Patents

Literature

234results about "Mould pallets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

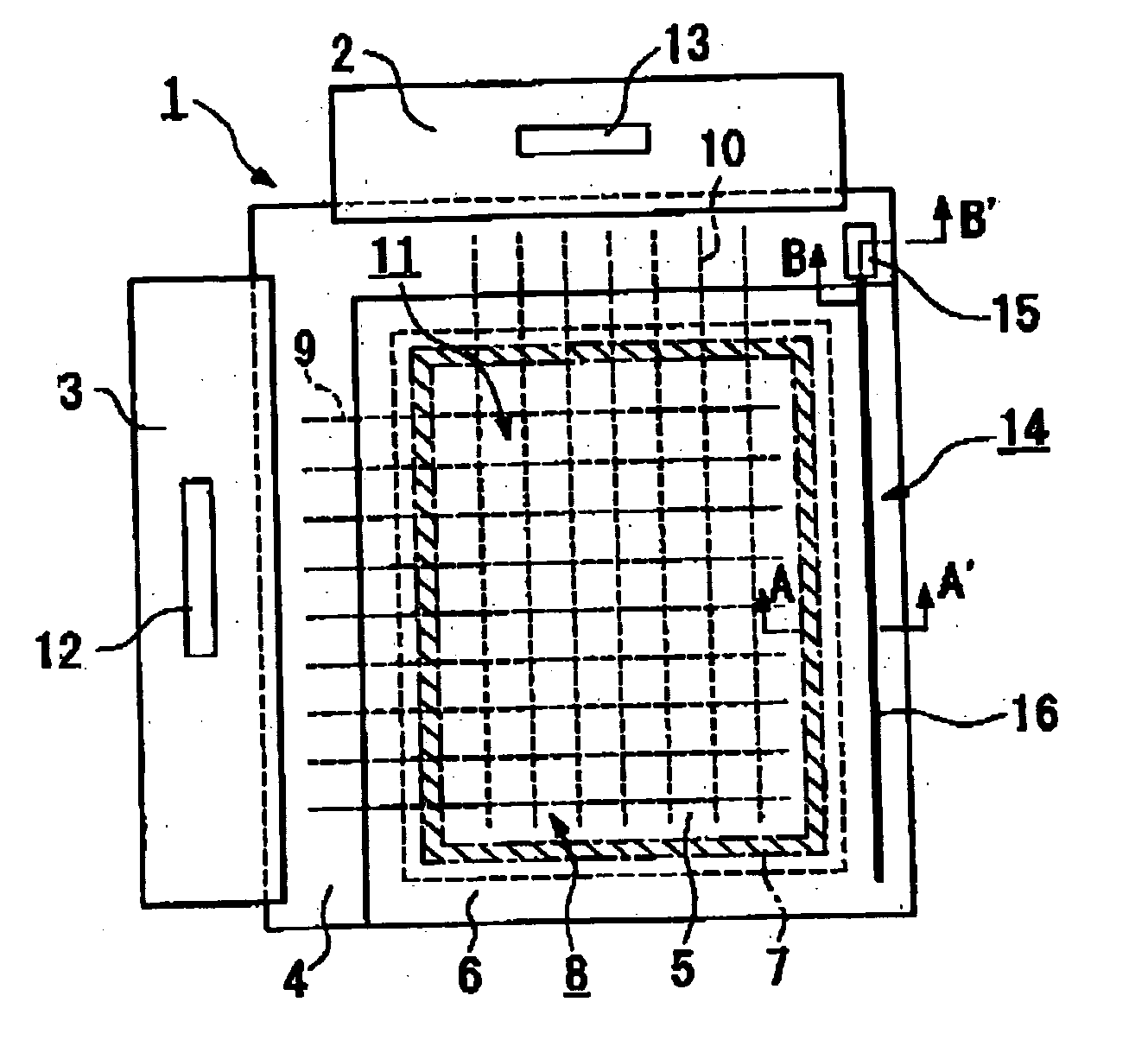

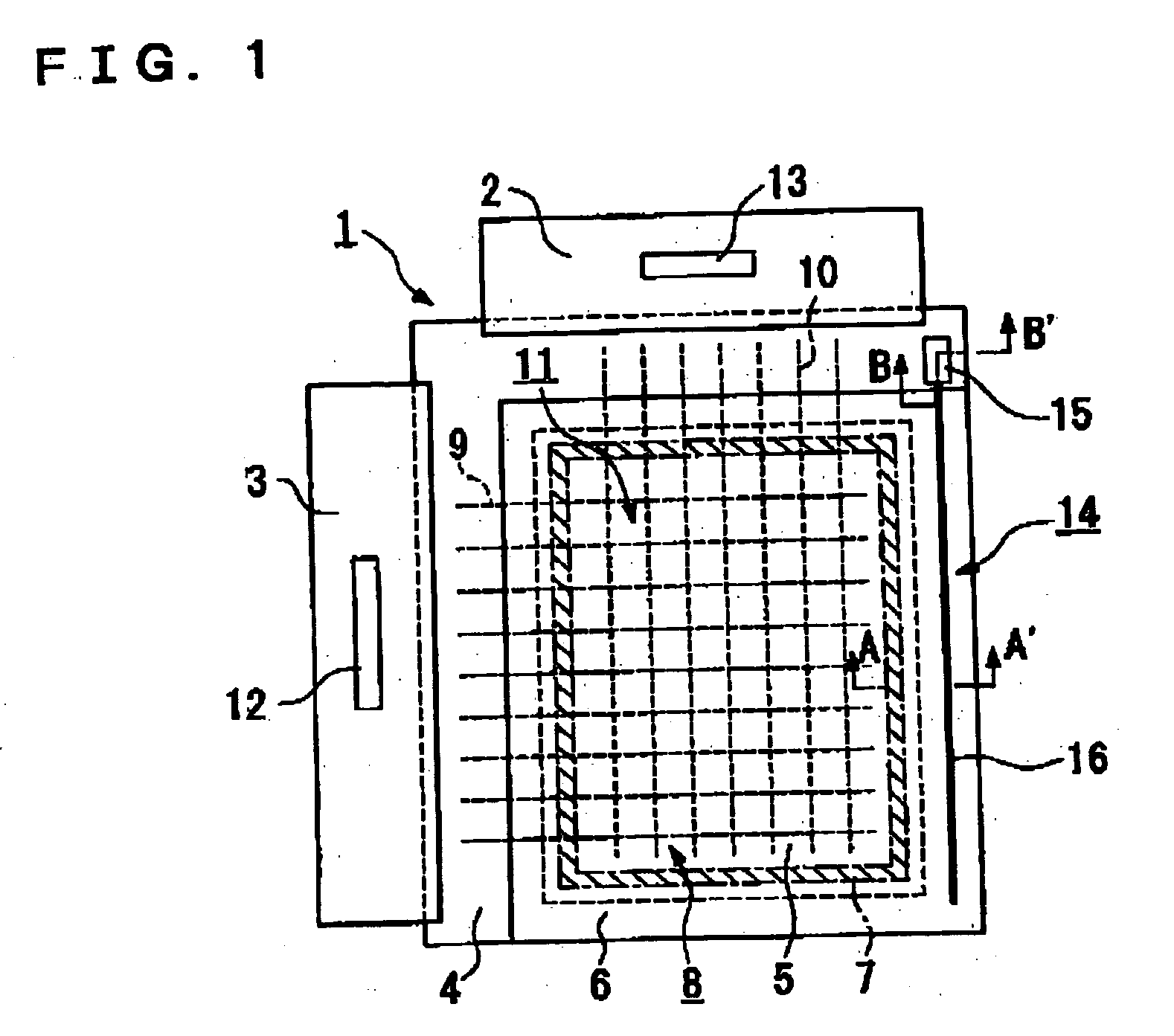

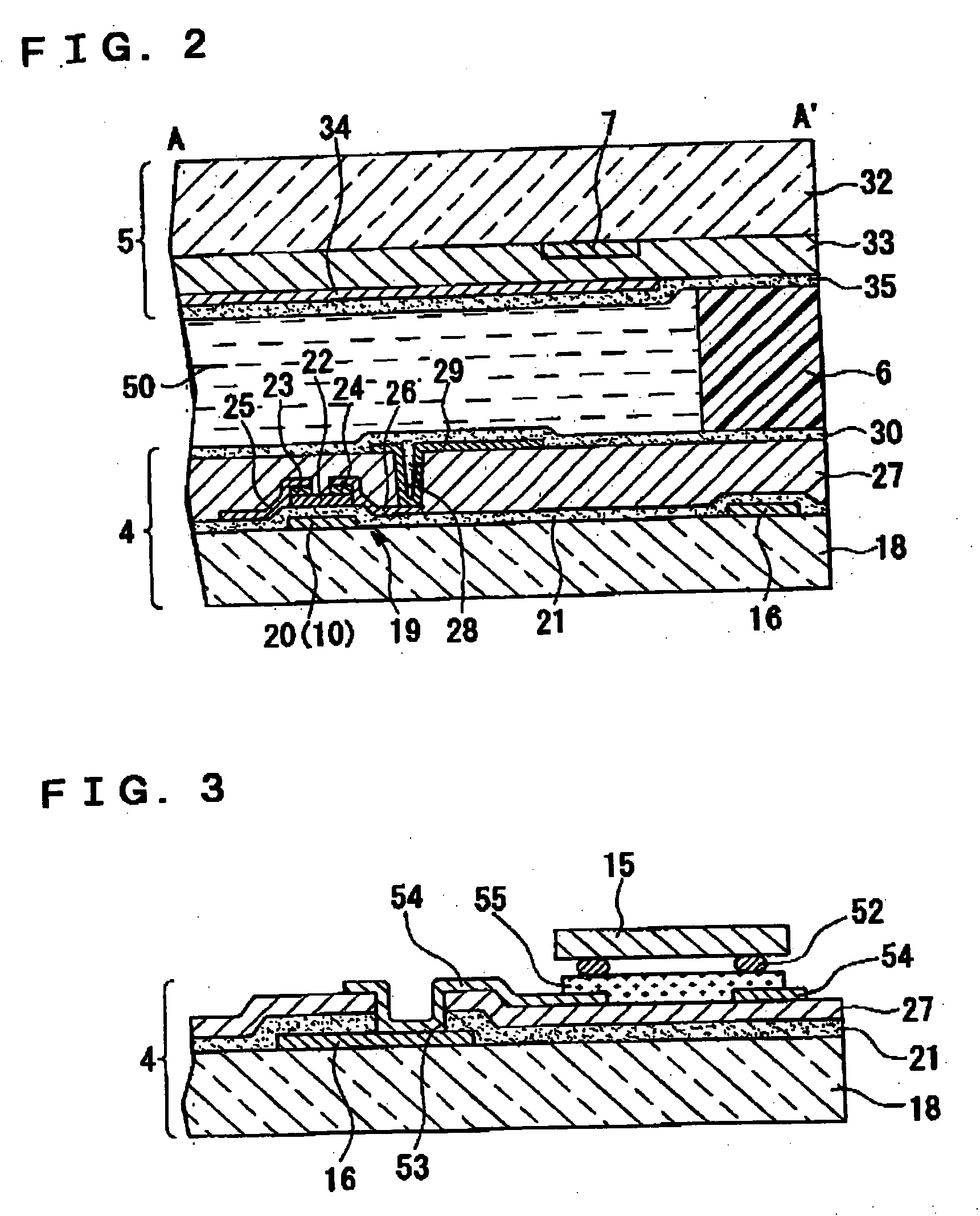

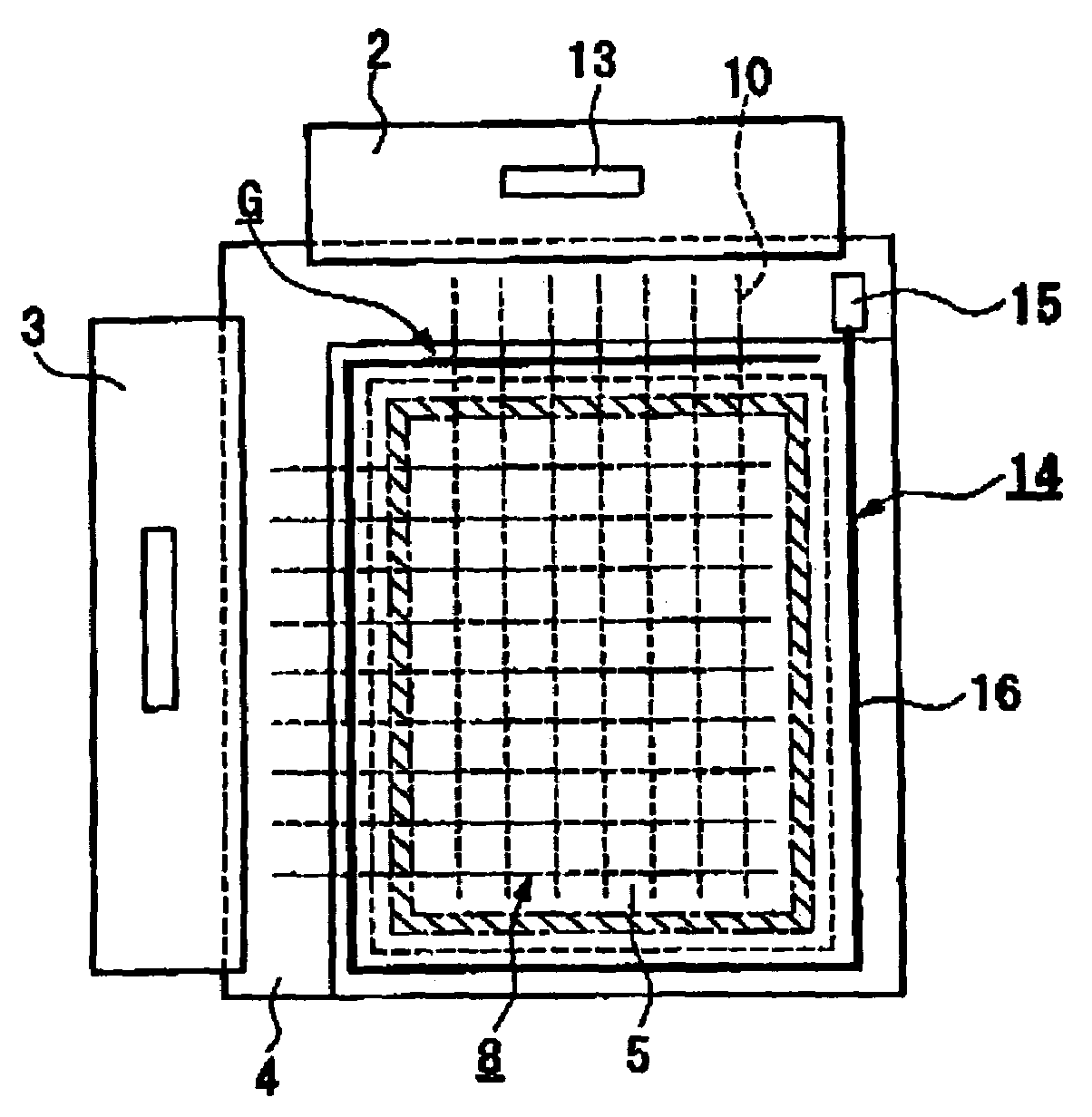

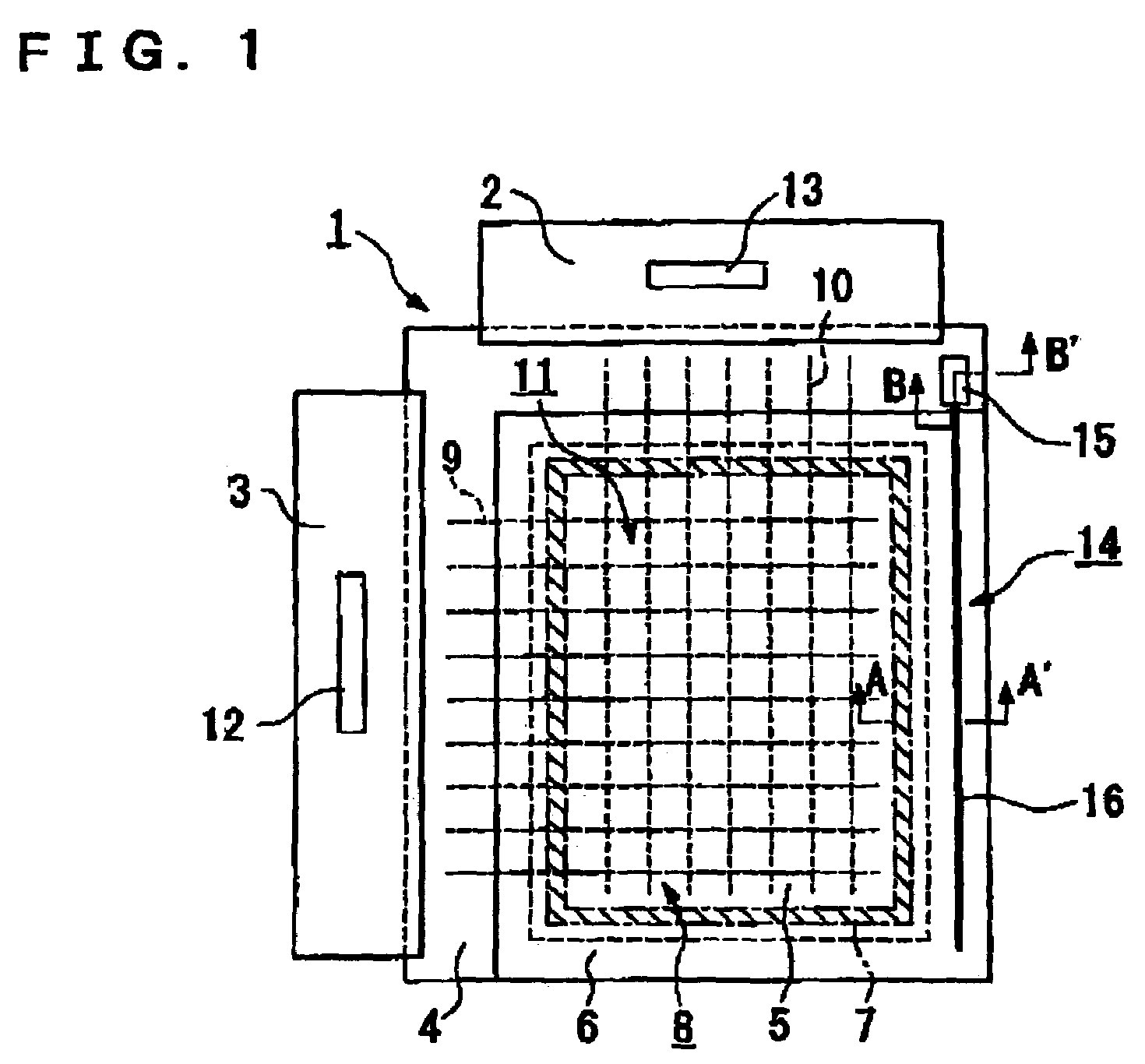

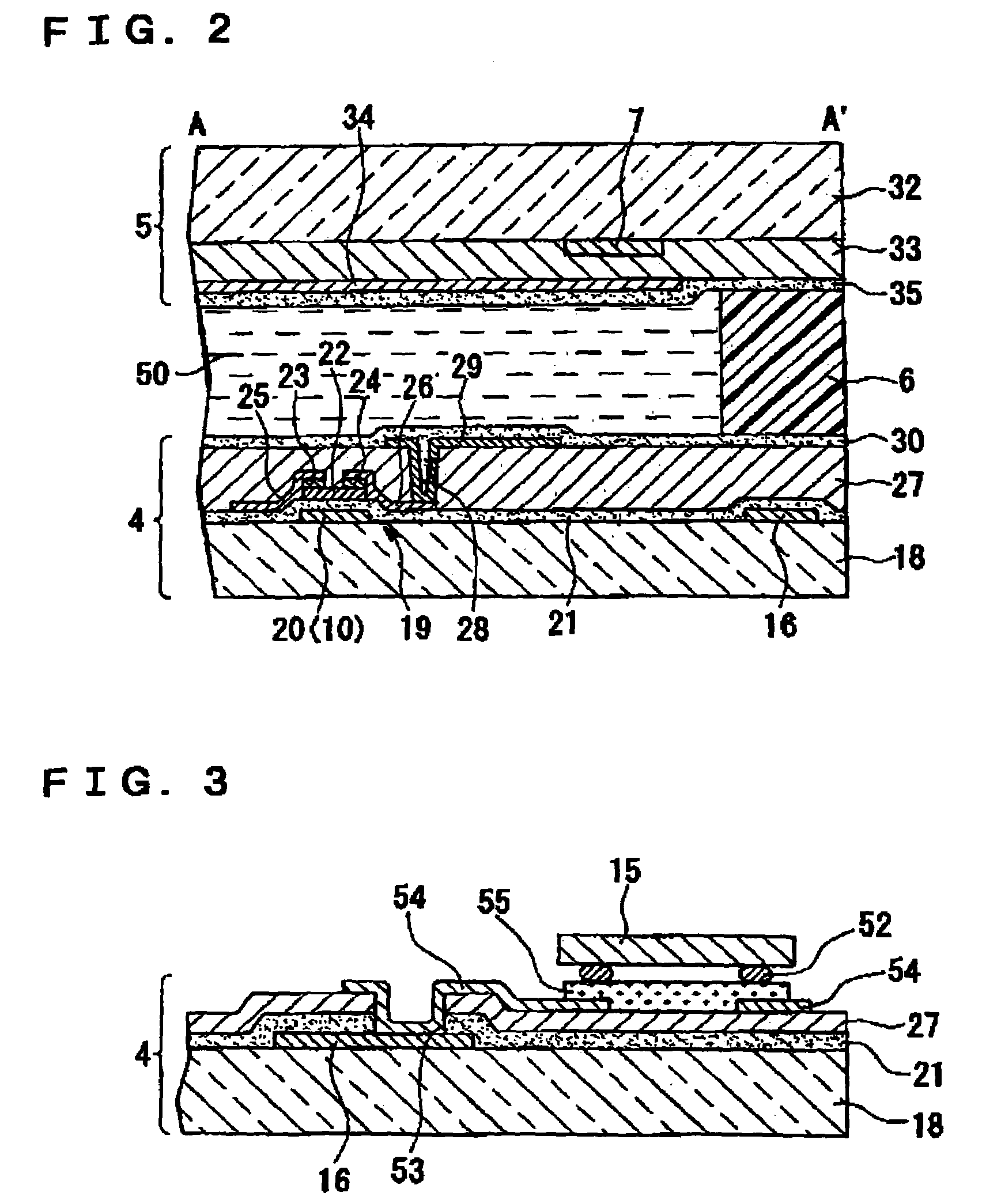

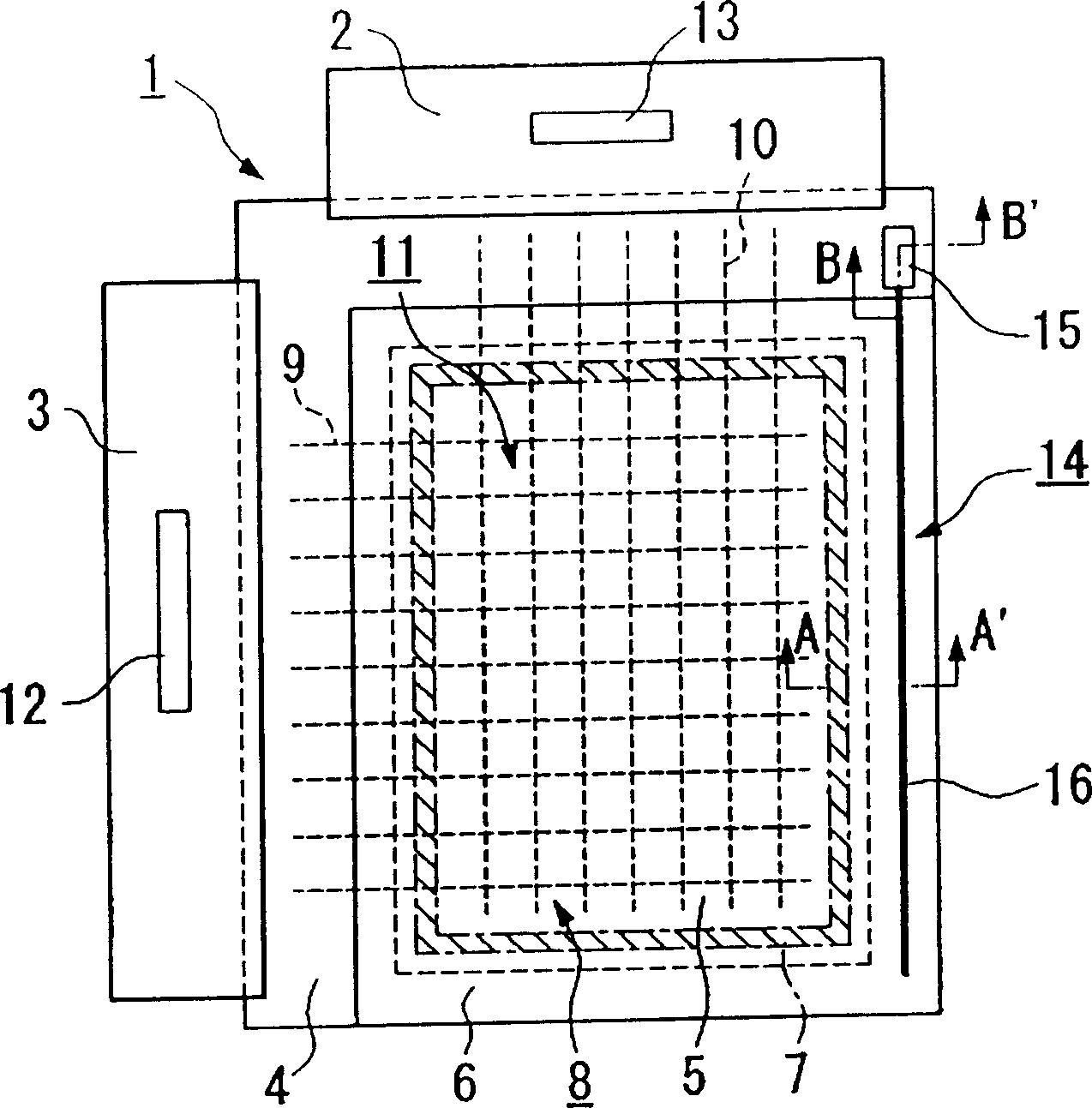

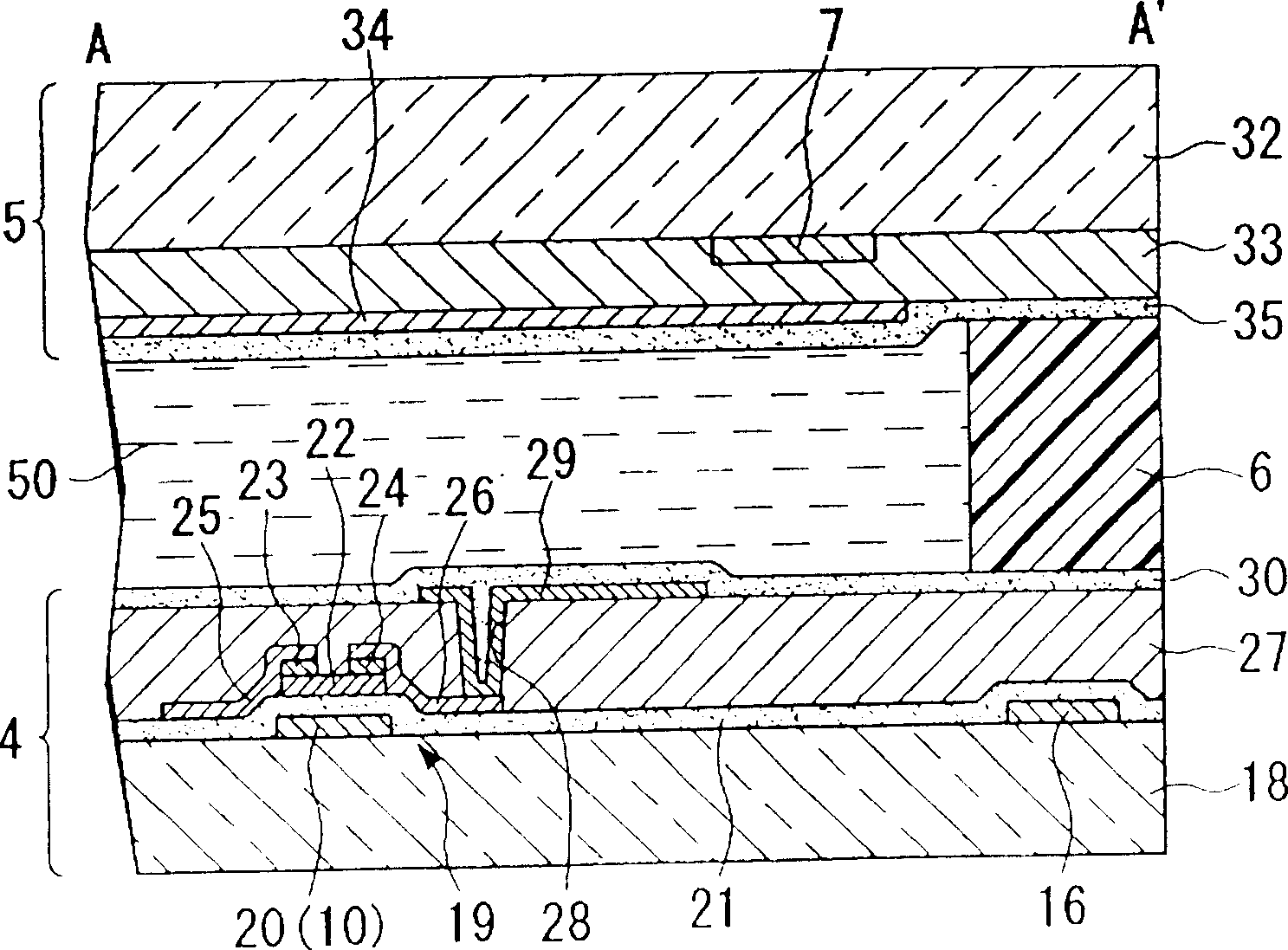

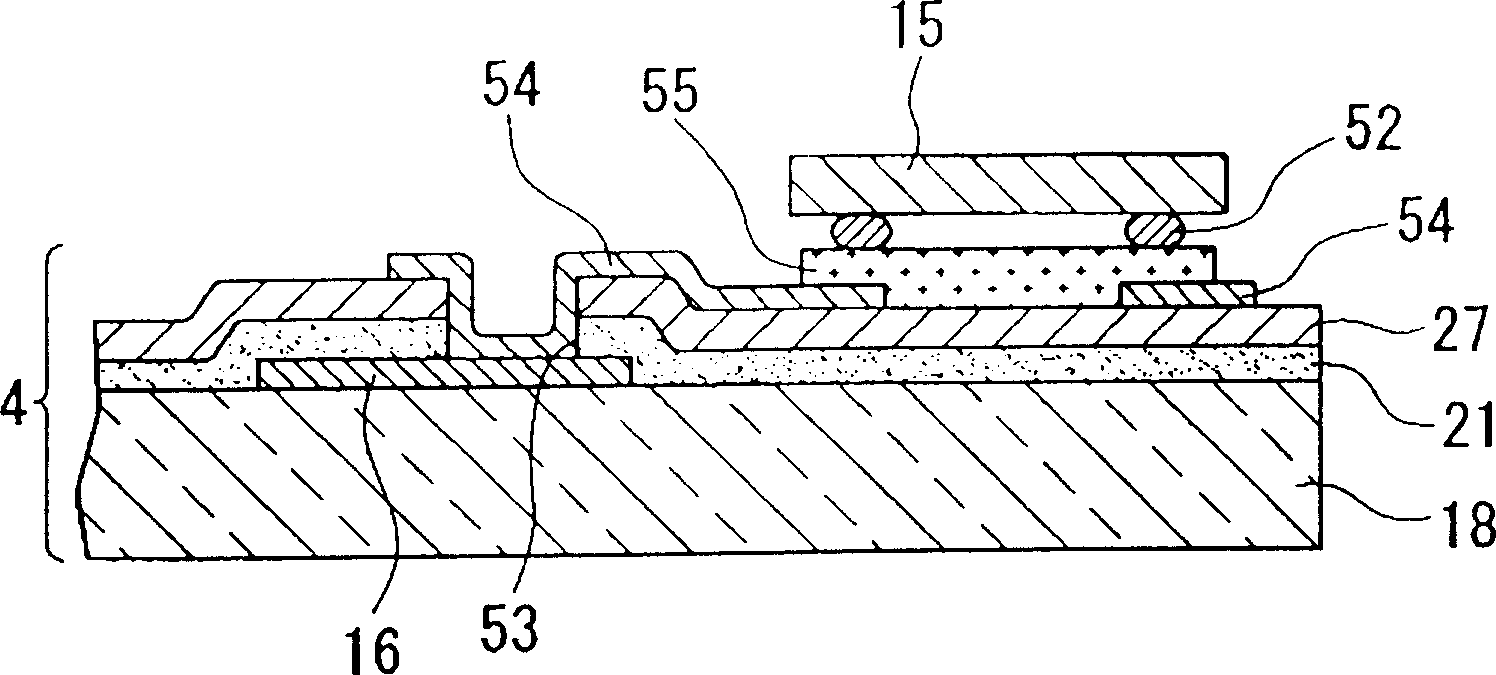

Display device and electronic apparatus

ActiveUS20040189625A1Simple structureReduce amount of effort and timeMouldsSolid-state devicesElectrical conductorDisplay device

To provide a display device and an electronic apparatus including a radio communication device, such as an IC tag, which do not need a special space to attach the IC tag and is capable of reducing the amount of time and effort required for attaching the IC tag, a display device including a radio communication device having at least one substrate provided with a display unit and display-unit-driving wiring lines 9 and 10, a communication integrated-circuit unit, and an antenna is provided. At least a part of the antenna is formed on the substrate and formed of a conductor formed in the same layer as a conductor that constitute the display unit or conductors that constitute the display-unit-driving wiring lines.

Owner:BOE TECH GRP CO LTD

Display device and electronic apparatus

To provide a display device and an electronic apparatus including a radio communication device, an embodiment of the radio communication device being an IC tag, which do not need a special space to attach the IC tag and is capable of reducing the amount of time and effort required for attaching the IC tag, a display device including a radio communication device having at least one substrate provided with a display unit and display-unit-driving wiring lines9 and 10, a communication integrated-circuit unit, and an antenna is provided. At least a part of the antenna is formed on the substrate and formed of a conductor formed in the same layer as a conductor that constitute the display unit or conductors that constitute the display-unit-driving wiring lines.

Owner:BOE TECH GRP CO LTD

Displaying device and electronic apparatus

To provide a display device and an electronic apparatus including a radio communication device, an embodiment of the radio communication device being an IC tag, which do not need a special space to attach the IC tag and is capable of reducing the amount of time and effort required for attaching the IC tag, a display device including a radio communication device having at least one substrate provided with a display unit and display-unit-driving wiring lines 9 and 10 , a communication integrated-circuit unit, and an antenna is provided. At least a part of the antenna is formed on the substrate and formed of a conductor formed in the same layer as a conductor that constitute the display unit or conductors that constitute the display-unit-driving wiring lines.

