with side holes is fixedly arranged in an air bag; an air bag plug comprises a rubber plug arranged at an air inlet of the air bag core; a sleeve type air inflation needle comprises an outer sleeve, an air inflation needle head and an air inflation pipe, and the needle head and the air inflation pipe are arranged in the outer sleeve and can move relative to the outer sleeve; the needle head is used for penetrating through the rubber plug and injecting air into the air bag; the air inflation valve comprises an injector connecting port communicated with an air inflation pipe as well as an air inflation turning bolt which can control in-out of air; and after air inflation, the air bag can be separated, the surgery field of the lower section of an intestinal tract is not influenced. The device effectively guarantees the clean and sterile state of the lower section of the intestinal tract, protects the admission passage of an orifice transluminal endoscopic surgery and protects perforation parts from being polluted in the processes of endoscopic full-thickness resection for the intestinal tract and other intestinal tract surgeries, so that sterile surgery of the lower section of the intestinal tract becomes possible, and peritonitis after the surgery can be prevented.

Owner:HARBIN MEDICAL UNIVERSITY

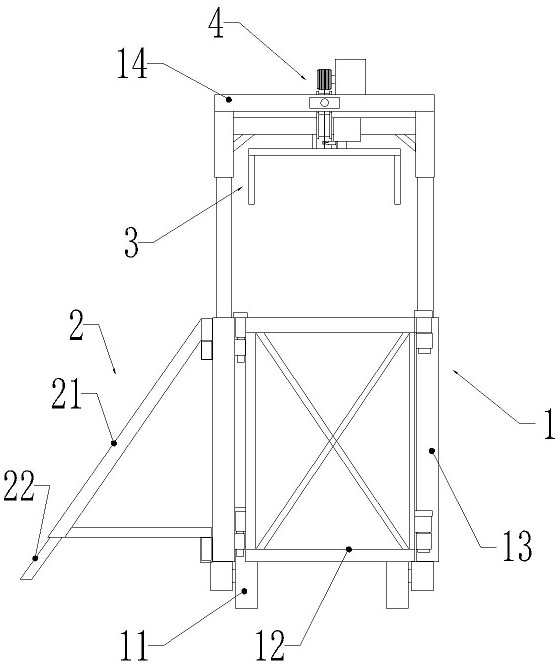

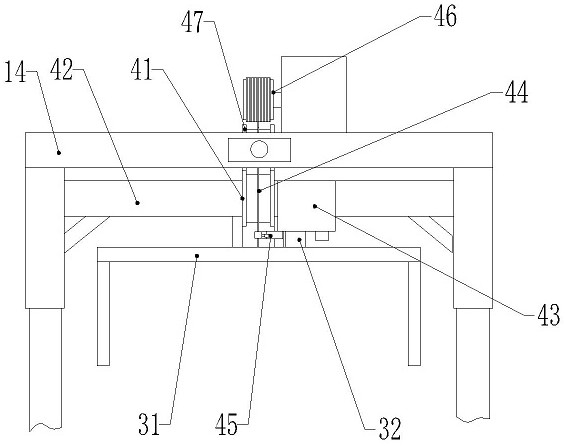

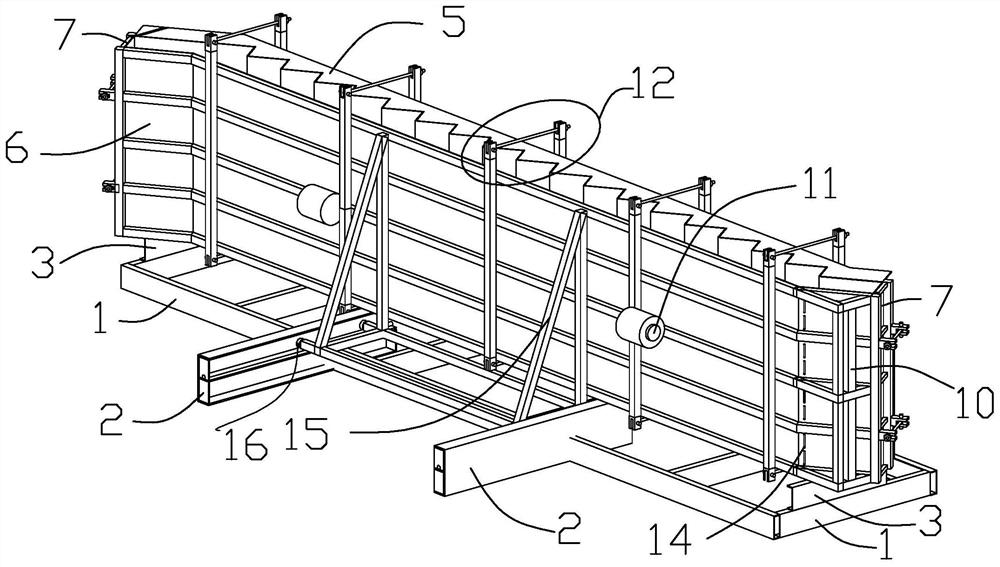

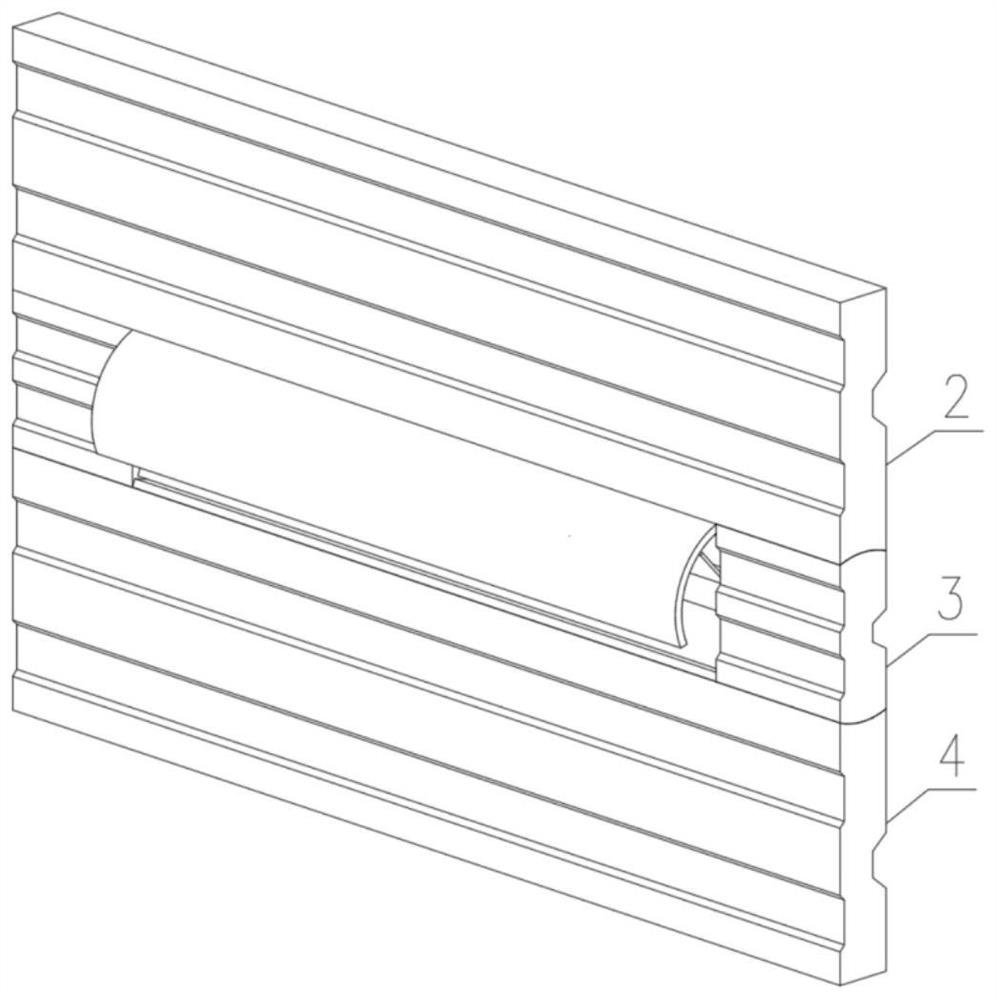

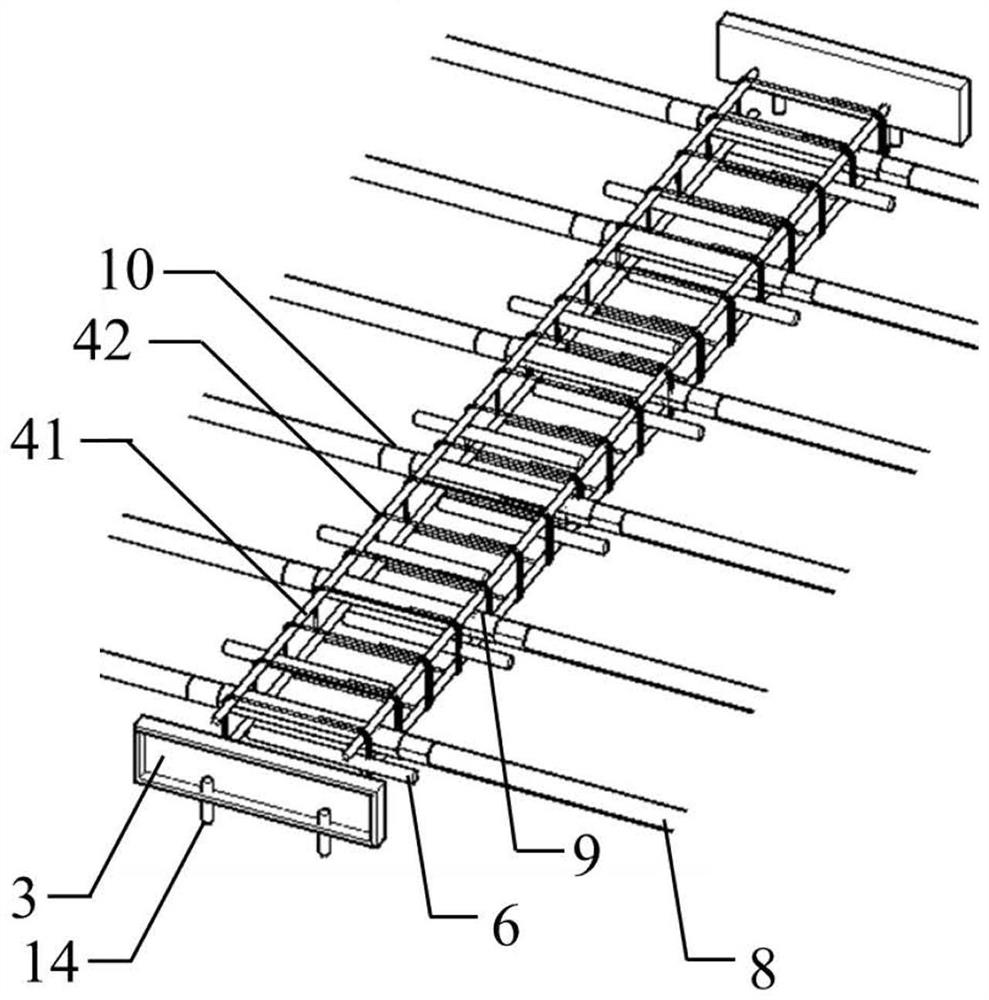

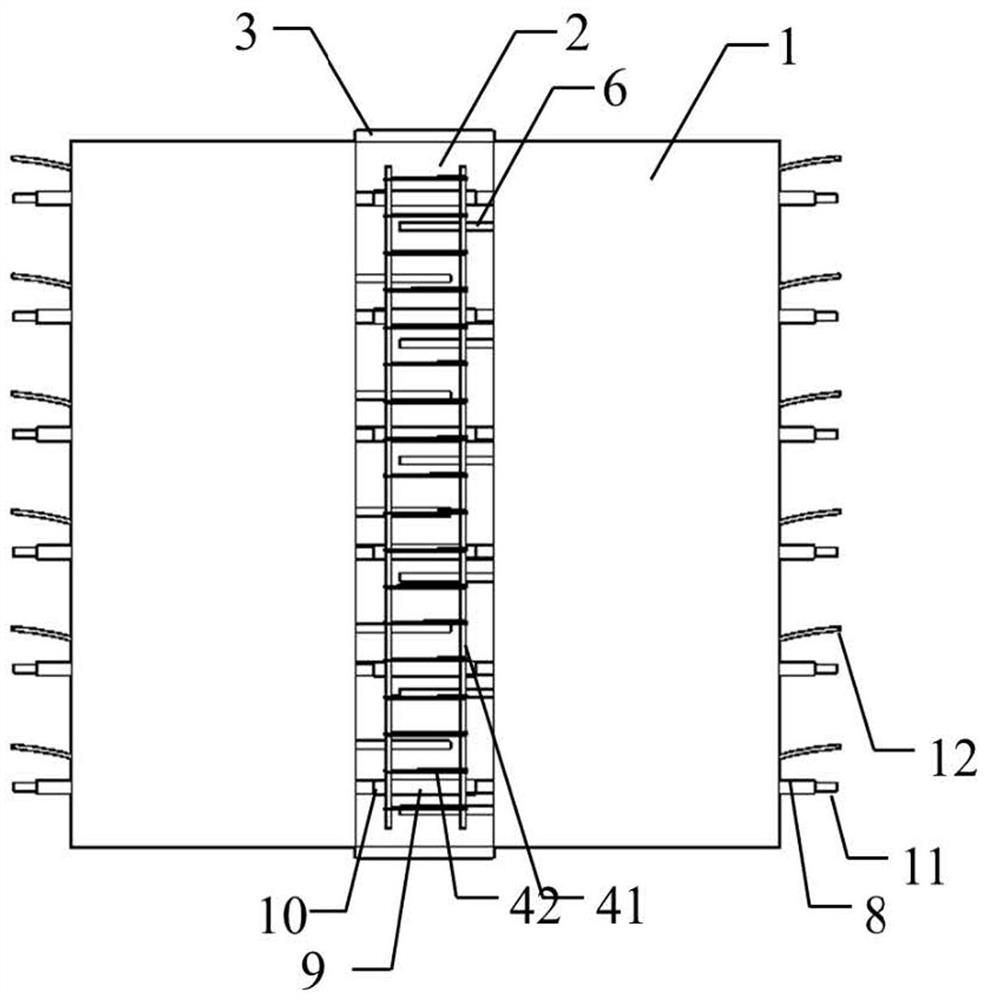

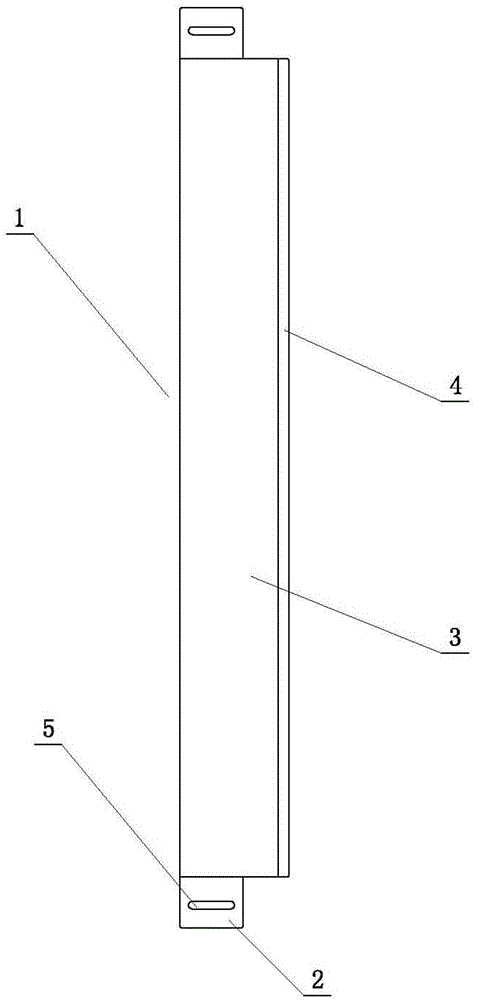

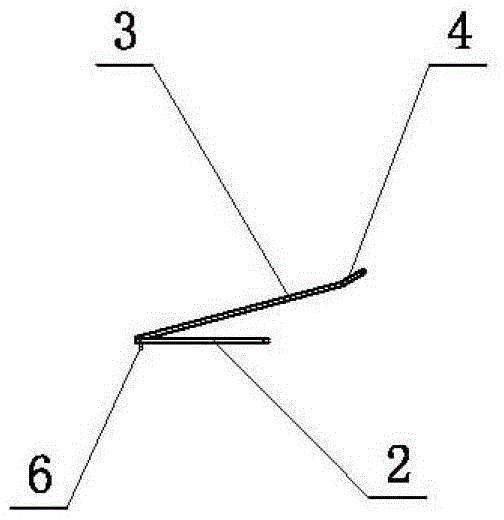

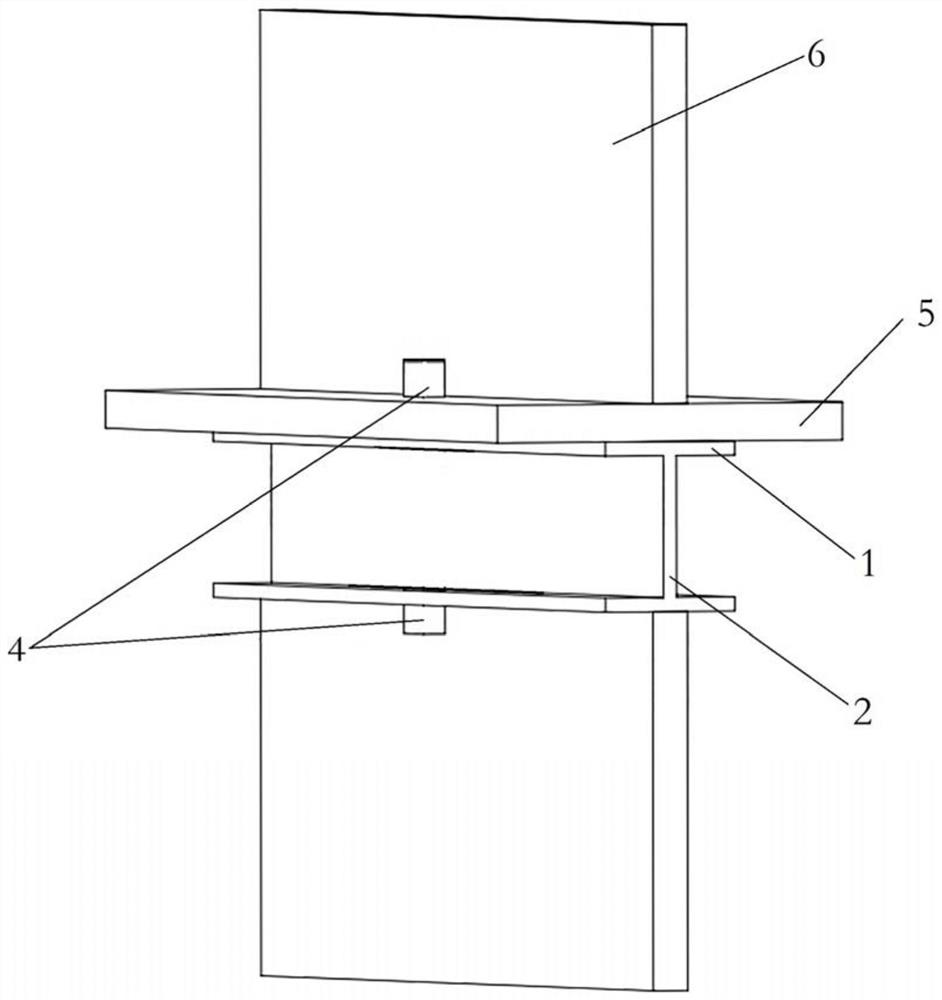

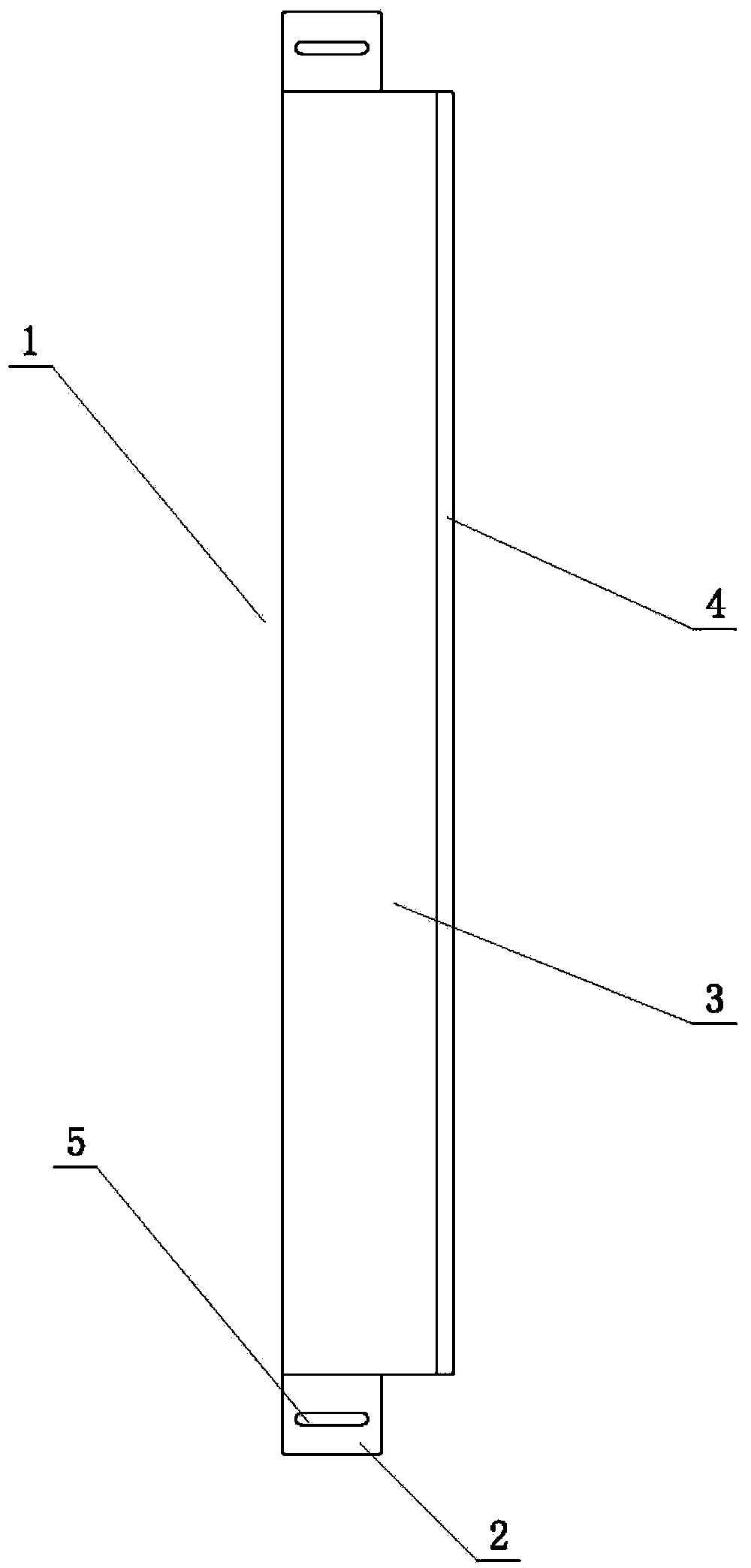

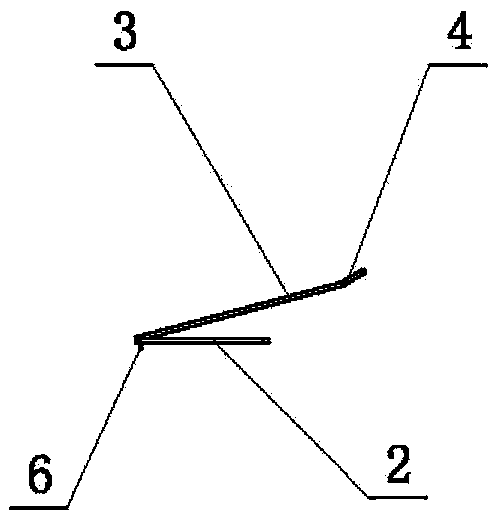

Equipment and method for carrying and in-place installation of vertical battens of a building infilled wall

PendingCN112850539AEasy to makeEasy to useLiquid surface applicatorsPortable liftingArchitectural engineeringEngineering

