A pedestal for preventing tension cracks at beam ends and its construction method

A technique for tensioning cracks and pedestals, which is used in the manufacture of tools, mold trays, ceramic molding machines, etc., can solve the problems of poor concrete pouring quality at the bottom of the beam end, easy cracks at the beam end tension, and easy cracks at the beam end, so as to avoid Beam end cracks, ensure pouring quality, structure and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

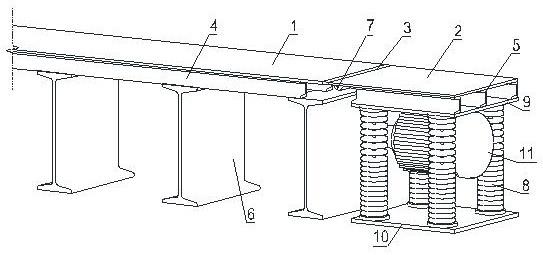

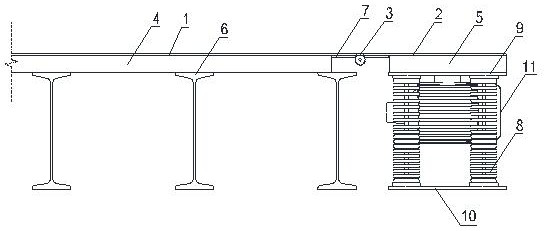

[0053] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0054] see Figure 1 to Figure 2 , the present invention is: a pedestal for preventing beam end tension cracks, which includes a first formwork 1 and a second formwork 2 with one end surface close to each other, equal in width and thickness, and arranged evenly, and arranged between the bottom surface of the first formwork 1 and the The connecting hinges 7 between the bottom surfaces of the second formwork 2 close to each other are filled with the water-proof adhesive strips arranged between the close end surfaces of the first formwork 1 and the second formwork 2 and laid on the top surface of the connecting hinges 7 3. The first supporting part arranged at the bottom of the first template 1, and the second supporting part arranged at the bottom of the second template 2;

[0055] The first support part includes several bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com