Owner:BOE TECH GRP CO LTD

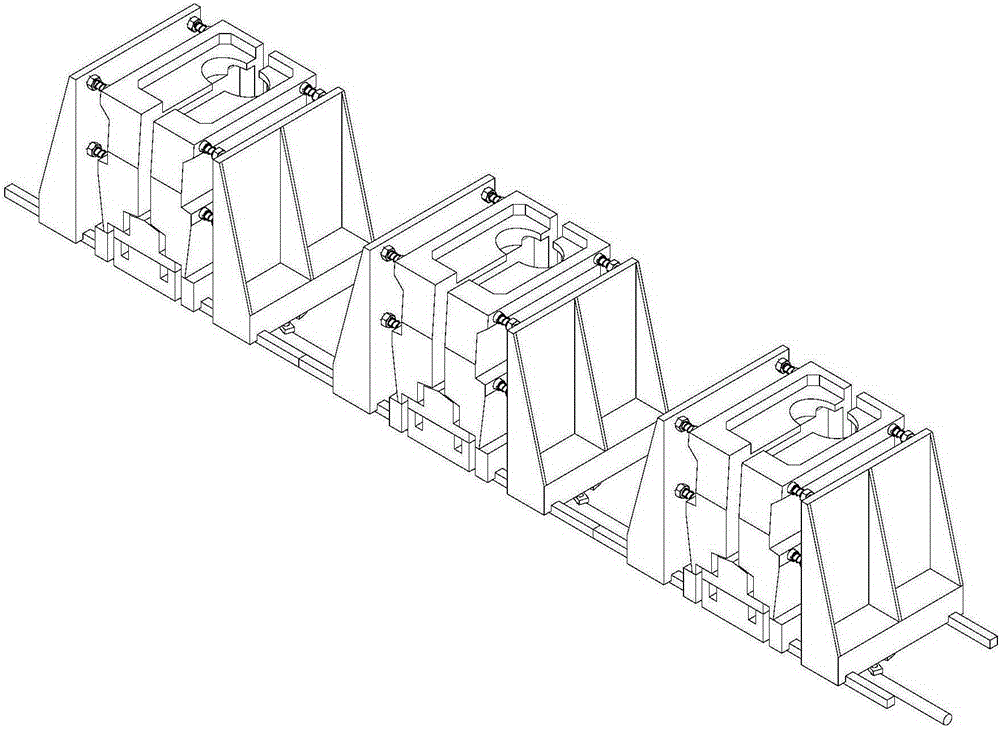

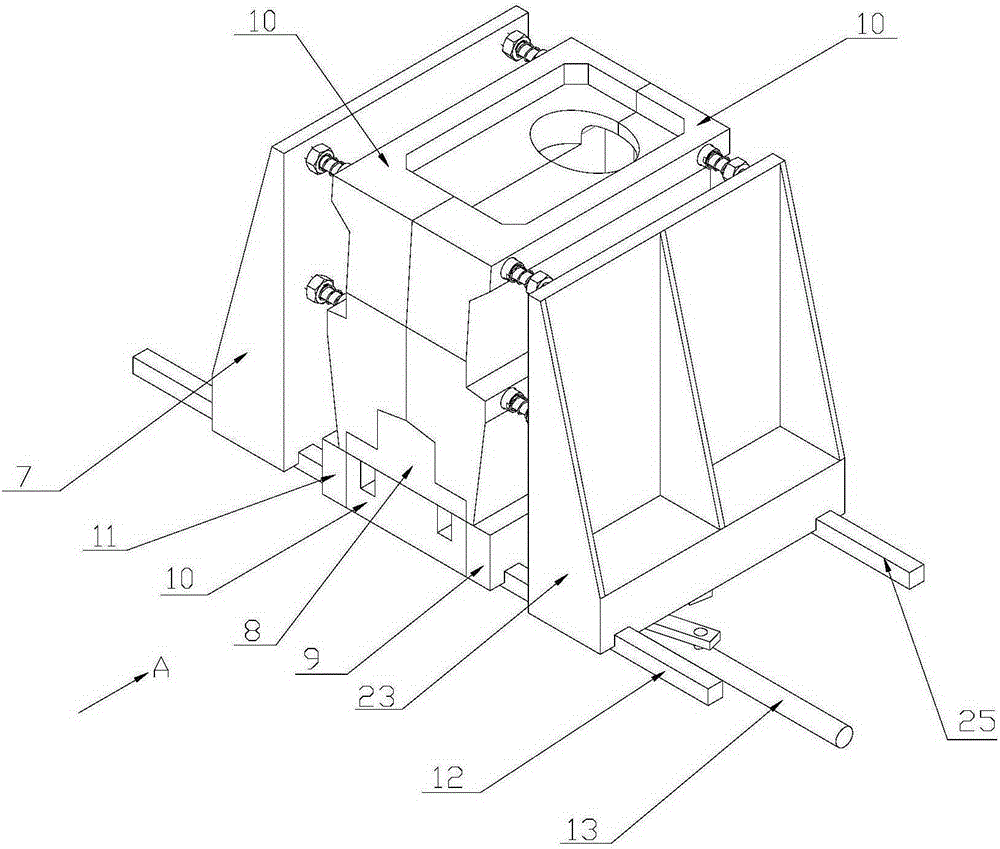

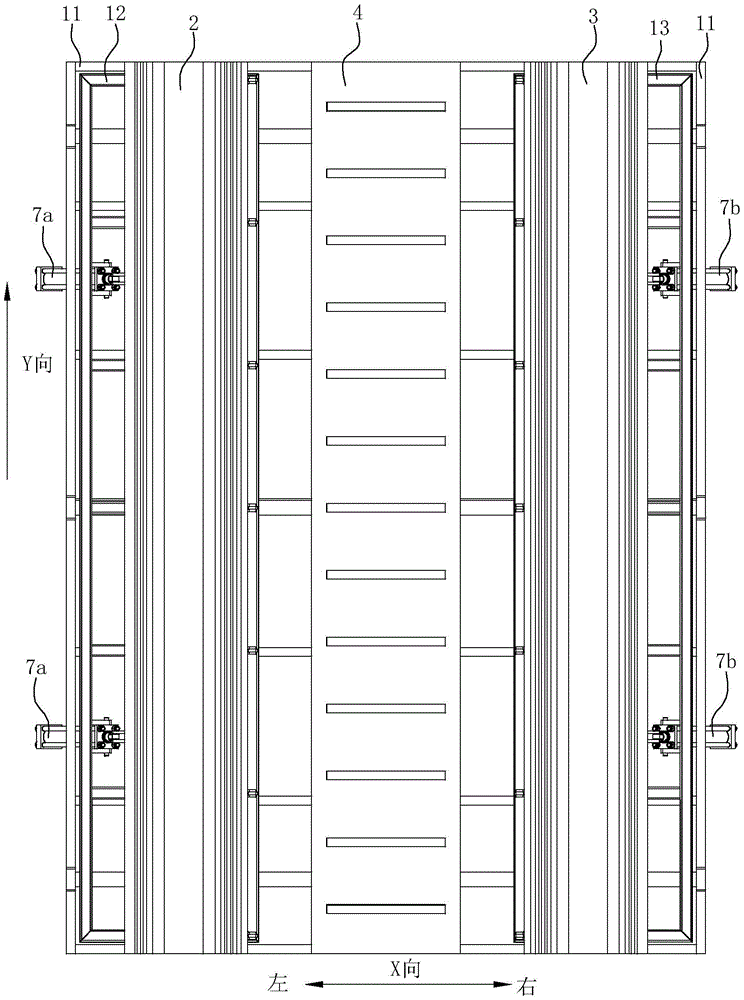

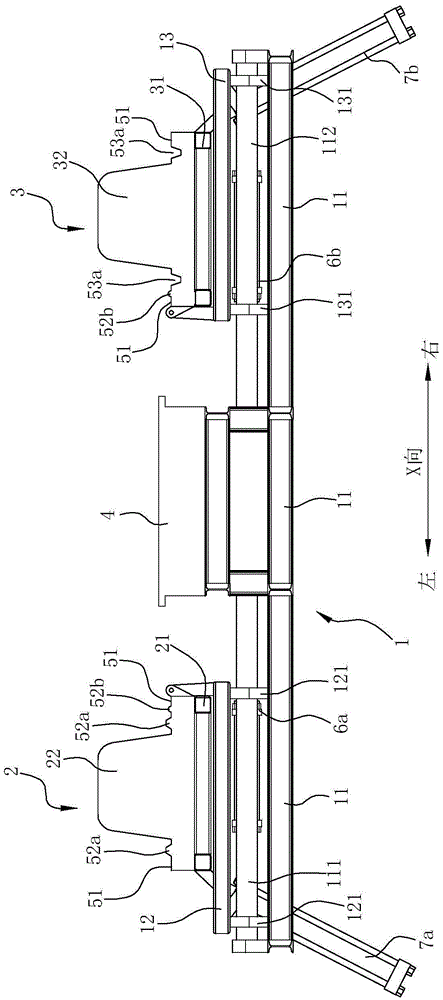

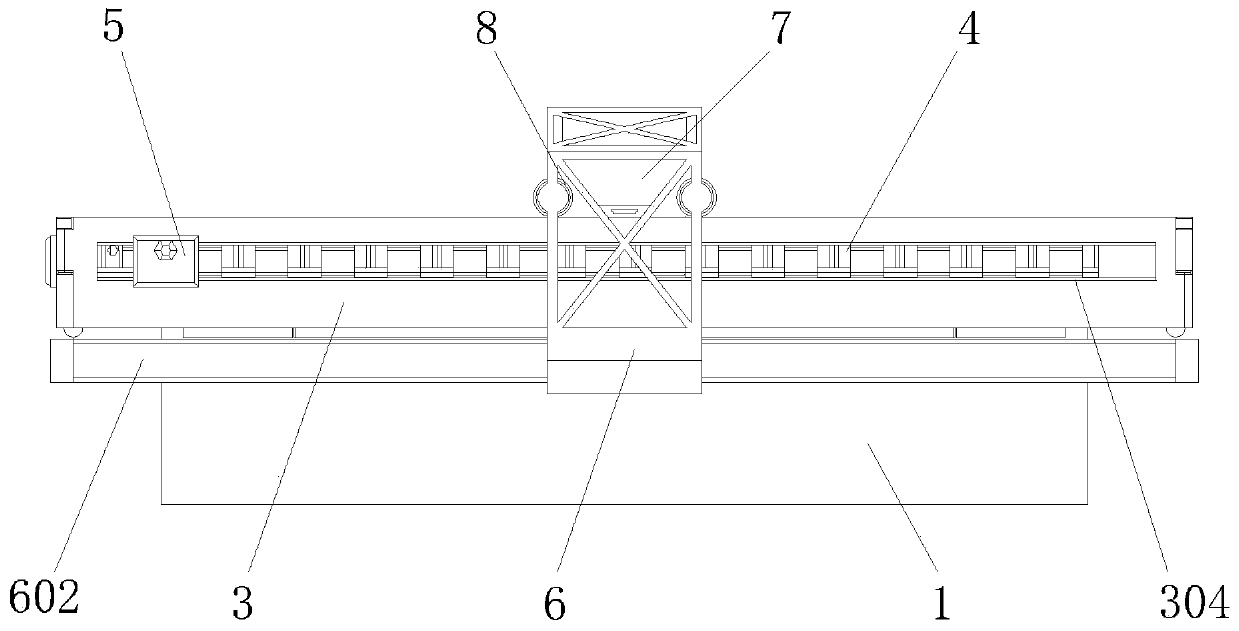

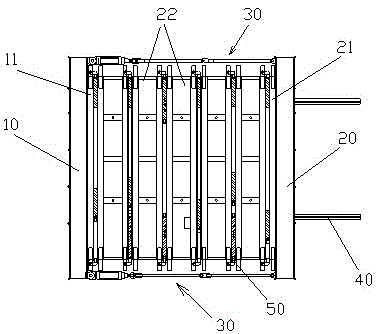

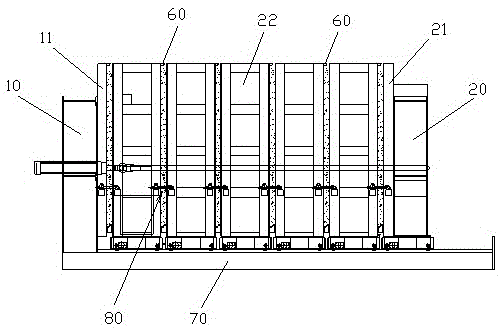

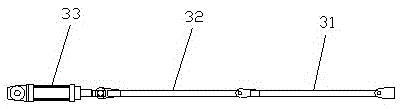

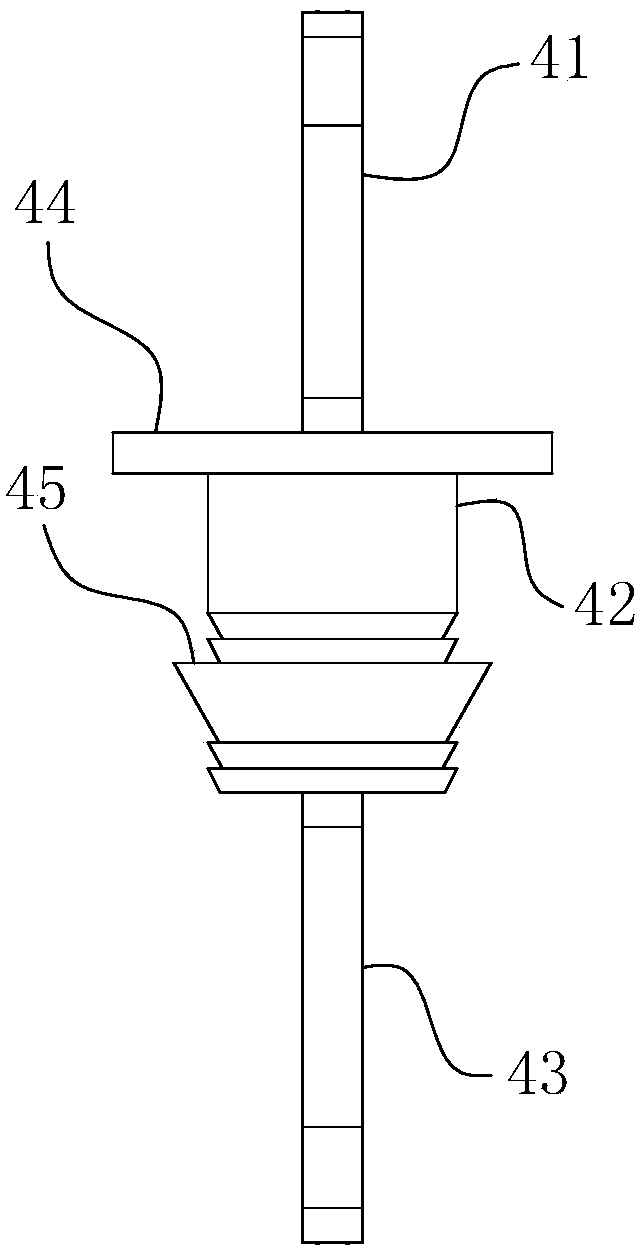

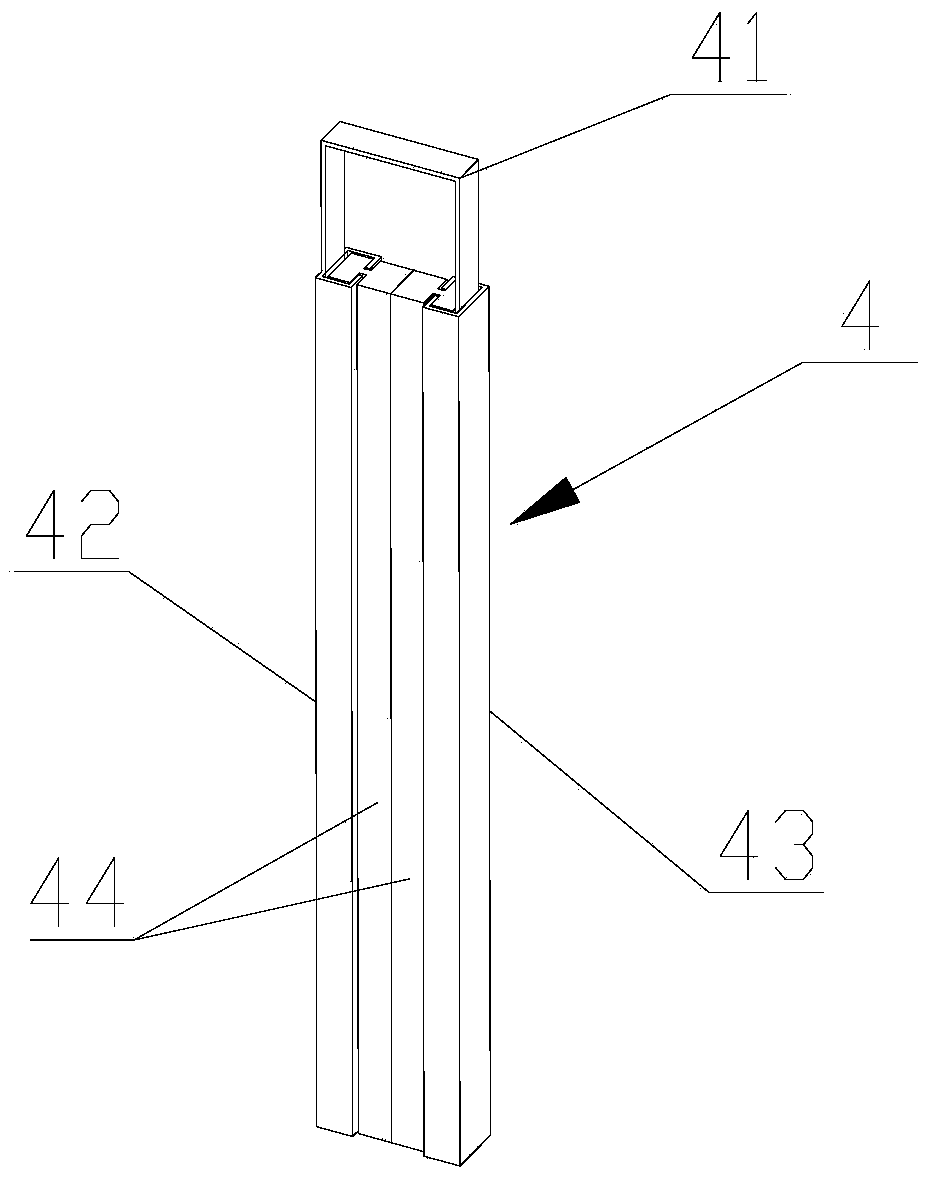

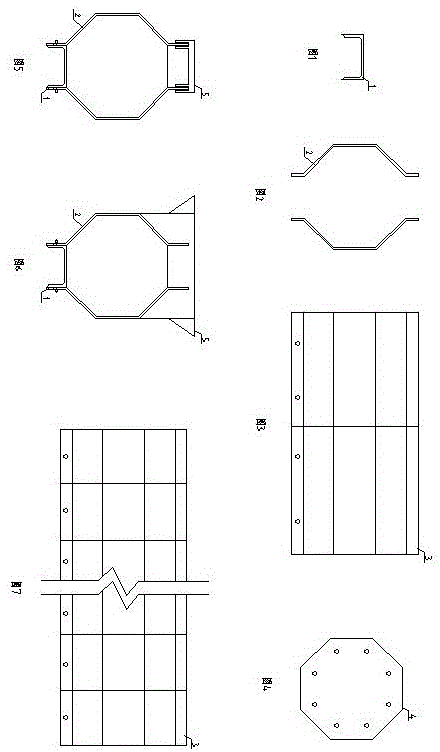

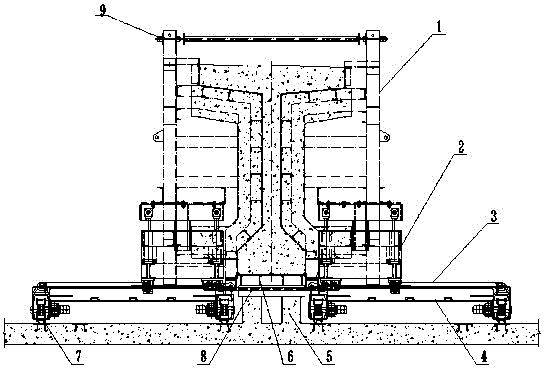

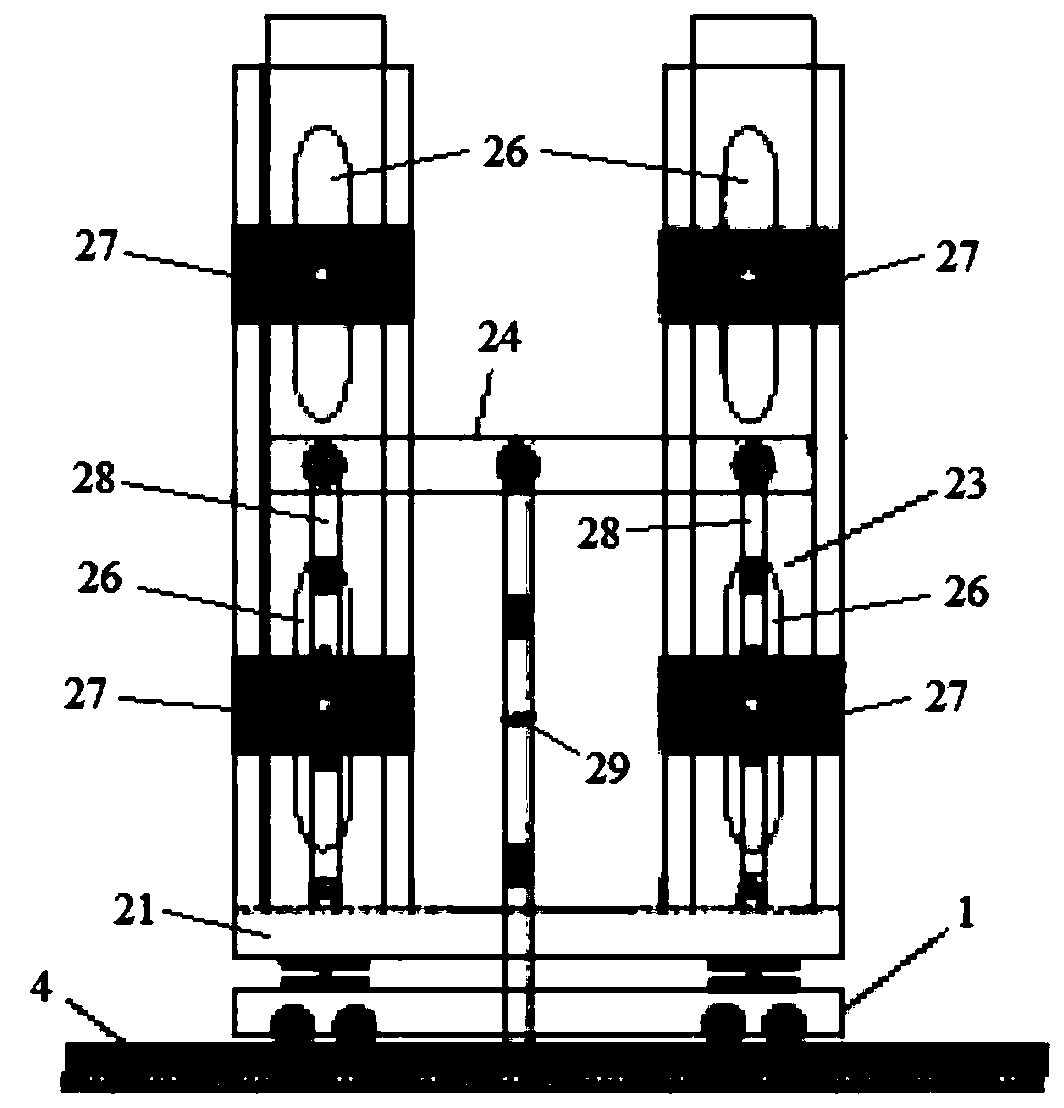

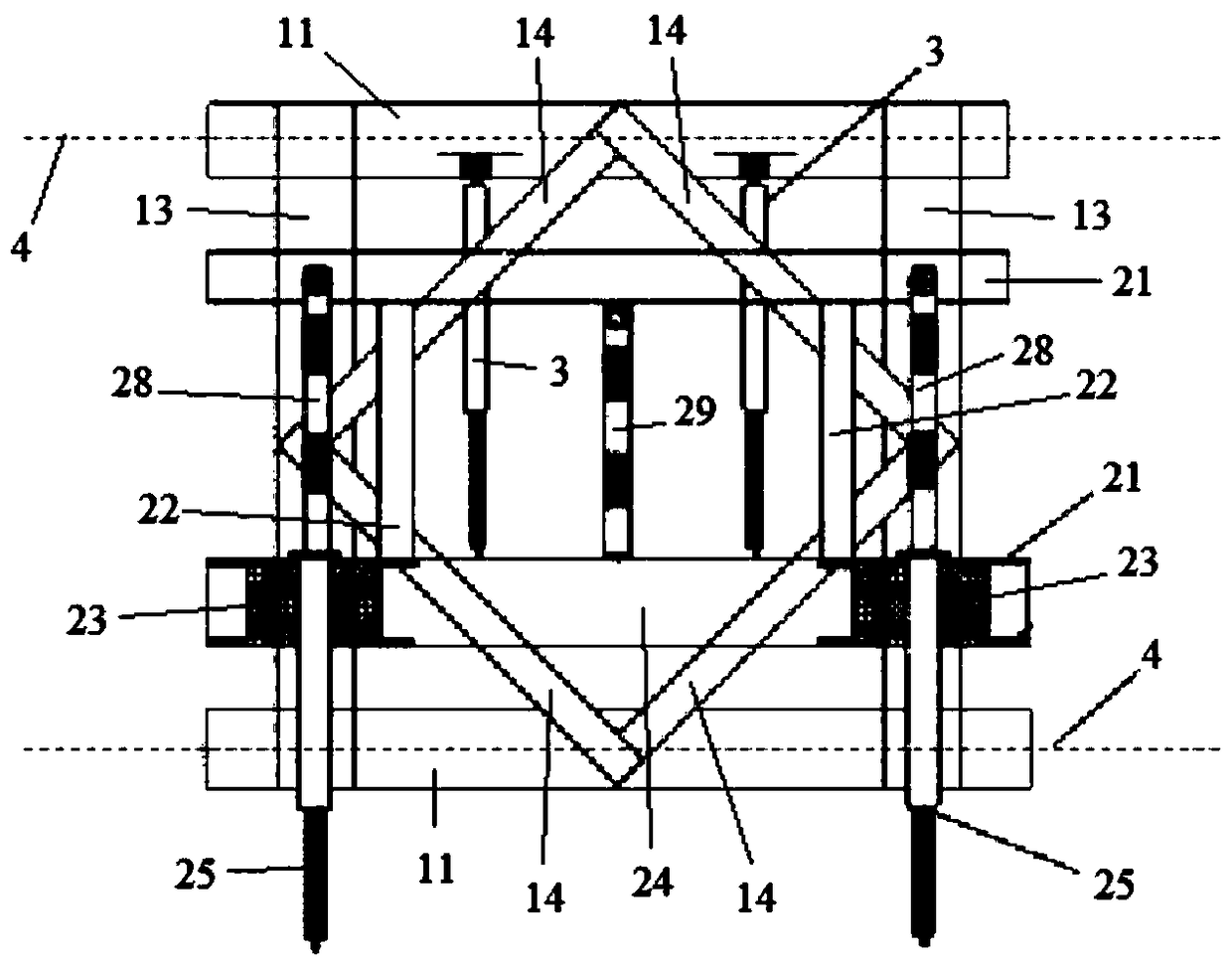

Multistation synchronous symmetric mold opening and closing mechanism of ceramic bathroom accessory

ActiveCN105291256AGuaranteed reliabilityReduce mold clamping stiffnessMould separation apparatusMouldsMechanical engineering

The invention provides a multistation synchronous symmetric mold opening and closing mechanism of a ceramic bathroom accessory. The multistation synchronous symmetric mold opening and closing mechanism comprises molds, guide rails, a translational mechanism, supporting mechanisms, a power mechanism and elastic assemblies. The molds comprise a plurality of sets of left molds and right molds which correspond to each other. The distances between the left molds and the right molds in all sets are equal. The supporting mechanisms comprise the left supporting mechanism and the right supporting mechanism which are connected to the left molds and the right molds respectively, and the supporting mechanisms move on the guide rails through the translational mechanism. The power mechanism is used for driving the translational mechanism to drive the supporting mechanisms to move on the guide rails. The elastic assemblies are arranged on the supporting mechanisms. It is guaranteed that the multistation opening and closing mechanism has the unified mold opening and closing time, so that green bodies are stressed evenly, the quality of grouting forming products is improved, and the reject ratio is lowered.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