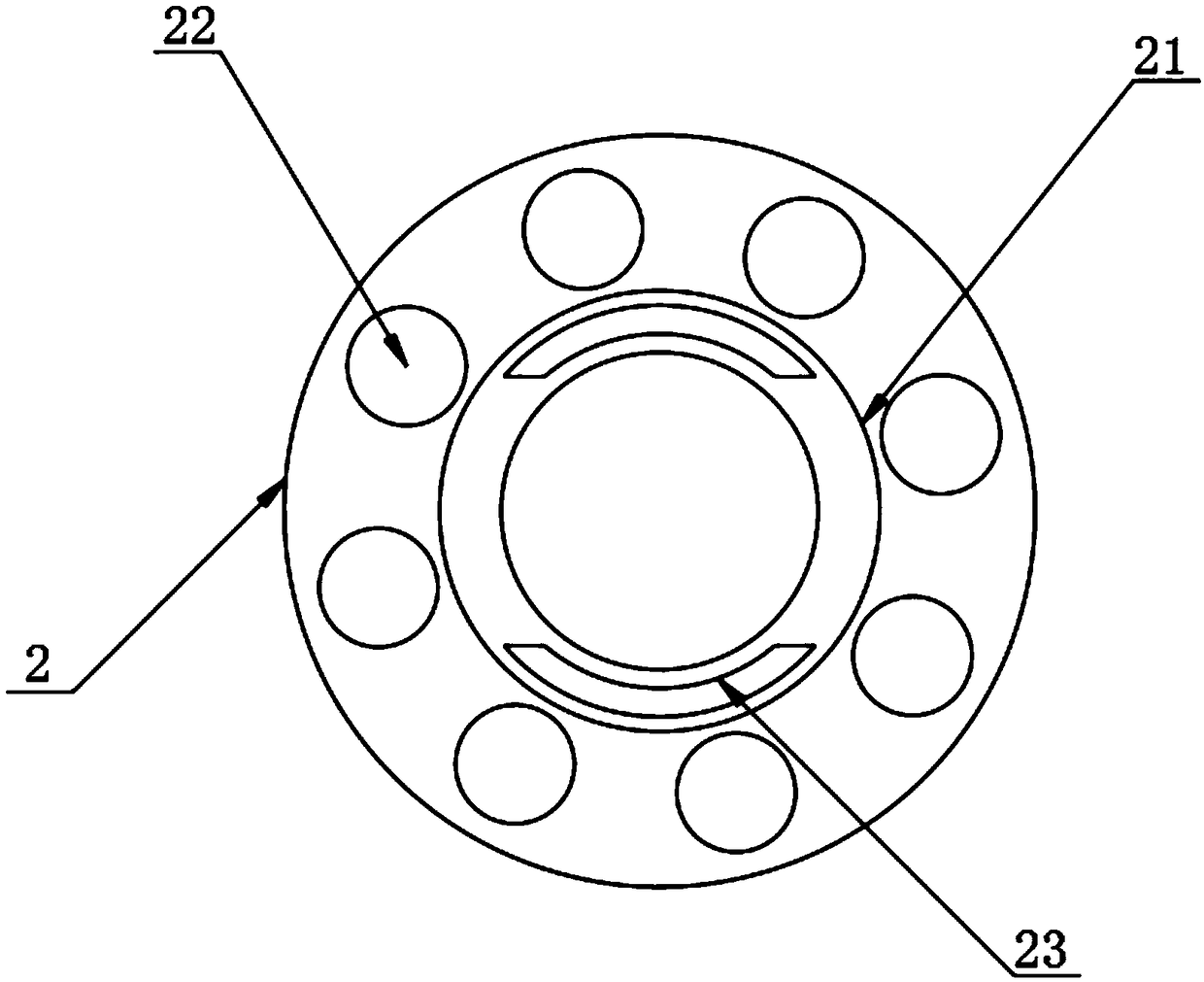

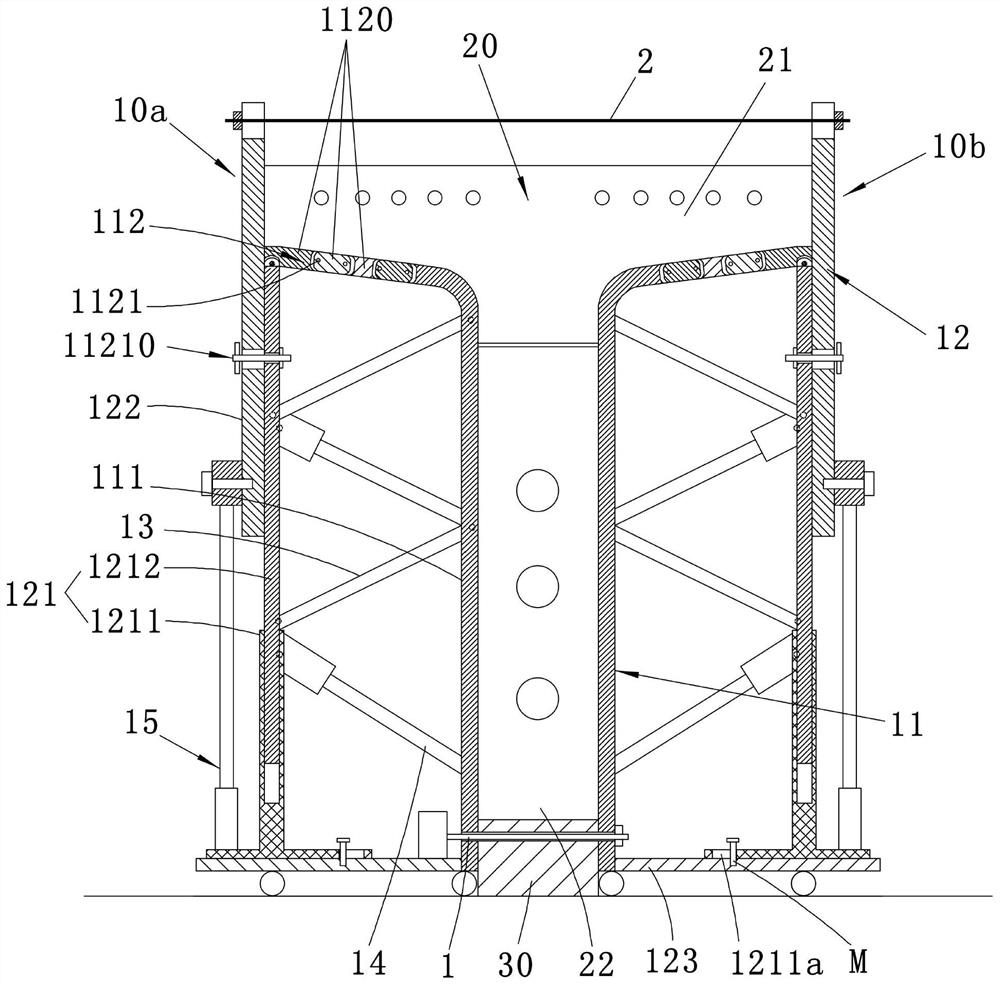

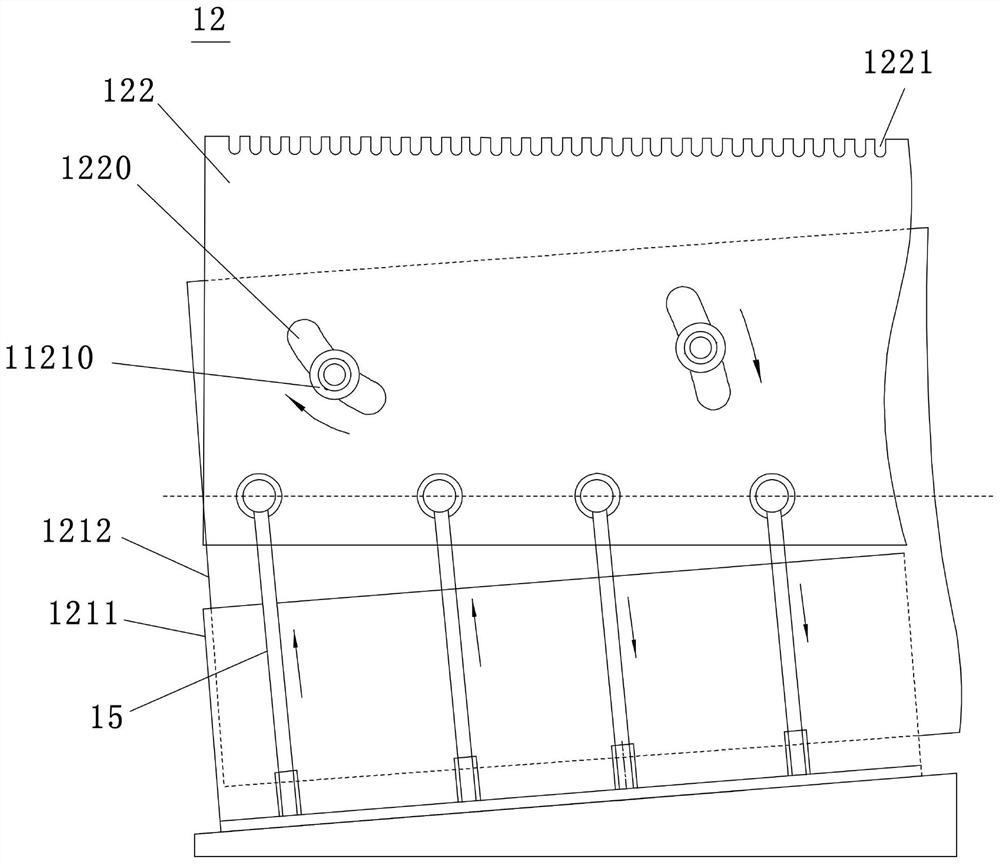

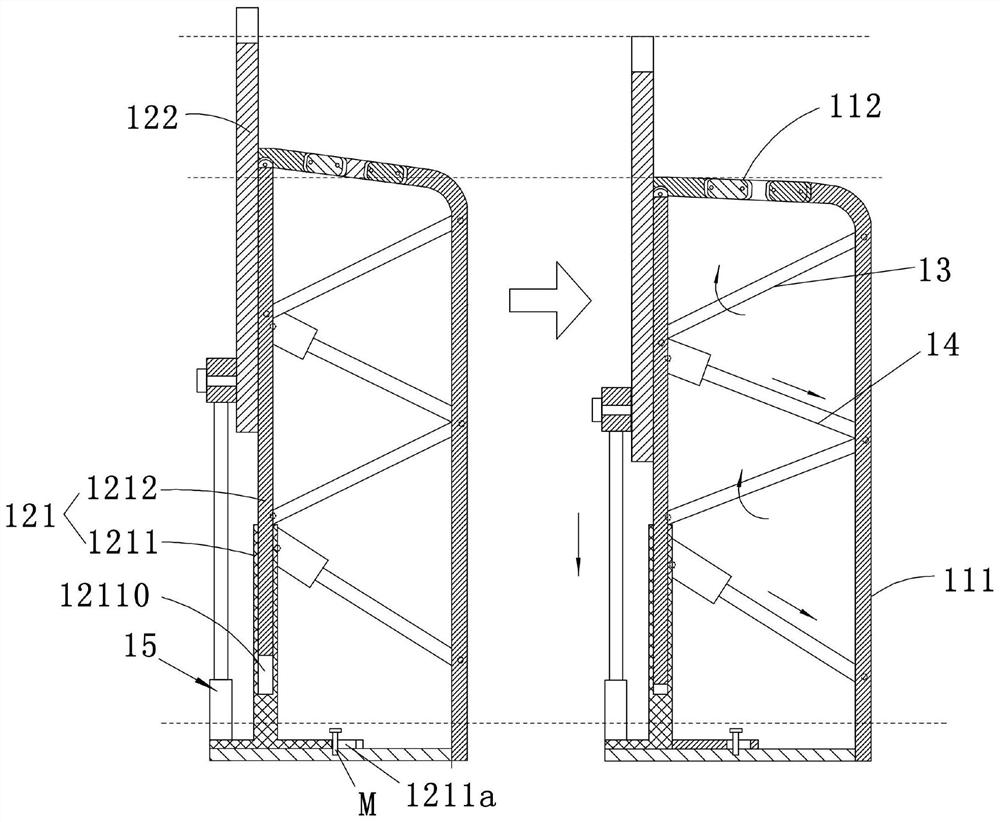

The invention relates to equipment and a method for carrying and in-place installation of vertical battens of a building infilled wall. The equipment for carrying and in-place installation of the vertical battens of the building infilled wall comprises a batten carrying system, a batten clamping system and a batten lifting and rotating system. The batten conveying system comprises a movable frame and a lifting support. The batten clamping system comprises two sets of mechanical clamping jaws, and the two sets of mechanical clamping jaws are located at the open end and the closed end of the movable frame correspondingly. The batten lifting and rotating system comprises a first pulley, a second pulley, a third pulley, a steel wire rope, steel wire rope winding equipment and a steel wire rope locking device. When a batten is overturned, a first steel wire rope non-return switch device locks the steel wire rope, the steel wire rope winding equipment releases the steel wire rope, and the end, close to the closed end of the movable frame, of the batten slowly descends until overturning of the batten is completed. The traditional method of carrying and mounting by multiple persons is changed, so that the labor intensity is reduced, the mounting time is shortened, and the manual carrying and mounting cost is greatly reduced.

Owner:李洪宾

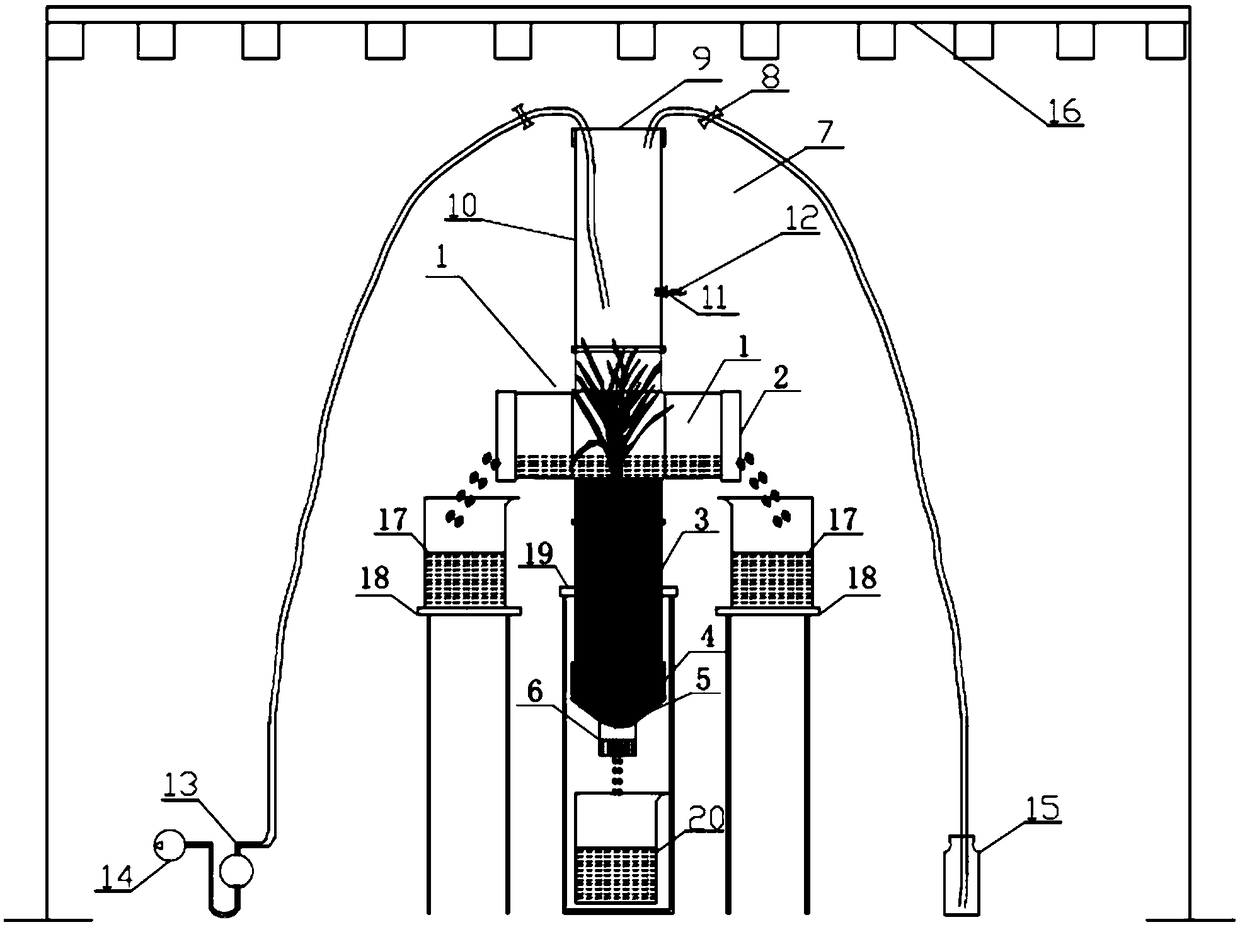

Indoor testing device for quantitative analysis of farmland nitrogen emission

PendingCN109342694AReduce system errorAvoid the problem of low release resultsEarth material testingSurface runoffNitrogen emission

The invention discloses an indoor testing device for the quantitative analysis of the farmland nitrogen emission, and is used to quantitatively analyze the discharge of farmland nitrogen by three ways, which is surface runoff, leakaging and leaching, and gas loss. The device mainly comprises a plant culturing unit, a leakage fluid collecting device, a runoff liquid collecting device, an artificialrainfall device, and gas collecting device. Most of the main body of the device is made of PVC pipes and its accessories. The plant culturing unit is placed smoothly through a fixing holder, and theleakage fluid can be collected underneath. The plant culturing unit is connected to accessories to collect runoff liquid sample during or after an artificial rainfall. When the gas sample is collected, a sampling space above the plant culturing unit is connected to the gas sampling pump through a plastic hose and a bubble absorbing tube, and the gas sample is collected by an acid absorption methodfor measuring the amount of ammonia volatilization. A hole is opened near the lower end of the gas collecting device body, and the gas sample is taken with a needle tube for measuring the amount of nitrous oxide released.

Owner:NANJING UNIV OF TECH

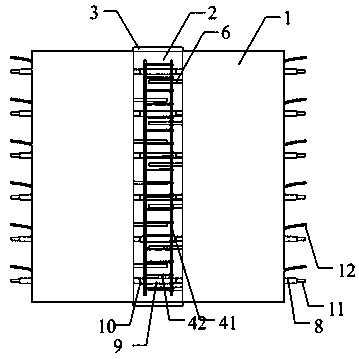

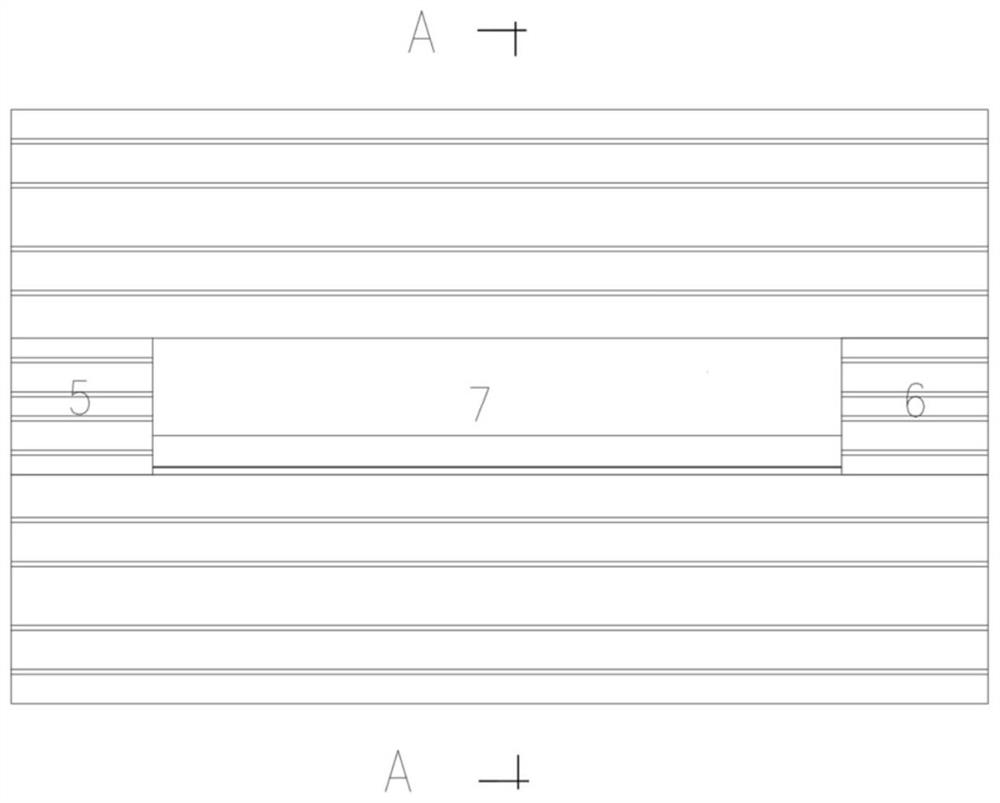

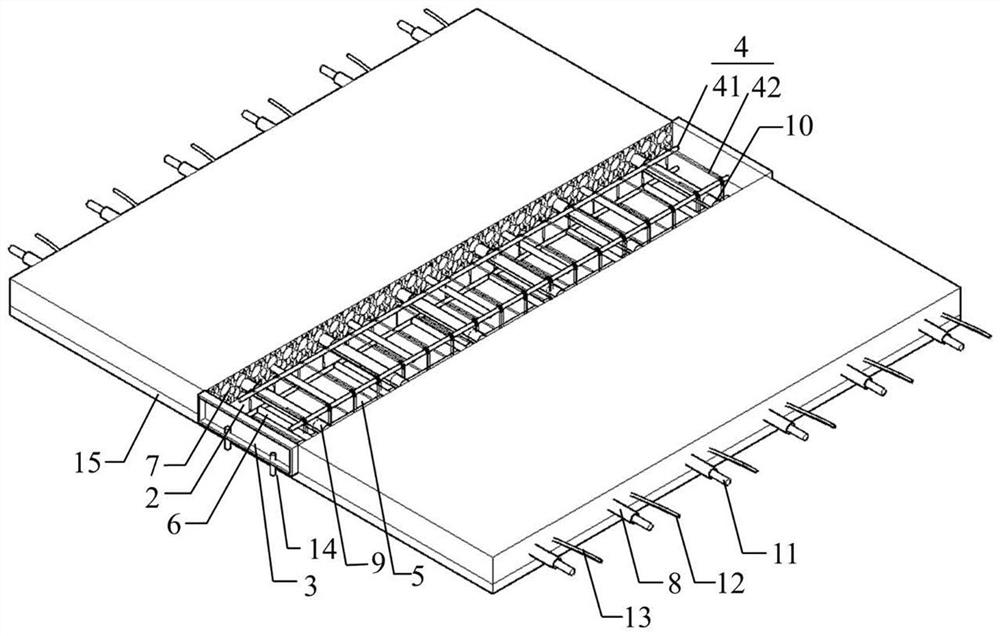

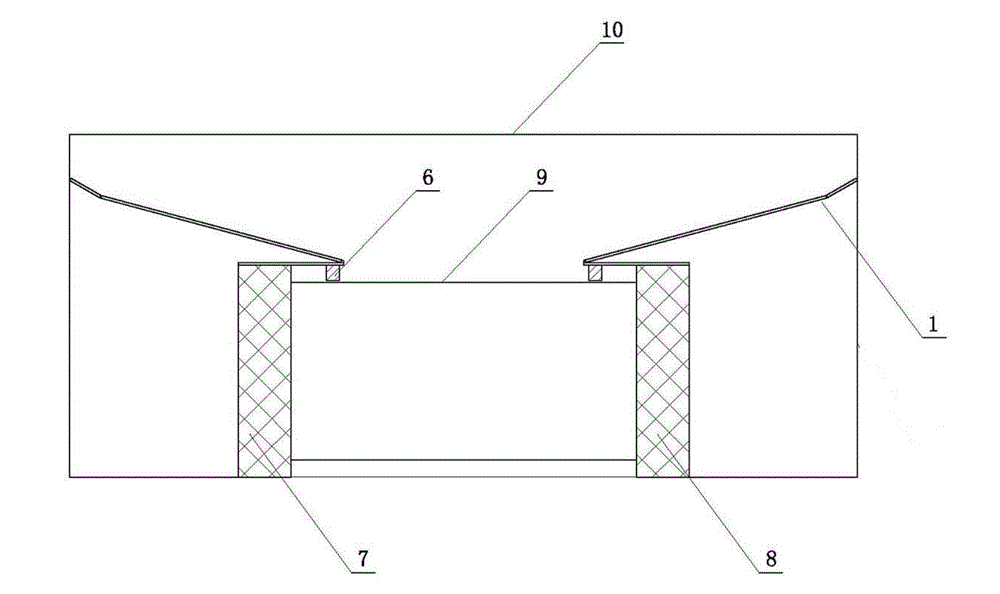

Wet joint structure suitable for fabricated pavement and construction method thereof

ActiveCN111485471AGuaranteed performanceImprove shear resistanceSingle unit pavingsPaving detailsButt jointPre stress

The invention discloses a wet joint structure suitable for a fabricated pavement and a construction method thereof. A prestress hole channel is reserved in a prefabricated cement pavement slab, and adowel bar is arranged on the slab surface and chiseled; the cement board is hoisted and located on a flat sliding layer, a cast-in-place seam is reserved, a formwork is installed at the end of the cast-in-place seam, and the corrugated pipe is connected with two adjacent plate prestress ducts and penetrates through ribs; structural steel bars are overlapped between the two panels, and micro-expansion high-performance concrete is poured; and prestress tensioning is conducted, and cement paste is poured from a grouting opening. The wet joints are arranged, and the prestressed tendons are tensioned so that the pavement integrity is enhanced, and the anti-shearing capacity is improved; the problem that assembly and butt joint of the assembled pavement are difficult is solved, and the construction progress is accelerated; the problem that the joint of the fabricated prestressed pavement slab is prone to breakage and water leakage is solved by chiseling the pavement, arranging the dowel barsand pouring the micro-expansion high-performance concrete, the structural stability is improved, and the service life of the pavement is prolonged.

Owner:山东智行勘察设计院有限公司 +1

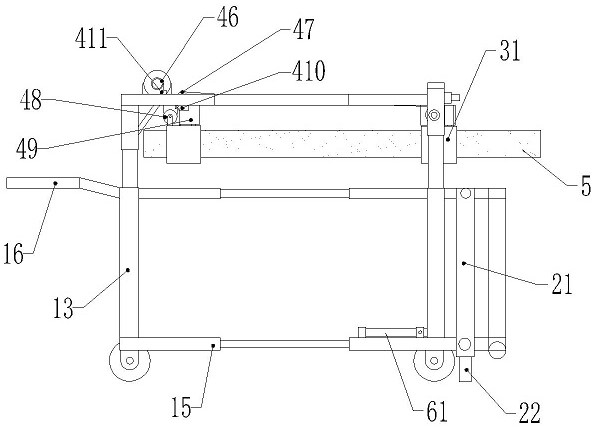

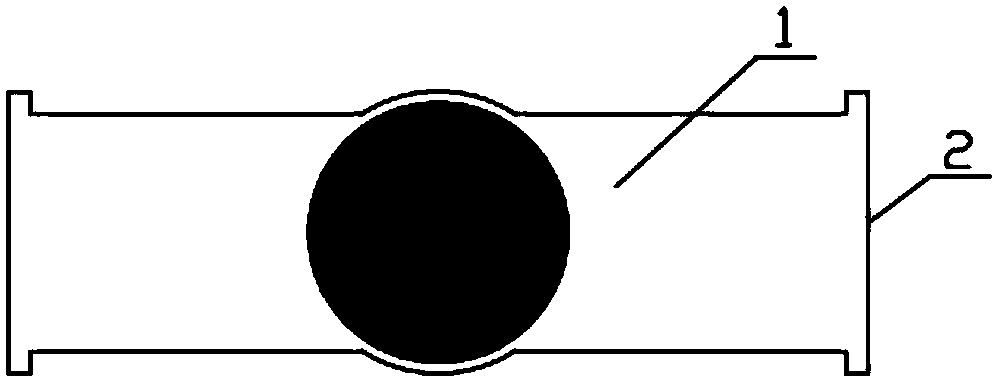

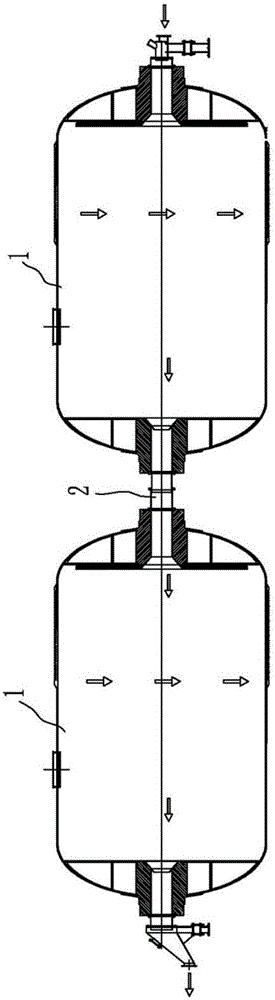

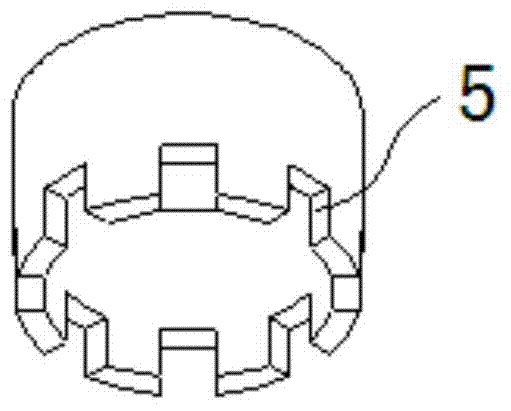

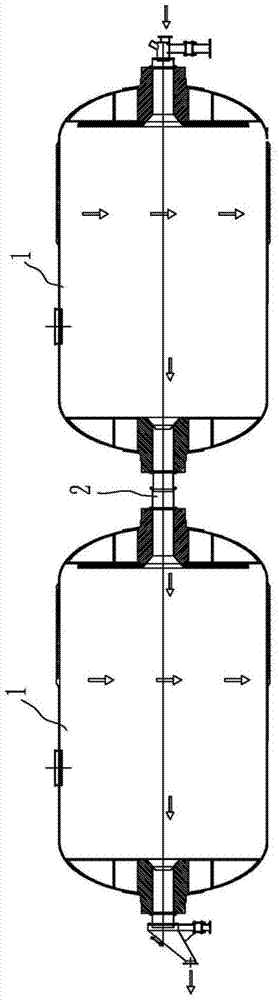

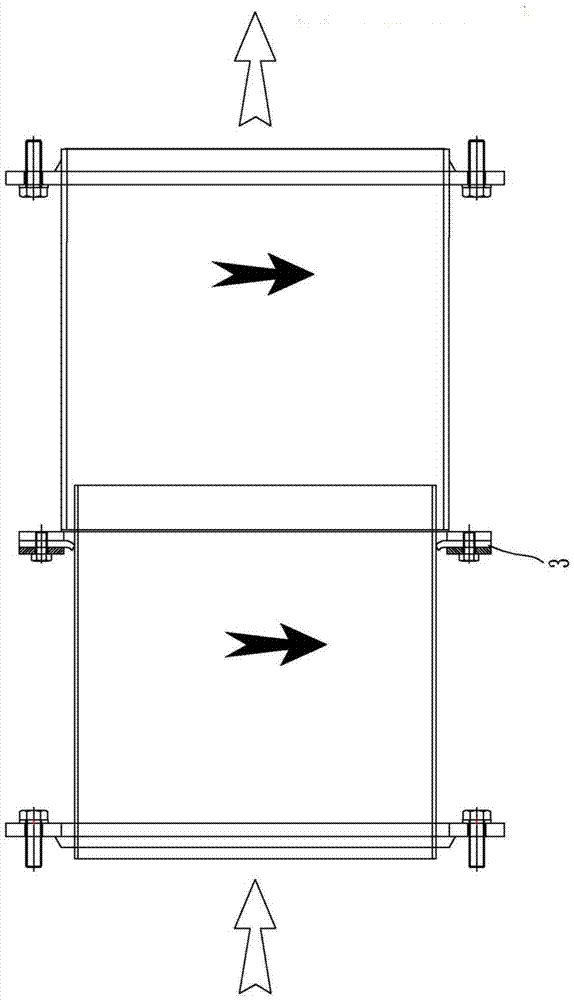

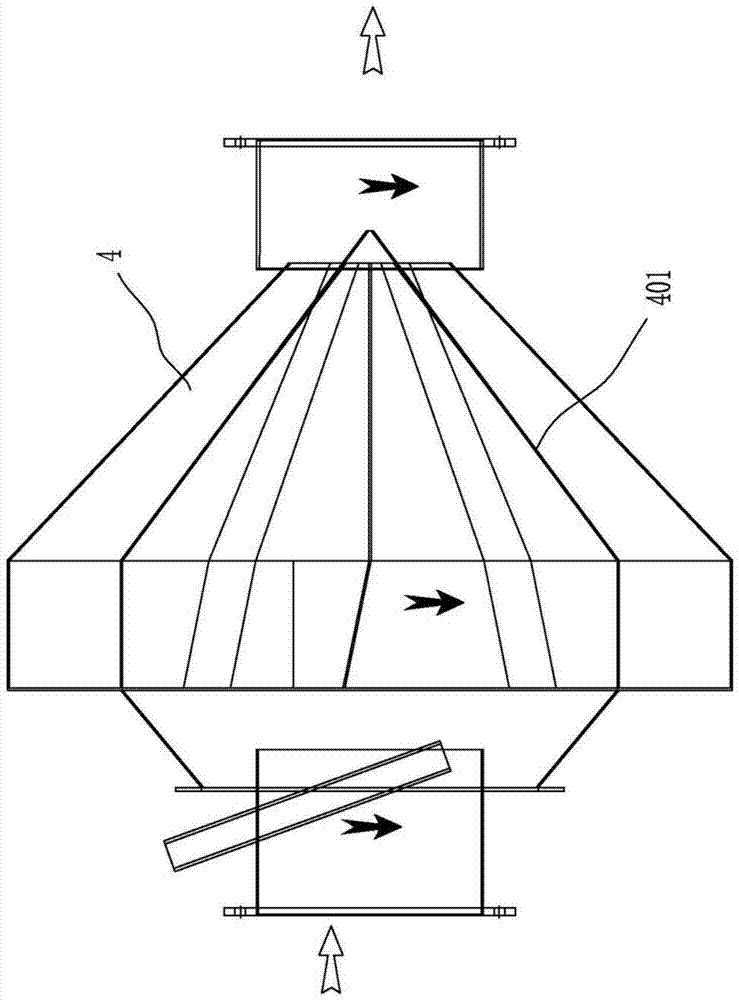

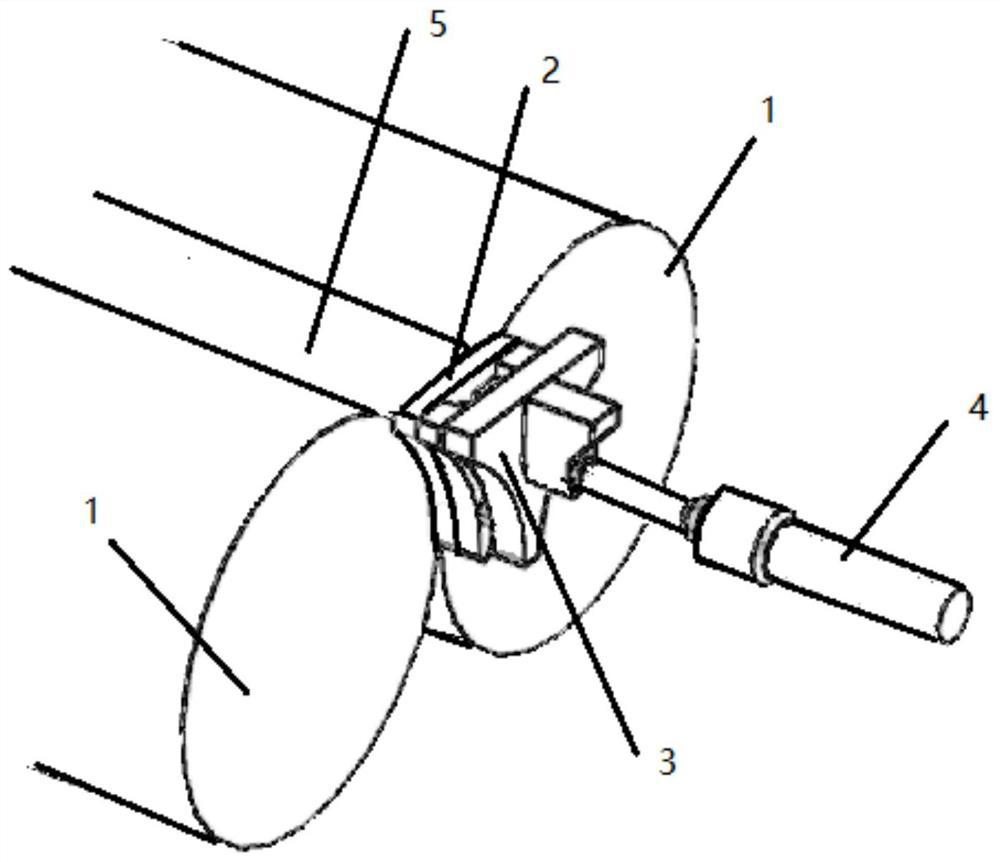

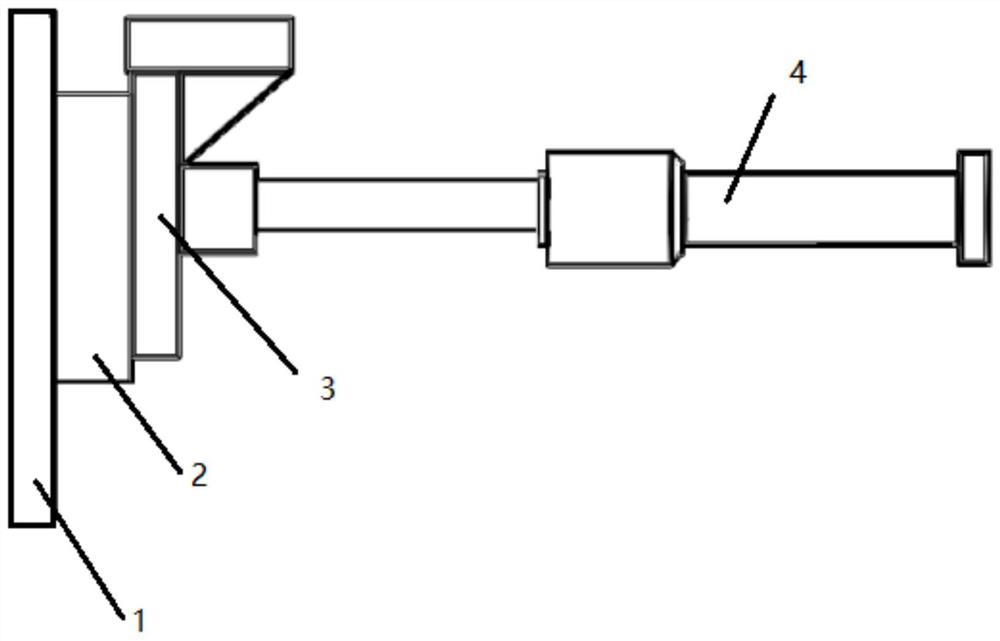

Non-contact slurry passing device used in continuous ball mill

The invention provides a non-contact slurry passing device used in a continuous ball mill. The non-contact slurry passing device is simple in structure, stable and reliable in work, long in service life and capable of effectively preventing slurry leaking, and comprises adjacently-arranged ball mill cylinders and further comprises a non-contact slurry passing device body arranged between the adjacent ball mill cylinders. The non-contact slurry passing device body comprises a slurry outlet pipe arranged at a discharging opening and a feeding opening of the adjacent ball mill cylinders in a fastened mode and a conical slurry scooping cone hopper, wherein the slurry outlet pipe is sleeved with the slurry scooping cone hopper in an embedded mode, and meanwhile a plurality of spiral chutes used for rapidly scooping slurry are further distributed in an inner cavity of the slurry scooping cone hopper in the circumferential direction. By means of the scheme, when the non-contact slurry passing device works, the slurry can flow into the slurry scooping cone hopper from the slurry outlet pipe and can be rapidly scooped into the ball mill through the spiral chutes in the slurry scooping cone hopper, the liquid level of the slurry is controlled to be quite low accordingly, then the adjacent ball mill cylinders are not in contact, and it can be guaranteed that the slurry is not leaked in the transmission process.

Owner:佛山市恒力泰科技有限公司

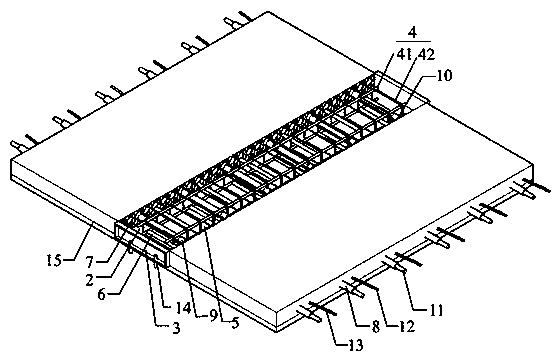

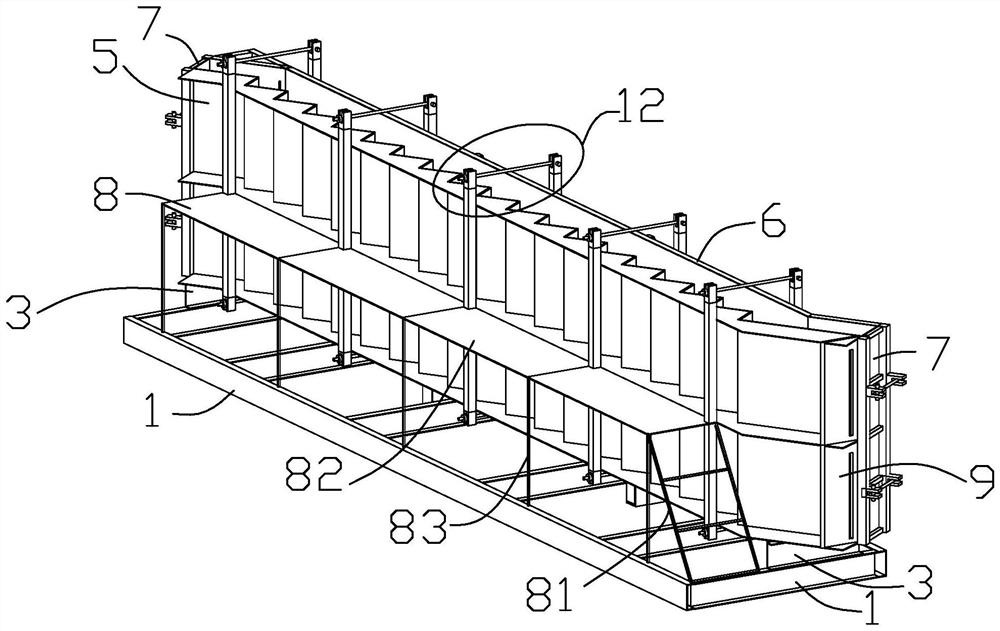

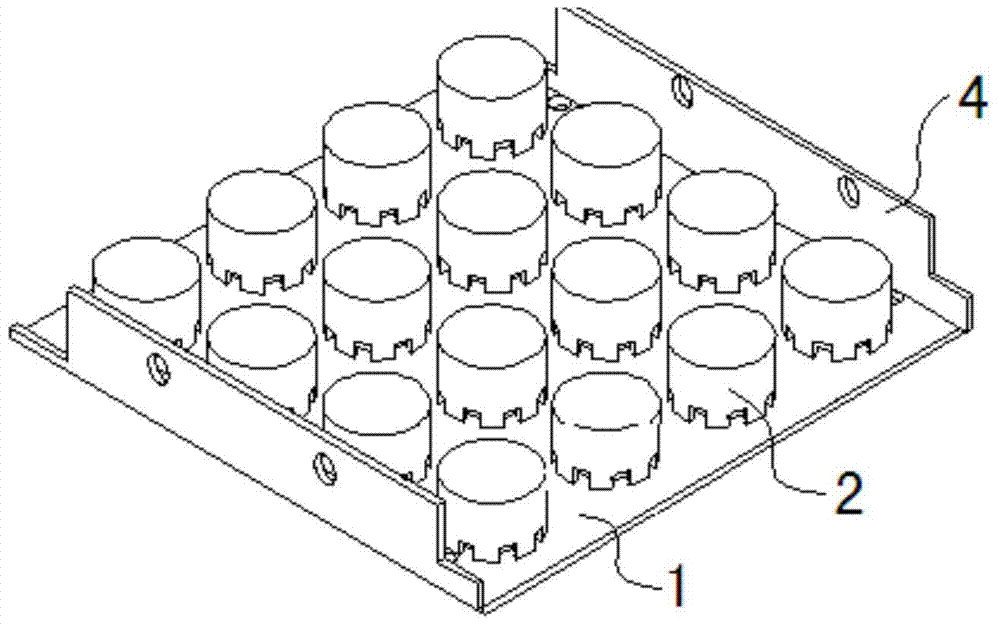

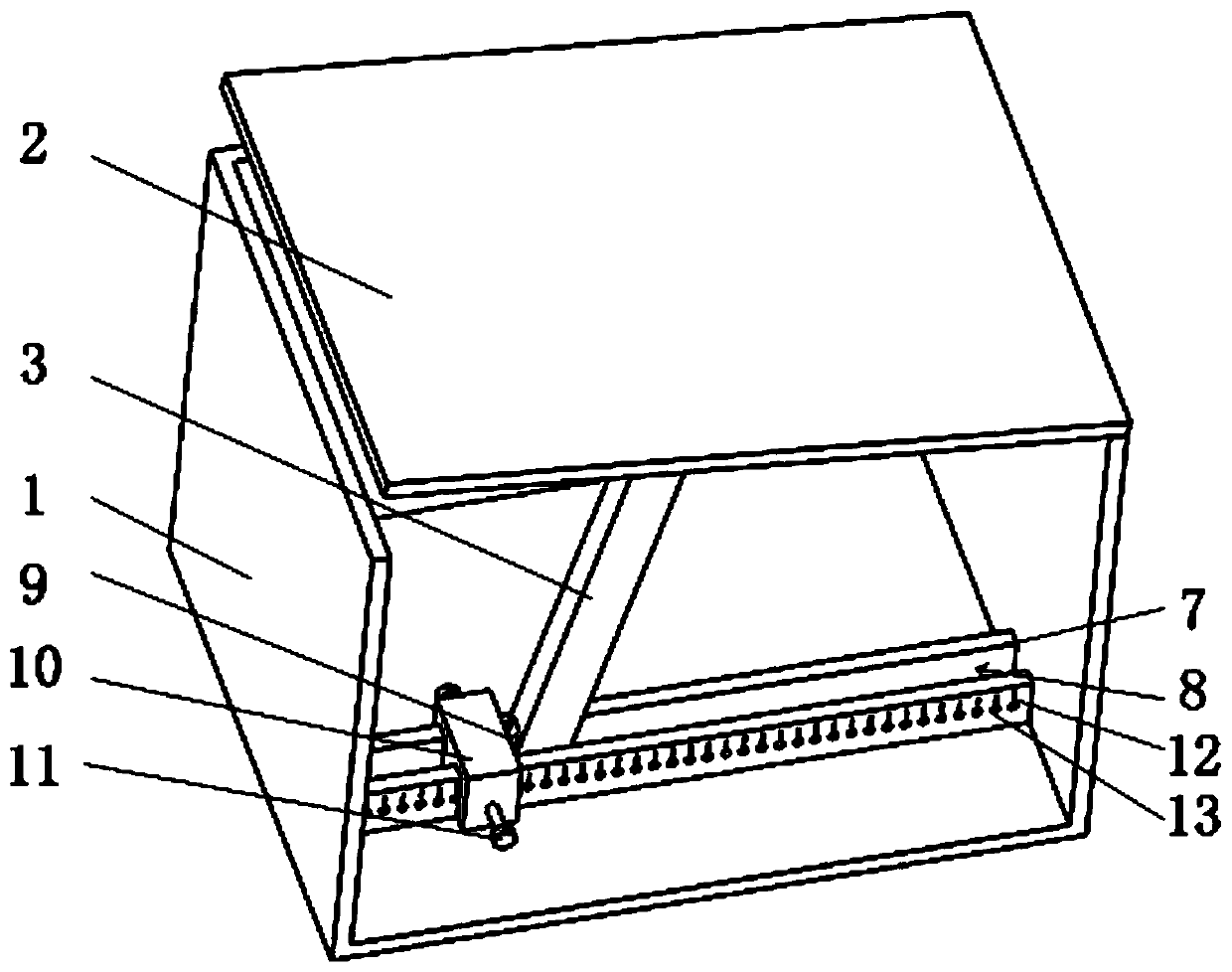

Vibrating automatic precast prestressed concrete stair mold and making method

PendingCN112265115AGuaranteed no leakageImprove flatnessDischarging arrangementMouldsPre stressArchitectural engineering

The invention discloses a vibrating automatic precast prestressed concrete stair mold and a making method, and belongs to the technical field of constructional engineering. The vibrating automatic precast prestressed concrete stair mold structurally comprises a base, sliding rails, supporting channel steels, an upper mold plate, a opposite-pulling device and a high-frequency vibrating motor; the upper mold plate comprises a bottom mold, a fixed side mold, a movable side mold and an end mold; the peripheries of the fixed side mold, the end mold and the movable side mold are tensioned through opposite-pulling devices; the two sliding rails are arranged on the base; supporting channel steels are arranged at the two ends of the base in the length direction; the movable side mold is connected with rolling wheels through triangular supporting frames; the rolling wheels are arranged on the sliding rails; and a high-frequency vibration motor is arranged on the movable side mold. The inventionfurther discloses a making method of the vibrating automatic precast prestressed concrete stair. The vibrating automatic precast prestressed concrete stair mold has the advantages that no slurry leakage at the joint of the mold during concrete pouring is guaranteed, the stair surface flatness is improved, automatic vibration is achieved in the concrete pouring process, time and labor are saved, and the problems of embedded part displacement, prestress loss and the like are effectively avoided.