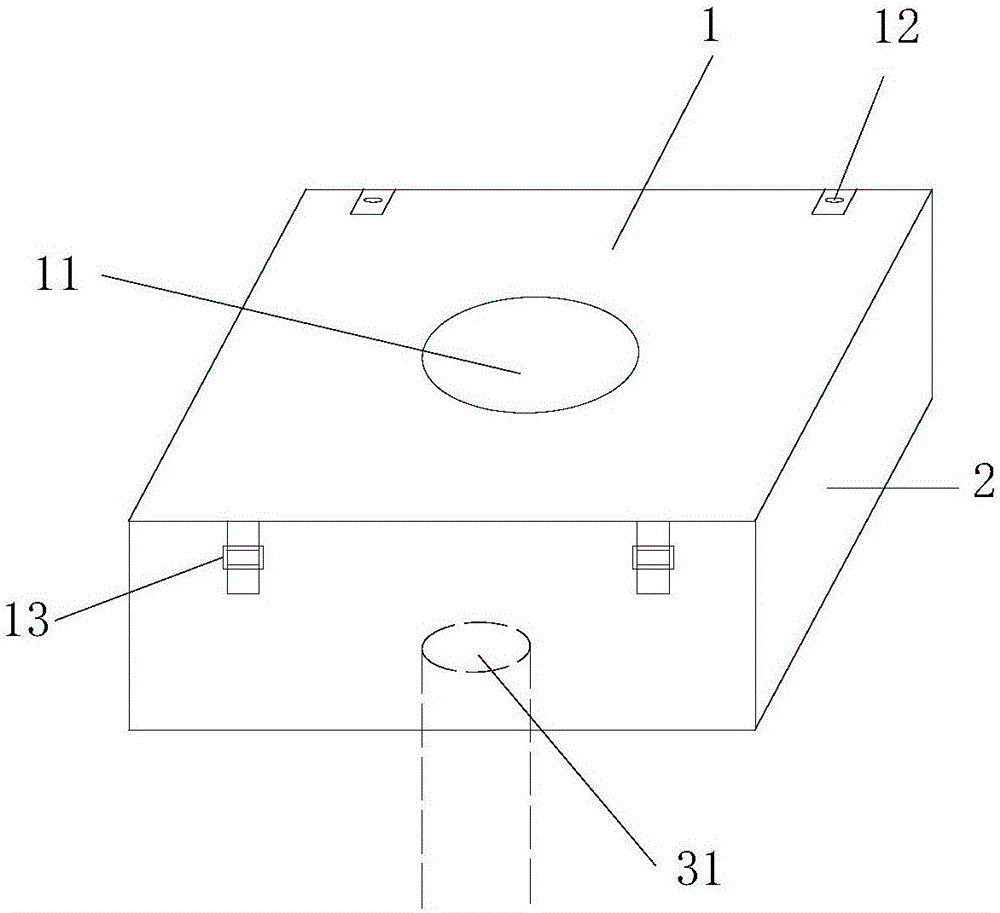

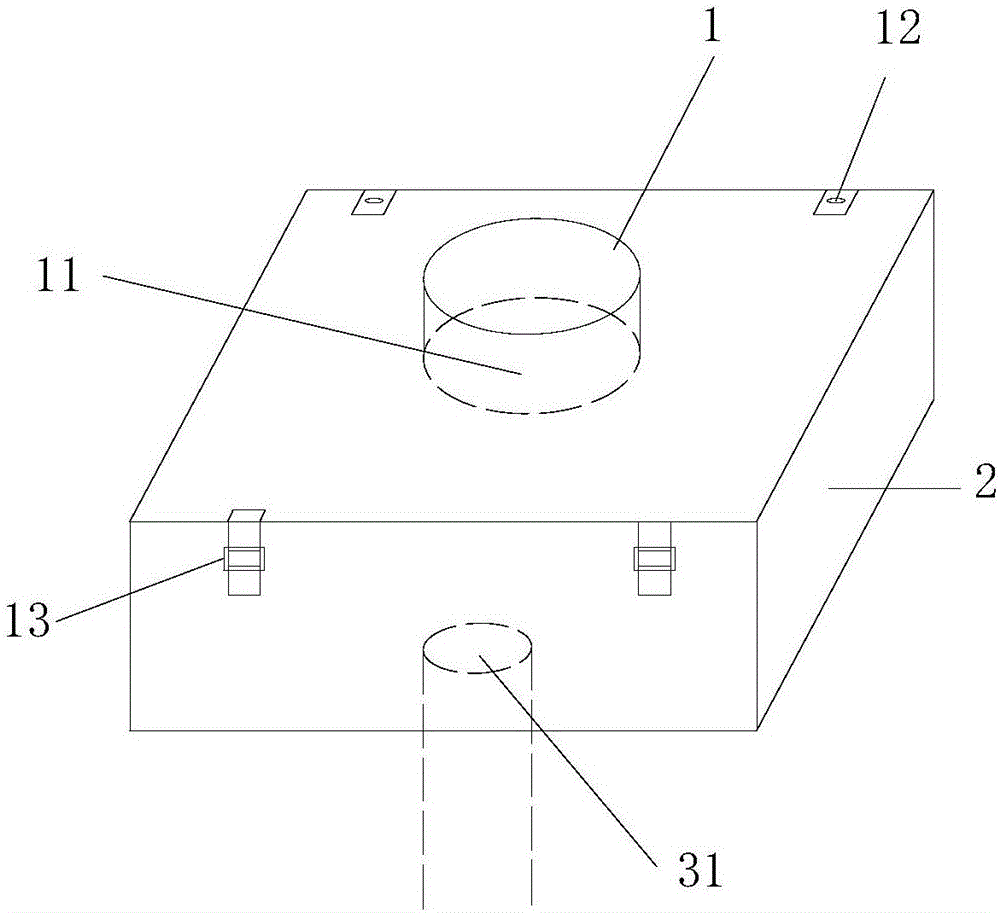

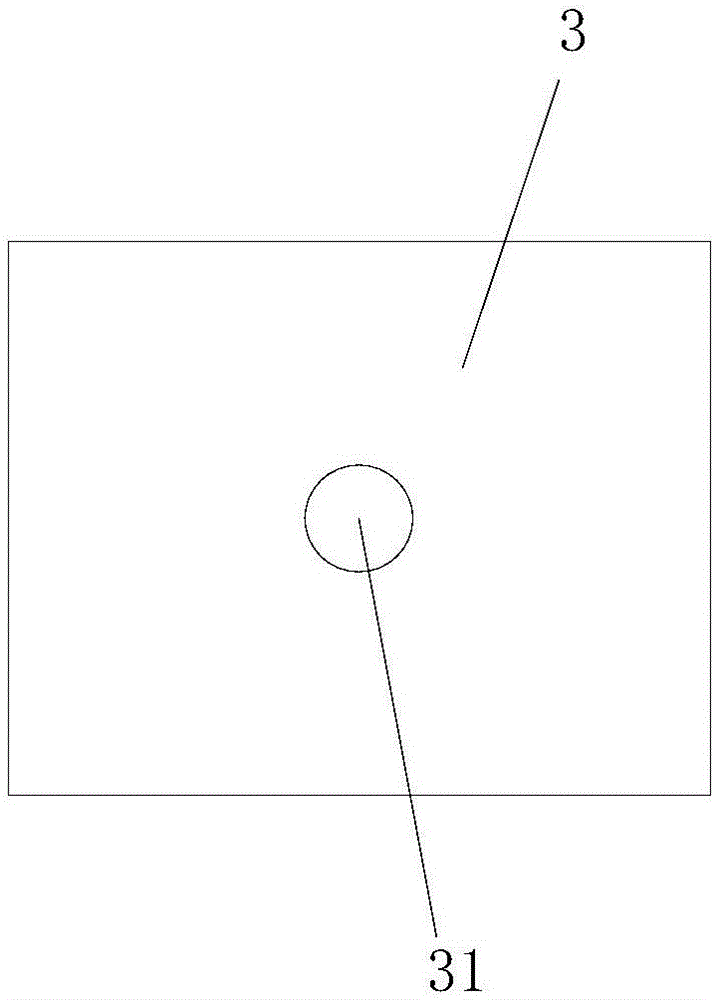

Die and process for producing ceramsite foamed precast concrete

ActiveCN106166788AAvoid floating on the surfaceEvenly distributedMoulding surfacesMould auxillary partsEngineeringPrecast concrete

The invention discloses a die for producing ceramsite foamed precast concrete. The die comprises a top cover, a side template and a base plate which are arranged in the vertical direction in sequence, wherein the side template surrounds the top cover and the base plate and is connected with the top cover and the base plate, the top cover is provided with an overflow hole, and a residual grout pipe is connected to the upper side of the overflow hole; the inner diameter of the overflow hole is 3-5 cm, and the height of the overflow hole is 10-15 cm; a screen net is arranged at the position where the overflow hole is connected with the residual grout pipe, and the aperture of the screen net is smaller than the grain size of ceramsite; a grouting hole is formed in the base plate. The invention further provides a process for producing ceramsite foamed precast concrete. By the adoption of the die and process, a traditional method that mixing is conducted first and then grouting is conducted is replaced, grouting and mixing are conducted at the same time, ceramsite floating is prevented through pre-compacting and the blocking action of the top cover, so that ceramsite is distributed uniformly, ceramsite mixing amount is the largest, the heat insulation property and sound insulation property of the ceramsite foamed precast concrete are improved, and the overall quality of products is improved.

Owner:HUAIHAI INST OF TECH

Mould for preparing H-shaped concrete pile

InactiveCN105643776AEasy to clean and maintainEasy to manufactureMouldsOrnamental structuresEngineeringH shaped

The invention relates to a mould for preparing an H-shaped concrete pile. The mould comprises a frame body, a right mould plate, a left mould plate, a lower mould plate and a driving structure; the mould is characterized in that the frame body comprises a fixed seat, a left moving seat and a right moving seat, the left moving seat and the right moving seat are restrained to the left side and the right side of the fixed seat and can slide left and right, the left mould plate is hinged to the left moving seat, the right mould plate is hinged to the right moving seat, and the lower mould is fixed to the fixed seat; the driving structure comprises a transverse driving portion used for driving the left moving seat and the right moving seat to slide relative to the fixed seat and a turning driving portion used for driving the left mould plate to be vertically turned relative to the left moving seat and driving the right mould plate to be vertically turned relative to the right moving seat. When demoulding is performed, the left mould plate and the right mould plate can be synchronously and outwards moved until convex portions in all mould cavities are completely separated from the moulded H-shaped concrete pile, then the left mould plate and the right mould plate can be smoothly turned, and clamping stagnation cannot completely occur when the left mould plate and the right mould plate are turned.

Owner:俞晓东

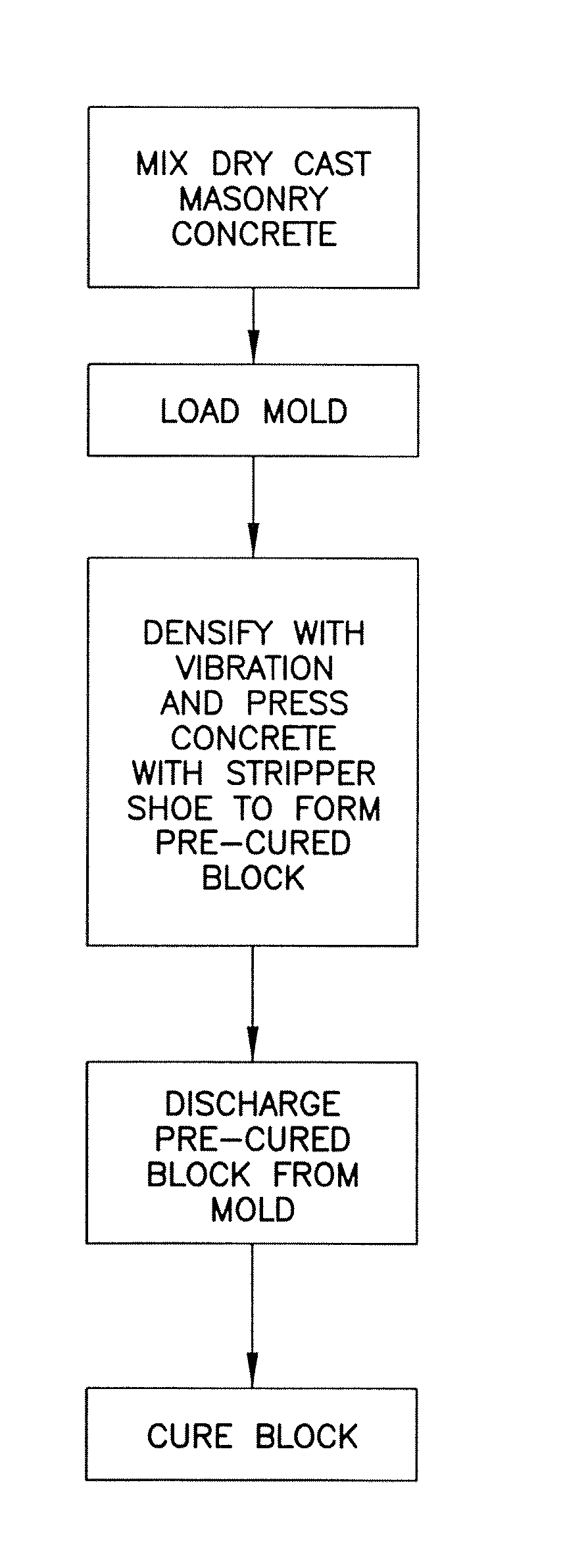

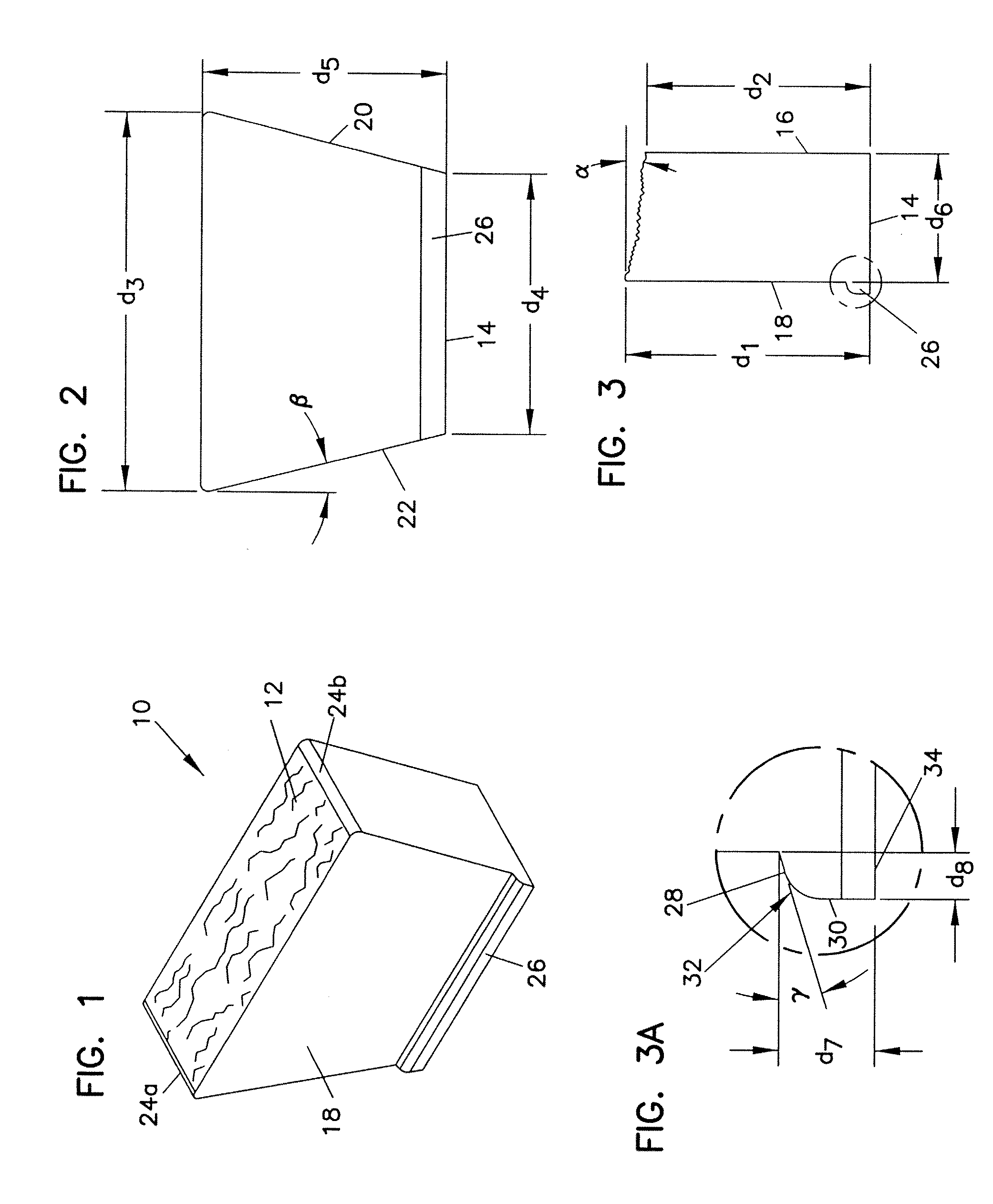

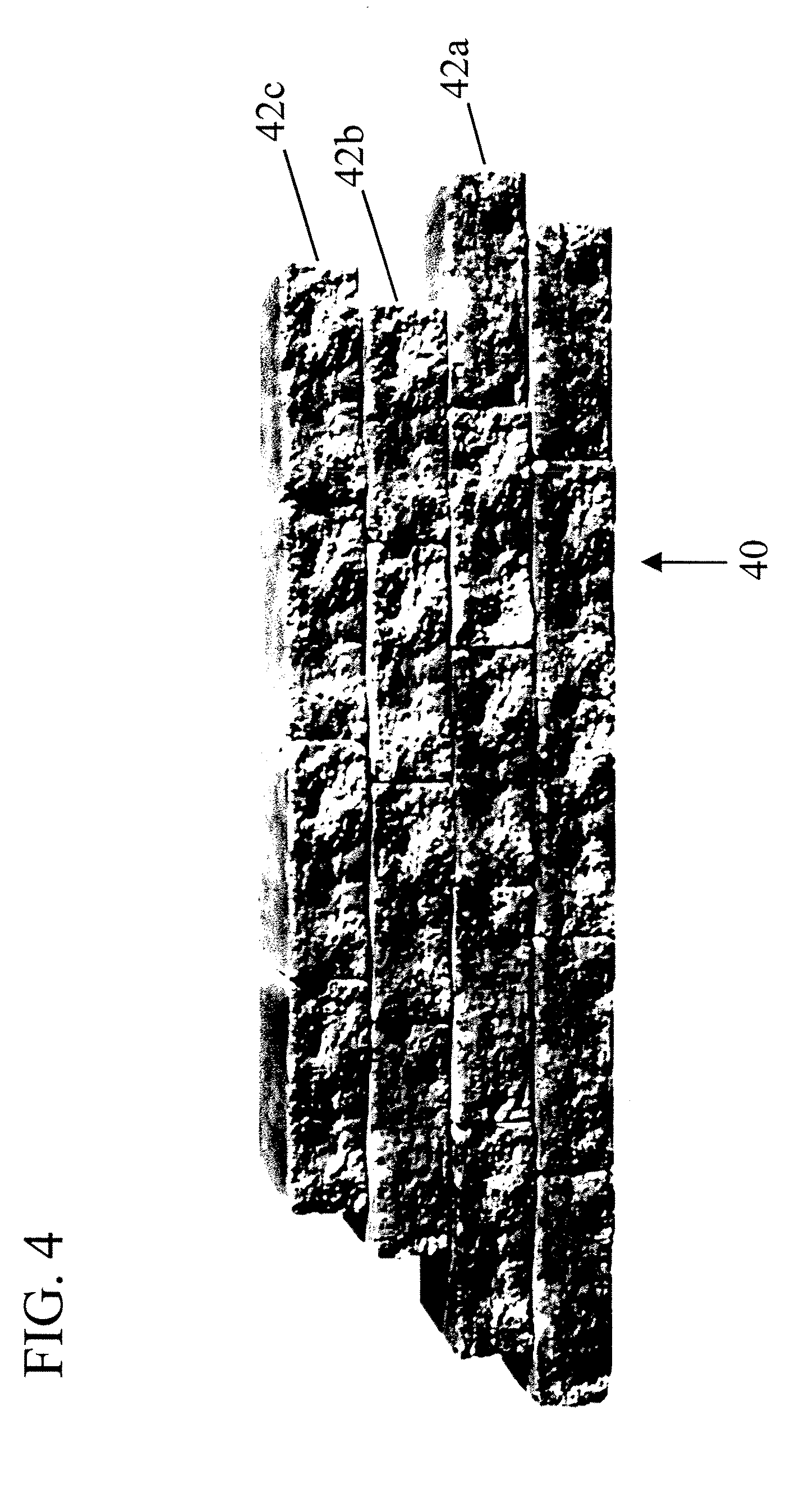

Concrete block and method of making same

Owner:ANCHOR WALL SYST

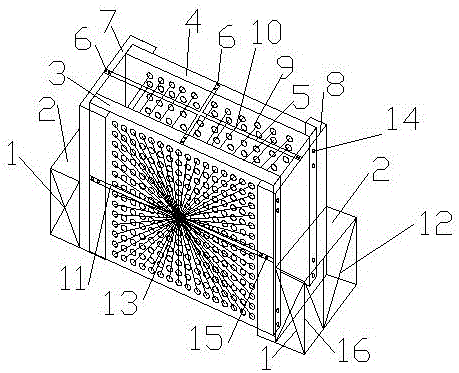

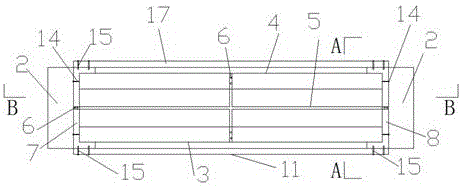

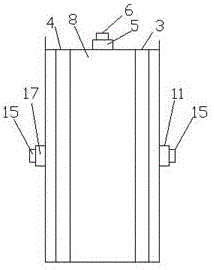

Prefabricated light transmitting concrete plate production mold and manufacturing method thereof

ActiveCN105818252AHigh light transmittanceStable structureMould separation apparatusMouldsOptical transmittanceEngineering

The invention discloses a prefabricated light transmitting concrete plate production mold and a manufacturing method thereof, and belongs to the technical field of concrete. The prefabricated light transmitting concrete plate production mold comprises a front pedal, a left side template, a right side template, a cross pull support, pull support fixed bolts, a back side U-shaped steel template, a front side U-shaped steel template, optical fiber holes, optical fibers, left side straight pull supports, combined bolts, straight pull support fixed bolts and right side straight pull supports; the front pedal includes a transverse inclined support, a bearing plate, an inclined rod and a vertical rod; the left side straight pull supports are fixed at the middle parts of the left sides of the front side U-shaped steel template and the back side U-shaped steel template through the straight pull support fixed bolts; multiple optical fibers are provided; each optical fiber penetrates through the optical fiber hole in the right side template and the optical fiber hole in the left side template in sequence; and the two ends of the optical fibers are respectively tensioned and fixed on hook rings in the left side straight pull supports and hook rings in the right side straight pull supports. The prefabricated light transmitting concrete plate production mold can realize industrial production of light transmitting concrete plates; and the manufacturing method is safe and reliable, and can obtain the prefabricated concrete plates with high light transmittance.