Owner:山东省建筑科学研究院有限公司

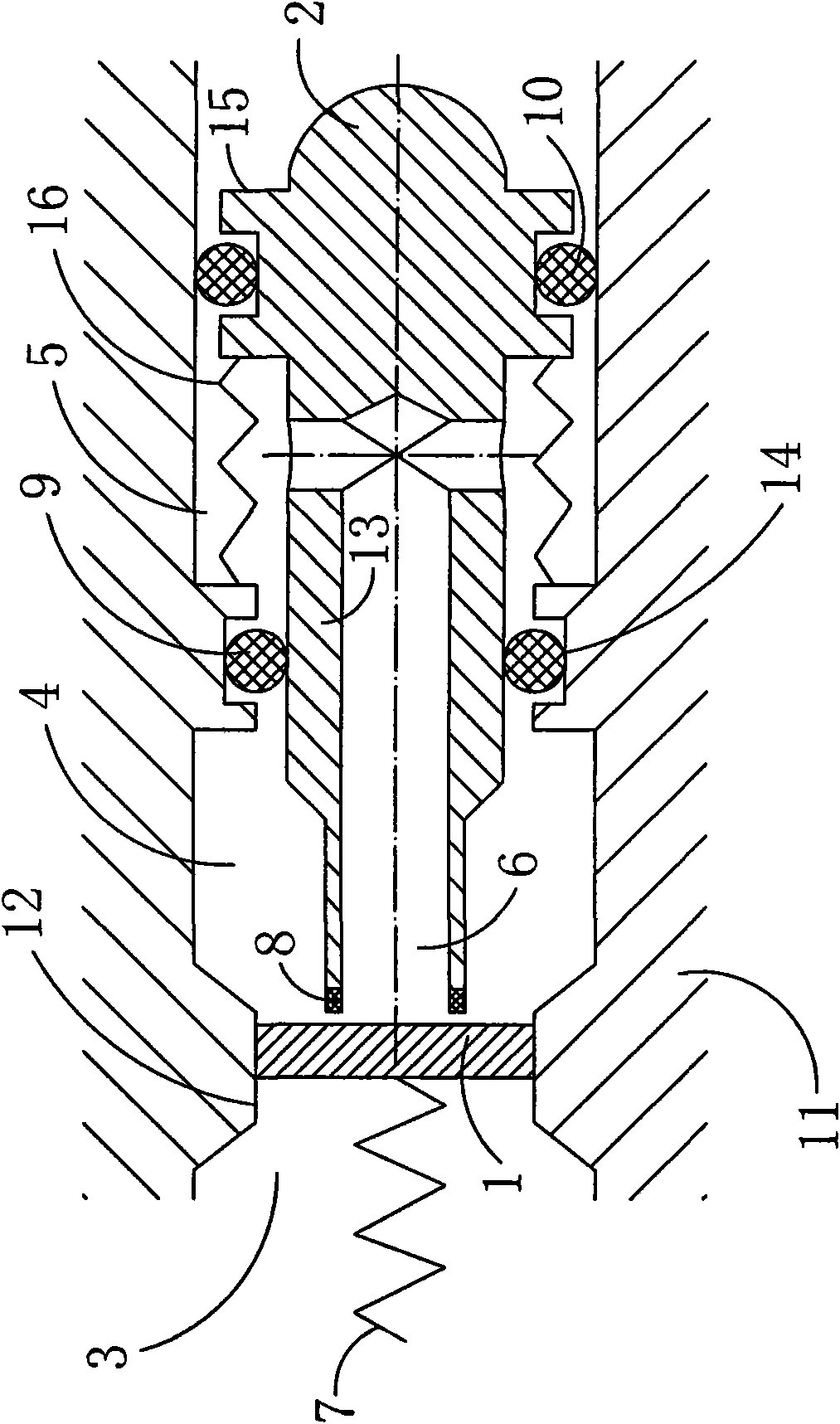

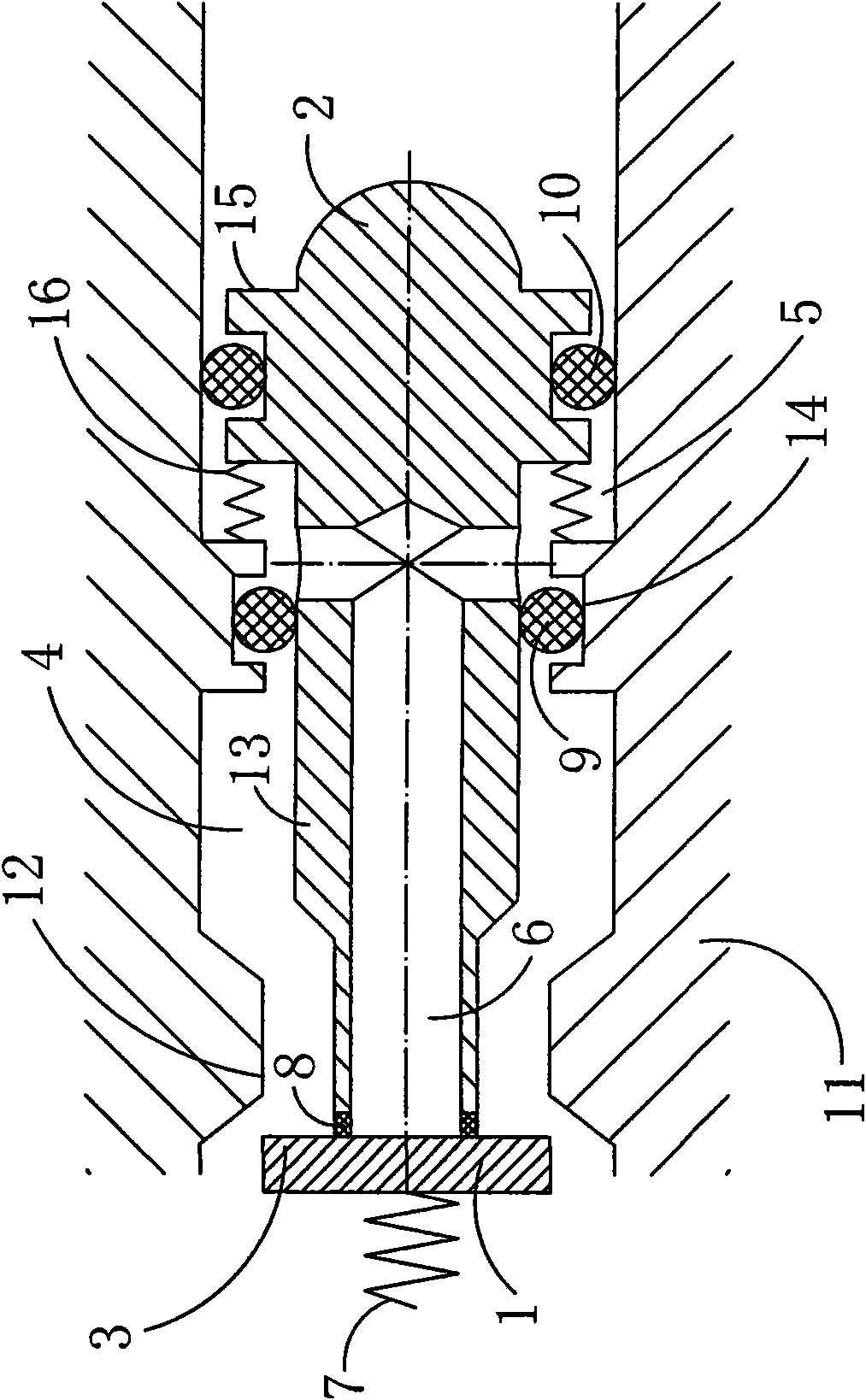

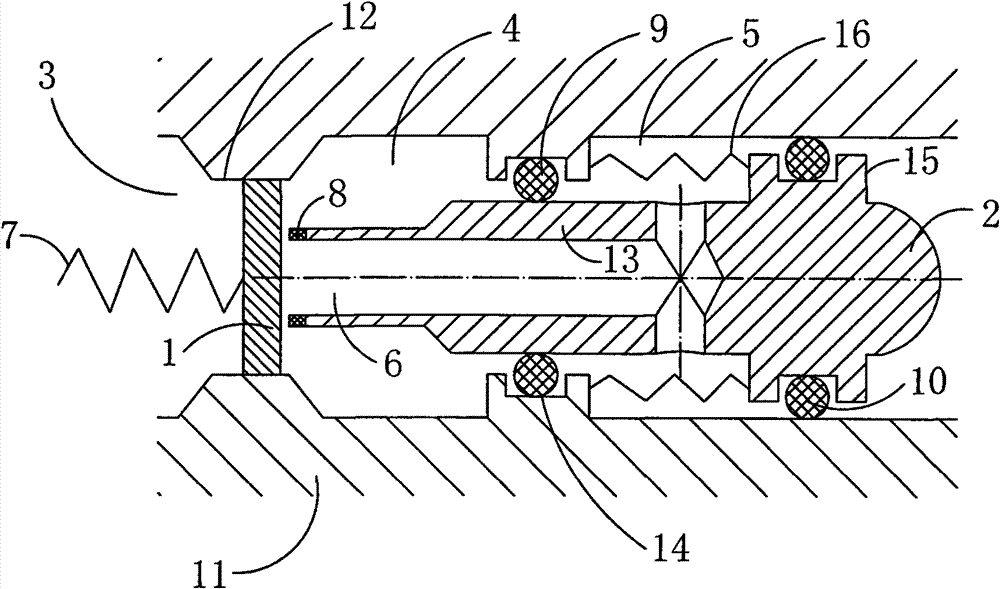

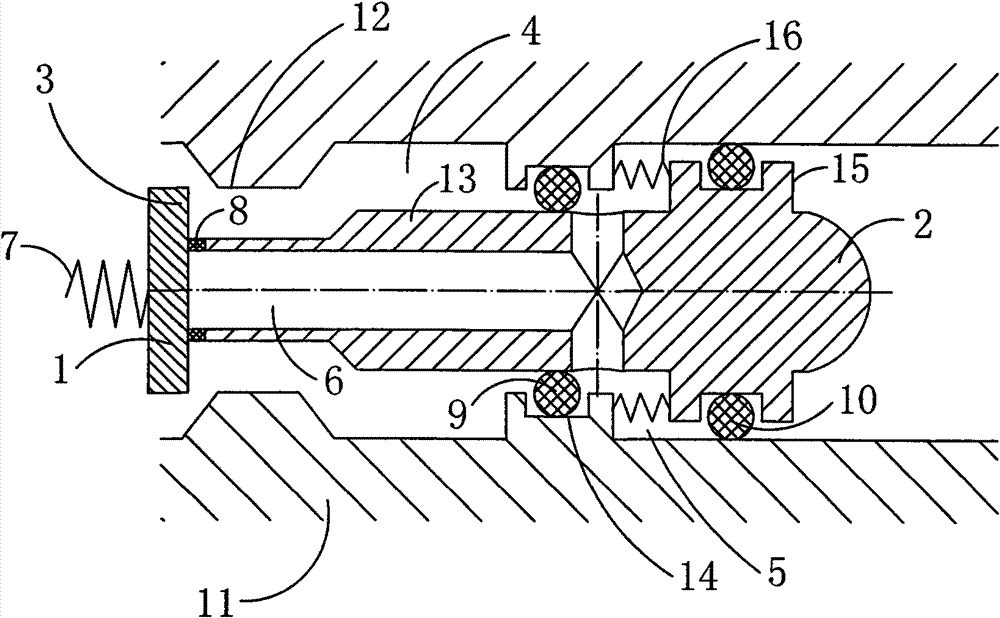

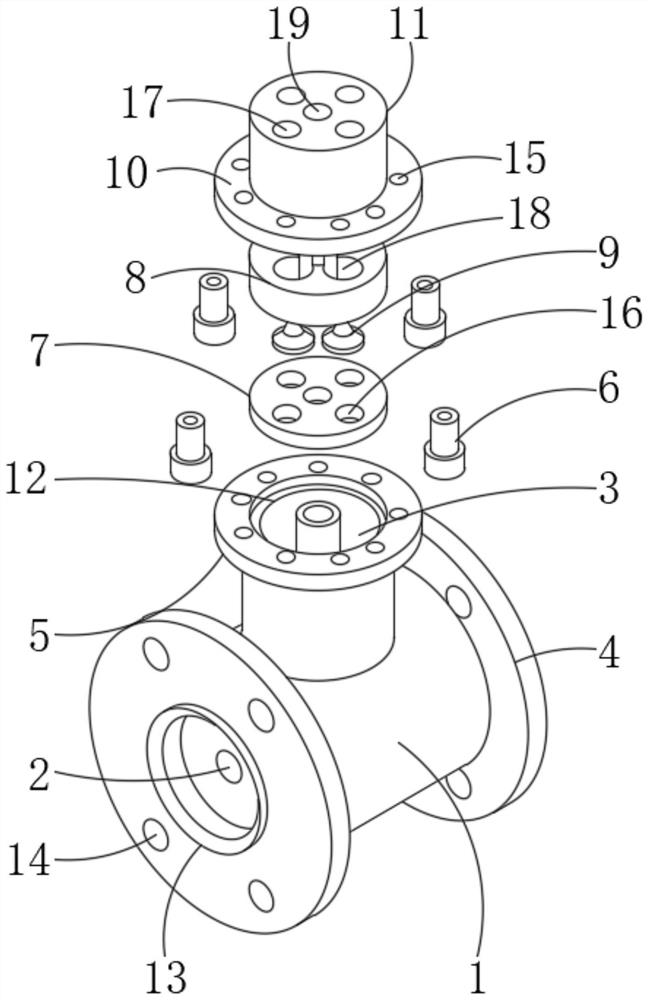

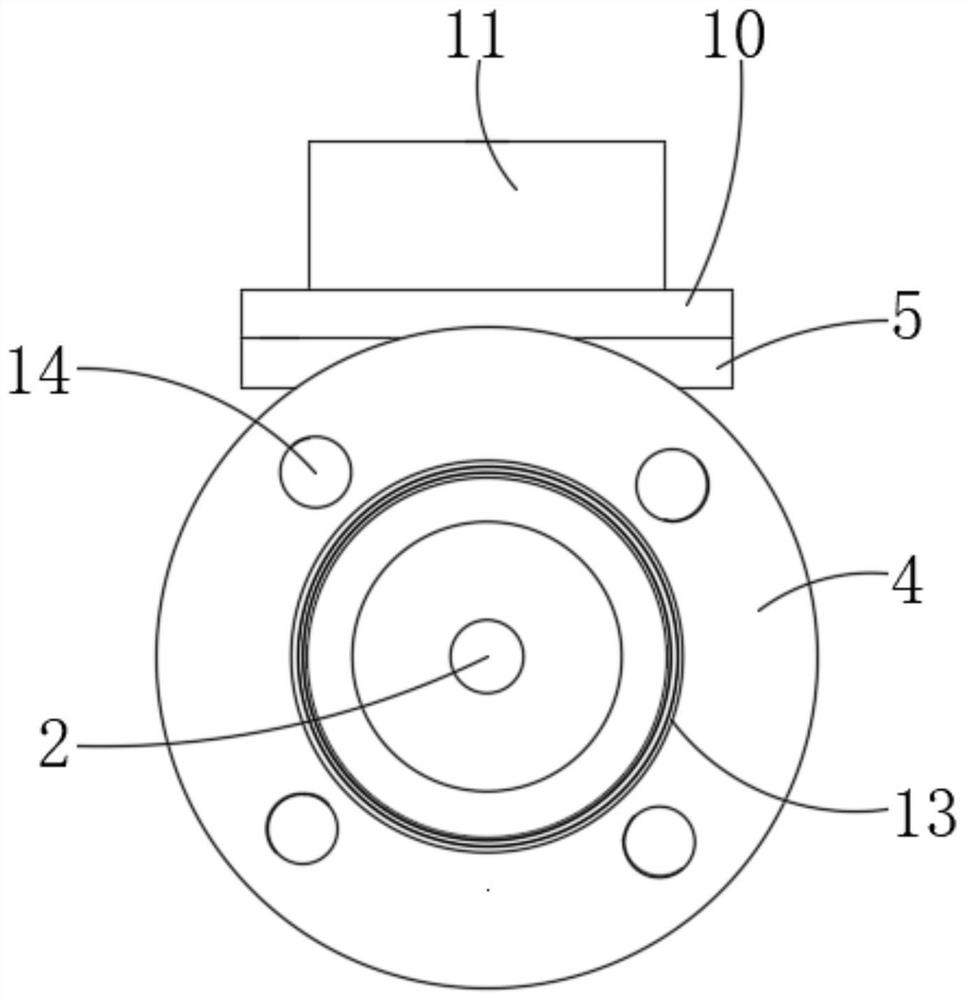

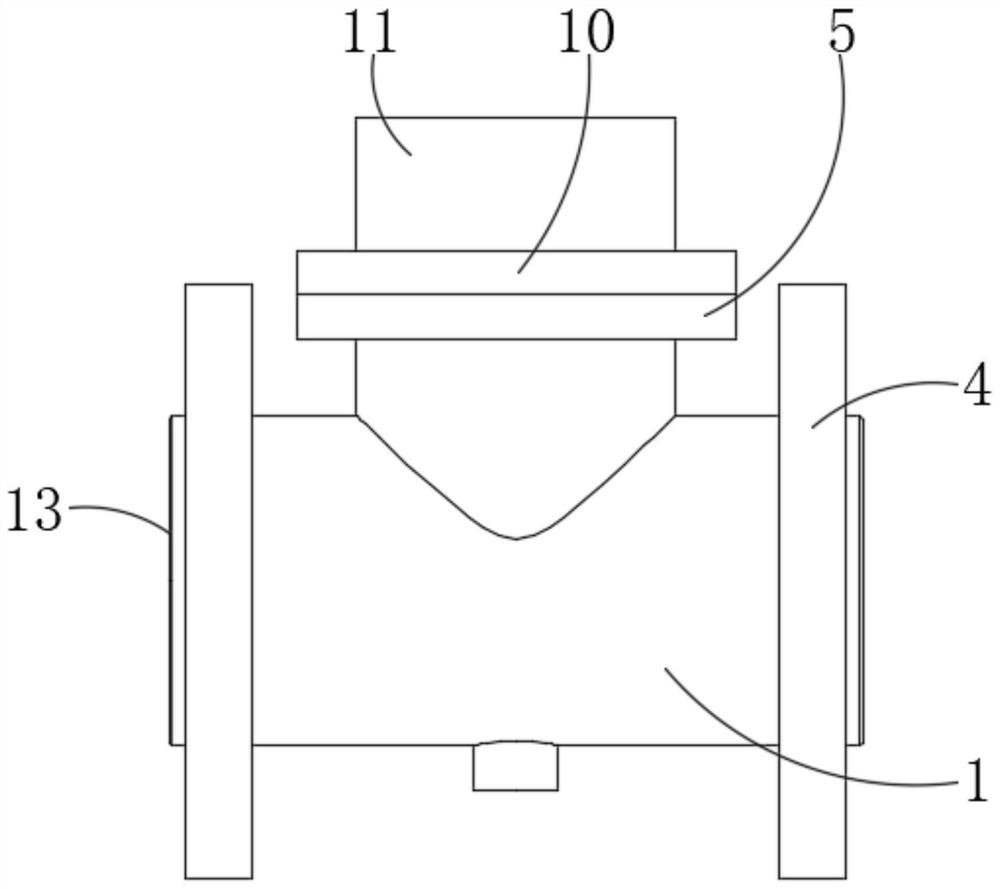

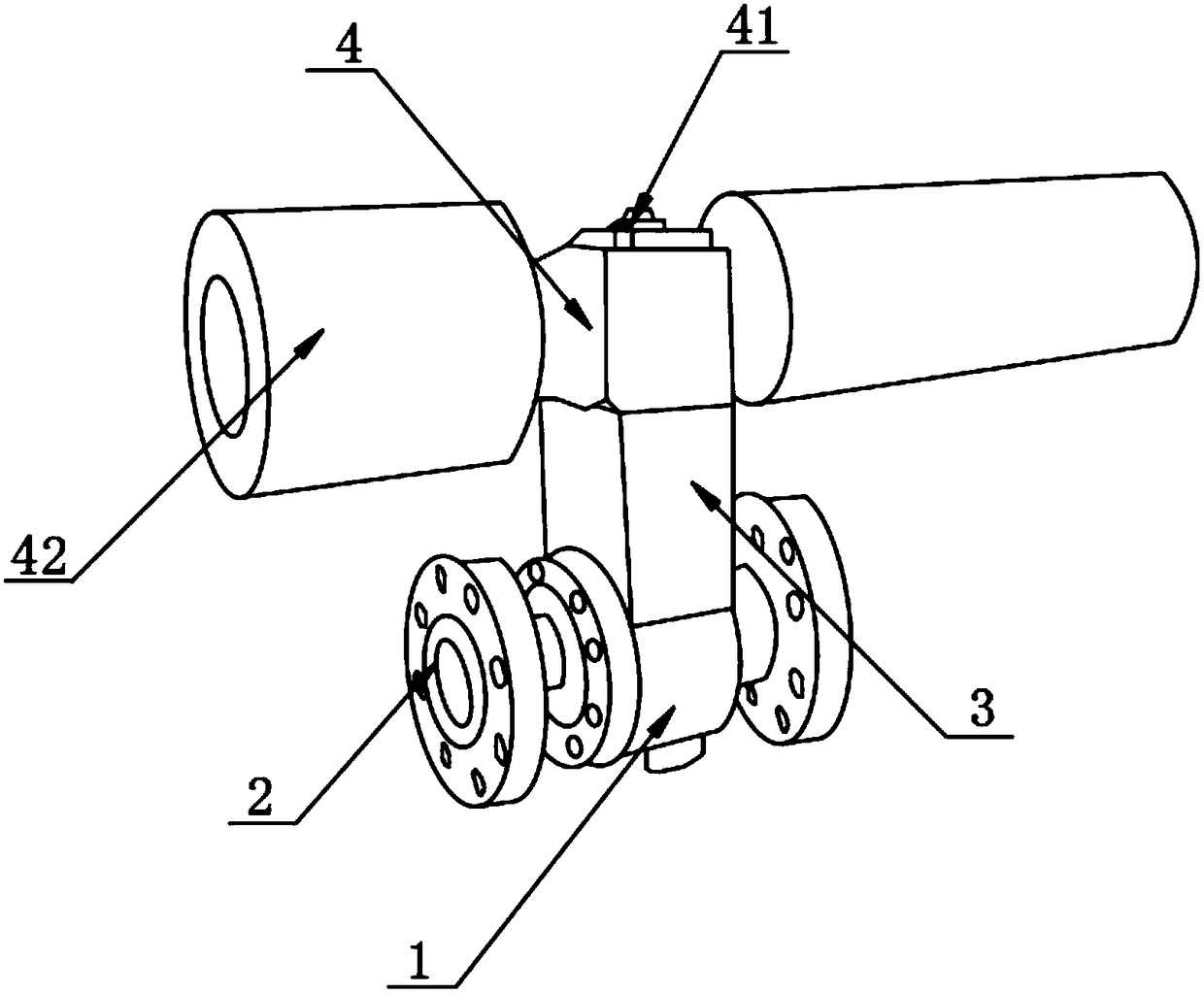

Valve used in shifting devices of engineering automobiles

The invention relates to a valve used in shifting devices of engineering automobiles. The valve comprises a valve body, a valve seat arranged in the valve body, a valve rod and a first spring, whereinthe valve body, the valve seat and a first boss form a gas inlet; the valve body, the valve seat, the valve rod, the first boss and a second boss form a control port; the valve body, the valve rod, the second boss and a second frustum form an exhaust port; a medium channel is arranged in the valve rod; the medium channel is communicated with the control port and the exhaust port respectively; thecontact part of the valve rod and the valve seat is provided with a first sealing piece; the contact part of a first frustum on the valve rod and the second boss arranged on the valve body is provided with a second sealing piece; the contact part of the second frustum on the valve rod and the valve body is provided with a third sealing piece; and a second spring is arranged between the second boss and the second frustum. The valve overcomes the defects that valves in the prior art are large in volume, complex in structure and high in probability of breaking down in use. The valve has the advantages of compact structure, convenient manufacture and installation and reliable use.

Owner:XIAN AEROSPACE YUANZHENG FLUID CONTROL

Separable air bag device for protecting intestinal tract surgery field

ActiveCN104083215BGuaranteed no leakageSolve pollutionDiagnosticsSurgeryFull thickness resectionEndoscopic surgery

The invention relates to a separable air bag device for protecting an intestinal tract surgery field. An air bag core with side holes is fixedly arranged in an air bag; an air bag plug comprises a rubber plug arranged at an air inlet of the air bag core; a sleeve type air inflation needle comprises an outer sleeve, an air inflation needle head and an air inflation pipe, and the needle head and the air inflation pipe are arranged in the outer sleeve and can move relative to the outer sleeve; the needle head is used for penetrating through the rubber plug and injecting air into the air bag; the air inflation valve comprises an injector connecting port communicated with an air inflation pipe as well as an air inflation turning bolt which can control in-out of air; and after air inflation, the air bag can be separated, the surgery field of the lower section of an intestinal tract is not influenced. The device effectively guarantees the clean and sterile state of the lower section of the intestinal tract, protects the admission passage of an orifice transluminal endoscopic surgery and protects perforation parts from being polluted in the processes of endoscopic full-thickness resection for the intestinal tract and other intestinal tract surgeries, so that sterile surgery of the lower section of the intestinal tract becomes possible, and peritonitis after the surgery can be prevented.

Owner:HARBIN MEDICAL UNIVERSITY

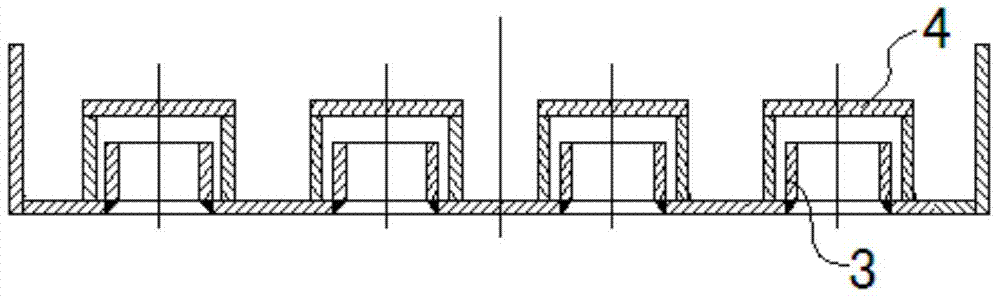

Maze-sealing clinker cooling grate

InactiveCN103496864AAvoid short replacement cycles and increase maintenance costsEasy to manufactureHandling discharged materialProcess engineeringMechanical engineering

The invention discloses a maze-sealing clinker cooling grate comprising a bottom plate, grate upper caps and side plates. The bottom plate is provided with projecting wall plate air holes. The grate upper caps are cylinders with one end closed, and reversely covering the wall plate air holes. A gap forms between the closed end of each grate upper cap and the corresponding wall plate air hole, and meanwhile, the lower end of each grate upper cap is provided with a plurality of vent notches, so that the vent notches and the wall plate air holes form maze outlets. The side plates are vertically disposed on two sides of the bottom plate. The grate of the maze sealing structure is formed by welding steel tubes, production cost is reduced greatly, the structure is simple, the maze sealing structure ensures no leakage of the grate, the service life of the grate is prolonged, and maintenance costs are reduced.