Owner:CHINA MCC17 GRP

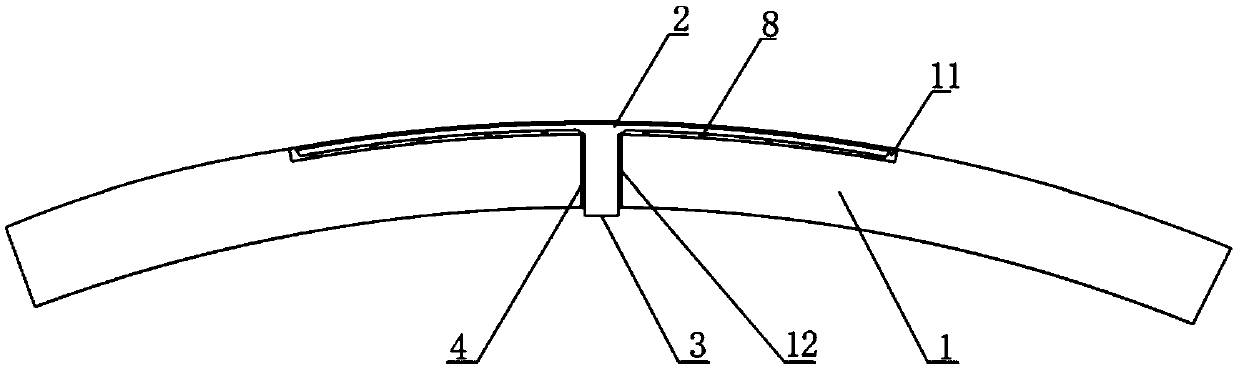

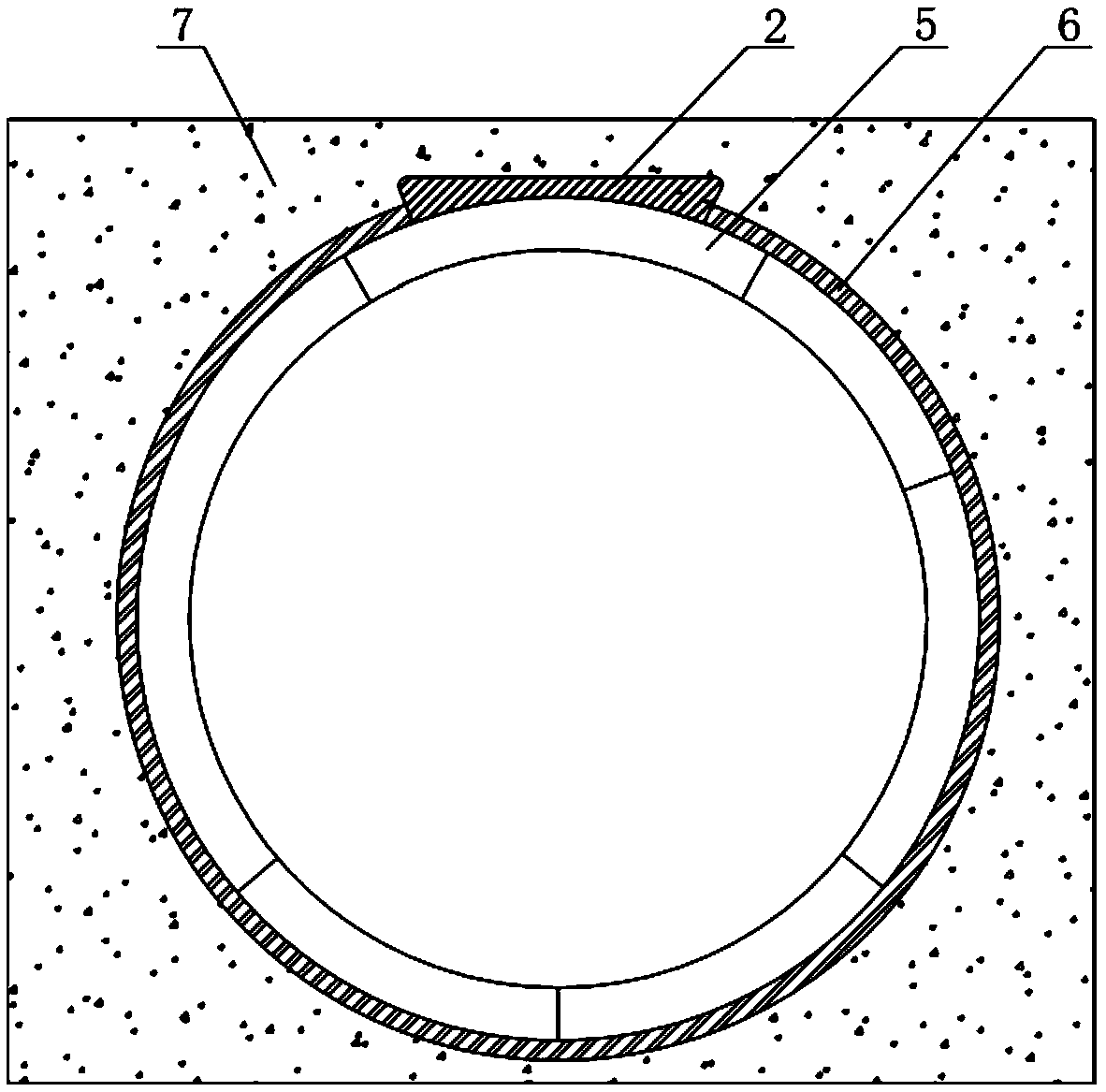

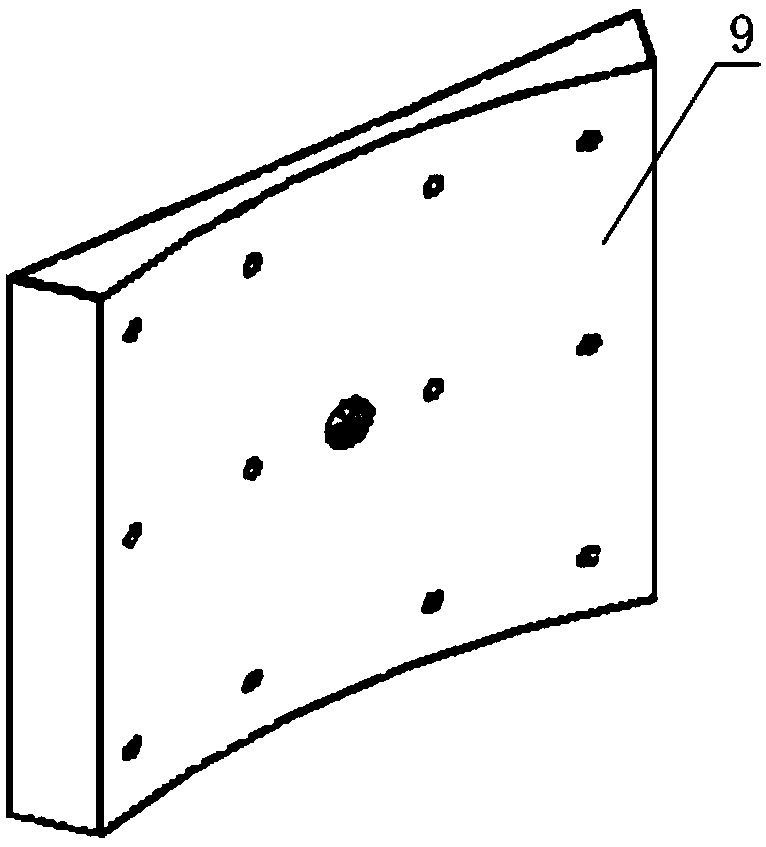

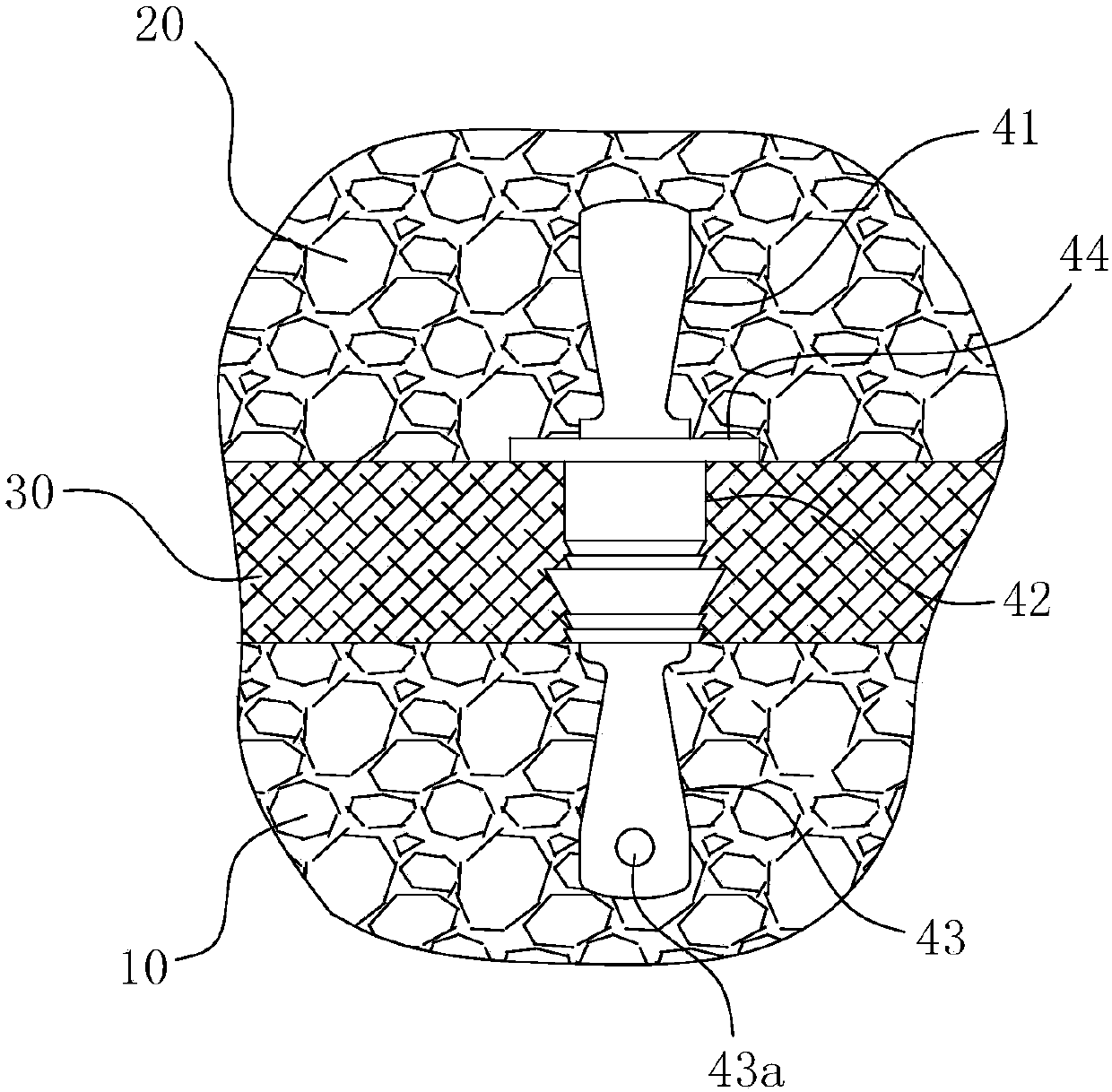

Shield tunnel anti-floating segment and processing and applying methods thereof

ActiveCN109653767ASimple preparation processReduce construction difficultyUnderground chambersMould panelsShield tunnelingPipe

The invention provides a shield tunnel anti-floating segment and processing and applying methods thereof and relates to the technical field of shield tunnel construction. The shield tunnel anti-floating segment comprises a top segment, the outside of the top segment is provided with a groove inside which a grout pocket is fixed, the grout pocket is made of flexible materials, the bottom of the groove is provided with a grouting hole penetrating through the top segment, and the grouting hole is fixedly provided with a grouting pipe communicated with the grout pocket. The shield tunnel anti-floating segment solves the problem of floating of lining rings of shield tunnel segments in the prior art.

Owner:SOUTHWEST JIAOTONG UNIV

Through bar type concrete composite floor slab structure and manufacturing and assembling method thereof

The invention relates to the field of assembled concrete buildings, in particular to a through bar type concrete composite floor slab structure and a manufacturing and assembling method thereof. The structure comprises prefabricated base plates, longitudinal stressed steel bars, reserved transverse stressed steel bar grooves, hogging moment steel bars, transverse stressed steel bars and the like. Due to the fact that transverse stressed steel bars of the unique prefabricated base plates are continuous, additional connecting measures and additional connecting steel bars are not needed for connection of the prefabricated base plates, construction is simplified, materials are saved, and the integrity of composite slabs is greatly strengthened. The reserved transverse stressed steel bar grooves of the through bar type concrete composite floor slabs reinforce shear resisting and tensile resisting connection of a cast-in-place concrete layer and the prefabricated base plates, and the overall performance of the composite slabs is greatly improved. The transverse stressed steel bars of the through bar type concrete composite floor slab structure are placed in the reserved transverse stressed steel bar grooves formed in the prefabricated base plates, maximum approximating to the prefabricated base plates is achieved, and the anti-bending stress performance of the prefabricated base plates can be same as the performance of cast-in-place slabs.

Owner:SHENYANG SANXIN IND

Concrete prefabricated floor slab pouring forming device

The invention discloses a concrete prefabricated floor slab pouring forming device. The concrete prefabricated floor slab pouring forming device comprises a base, fixed side formworks, split side formworks and an adjusting sliding seat, wherein a square bottom plate of a square structure is arranged on the base; the fixed side formworks are rotatably connected to the four edges of the square bottom plate through connecting rotating shafts; the split side formworks are connected into a whole through folding rotating shafts and vertically arranged on the upper surface of the square bottom plate;and a connecting sleeve is arranged in the middle of the adjusting sliding seat, and a hexagonal fixing rod is arranged in the middle of the connecting sleeve in a nested mode. According to the concrete prefabricated floor slab pouring forming device, a prefabricated floor slab pouring formwork is formed through the square bottom plate and the fixed side formworks, the split side formworks arranged on the inner sides of the fixed side formworks are connected into a whole through the folding rotating shafts, the multiple split side formworks are spliced through folding and fixed through the hexagonal fixing rod, thus the sizes of the two side edges of the formwork can be adjusted, the pouring size of a prefabricated floor slab is adjusted accordingly, adjusting is convenient and rapid, andthe applicability and using flexibility of the device are improved advantageously.