Owner:NANJING XIPU CEMENT ENG GROUP

Load shedding sound barrier unit and sound barrier thereof

PendingCN114753275AEasy to achieve seamless fixationAvoid affecting the sound insulation performanceNoise reduction constructionPhysicsImpeller

The invention provides a load shedding sound barrier unit and a sound barrier thereof. The load shedding sound absorption screen body comprises at least one load shedding unit structure arranged in the vertical direction, and an upper screen body and a lower screen body which are adjacent to the load shedding unit structure. The load shedding unit structure comprises a left screen body, a right screen body and a load shedding structure located between the left screen body and the right screen body. The load shedding structure comprises a rotating wheel and an outer cylinder. The rotating wheel comprises a rotating shaft and at least three impellers, the two ends of the rotating shaft are connected with the left screen body and the right screen body respectively and can rotate freely, and the impellers are evenly arranged on the rotating shaft in a surrounding mode. The outer cylinder is fixed to the upper screen body and the lower screen body which are adjacent to the outer cylinder, each screen body is provided with an arc-shaped attaching face matched with the outer cylinder, and the gap between the outer end of the impeller and the inner side of the outer cylinder is not larger than 2 mm. The connecting surfaces of the upper and lower adjacent screen bodies are bent arc-shaped binding surfaces; the diameter of the outer cylinder is at least 200 mm, and the outer cylinder is provided with an end air opening and a surface air opening. After wind pressure acts on the two-end tuyeres and the surface tuyeres, the impeller is pushed to rotate around the rotating shaft, the pressure is converted, and the wind load is effectively reduced.

Owner:CHINA SHIPPING ENVIRONMENT SCI & TECH SHANGHAI CO LTD

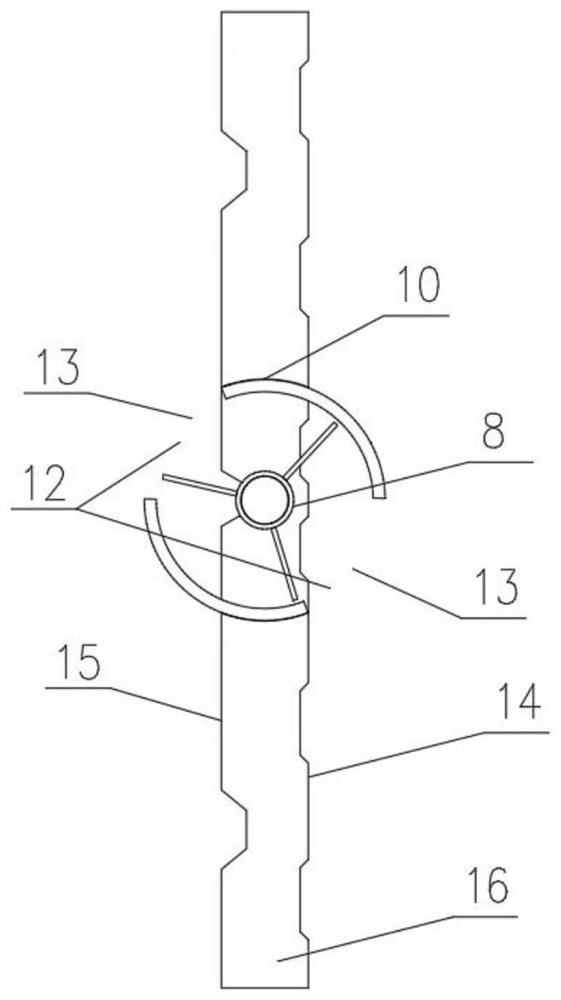

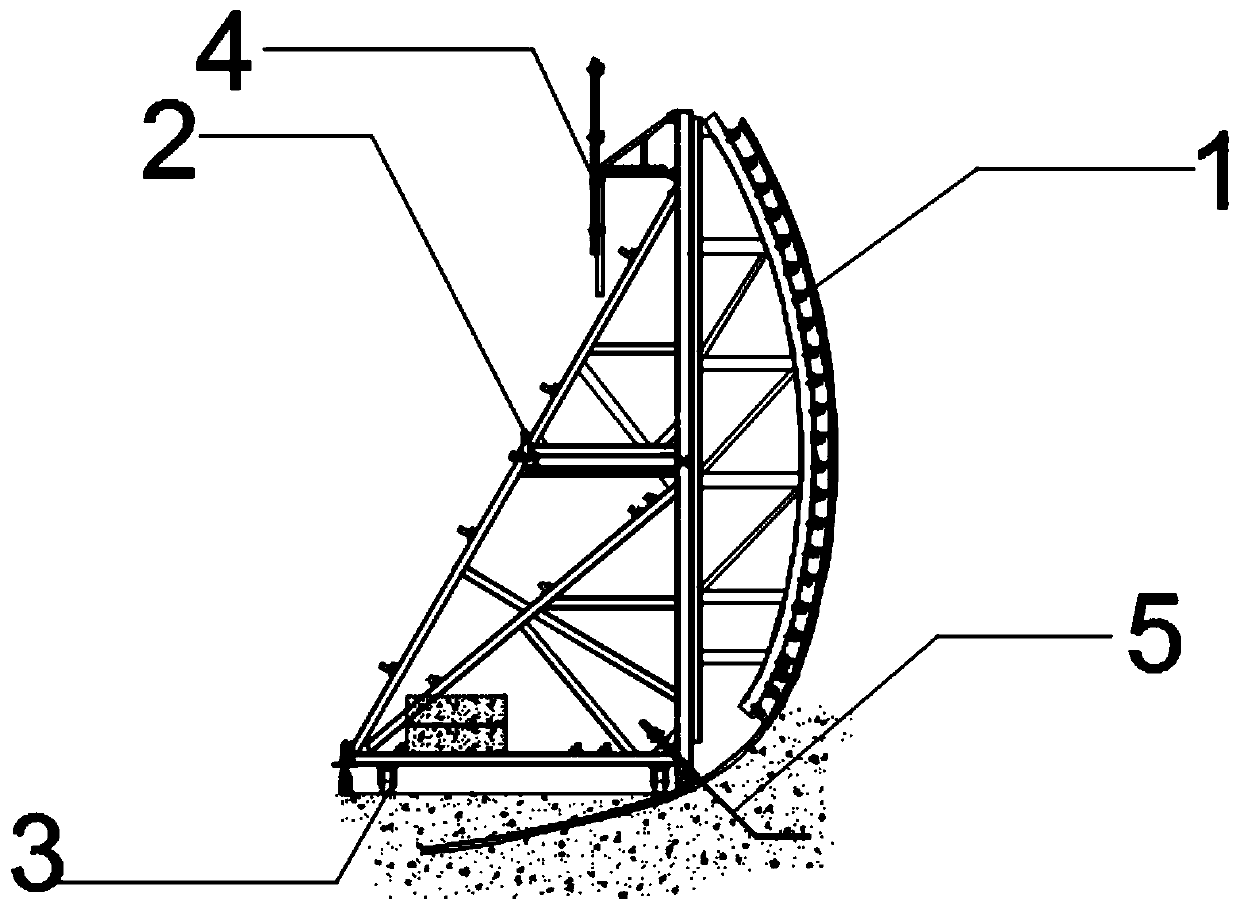

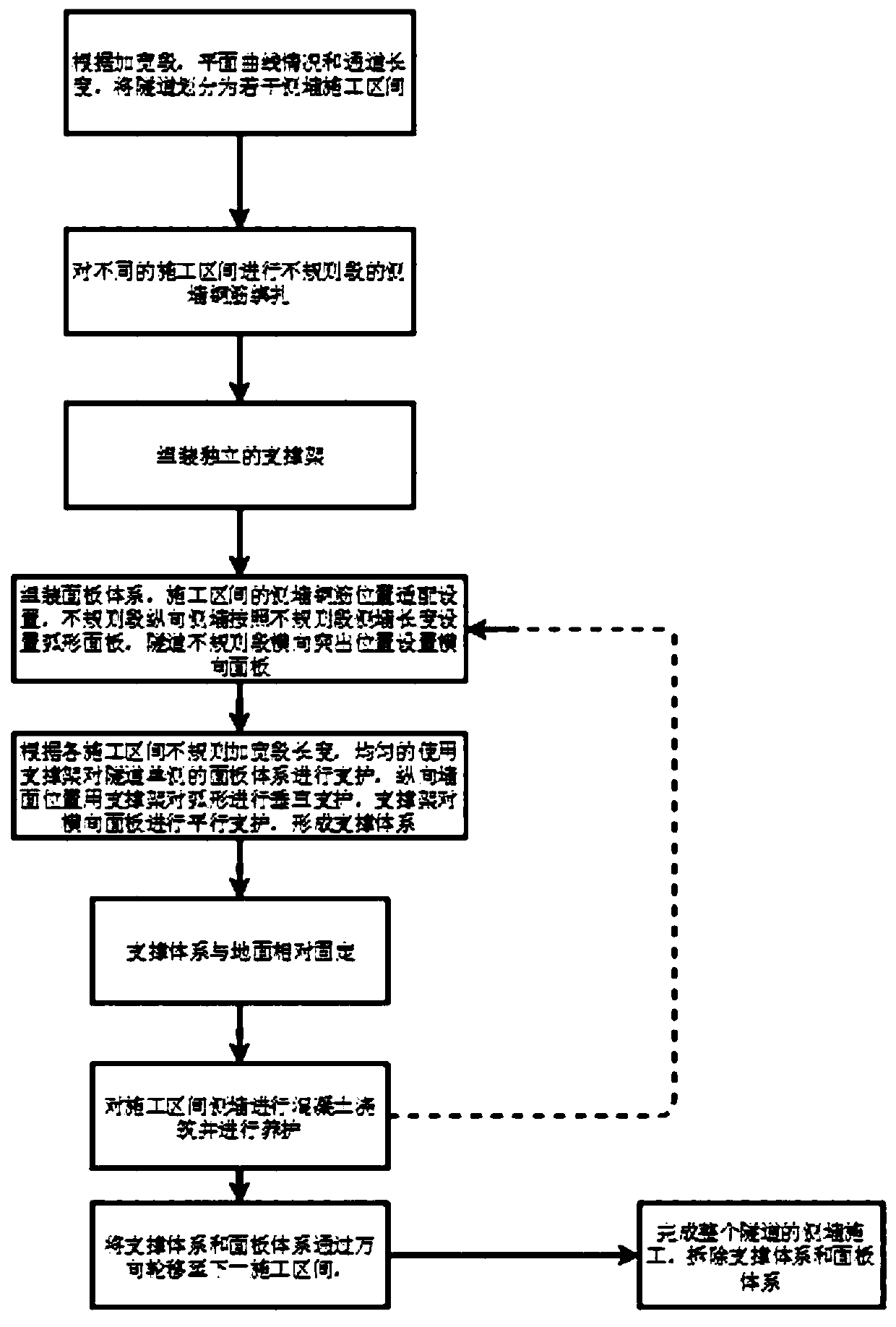

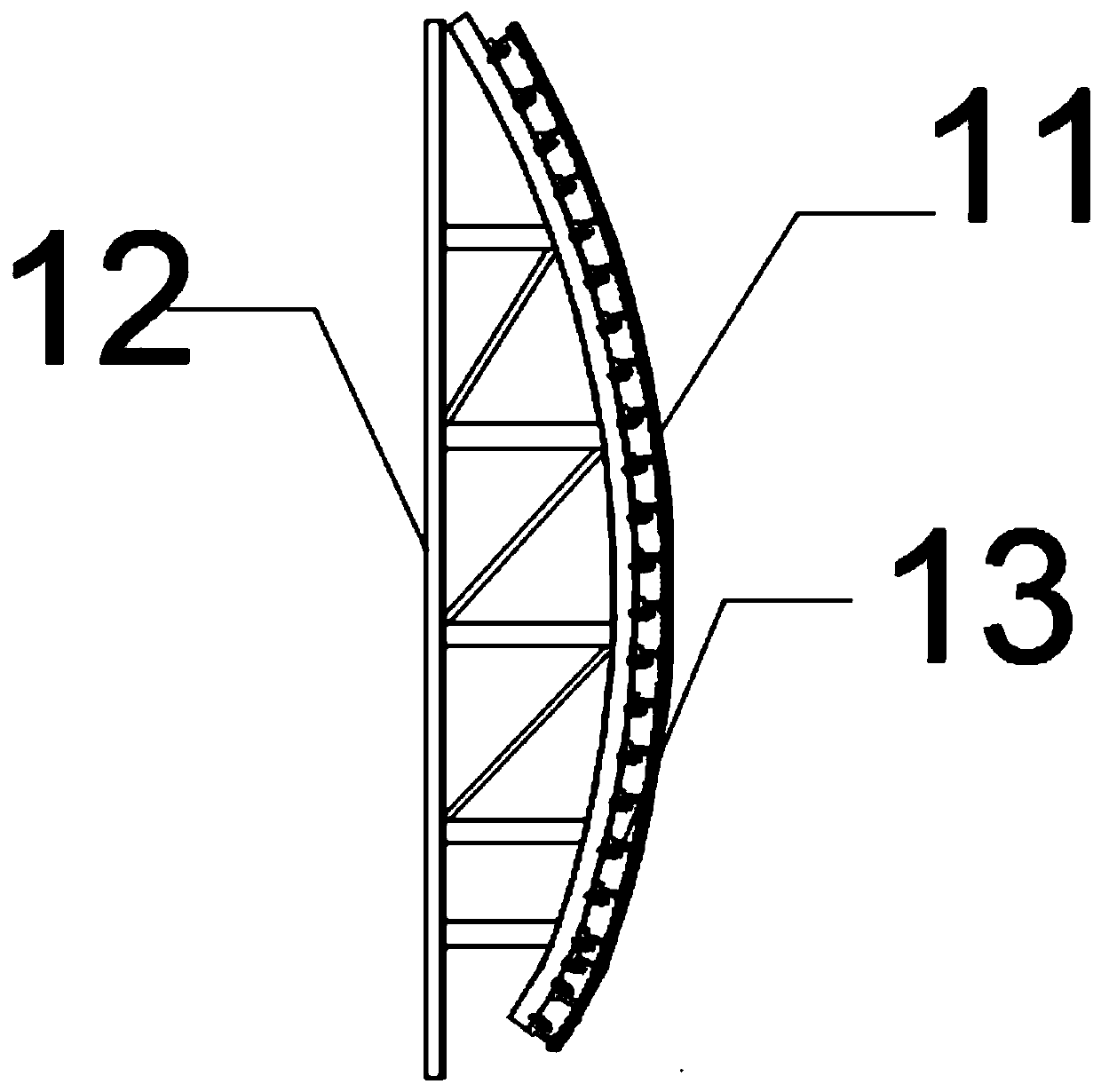

Irregularly widened arched section tunnel construction device and construction method

ActiveCN109944609AGuaranteed not to open the moldGuaranteed no leakageUnderground chambersTunnel liningSupporting systemLongitudinal plane

The invention provides an irregularly widened arched section tunnel construction device and a construction method. The construction device comprises a supporting system and a panel system which is arranged on a vertical side surface of the supporting system and is in a smooth arc shape, wherein a longitudinal plane of the supporting system is provided with a vertical I-shaped wooden beam supporting seat, and a lower end of the supporting system is provided with a universal wheel. The construction method adopts a small unit combination method and comprises the following steps: a left side walland a right side wall are respectively formed into a system; the tunnel is divided into a plurality of side wall construction intervals according to a widened section, a plane curve condition and thechannel length; side wall reinforcing steel bars of irregular sections in different construction intervals are bound; an independent support frame is assembled; transverse and longitudinal panel systems are assembled; the supporting system is formed according to the length of an irregularly widened section of each construction interval; concrete pouring and curing are carried out on the side wallof the construction interval; and the supporting system and the panel system are moved to a next construction interval through the universal wheel. The irregularly widened arched section tunnel construction device is convenient to move and is suitable for side wall construction in the irregularly widened arched section tunnel.

Owner:CHINA RAILWAY BEIJING ENG GRP CO LTD +1

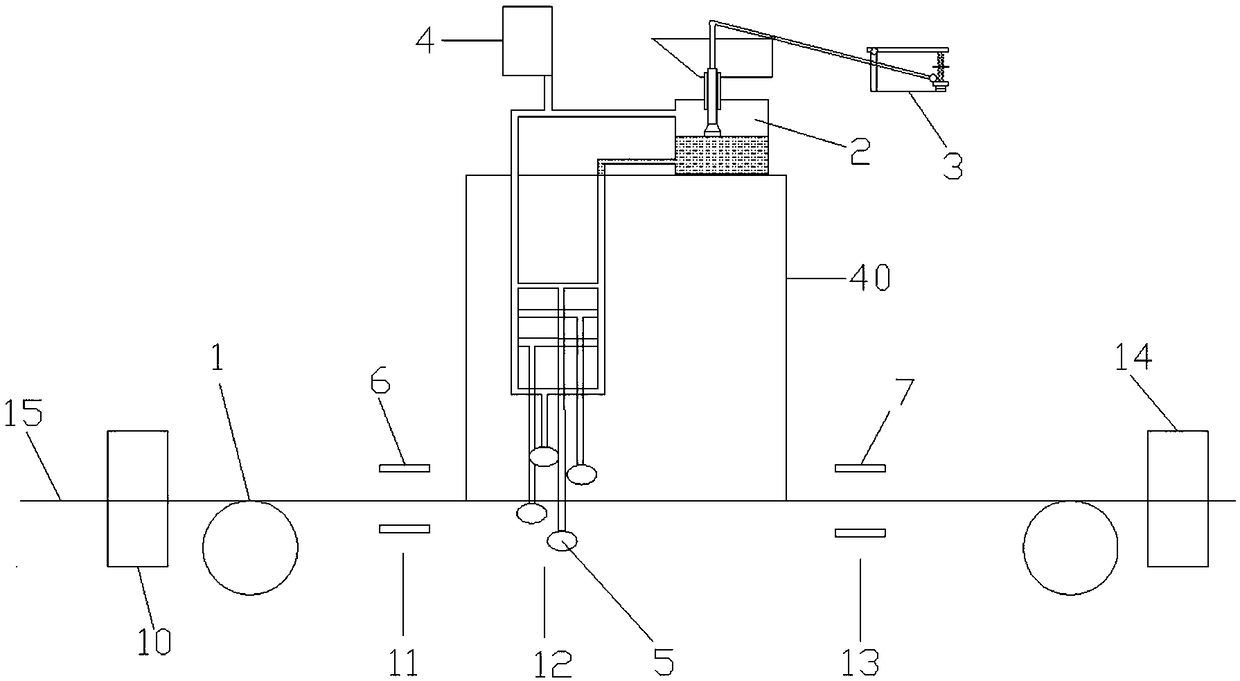

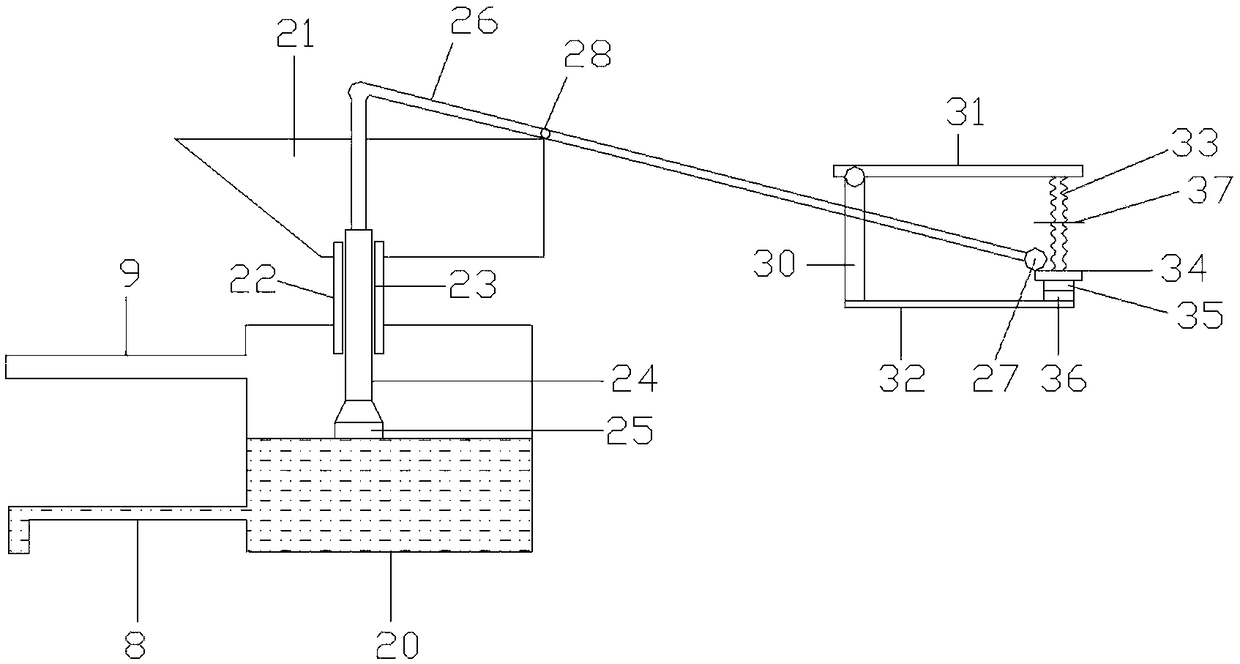

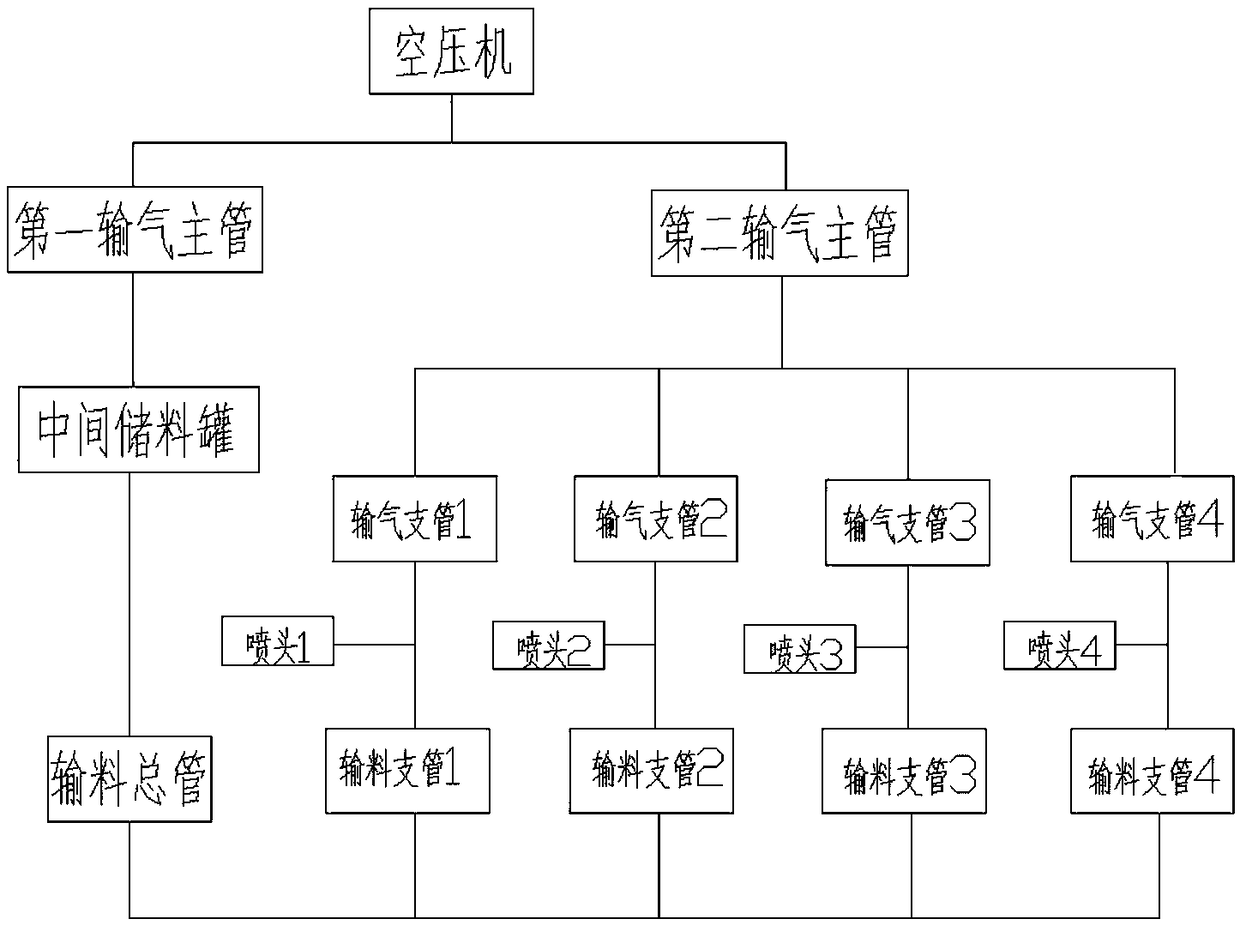

Billet Automatic Coating Equipment

ActiveCN106925471BWith automatic feeding functionGuaranteed continuitySpraying apparatusAutomatic controlControl system

The invention discloses automatic billet coating equipment. The automatic billet coating equipment comprises a conveying system, a detecting system, a coating input and output system and a control system. The conveying system comprises a conveying roller bed, a roller bed motor connected with the conveying roller bed, a first guide disc pair and a second guide disc pair. The coating input and output system comprises a coating conveying box, an automatic control switch, an air compressor, a coating conveying pipeline, a gas conveying pipeline and a spray head. The first guide disc pair, a first detection station, a spraying station, a second detection station and the second guide disc pair are sequentially arranged on the conveying roller bed in the conveying direction. The automatic billet coating equipment has an automatic feeding function, and continuity of production can be guaranteed. The automatic billet coating equipment can recognize whether a billet arrives at the place in front of the spray head or not, and unnecessary coating waste is avoided in the continuous production process; and moreover, the automatic billet coating equipment can count the billet, and a user can prepare the billet in advance and carry out corresponding counting. The automatic billet coating equipment can guarantee that the billet is coated completely and can give an alarm when a failure occurs.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

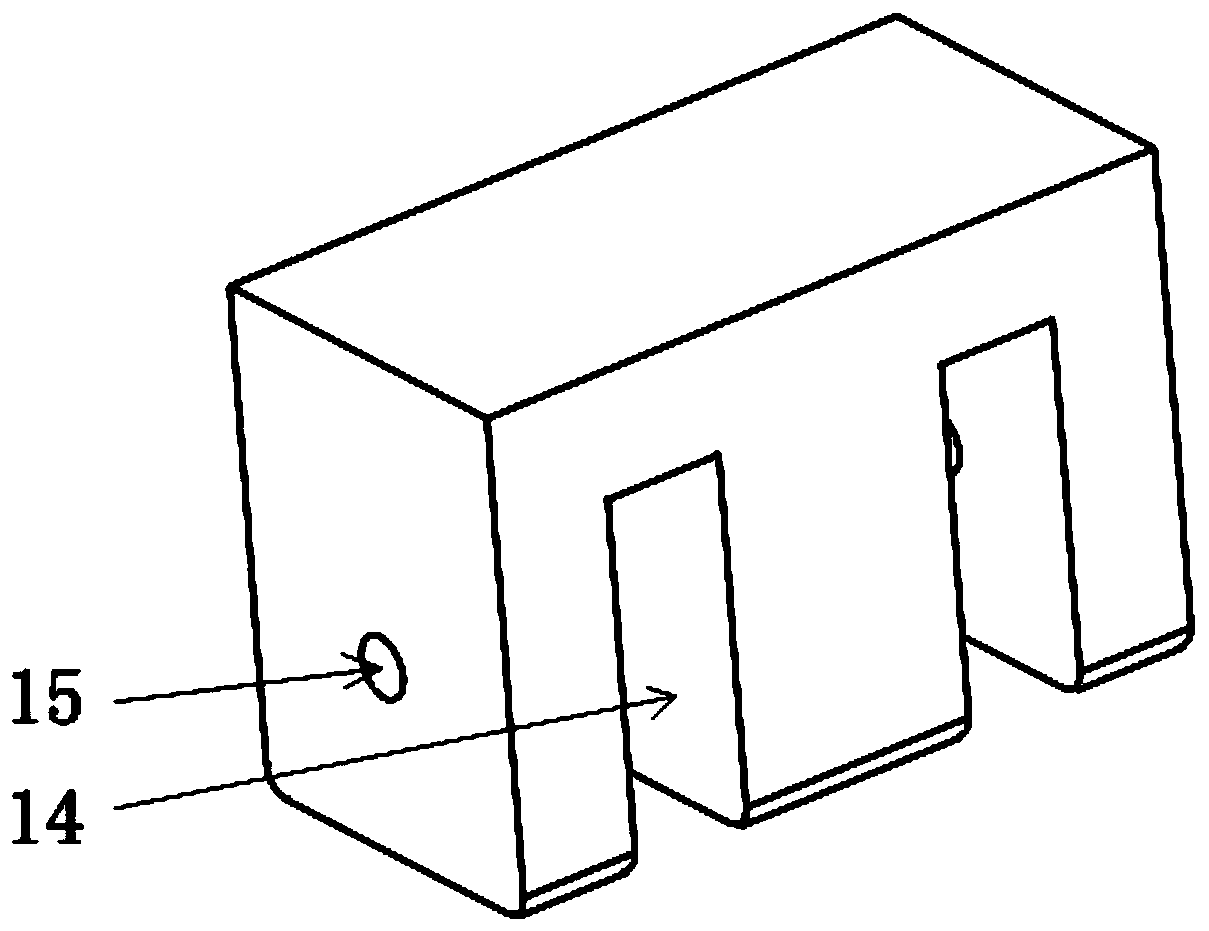

A non-contact pulping device used between continuous ball mills

The invention provides a non-contact slurry passing device used in a continuous ball mill. The non-contact slurry passing device is simple in structure, stable and reliable in work, long in service life and capable of effectively preventing slurry leaking, and comprises adjacently-arranged ball mill cylinders and further comprises a non-contact slurry passing device body arranged between the adjacent ball mill cylinders. The non-contact slurry passing device body comprises a slurry outlet pipe arranged at a discharging opening and a feeding opening of the adjacent ball mill cylinders in a fastened mode and a conical slurry scooping cone hopper, wherein the slurry outlet pipe is sleeved with the slurry scooping cone hopper in an embedded mode, and meanwhile a plurality of spiral chutes used for rapidly scooping slurry are further distributed in an inner cavity of the slurry scooping cone hopper in the circumferential direction. By means of the scheme, when the non-contact slurry passing device works, the slurry can flow into the slurry scooping cone hopper from the slurry outlet pipe and can be rapidly scooped into the ball mill through the spiral chutes in the slurry scooping cone hopper, the liquid level of the slurry is controlled to be quite low accordingly, then the adjacent ball mill cylinders are not in contact, and it can be guaranteed that the slurry is not leaked in the transmission process.

Owner:佛山市恒力泰科技有限公司

Valve used in shifting devices of engineering automobiles

The invention relates to a valve used in shifting devices of engineering automobiles. The valve comprises a valve body, a valve seat arranged in the valve body, a valve rod and a first spring, whereinthe valve body, the valve seat and a first boss form a gas inlet; the valve body, the valve seat, the valve rod, the first boss and a second boss form a control port; the valve body, the valve rod, the second boss and a second frustum form an exhaust port; a medium channel is arranged in the valve rod; the medium channel is communicated with the control port and the exhaust port respectively; thecontact part of the valve rod and the valve seat is provided with a first sealing piece; the contact part of a first frustum on the valve rod and the second boss arranged on the valve body is provided with a second sealing piece; the contact part of the second frustum on the valve rod and the valve body is provided with a third sealing piece; and a second spring is arranged between the second boss and the second frustum. The valve overcomes the defects that valves in the prior art are large in volume, complex in structure and high in probability of breaking down in use. The valve has the advantages of compact structure, convenient manufacture and installation and reliable use.

Owner:XIAN AEROSPACE YUANZHENG FLUID CONTROL

Three-way die head body and die special for double-color extruded puffed food

ActiveCN113100467AGuaranteed not to crossGuaranteed no leakageFeeding-stuffFood shapingMaterial distributionIndustrial engineering

The invention discloses a three-way die head body and a die special for double-color extruded puffed food, and belongs to the technical field of extruded puffed food processing equipment. The three-way die head body comprises a three-way die head body; a first material channel and a second material channel are formed in an inner cavity of the three-way die head body, and snap fastener flanges are fixedly installed at the two ends of the three-way die head body. According to the invention, the snap fastener flanges are used for achieving effective connection with the main machines, high pressure and no material leakage are achieved, material distribution adopts an internal and external distribution mode, materials of the first main machine pass through the first material channel in the middle, materials of the second main machine pass through the second material channels on the two sides, and therefore it is guaranteed that the materials do not intersect, and energy loss can be reduced; according to the design of the mold cavity, a modular design scheme capable of being rapidly replaced is adopted, materials in different shapes can be manufactured only by replacing a small mold, the mold is economical and practical, and in the aspect of component sealing, a snap fastener matched sealing mode is adopted to ensure that materials are not leaked during production of high-pressure products.

Owner:济南上瑞机械有限公司

Wet joint structure and construction method suitable for prefabricated pavement

ActiveCN111485471BGuaranteed performanceImprove shear resistanceSingle unit pavingsPaving detailsPre stressArchitectural engineering

The invention discloses a structure and a construction method suitable for wet joints of assembled pavement. The prefabricated cement road slab is reserved with prestressed channels, and the slab surface is provided with dowel rods and chiseled; the cement board is hoisted on the smooth sliding layer On the top, the wet joint position is reserved and the formwork is installed at its end. The bellows connects the prestressed tunnels of the two adjacent slabs and passes through the reinforcement; Connection; tensioning of prestressed tendons, and pouring cement slurry from the grouting port. The invention arranges wet joints and stretches prestressed tendons, enhances the integrity of the road surface, and improves the shear resistance; solves the problem of difficult assembly and docking of the assembled prestressed road surface, and speeds up the construction progress; Pouring micro-expansion high-performance concrete to solve the problems of easy fracture and water leakage at the joints of prefabricated prestressed road slabs, improve structural stability, and prolong the service life of the road surface.

Owner:山东智行勘察设计院有限公司 +1

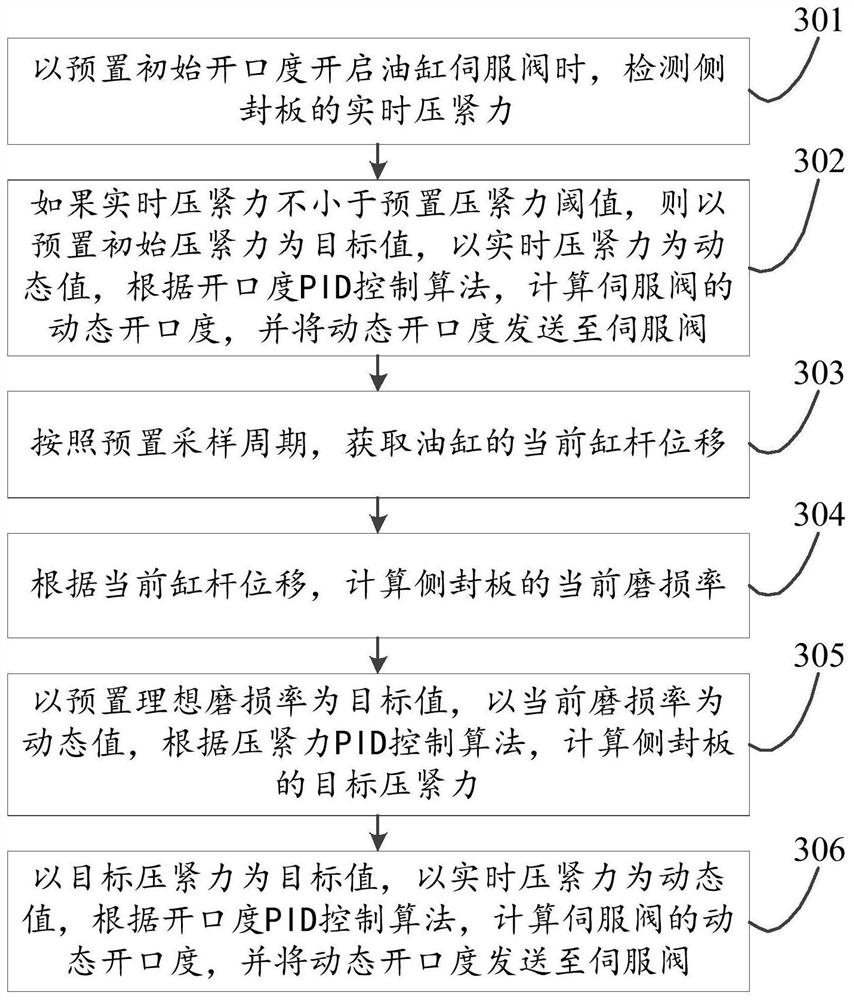

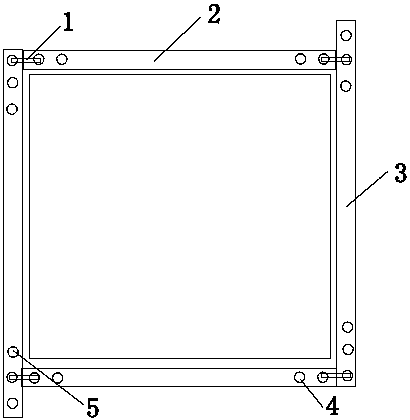

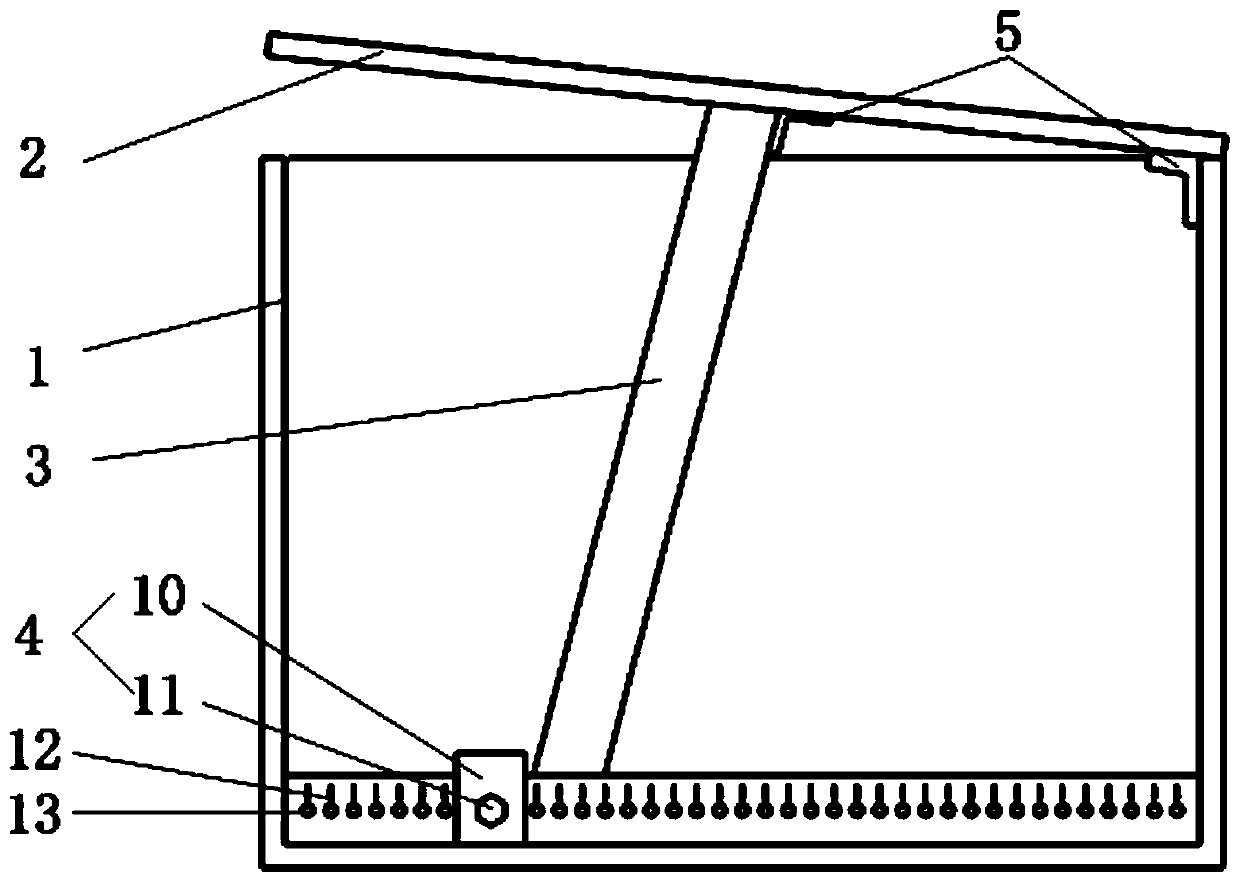

Control method and device for thin-strip continuous casting side sealing pressing mechanism

The invention discloses a control method and device for a thin-strip continuous casting side sealing pressing mechanism, relates to the technical field of metallurgy, and aims to solve the problems that in the prior art, in the process that a thin-strip continuous casting side sealing pressing mechanism presses a side sealing plate, the conditions of guaranteeing avoiding of liquid leakage betweenthe side sealing plate and a continuous casting molten pool, reducing the abrasion speed of the side sealing plate as much as possible, and prolonging the pouring time as much as possible cannot be achieved. The method mainly comprises the steps that the real-time pressing force of the side sealing plate is detected; if the real-time pressing force is not smaller than a preset pressing force threshold value, the dynamic opening degree of a servo valve is calculated according to an opening degree PID control algorithm, and the dynamic opening degree is sent to the servo valve; the current cylinder rod displacement of an oil cylinder is obtained; the current wear rate of the current cylinder rod displacement is calculated; according to the pressing force PID control algorithm, the target pressing force of the side sealing plate is calculated; and the dynamic opening degree of the servo valve is calculated according to the opening degree PID control algorithm, and the dynamic opening degree is sent to the servo valve. The method is mainly applied to the thin-strip continuous casting pouring process.

Owner:NORTHEASTERN UNIV

A Construction Technology of High-grade Concrete Column Foot

InactiveCN104831932BGuaranteed no leakageAvoid honeycombForms/shuttering/falseworksBuilding material handlingEconomic benefitsHoneycomb

The invention provides a construction technology for a high-grade concrete column base, and belongs to the technical field of building construction. The construction technology comprises the following steps of steel bar binding, column formwork installing, paste stop strip arranging, isolation steel bar mesh installing, first-time vibrating of concrete pouring and tamping, secondary vibrating of concrete pouring and tamping, curing and finishing after pouring and column formwork dismantling. The construction quality problems of the high-grade concrete column base are successfully solved, the quality problems such as column honeycombs, pitted surfaces and steel bar exposure are solved, the concrete column quality is improved, the quality passing percent of the concrete column base obtained by the method is improved from the present 85 percents to more than 95 percents, the economic benefits are generated, the economy consciousness of all workers is improved, the enterprise popularity is improved while the construction cost is reduced and the construction quality is improved, and the competitive power of the building market is enhanced.

Owner:ZHEJIANG HONGCHAO CONSTR GRP CO LTD

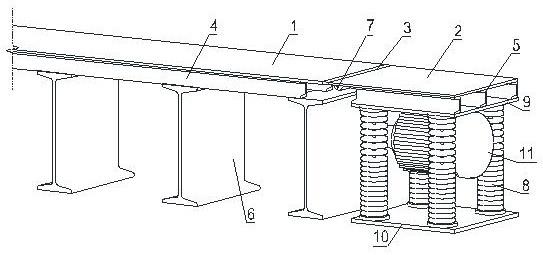

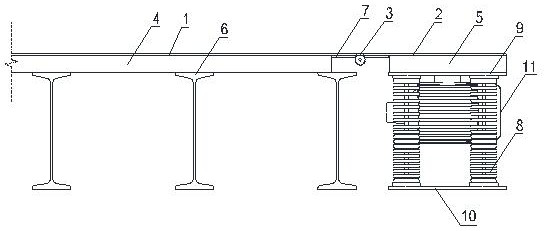

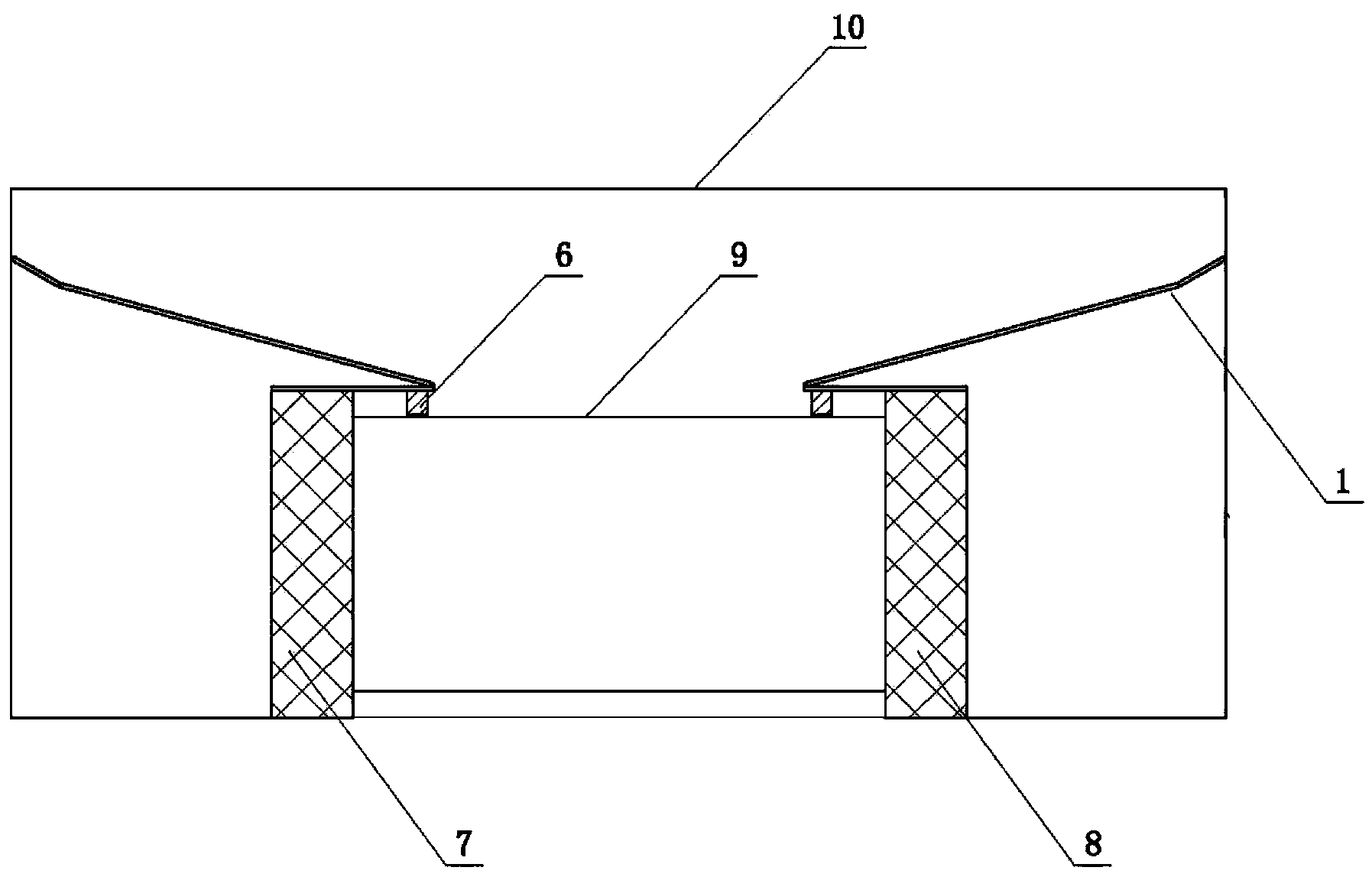

Prefabricated T-beam bottom longitudinal slope adjusting device

PendingCN111283864AGuaranteed no leakageEasy to useCeramic shaping apparatusBridge materialsStructural engineeringMechanical engineering

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

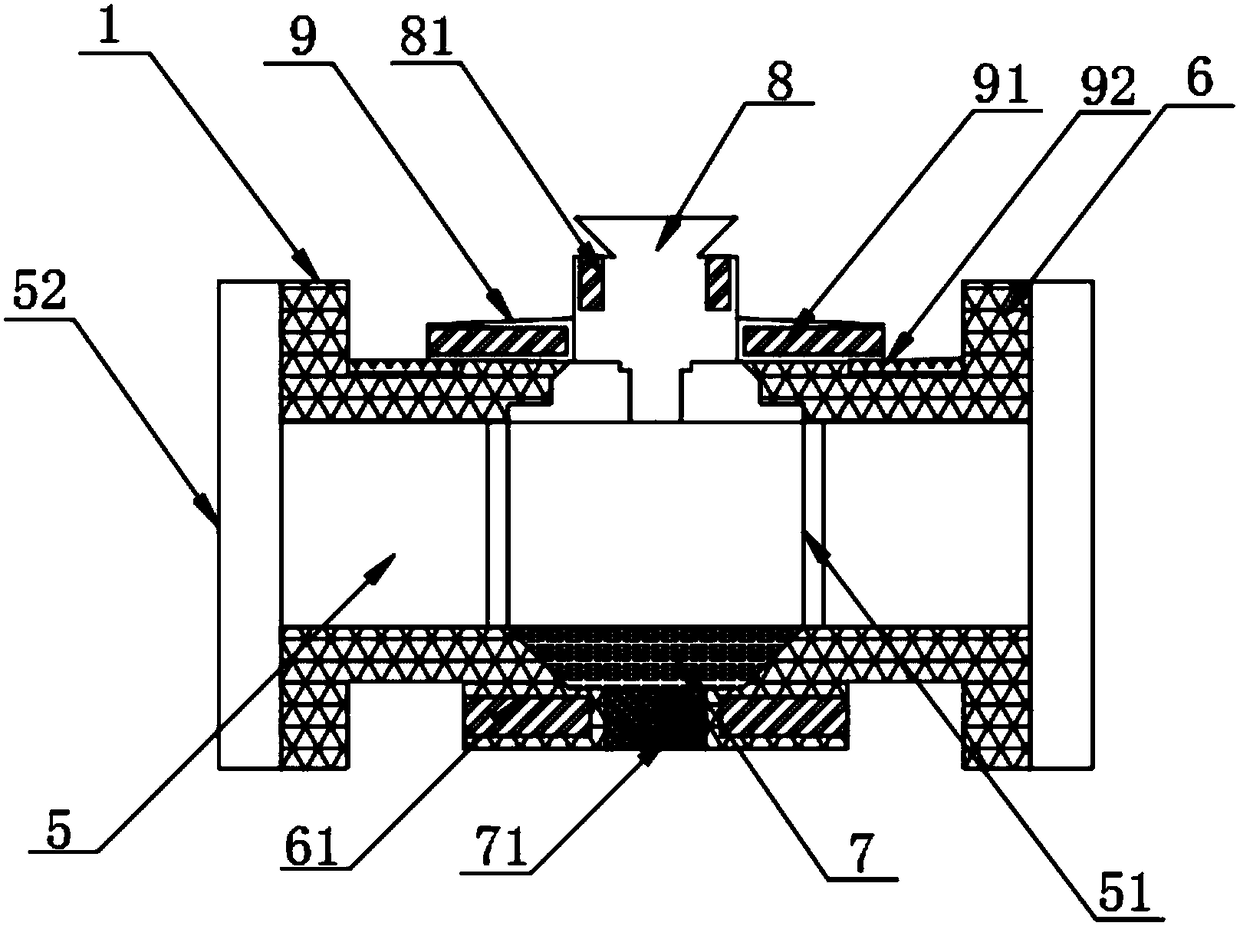

Special ball valve for oxygen

InactiveCN109268530AExtended service lifeReduce wearPlug valvesOperating means/releasing devices for valvesSurface layerHigh pressure oxygen

The invention discloses a special ball valve for oxygen. The special ball valve comprises a valve body. A connecting seat is arranged on both sides of the valve body respectively, a valve stem housingis connected to the top of the valve body, and an actuator is connected to the top of the valve stem housing. The valve body comprises a valve chamber and a valve seat, the valve chamber is surrounded by the valve seat, the bottom of the valve chamber is provided with a support seat disposed inside the valve seat, the top of the valve chamber is communicated with a valve stem connecting seat, andtop fixed seats are arranged on two sides of the valve stem connecting seat. The valve is provided with the connecting seats and the valve chamber, and the surfaces of the valve body and the valve seat are subjected to special hardening treatment, so that the wear resistance and the anti-high pressure oxygen purging capability can be greatly improved. The edge of a ball passage hole inside the valve body is passivated to ensure that a hardened surface layer does not fall off. A ball body is positioned by two sides, the front side and the rear side by means of a positioning ring and an insertion plate inserted into the valve chamber, the friction between the ball body and the valve chamber is reduced during the working process, and the service life of the ball valve is prolonged.