Owner:颍上晶宫绿建节能建筑有限责任公司

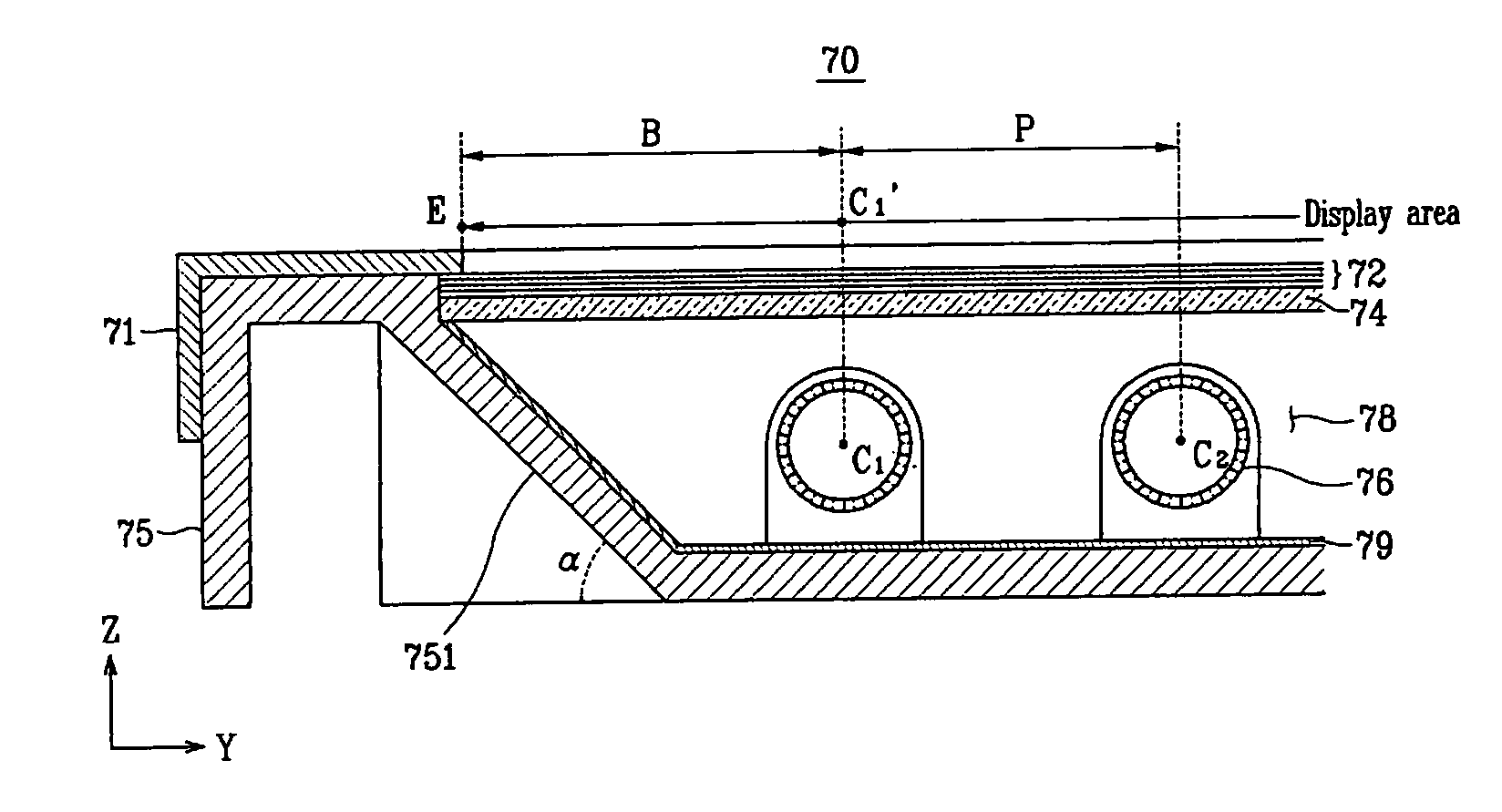

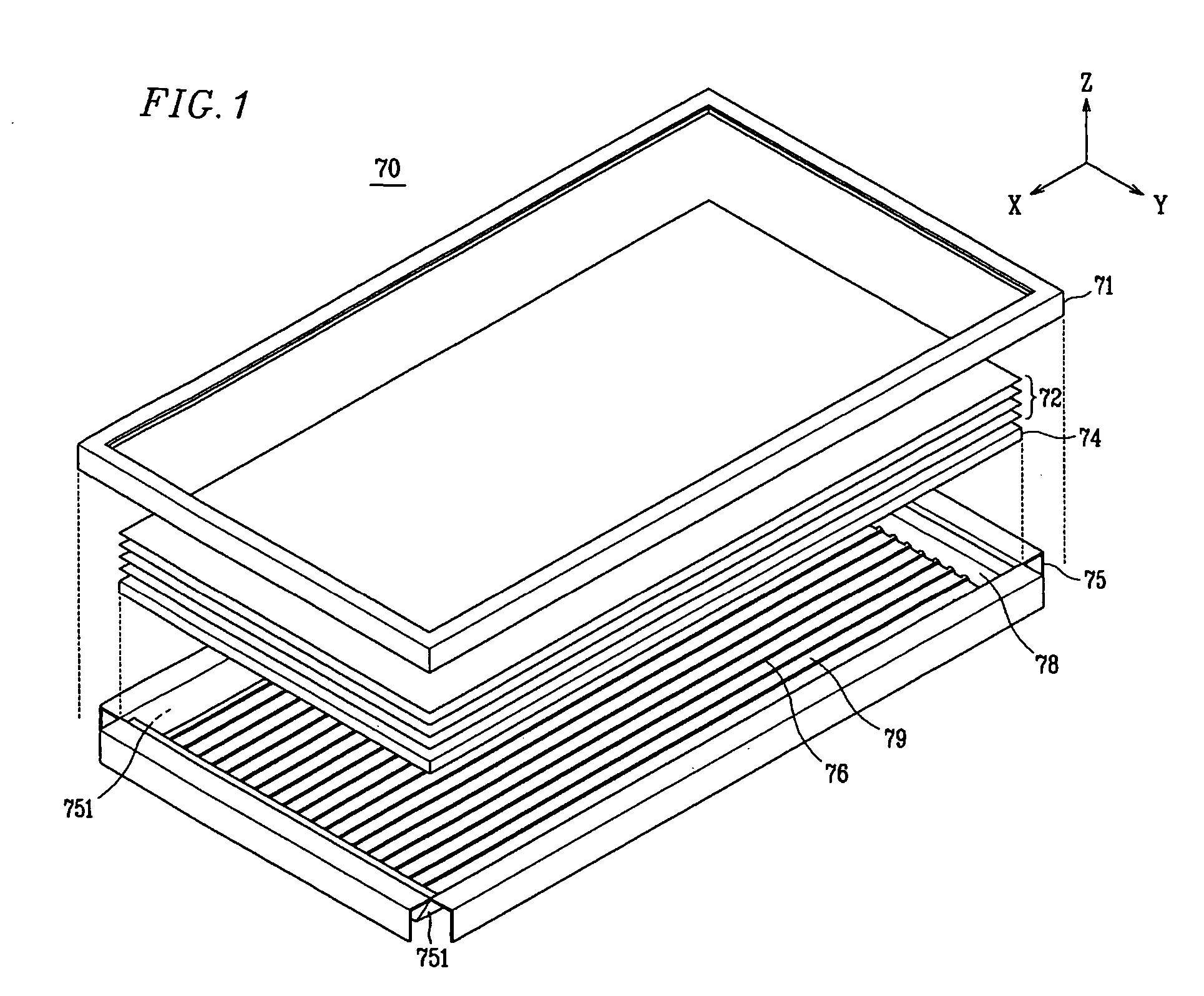

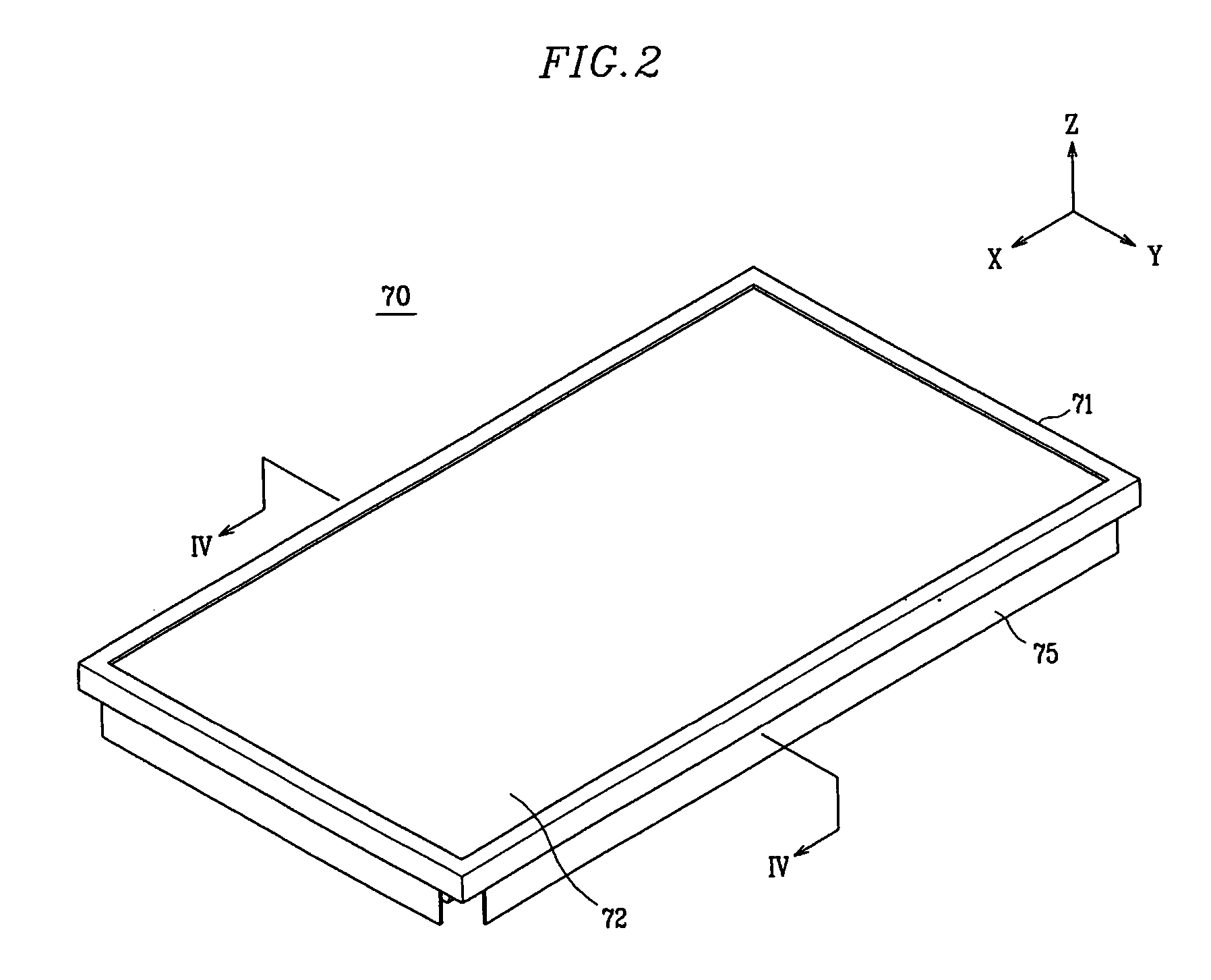

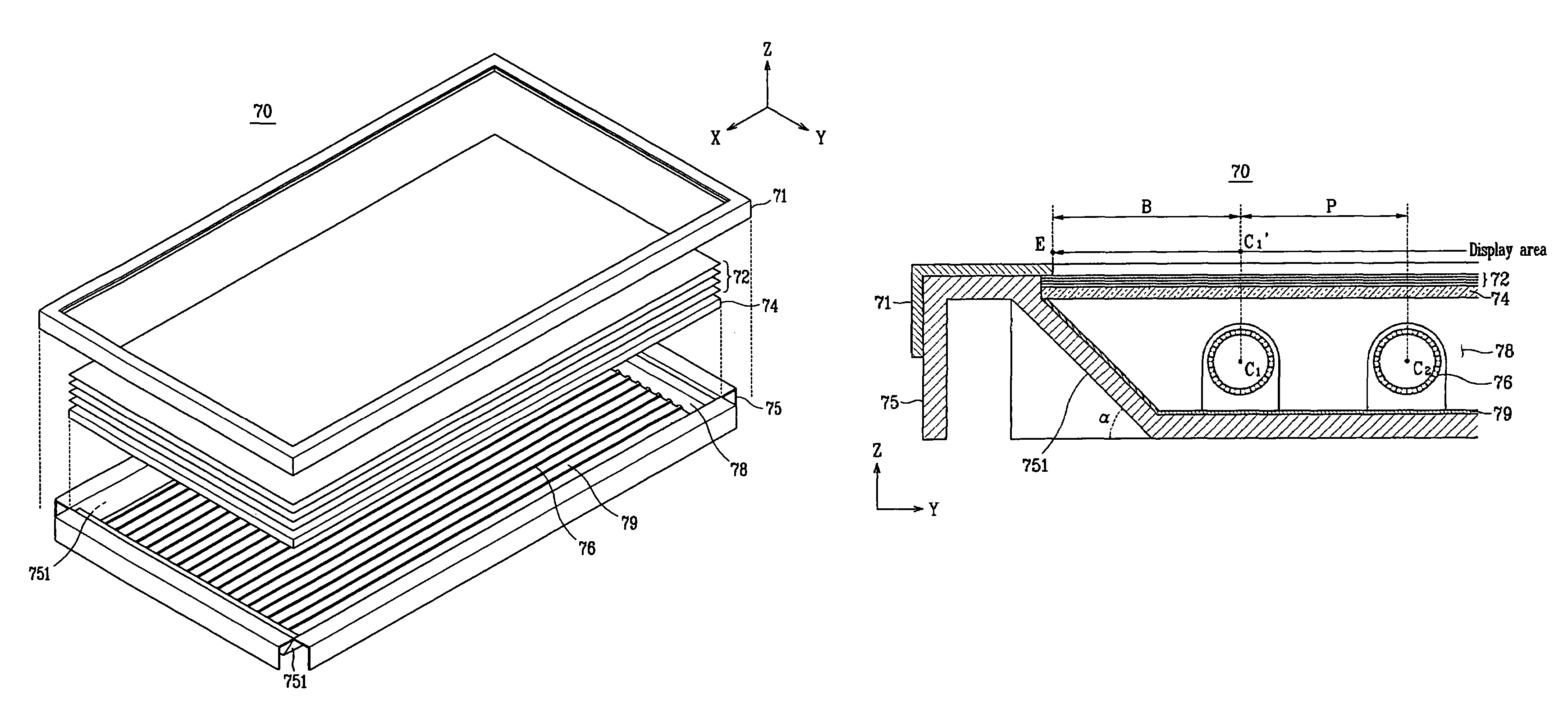

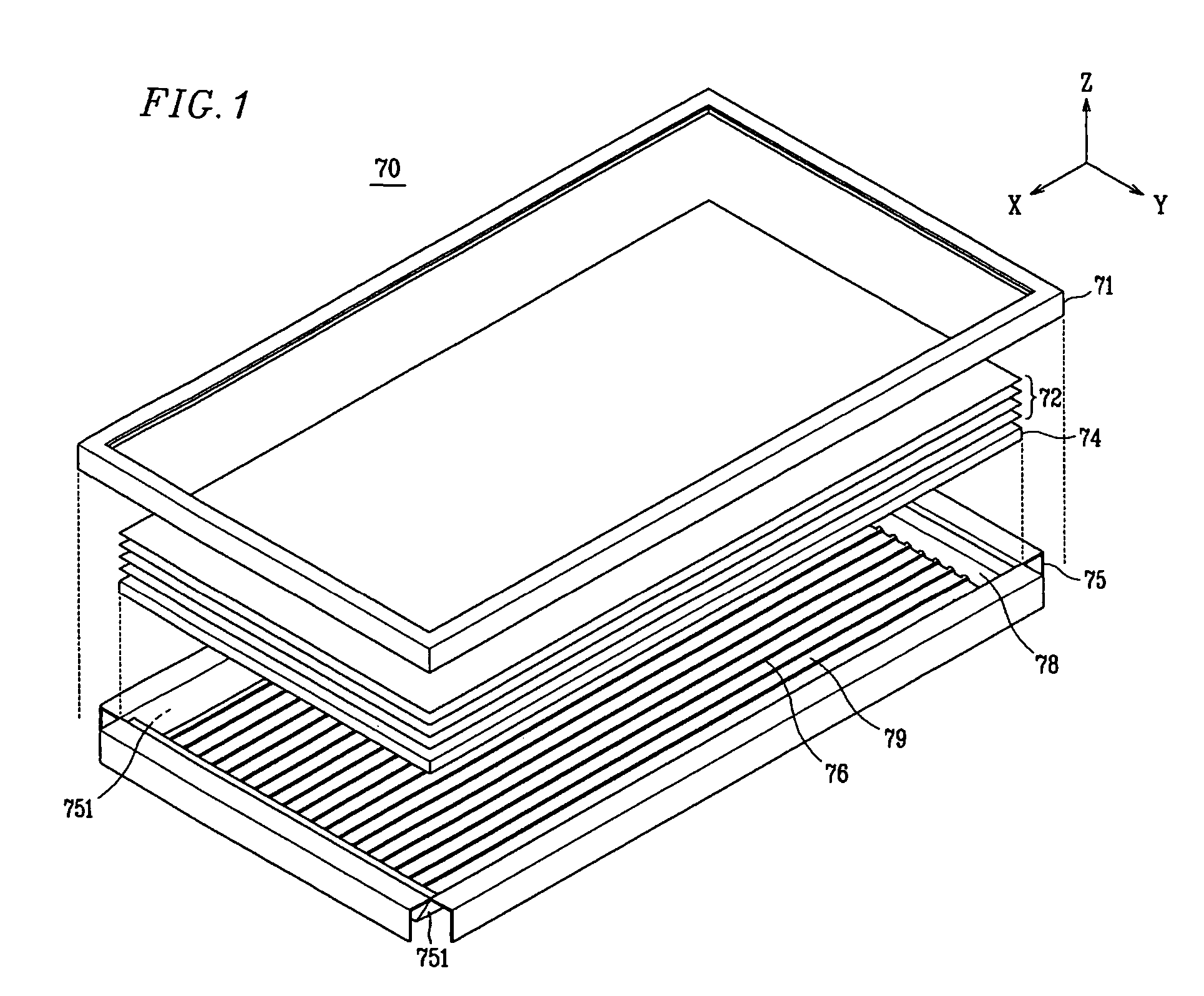

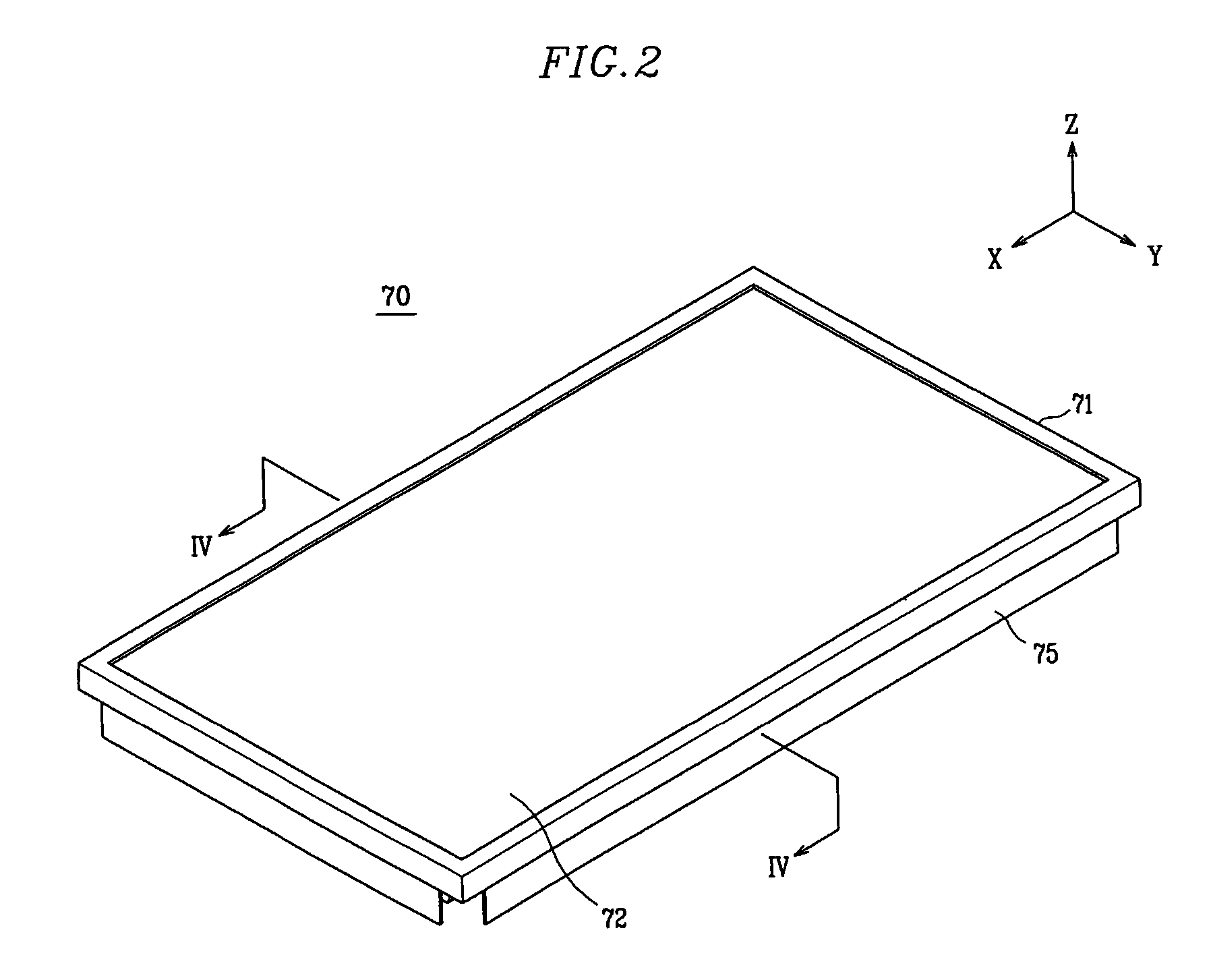

Backlight assembly with excellent light efficiency and display device having the same

ActiveUS20060203464A1Improve lighting efficiencyPoint-like light sourceLighting support devicesDisplay deviceOptoelectronics

A backlight assembly with excellent light efficiency and a display device provided with the backlight assembly is provided where the backlight assembly includes a plurality of light sources longitudinally arranged in parallel to each other, and a fixing member receiving the plurality of light sources. When a display area, formed by light emitted from the plurality of light sources, is divided by the plurality of light sources into a plurality of display area sections, an average area of the display area sections between light sources adjacent to each other is less than or equal to an area of a display area section between an edge of the display area and the light source most adjacent thereto.