Owner:CHINA KIST VALVE GRP

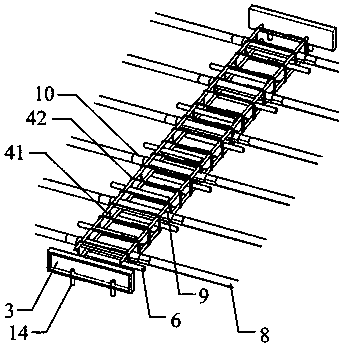

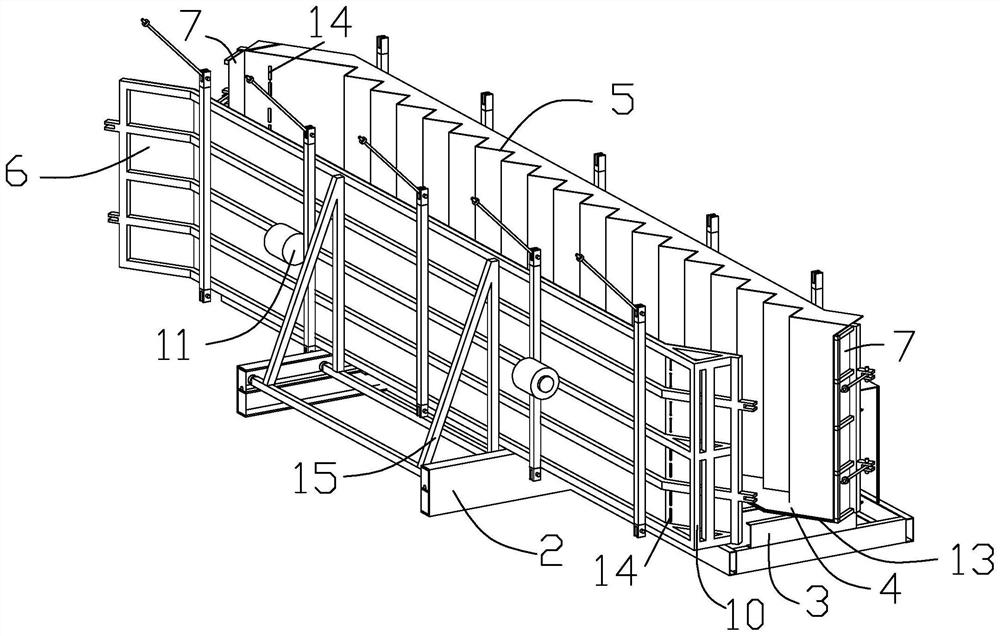

T-shaped beam prefabricating equipment suitable for large longitudinal slope beam field

ActiveCN112706258AGuaranteed no leakageMeet different prefabrication needsMouldsShaped beamClassical mechanics

The invention discloses a T-shaped beam prefabricating equipment suitable for a large longitudinal slope beam field. A side formwork of the T-shaped beam prefabricating equipment comprises a left formwork body and a right formwork body, wherein the left formwork body and the right formwork body each comprise an inner formwork body and an outer formwork body, each inner formwork body comprises a vertical plate right opposite to the right formwork body on the opposite side and a wing plate connected to the top of the vertical plate and extending outwards and obliquely upwards, each outer formwork body comprises an outer lower formwork body and an outer upper formwork body, the outer lower formwork body is arranged below the wing plate, the lower portion of the outer upper formwork body is rotatably attached to the outer side surface of the outer lower formwork body, the upper portion of the outer upper formwork body is higher than the wing plate, and the inner side face of the outer upper formwork body abuts against the wing plate to define a prefabricated space of a T-shaped beam. According to the equipment, the outer formwork body, of the side formwork are arranged into a plurality of separated parts, the outer upper formwork body is rotated relative to the outer lower formwork body, and a height and an inclination angle of the outer upper formwork body can be adjusted according to the longitudinal slope adaptability of the beam field, so that the equipment can adapt to various longitudinal slope beam fields, and the wing plates on the two sides of the T-shaped beam are prevented from leaking slurry in a prefabricating process. Meanwhile, the cross slope of the T-shaped beam can be adjusted by adjusting the extending angles of the wing plates, and different prefabrication requirements are met.

Owner:中电建路桥集团有限公司

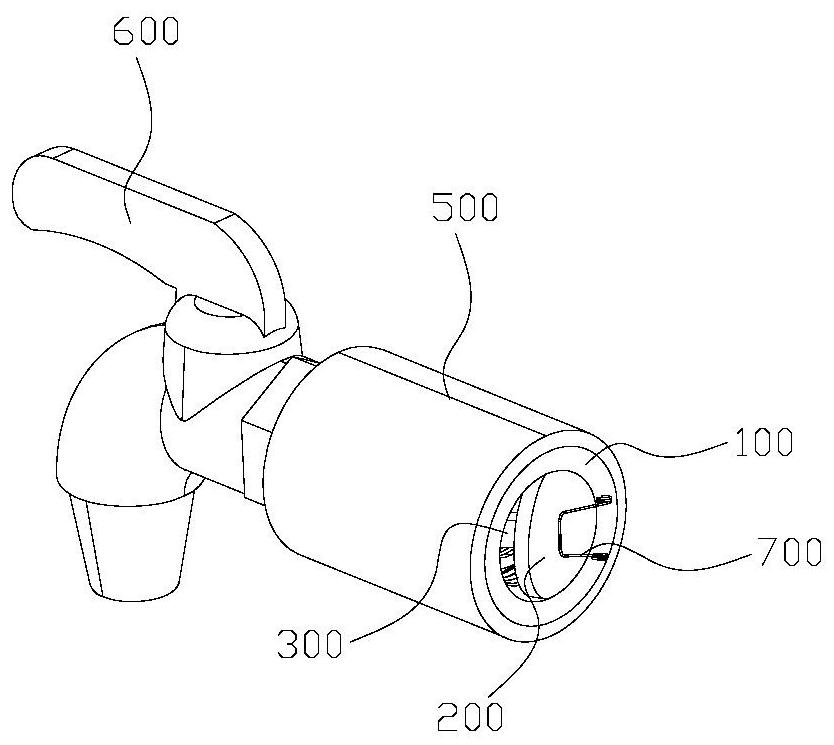

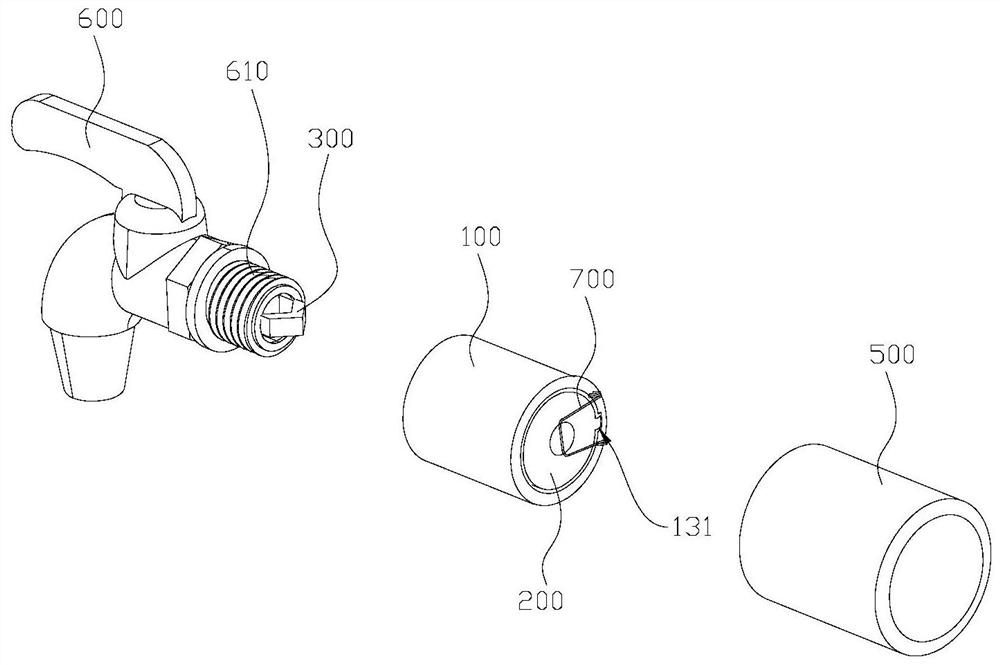

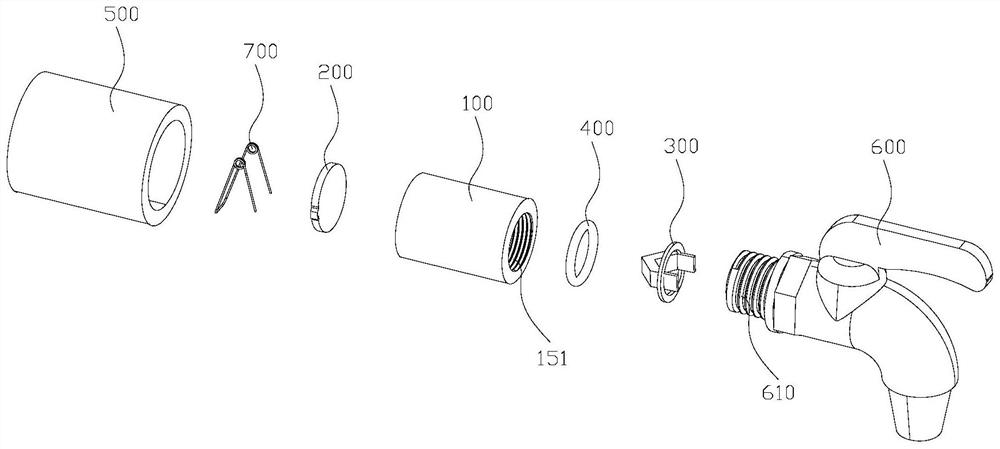

Automatic pipeline cut-off device free of raw material tape winding

PendingCN112128466ASimple structureEasy to manufactureValve arrangementsScrew threaded jointsProcess engineeringThread seal tape

The invention relates to an automatic pipeline cut-off device free of raw material tape winding. The automatic pipeline cut-off device is applied to a fluid pipeline system and is simple in structure,easy to manufacture, low in cost and free of electric power and any precise facility. Opening of a cut-off lifting cover is controlled through an ejection piece on a fluid using device, closing of the cut-off lifting cover is controlled through the fluid water pressure effect in a fluid pipeline, and the cut-off effect is good. The larger the fluid water pressure in the fluid pipeline is, the larger the sealing pressure intensity of the cut-off lifting cover is, and the better the sealing effect is. Meanwhile, raw material tape winding is not needed in the matched connection process of the fluid using device and a pipeline forming piece, only the fluid using device needs to be directly screwed in the pipeline forming piece, at the moment, the ejection piece tightly presses an anti-leakagesealing ring, the anti-leakage sealing ring seals the fluid inlet end of the fluid using device, the multi-point sealing effect is achieved, fluid is prevented from leaking from the fluid inlet end of the fluid using device, and therefore the effect of preventing fluid leakage is achieved without raw material tape winding.

Owner:吴小林

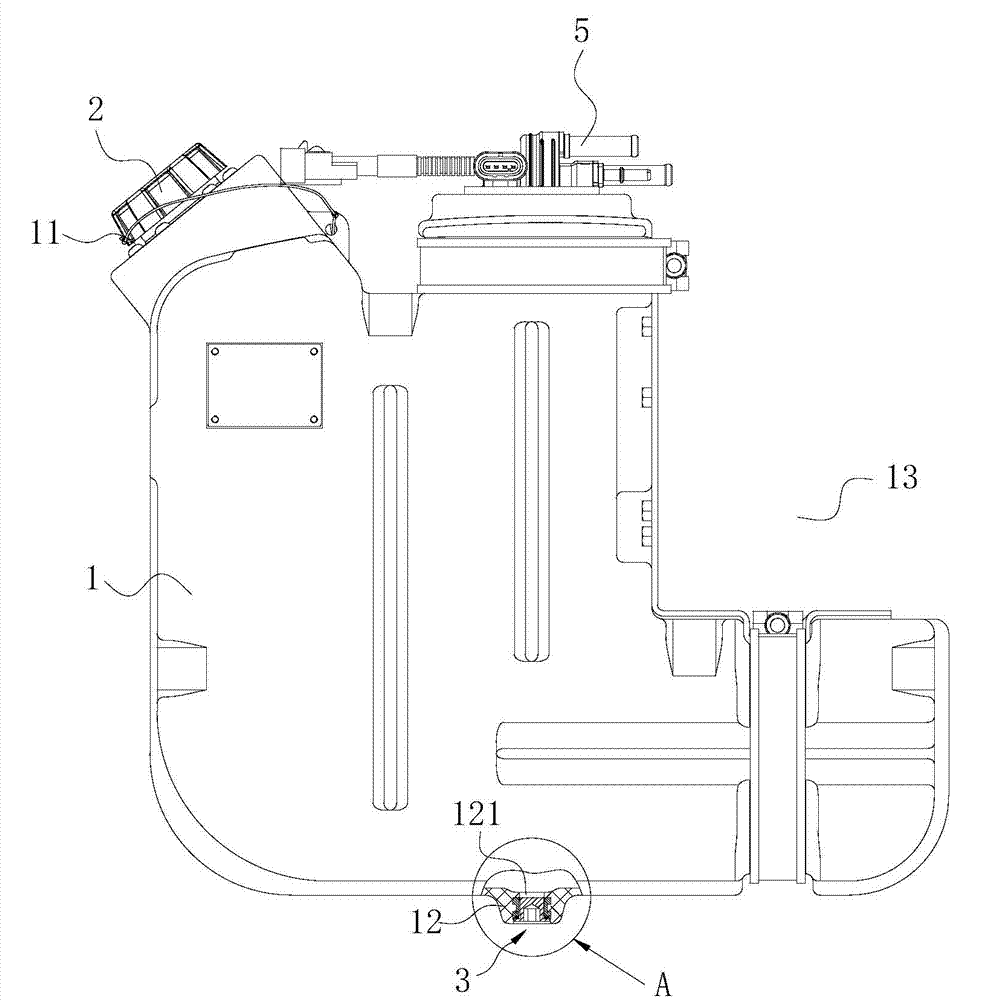

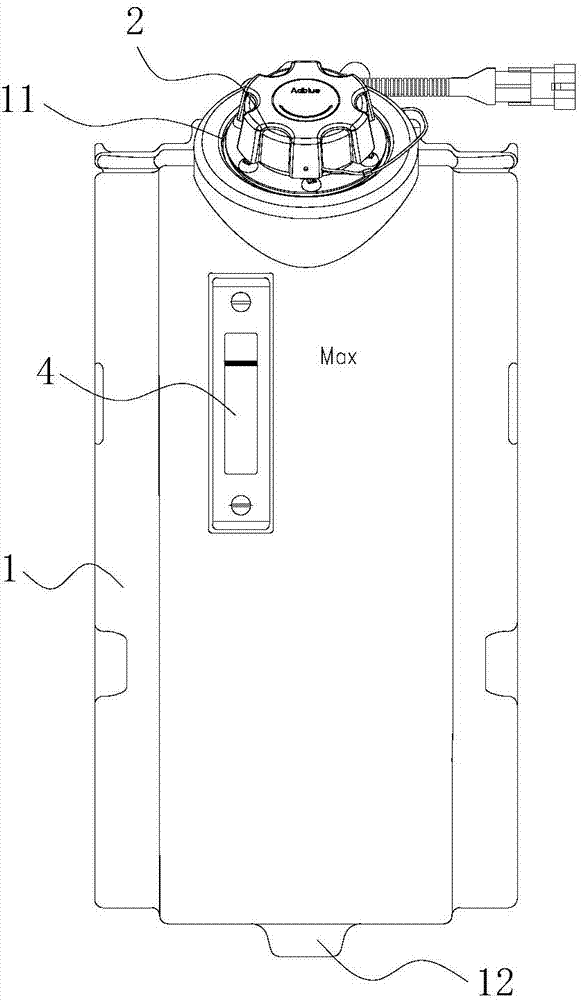

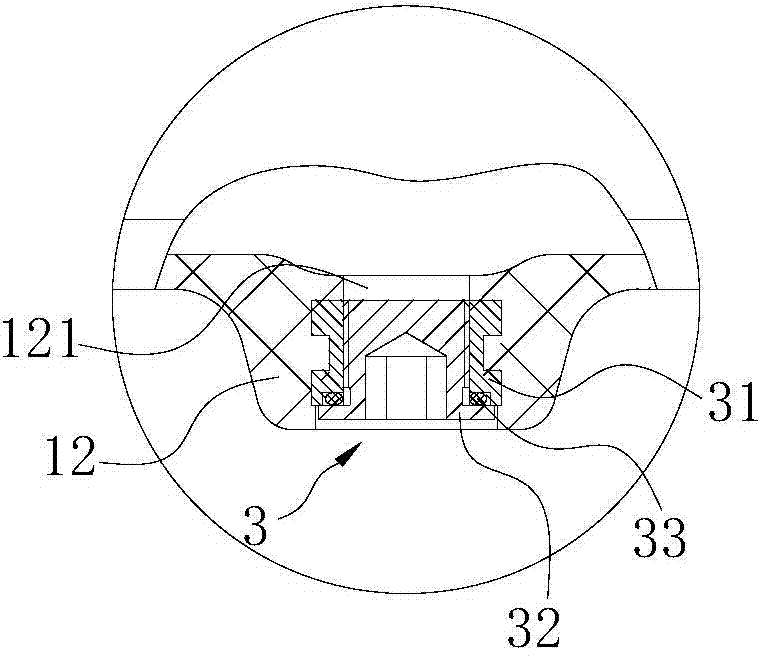

Urea solution tank for SCR aftertreatment system

InactiveCN103696835AAvoid bumpingGuaranteed no leakageExhaust apparatusSilencing apparatusUreaLiquid injection

The invention discloses a urea solution tank for an SCR aftertreatment system. The urea solution tank comprises a tank body. The tank body comprises at least one liquid injection port, at least one liquid discharging port and at least one liquid discharging valve group, wherein a tank cover for sealing the at least one liquid injection port is arranged on the at least one liquid injection port; the at least one liquid discharging port is arranged at the bottom of the tank body, and a liquid channel is arranged by enabling the at least one liquid discharging port to extend outwards; the at least one liquid discharging valve group is arranged in the liquid channel, every liquid discharging valve group comprises a valve body arranged in the liquid channel and a liquid discharging bolt movably arranged on the valve body, and the liquid discharging bolt is partially arranged in the liquid channel. By arranging the at least one liquid discharging valve group in the liquid channel of the at least one liquid discharging port, the liquid discharging bolts of the at least one liquid discharging valve group are not exposed outside the at least one liquid discharging port, collision of the liquid discharging bolts is effectively avoided, the liquid discharging bolts are prevented from being loosened or deformed, and the at least one liquid discharging port does not leak liquid.

Owner:KAILONG HIGH TECH

A pedestal for preventing tension cracks at beam ends and its construction method

ActiveCN111452211BGuarantee the pouring qualityAdjustable stiffnessMouldsMould auxillary partsClassical mechanicsStringer

The invention provides a pedestal for preventing tension cracks at beam ends and a construction method, belonging to the technical field of building construction. Its technical solution is: a pedestal for preventing beam end tension cracks, including a first formwork, a second formwork, a connecting hinge, a waterproof rubber strip, a first support part arranged at the bottom of the first formwork, and a first support part arranged at the second formwork. The second support part at the bottom of the formwork; the second support part includes a first connection plate and a second connection plate arranged directly below the second formwork from top to bottom, and the second connection plate evenly arranged between the second formwork and the first connection plate Several second longitudinal beam supports, several high-strength springs fixedly connected between the first connecting plate and the second connecting plate, and an attached vibrator fixedly connected on the bottom surface of the first connecting plate. The beneficial effects of the present invention are: the beam end tension crack prevention pedestal and construction method provided by the present invention can avoid beam end cracks, ensure the pouring quality of beam end concrete, have simple structure and manufacture, can be used repeatedly, and have strong adaptability.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

A bridge expansion joint and its construction technology

ActiveCN106498849BSimple construction processLow costBridge structural detailsBridge erection/assemblyWorking lifeBridge deck

The invention discloses a bridge expansion joint, which comprises embedded steel bars, an expansion joint, an installing groove, a laying layer and an elastic material layer. The construction process comprises the following steps that according to construction requirements and bridge expansion joint specifications, the concrete bridge deck is subjected to joint cutting treatment; the steel bar embedding work of the bridge expansion joint is performed; the fixation is performed after the regulation; the steel bar embedding welding work is performed when no bias is ensured; a waterproof film is laid and padded in the expansion joint; a separation interface layer is brushed and coated on the waterproof film; then, the concrete casting work of the laying layer starts; after the casting work is completed for 48h, a waterproof membrane laid in the expansion joint is taken out; water closing inspection and delivery-receiving acceptance are performed; after the qualification, the construction of the bridge expansion joint is completed. The bridge expansion joint provided by the invention has the advantages that good driving comfort and durability are realized; the application range is wide; the construction process is simple; the cost is low; the construction quality is high; the long-time work life of the bridge expansion joint is ensured.

Owner:HUNAN INSTITUTE OF ENGINEERING

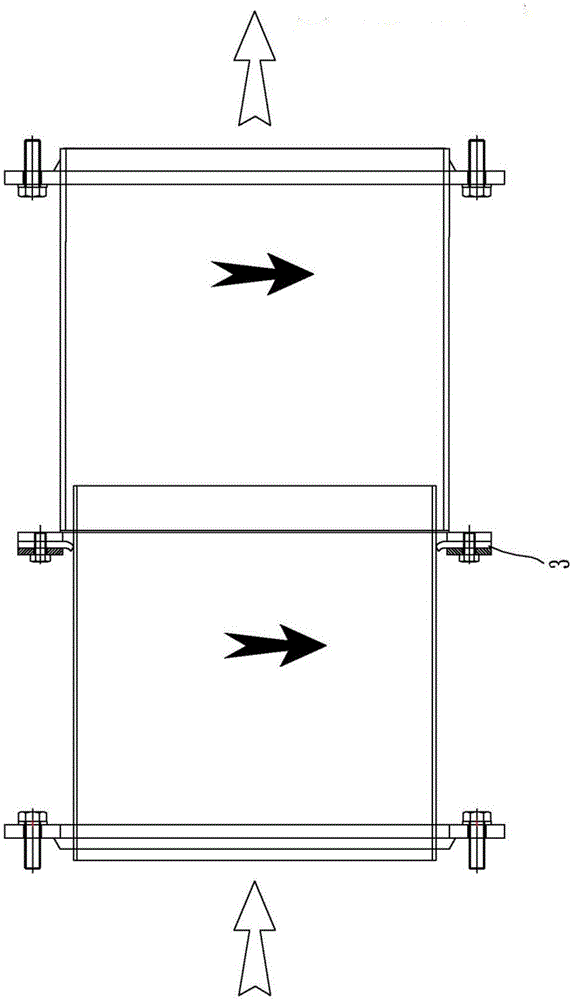

Material guide plate and waste material automatic exporting system including the material guide plate

ActiveCN103386447BGuaranteed no leakageGuaranteed to slipEjection devicesEngineeringMechanical engineering

The invention provides stock guides and an automatic waste discharge system comprising same. Each of the stock guides comprises a guide plate mounting frame, a middle guide plate and an edge guide plate, wherein the guide plate mounting frames are used for respectively mounting the stock guides on a left support and a right support of the automatic waste discharge system; the middle guide plates are arranged on one sides of the guide plate mounting frames close to the center of a material guide belt of the automatic waste discharge system, and the middle guide plates are upwards and outwards inclined relative to the center of the material guide belt; the edge guide plates are connected to the other sides of the middle guide plates, and the edge guide plates are close to the sides of waste ports; the automatic waste discharge system comprises the left support, the right support, the material guide belt and two stock guides. The stock guides, provided by the invention, have the advantages of simple structure, convenience for manufacturing, low cost and capability of preventing the edges of the stock guides from leaking materials, sliding wastes on the material guide belt, and adjusting the widths of the stock guides through mounting holes of the guide plate mounting frames, and is suitable for the waste ports of different widths.