Owner:SAMSUNG DISPLAY CO LTD

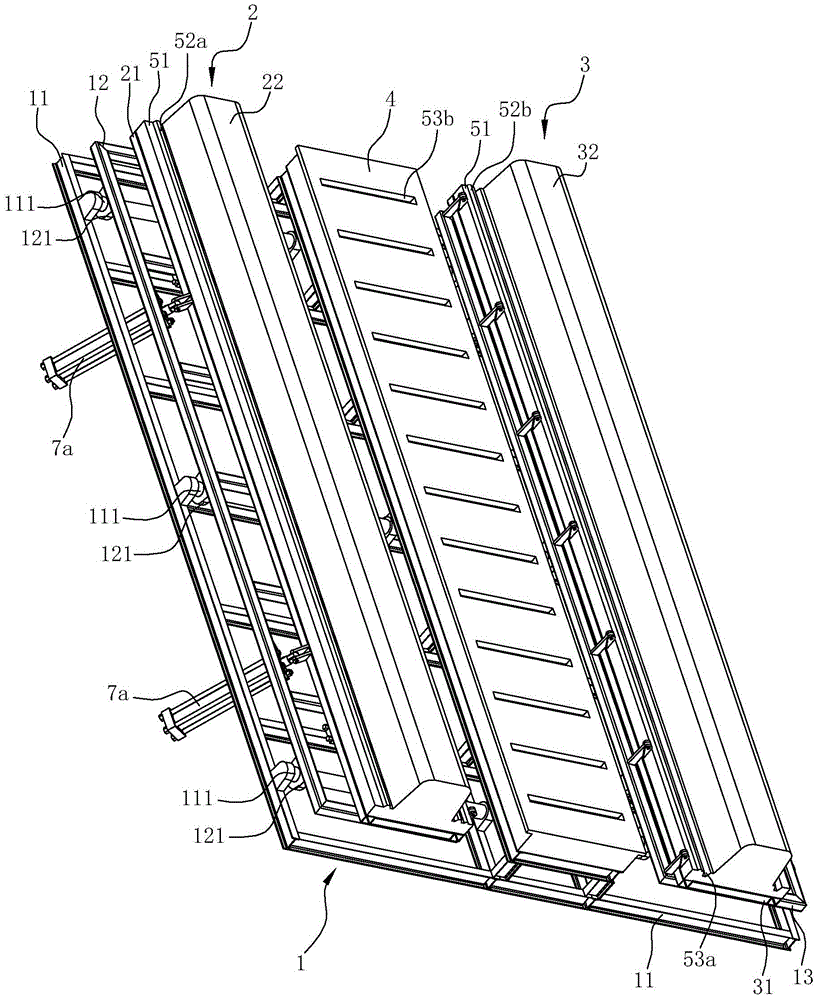

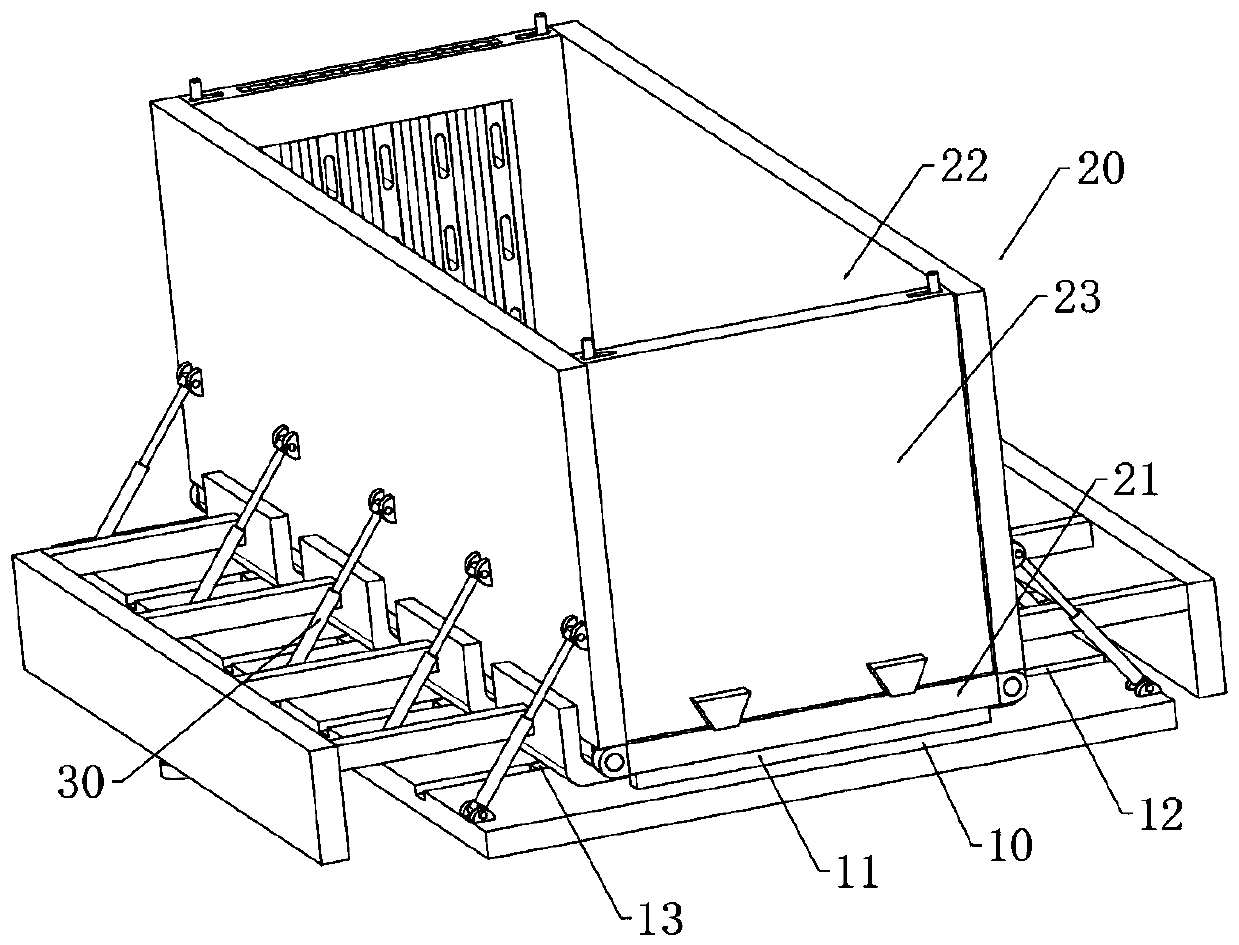

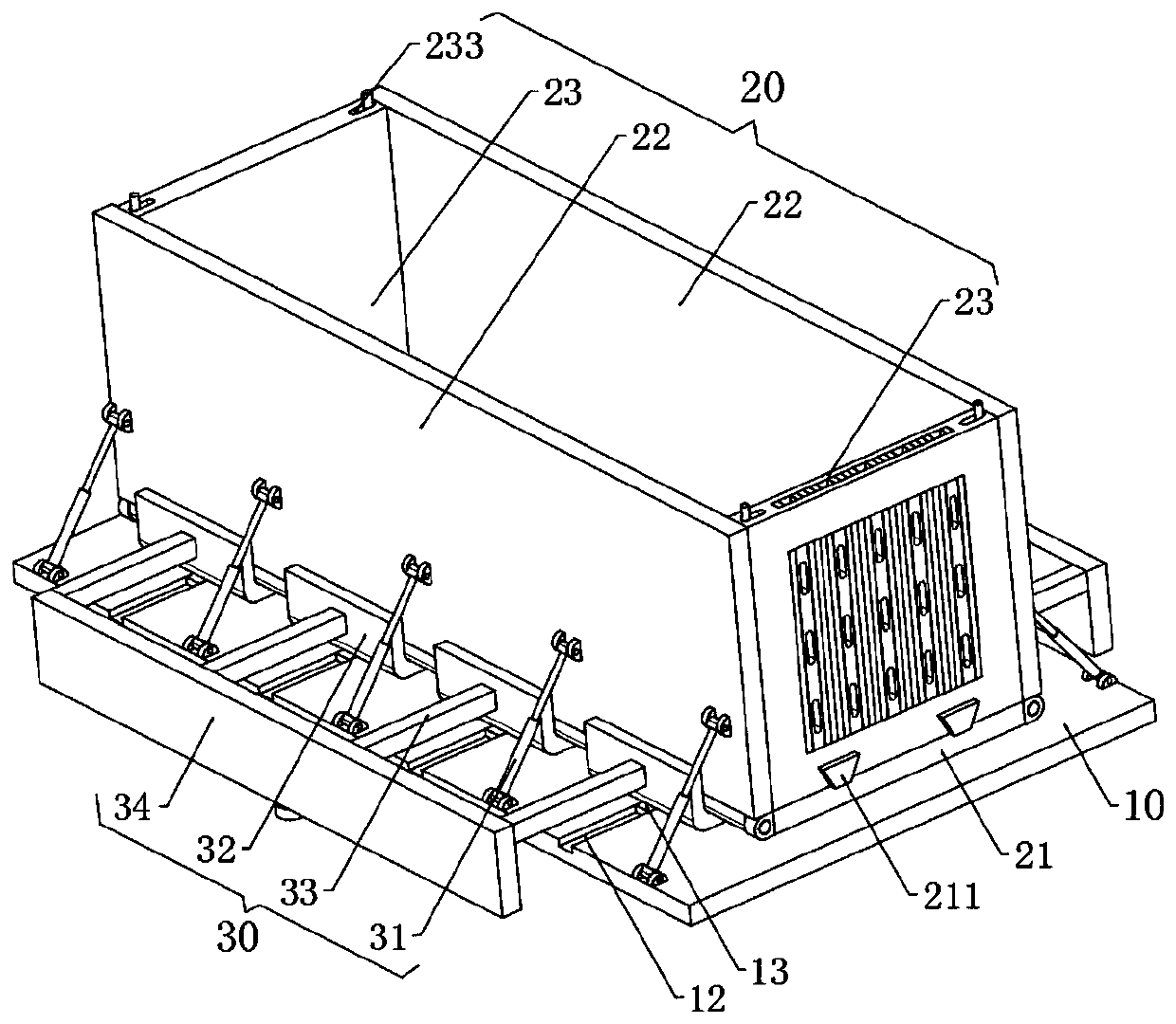

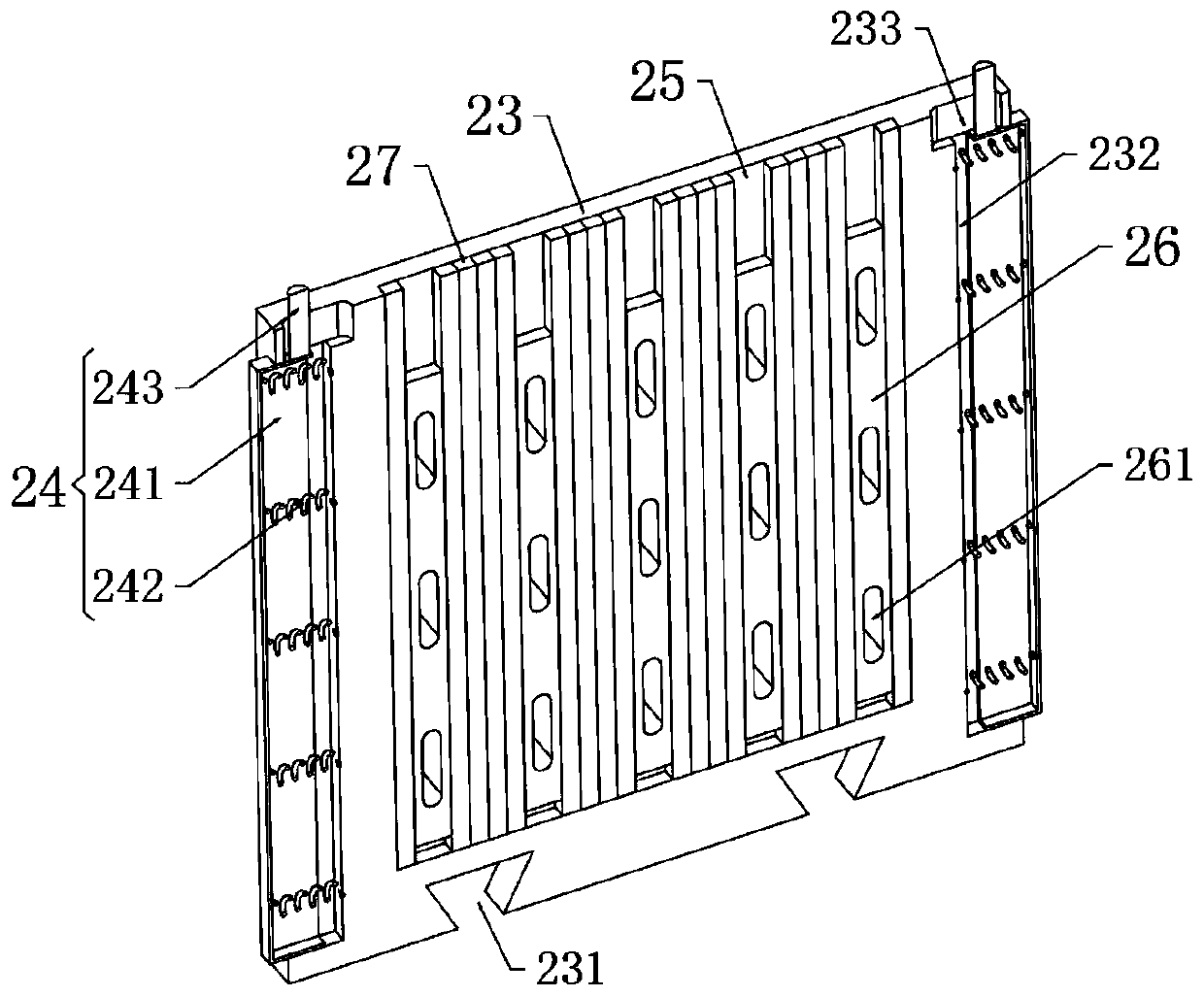

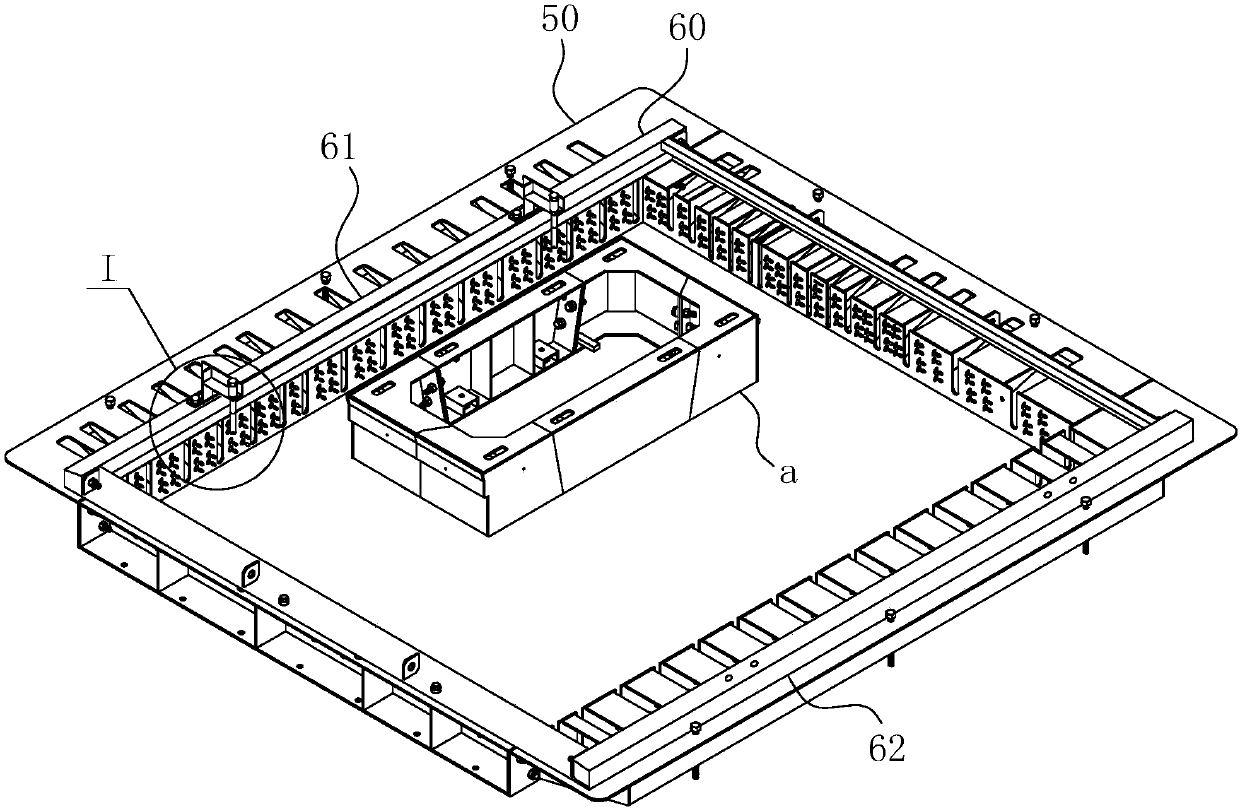

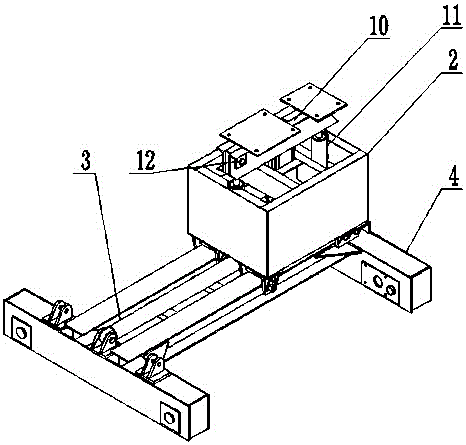

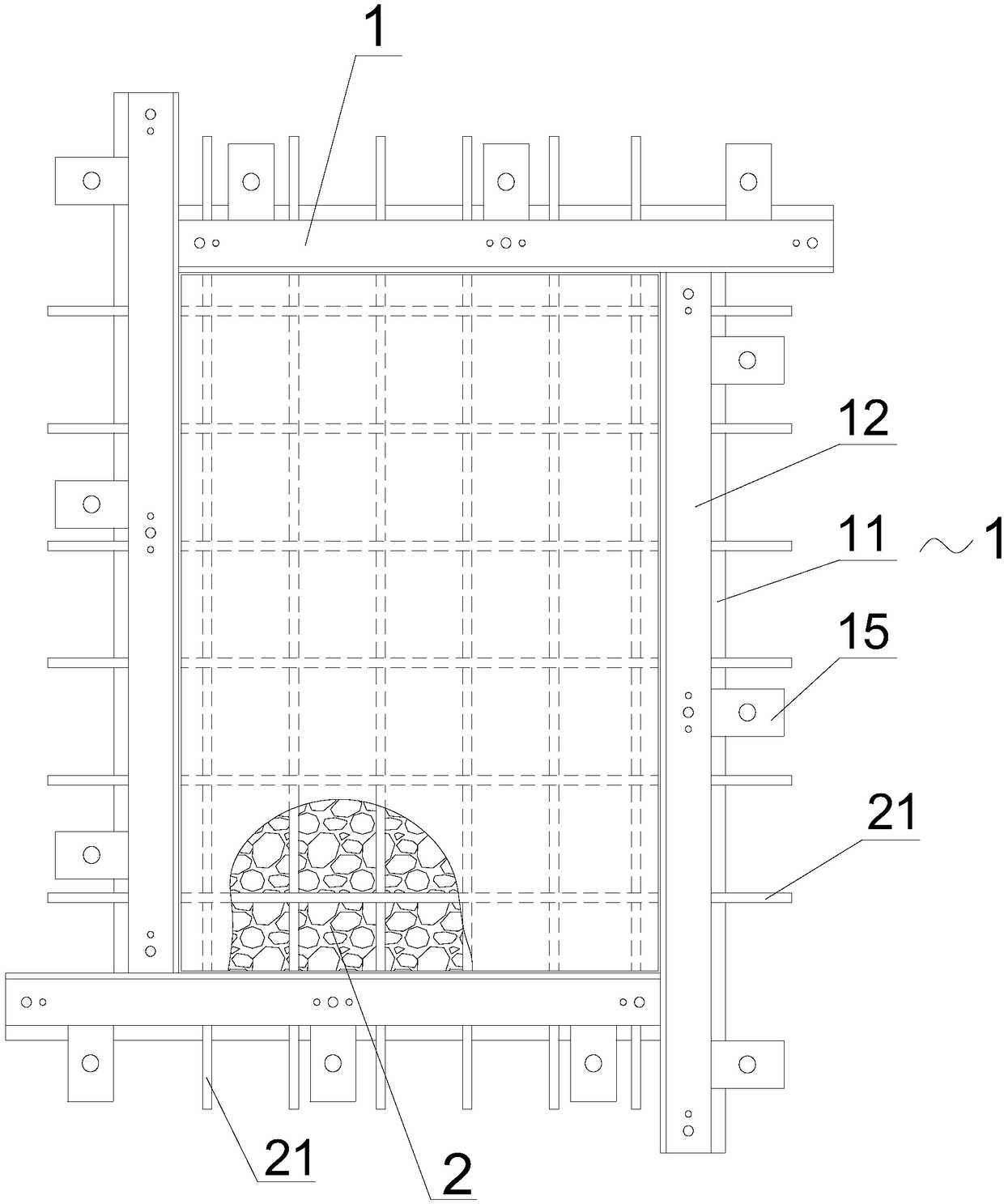

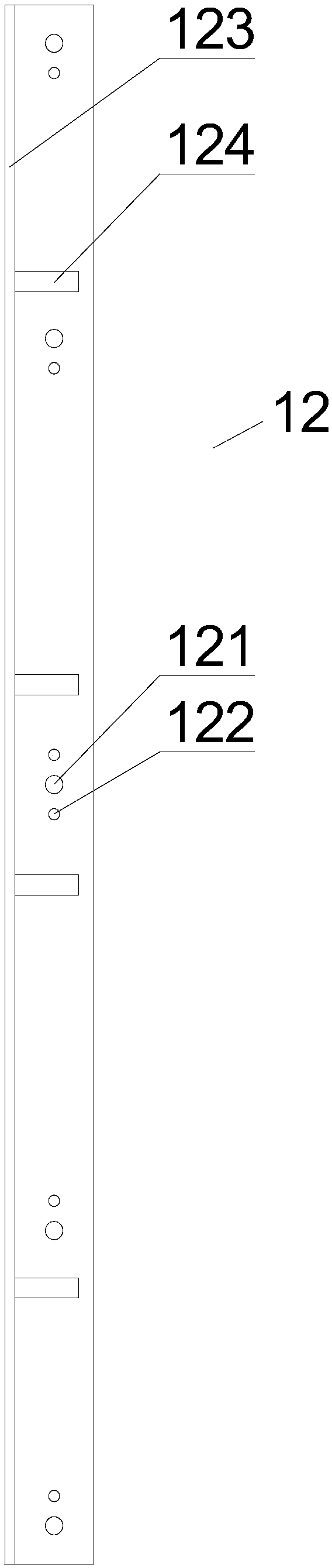

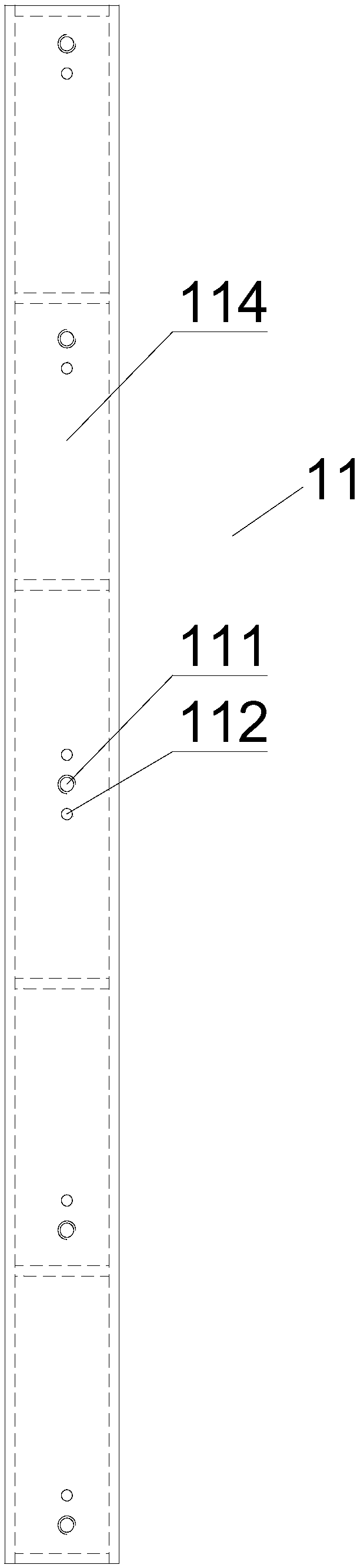

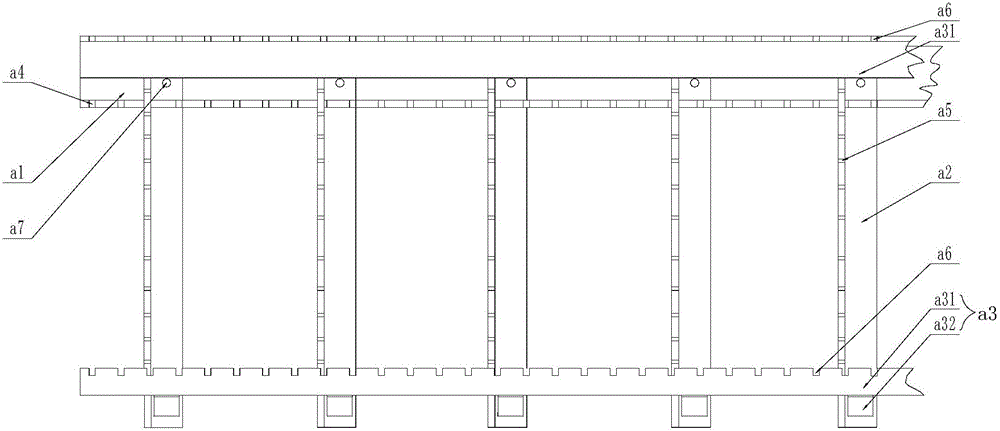

Vertical combination mold for production of precast concrete component

The invention discloses a vertical combination mold for production of a precast concrete component. A movable mounting rack and guide rails are connected in a sliding and guiding fit mode. The movable mounting rack is connected with a driving mechanism for driving the movable mounting rack to move. A fixed vertical mold is arranged on a fixed mounting rack. A movable vertical mold is arranged on the movable mounting rack. The guide rails are perpendicular to the fixed vertical mold. Movable side molds and movable top molds are arranged between the fixed vertical mold and the movable vertical mold. The movable side molds are arranged in the vertical direction and arranged on the outer side of a first side edge and the outer side of a second side edge of the fixed vertical mold respectively. The fixed vertical mold, the movable vertical mold, the movable side molds and the movable top molds define a mold cavity for accommodating the precast concrete component. The vertical combination mold has the advantages that the structure is simple, operation is convenient, time and space are saved, the labor intensity and cost are reduced, the labor efficiency is high, and the surface evenness of manufactured products is good; the vertical combination mold better makes up for the deficiency of production at the present stage and can be widely used for production of precast components.

Owner:安徽海龙建筑工业有限公司

Forming die for manufacturing reinforced concrete prefabricated columns of fabricated building

ActiveCN111546467APlay a supporting roleImprove support strengthMoulding surfacesMould auxillary partsReinforced concreteArchitectural engineering

The invention relates to a forming die for manufacturing reinforced concrete prefabricated columns of a fabricated building. The forming die comprises a workbench and a die arranged above the workbench, wherein the die comprises a bottom plate fixed on the workbench, side plates hinged to the two sides of the bottom plate and end plates slidably arranged at the two ends of the bottom plate, the workbench is fixedly connected with the bottom plate through supporting plates, and supporting devices are arranged at the positions, on the two sides of the bottom plate, of the top of the workbench. According to the forming die, oil cylinders and L-shaped plates which are arranged in a crossed manner are used to jointly support the side plates and the bottom plate, the supporting strength is increased, and meanwhile, the L-shaped plates can be synchronously separated under the driving of electric push rods during demoulding; and first rectangular plates and second rectangular plates are arranged on a group of end plates, the number of groups of second rectangular plates between two adjacent groups of first rectangular plates is increased or reduced to change the spacing between the first rectangular plates, and waist-shaped holes are formed at different heights of the first rectangular plates, so as to adapt to steel bar frameworks in different arrangement manners to pass through.

Owner:扬州通惠系统集成科技有限公司

Prefabricated wall plate with heat preservation interlayer and manufacturing method thereof

PendingCN107718241AEasy to fixImprove positional stabilityMoulding surfacesBuilding componentsBuilding productHeat conservation

The invention belongs to the technical field of building products and particularly relates to a prefabricated wall plate with a heat preservation interlayer and a manufacturing method thereof. The prefabricated wall plate comprises an inner wall plate body, an outer wall plate body and a heat preservation plate body and further comprises press buckles used for positioning the outer wall plate body, the heat preservation plate body and the inner wall plate body. The inner wall plate body, the heat preservation plate body and the outer wall plate body which constitute the wall plate are connected tightly and firmly, the integration degree is high, the splicing requirement of a modularized house can be met directly, accordingly heat preservation construction operation of the interlayer does not need to be conducted on site, and the efficiency of the construction progress can be guaranteed while the labor cost is reduced and the engineering quality is guaranteed. The invention further provides a manufacturing method of the prefabricated wall plate. According to the manufacturing method of the prefabricated wall plate, the prefabricated wall plate can be manufactured rapidly and conveniently. The manufacturing method at least comprises the step that cement mortar is poured into the inner wall plate body, the heat preservation plate body is laid, the press buckles pierce the heat preservation plate body, and cement mortar is poured into the outer wall plate body.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

Side mould, sealing clamp and mould and method for producing reinforced wall

InactiveCN104260190AReduce labor intensityImprove efficiencyMouldsMould auxillary partsRebarMechanical engineering

The invention discloses a side mould, a sealing clamp and a mould for producing a reinforced wall. The mould for producing the reinforced wall comprises the side mould and the sealing clamp; the side mould is provided with a bottom plate and side plates; vertical gaps with the preset number are arranged on the side plates at intervals; when the reinforced wall is produced, the side mould is fixed to a mould table according to the predefined specification, reinforcing steel bars are arranged in the side mould, and therefore a reinforcing steel bar framework is formed. When the reinforcing steel bars are arranged, the ends of the reinforcing steel bars are put from the tops of the vertical gaps, the positions between the reinforcing steel bars are fixed, and finally the sealing clamp is utilized for clamping the reinforcing steel bars and enabling the reinforcing steel bars to be tightly attached to the vertical gaps of the side plates. Compared with the prior art, the production mode is easier to operate, and automation of work is more facilitated. Therefore, the reinforced wall is produced through the mould, the production efficiency is high, and labor intensity of workers is low. On the basis, the invention further discloses a method for producing the reinforced wall.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