Owner:GREE ELECTRIC APPLIANCES INC

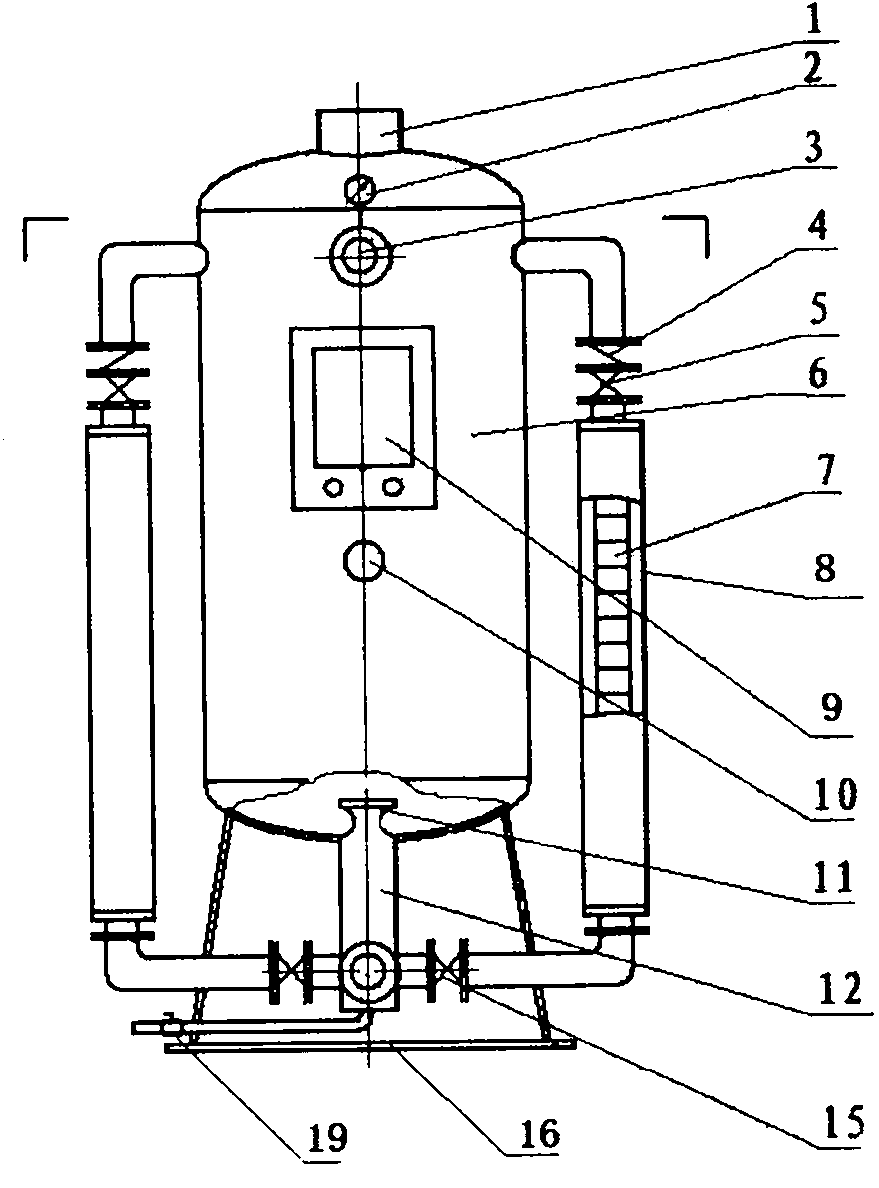

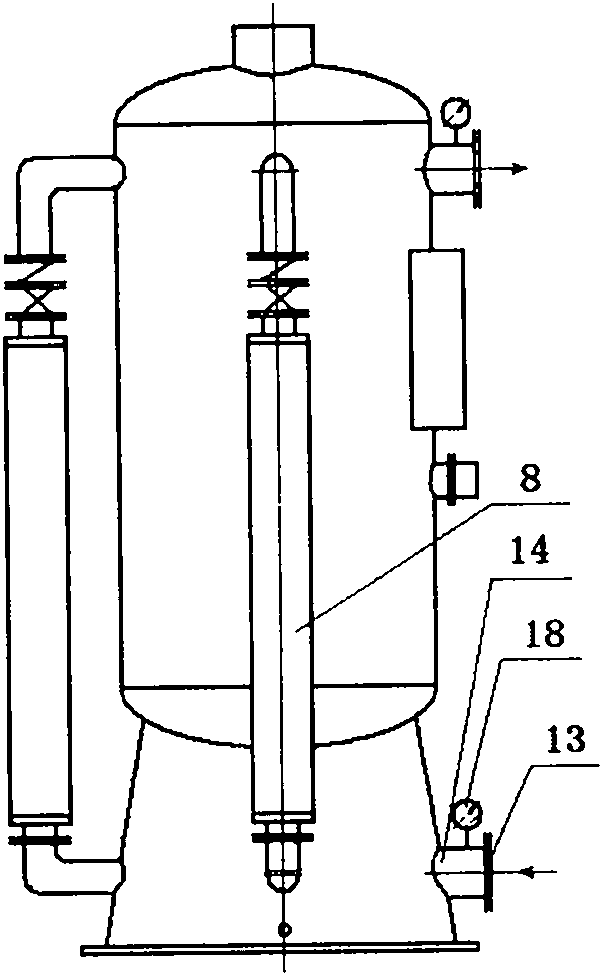

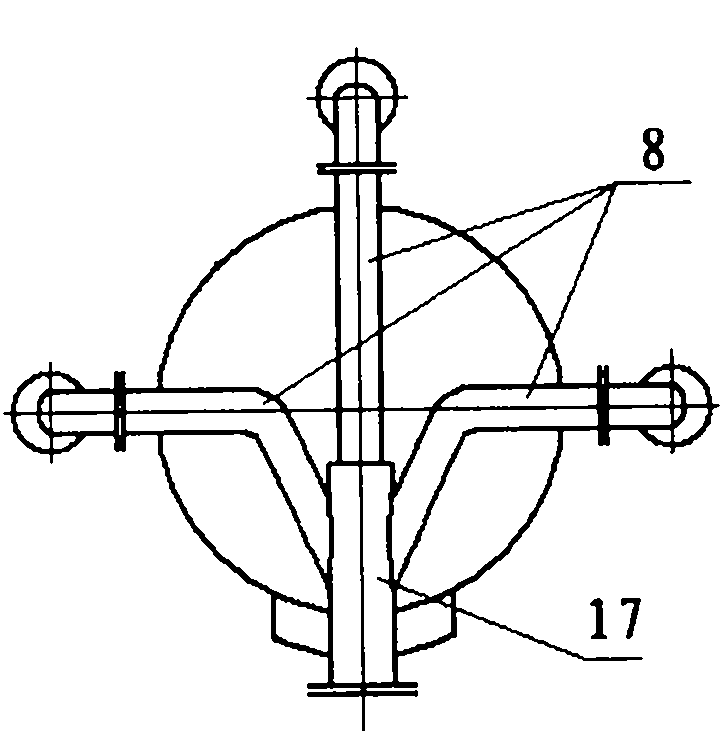

Suspension type mute non-negative-pressure variable frequency automatic water supply device

InactiveCN101871224AEnsure water qualityInnovative designService pipe systemsWater mainsSmall footprintInverted u

The invention relates to a suspension type mute non-negative-pressure variable frequency automatic water supply device, belonging to the field of automatic water supply equipment. The invention particularly relates to a suspension type mute non-negative-pressure variable frequency automatic water supply device ,which is characterized in that a water inlet (13) is arranged under the bottom of a flow-stabilizing tank (6), and is connected with a master water inlet pipe (14); the master water inlet pipe (14) is respectively connected with the lower end of a water feeding pipe (12) and the lower end of a water pump sleeve (8) by a multi-way hole; the upper end of the water feeding pipe (12) is inserted into the bottom of the flow-stabilizing tank (6); the water pump sleeve (8) is in a right inverted U shape which is vertically arranged along the outer side of a tank body, and is internally provided with a submersible pump (7); the upper end of the water pump sleeve is inserted into the upper part of the tank body of the flow-stabilizing tank (6), and is communicated with a master water outlet pipe (17); and a water outlet (3) is connected with the master water outlet pipe (17) and is positioned at the side part of the upper part of the flow-stabilizing tank (6). The suspension type mute non-negative-pressure variable frequency automatic water supply device has novel design, compact structure and small land occupying area, and is mute and environment-friendly.

Owner:刘延军

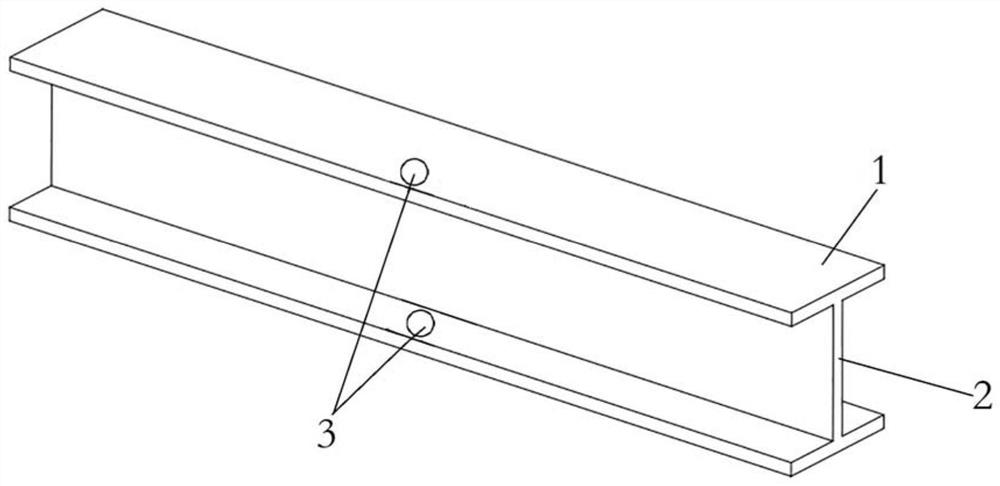

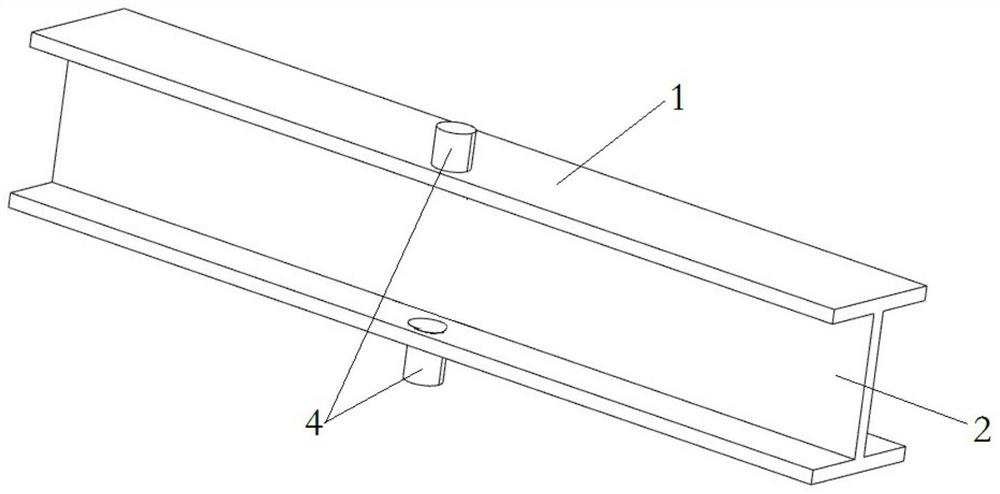

Component for fabricated building and fabricated building with same

PendingCN112012398AShorten the lengthReduce construction difficultyElectrical apparatusGirdersArchitectural engineeringMechanical engineering

Owner:CHINA CONSTR SCI & IND CORP LTD

Stock guides and automatic waste discharge system comprising same

The invention provides stock guides and an automatic waste discharge system comprising same. Each of the stock guides comprises a guide plate mounting frame, a middle guide plate and an edge guide plate, wherein the guide plate mounting frames are used for respectively mounting the stock guides on a left support and a right support of the automatic waste discharge system; the middle guide plates are arranged on one sides of the guide plate mounting frames close to the center of a material guide belt of the automatic waste discharge system, and the middle guide plates are upwards and outwards inclined relative to the center of the material guide belt; the edge guide plates are connected to the other sides of the middle guide plates, and the edge guide plates are close to the sides of waste ports; the automatic waste discharge system comprises the left support, the right support, the material guide belt and two stock guides. The stock guides, provided by the invention, have the advantages of simple structure, convenience for manufacturing, low cost and capability of preventing the edges of the stock guides from leaking materials, sliding wastes on the material guide belt, and adjusting the widths of the stock guides through mounting holes of the guide plate mounting frames, and is suitable for the waste ports of different widths.

Owner:GREE ELECTRIC APPLIANCES INC

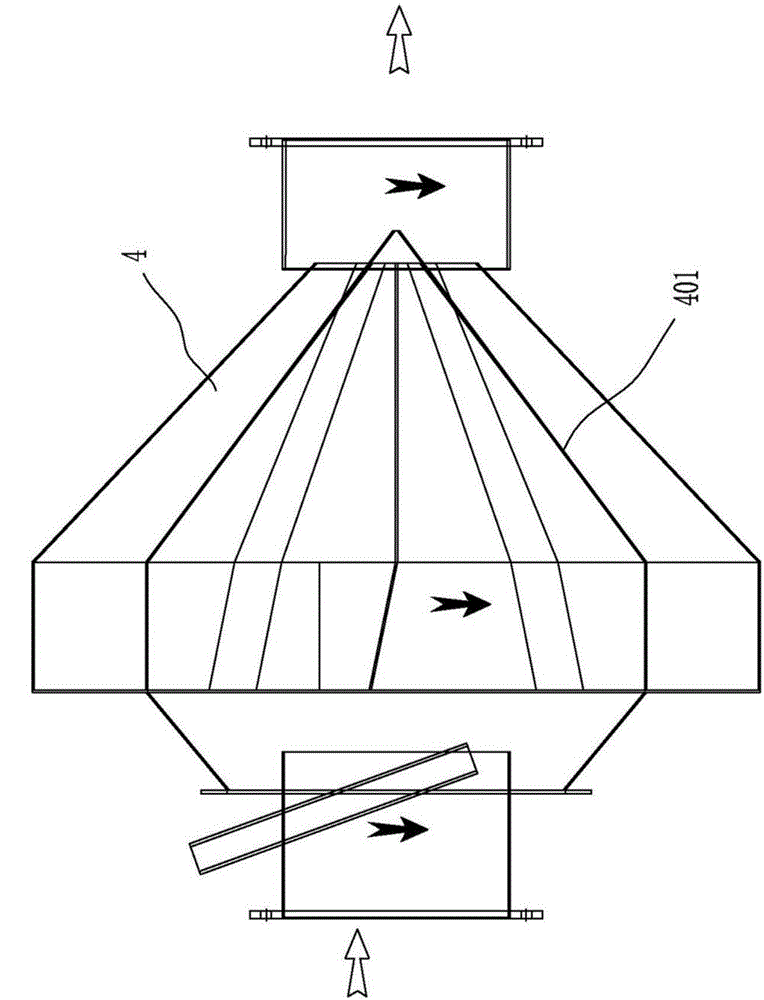

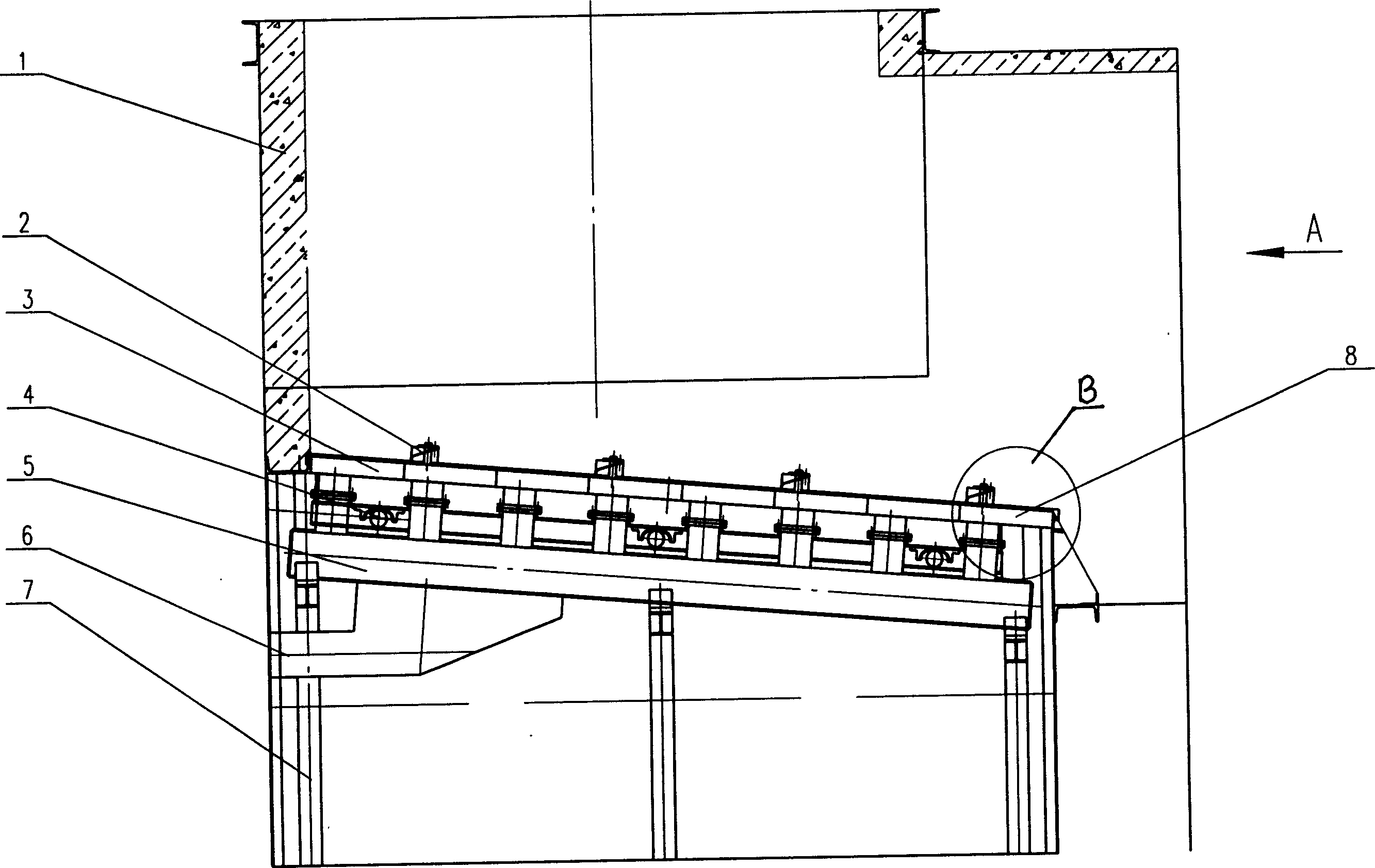

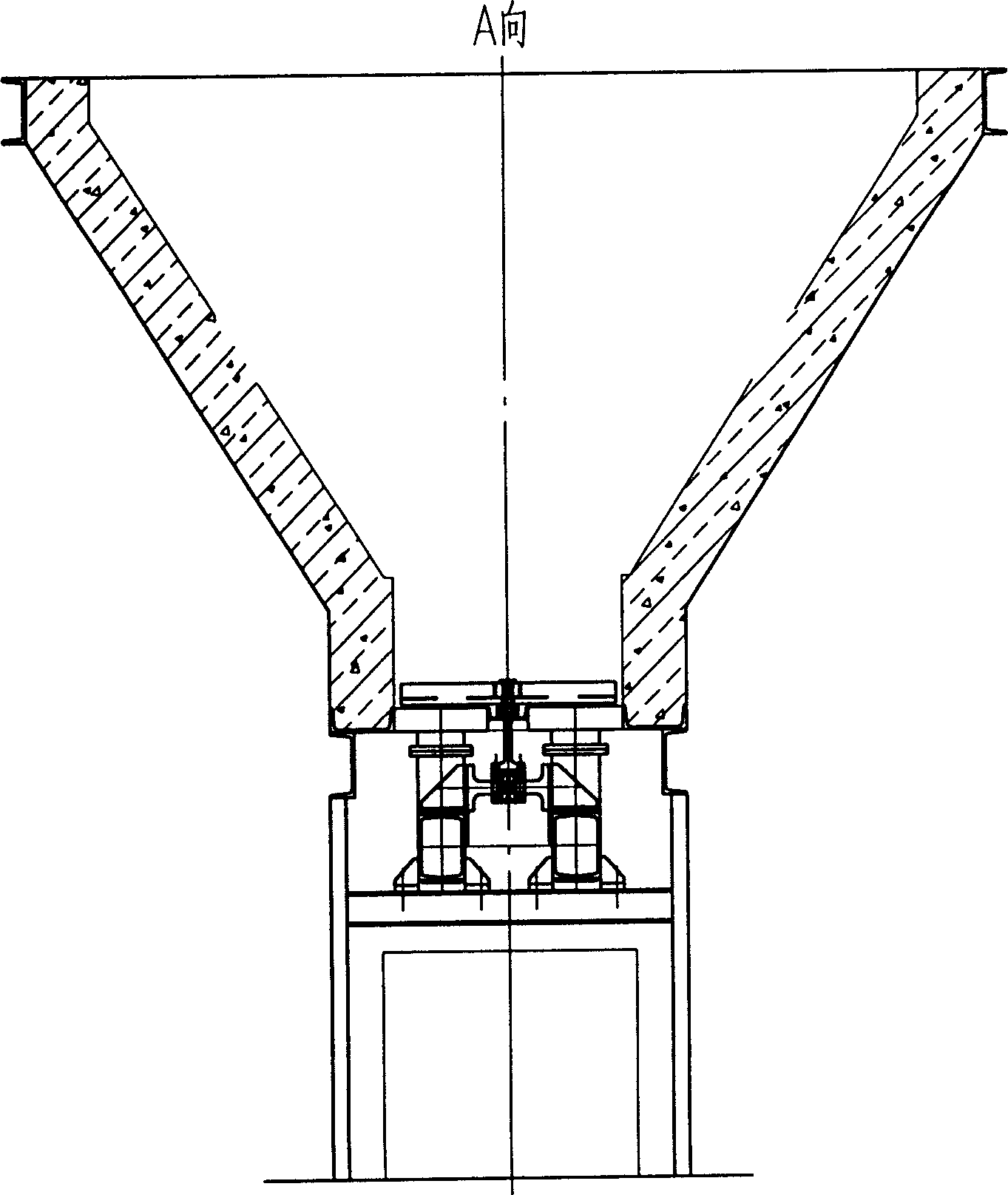

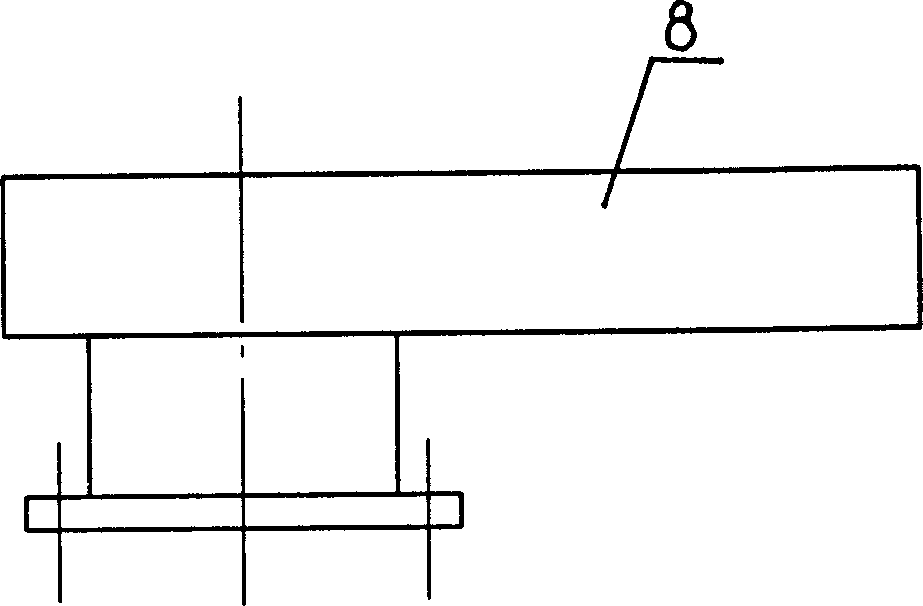

Inflating beam-grate type cooler for dry slag system of electric power boiler

InactiveCN1587816ARealize no leakageGuaranteed no leakageInstrumental cooling apparatusSolid removalSupporting systemSlag

The invention of aeration cooler relates to a electric boiler dry flushing 1 system, comprising upper shell, pusher mechanism, grate bed, gearing and supporting apparatus, gas feeding tube, under shell, grate support, lower shell, supporting apparatus and aeration grate. Its grate bed is linked to the lower shell and supporting apparatus though grate support which is linked to aeration grate of grate bed ; its grate support with gearing and supporting apparatus fixed on it, is linked to pusher mechanism of aeration grate ; there is suitable space for labyrinth type packing between pusher mechanism and grate bed ; three lateral surfaces of grate bed outside with the upper shell and fireproof, material is used on contact site ; the relevant position of support system is connected to gas feeding tube, with oblique layout. Its properties include high efficient heat exchange, good cooling effect, simple and compact structure, high running ratio and long service life.

Owner:中材(天津)重型机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com