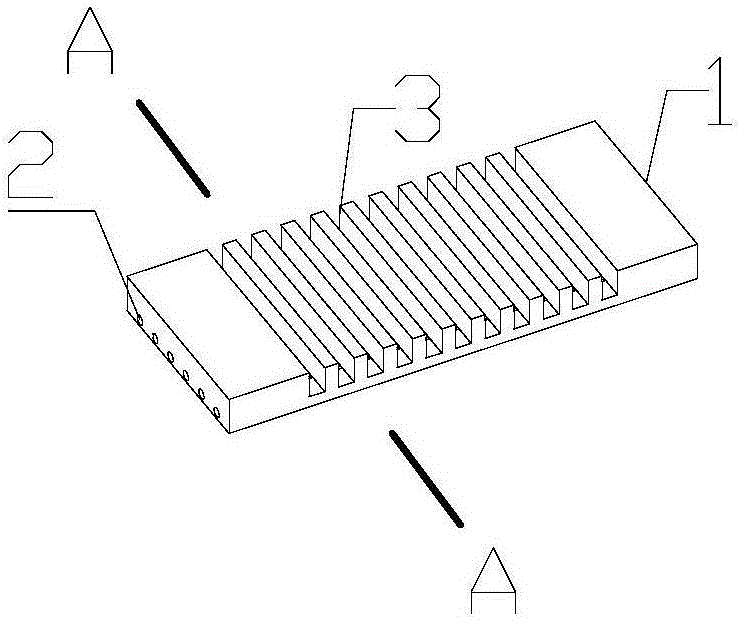

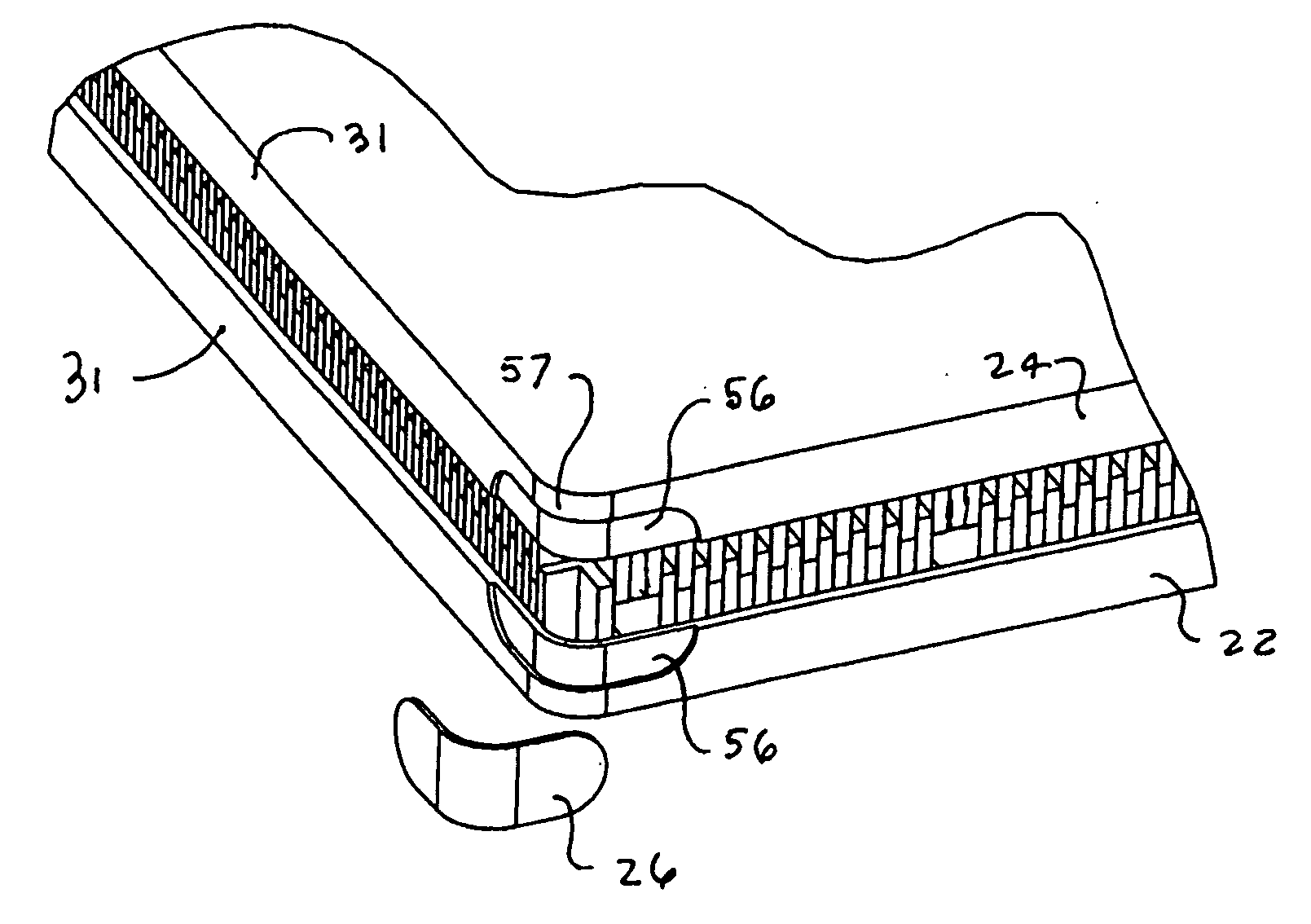

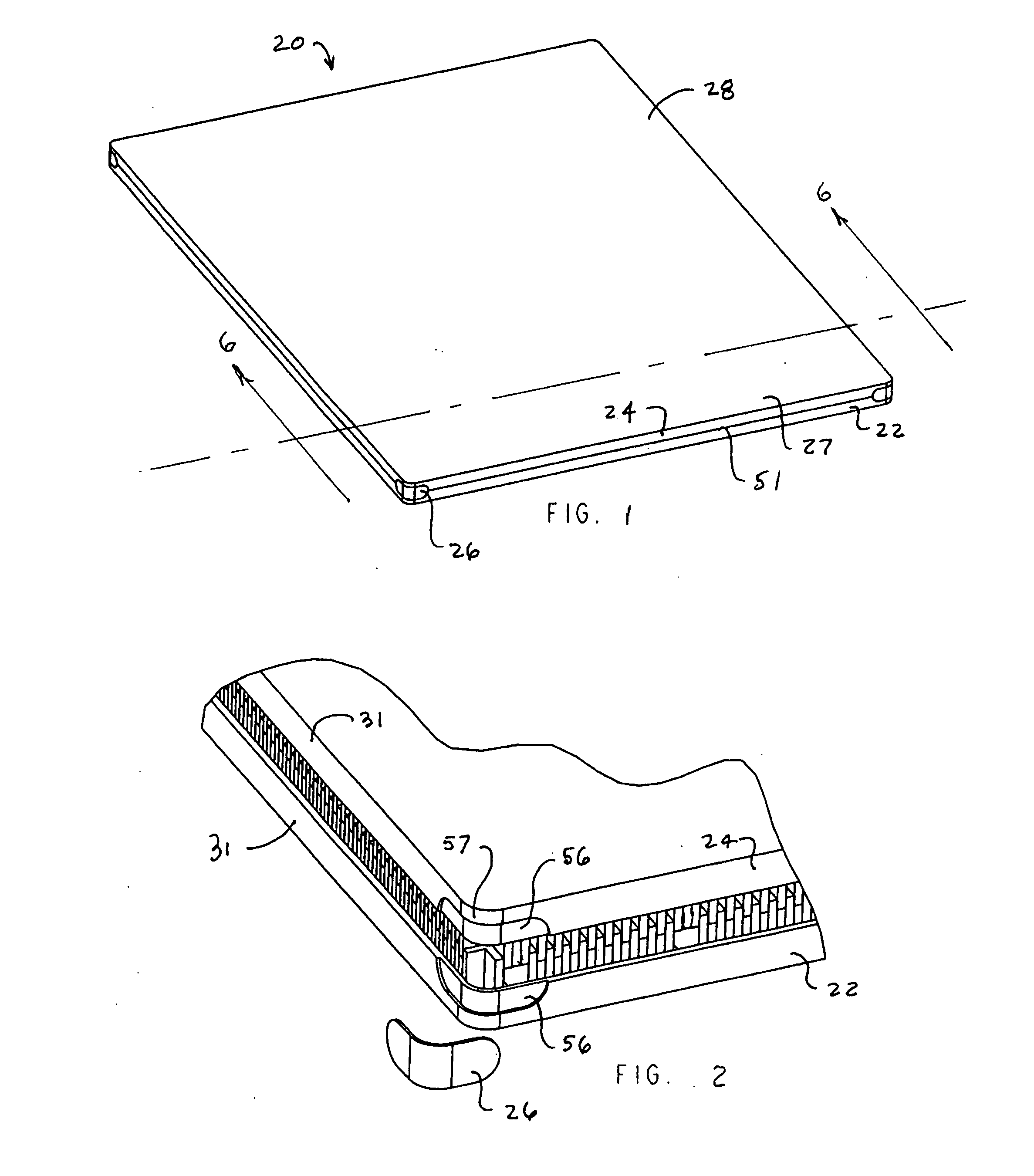

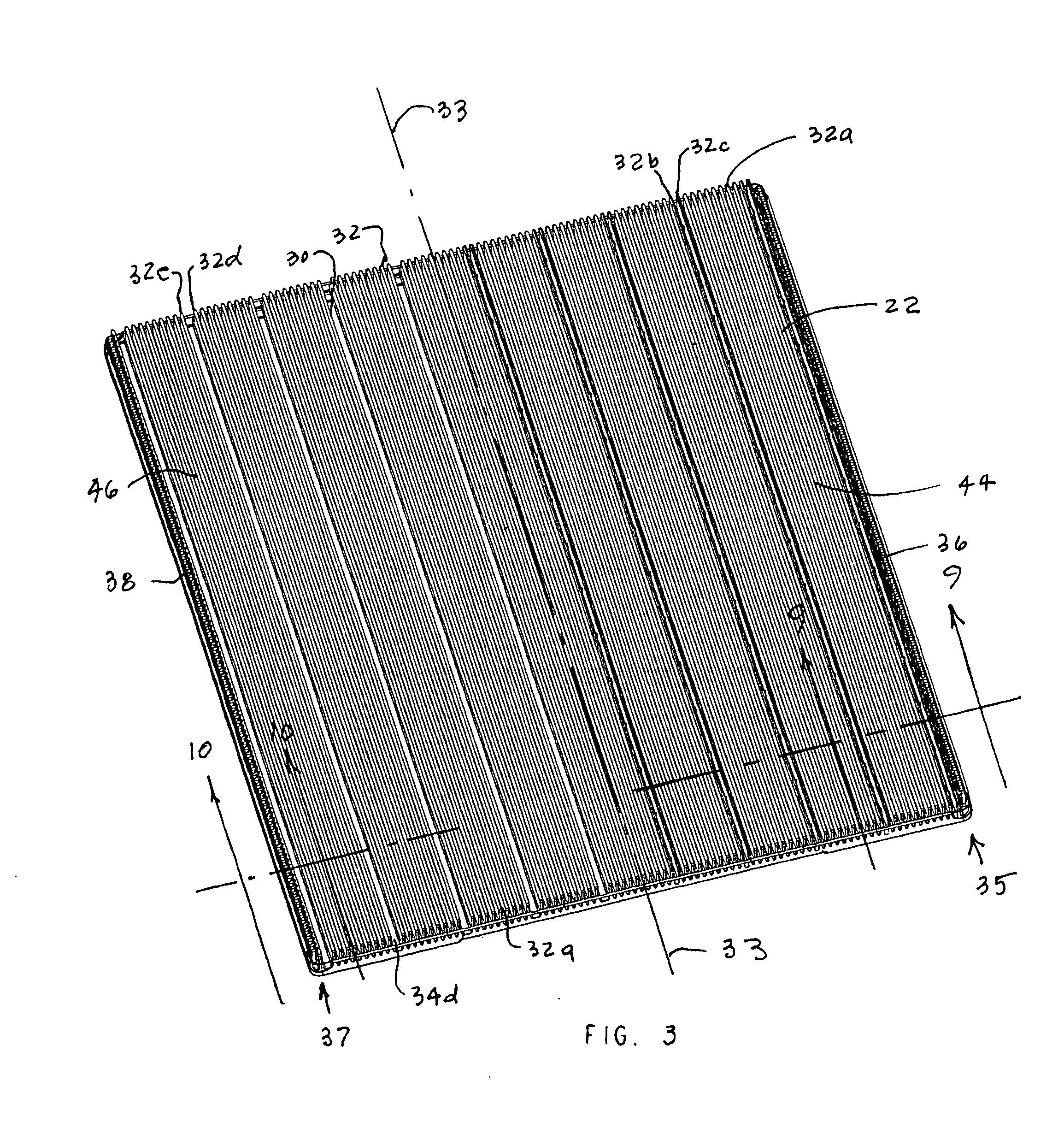

Plastic panel, particularly for use as production pallet

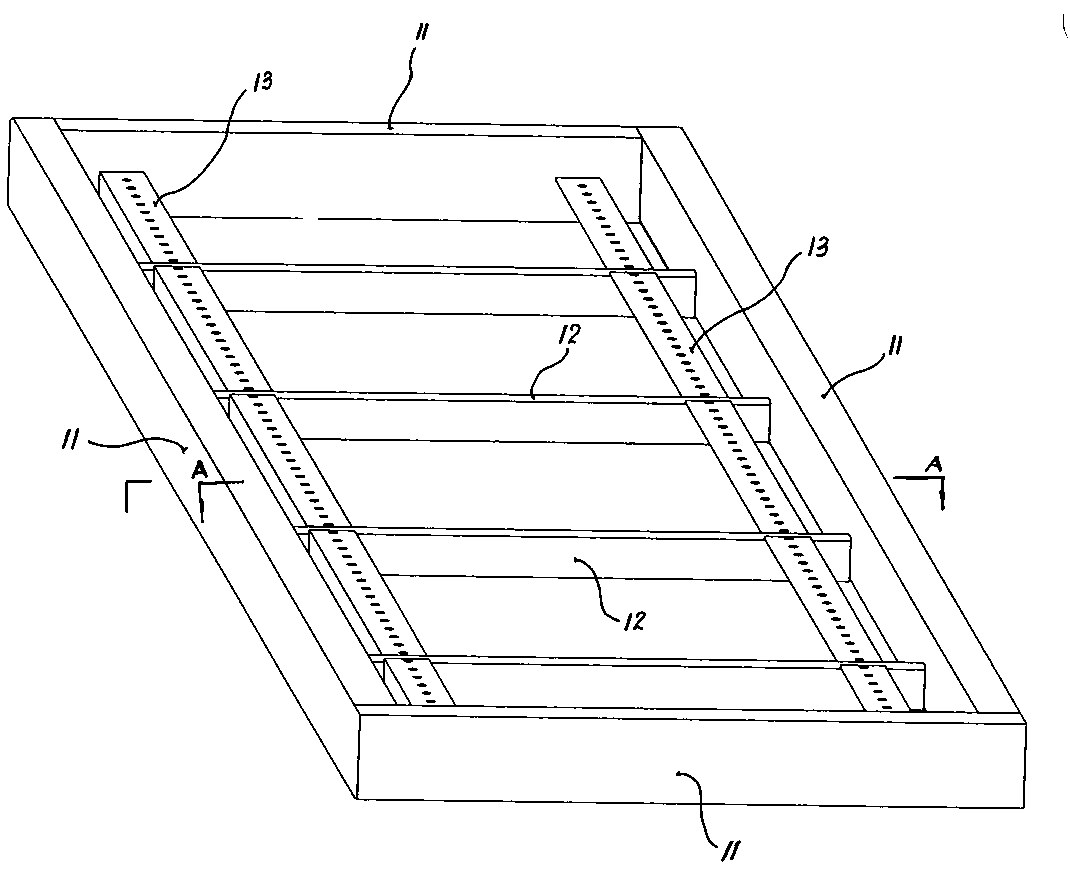

ActiveUS20080178775A1Easy to moldFacilitates strengtheningBuilding componentsMould panelsEngineeringPallet

A plastic panel which may be used as a production pallet in the production of unitary concrete masonry products includes first and second joinable portions. The portions each comprise a support backing including an outer surface and an inner face, and a plurality of ribs extending outwardly away from said inner face. The ribs of a first grouping thereof are parallel with one another and extend across a first area of the face in a first direction, and the ribs of a second grouping thereof extend across a second area of the face in a second direction which is not parallel with said first direction. The panel portions are configured, disposed and arranged so as to join with one another in generally overlapping and mated relationship with the outer surfaces disposed in spaced apart opposing relationship, with the first groupings of ribs of the respective portions disposed in intermeshing and mating relationship with each other, and with the second groupings of ribs of the respective portions also disposed in intermeshing and mating relationship with each other whereby to present said plastic panel.

Owner:STROBL JR FREDERICK P +1

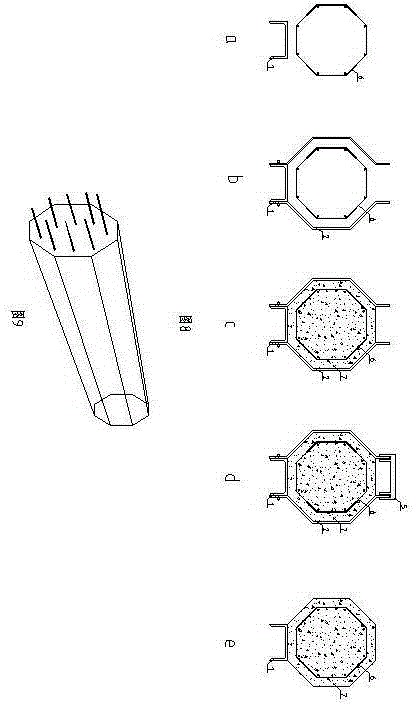

Multilateral mould of site precast concrete pile and manufacturing method of precast concrete pile

The invention provides a multilateral mould of a site precast pile. The multilateral mould is composed of a bottom formwork, lateral formworks and end formworks. The bottom formwork is a long strip made by steel and with certain height and width, the top face of the long strip is a plane, and the top face forms the bottom edge of the module after the bottom formwork is horizontally arranged. Each lateral formwork is composed of multiple same single formwork bodies which are pressed to be in a multi-row shape through a steel board. The outer edge wind plates of all the single formwork bodies and the bottom formwork are connected to form the double lateral formworks, and then the left and right sides of the mould are formed; the end formworks are in a polygonal shape and fixed to the two ends of the lateral formworks, and the multilateral mould with an upper opening where concrete is poured is formed. The invention further discloses a manufacturing method of the precast pile. The manufacturing method comprises the steps that 1, the bottom formwork is arranged, and a reinforcement cage is arranged on the bottom formwork; 2, the lateral formworks and the end formworks are installed on the bottom formwork to form the multilateral mould; 3, concrete is poured from the mould opening and is vibrated and compacted; 4, the concrete is maintained; and 5, the multilateral mould is detached, and a multilateral precast concrete pile body is obtained.

Owner:北京波森特岩土工程有限公司

Backlight assembly with excellent light efficiency and display device having the same

ActiveUS7377677B2Improve lighting efficiencyPoint-like light sourceLighting support devicesDisplay deviceOptoelectronics

A backlight assembly with excellent light efficiency and a display device provided with the backlight assembly is provided where the backlight assembly includes a plurality of light sources longitudinally arranged in parallel to each other, and a fixing member receiving the plurality of light sources. When a display area, formed by light emitted from the plurality of light sources, is divided by the plurality of light sources into a plurality of display area sections, an average area of the display area sections between light sources adjacent to each other is less than or equal to an area of a display area section between an edge of the display area and the light source most adjacent thereto.

Owner:SAMSUNG DISPLAY CO LTD

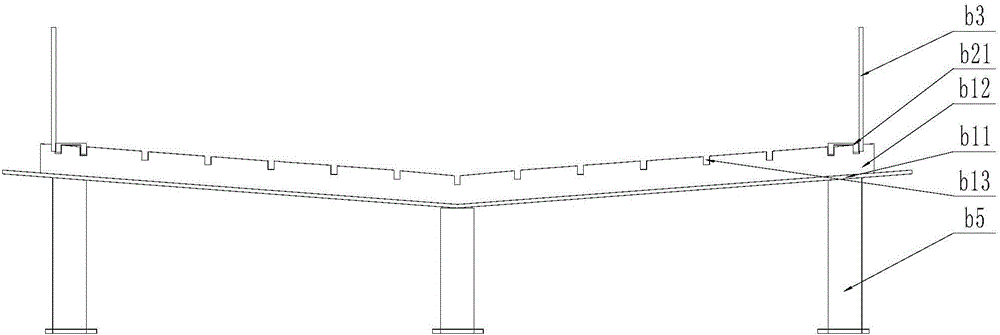

Hydraulic T-beam formwork construction device and technology

The invention provides a hydraulic T-beam formwork construction device. The device comprises lateral formworks, cross beam direction moving trolleys, horizontal hydraulic oil cylinders, longitudinal beam direction moving trolleys, a concrete pedestal foundation surface and a bottom formwork, wherein the bottom formwork is arranged on the concrete pedestal foundation surface; lower ends of the lateral formworks are connected with the bottom formwork; the upper end of the left lateral formwork and the upper end of the right lateral formwork are connected by the aid of a top pull rod; middles of the lateral formworks are connected with connecting pole beams; lower sides of the connecting pole beams are connected with vertical oil cylinders; lower ends of the vertical oil cylinders are fixed on the cross beam direction moving trolleys; one end of each cross beam direction moving trolley is connected with the horizontal hydraulic oil cylinder in a hinged manner, and the other end of the horizontal hydraulic oil cylinder is fixedly connected onto the longitudinal beam direction moving trolley. With the adoption of the movable hydraulic integrated formworks, the formworks are convenient and quick to assemble and adjust and take place accurately, and joints are closely attached; with the adoption of the movable hydraulic lateral formworks, the mounting efficiency of the formworks is improved, the lifting operation risk is reduced, the labor intensity of workers is reduced, and the utilization rate of the lateral formworks is increased.

Owner:中交二公局第四工程有限公司

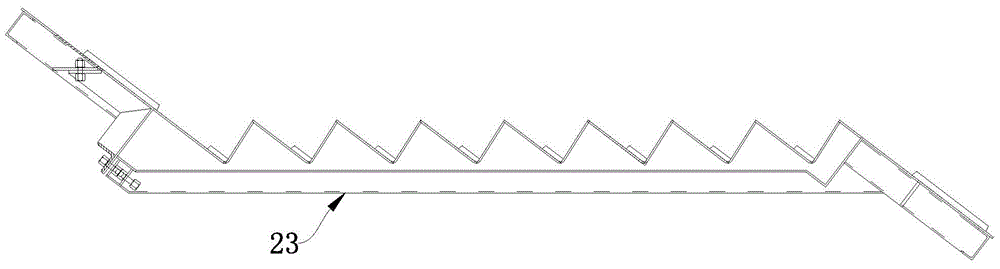

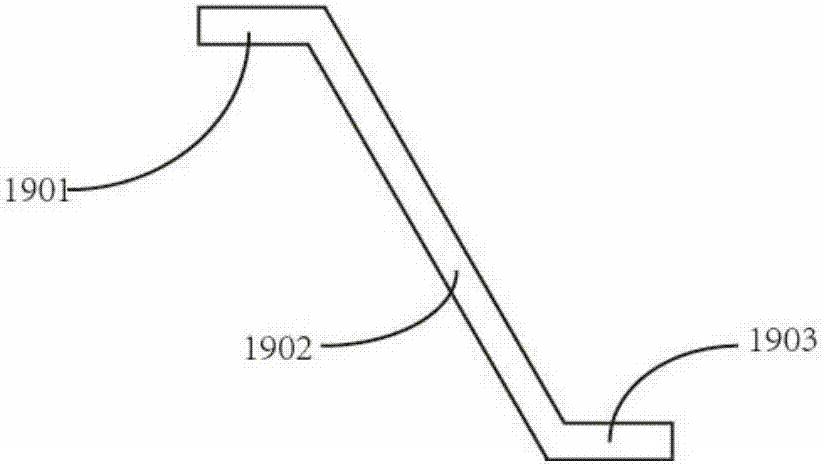

Producing device and mold for prefabricated stairs

The invention relates to a producing device and mold for prefabricated stairs. The production mold for the prefabricated stairs comprises a side mold plate, a bottom mold plate, a stair mold plate and two end sealing plates, wherein the side mold plate is arranged longitudinally, the bottom mold plate and the stair mold plate are longitudinally and oppositely arranged on the two longitudinal sides of the side mold plate in a spaced mode, and the two end sealing plates are arranged at the two longitudinal opposite ends of the bottom mold plate and the two longitudinal opposite ends of the stair mold plate. A mold cavity for forming the stairs is formed by the side mold plate, the bottom mold plate, the stair mold plate and the two end sealing plates. The transverse position of the stair mold plate is adjustably matched with the side face of the side mold plate so that the transverse position, relative to the bottom mold plate, of the stair mold plate can be adjusted. Due to the fact that the transverse position, relative to the bottom mold plate, of the stair mold plate can be adjusted, stairs with different widths can be formed by using the same mold, the utilization rate of the production mold is increased, cost is reduced, and production efficiency is improved.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

Universal mold for forming of house prefabricated part laminated slab

PendingCN108687939AReduce sizeImprove versatilityMoulding surfacesMould auxillary partsHigh volume manufacturingRebar

The invention relates to a universal mold for forming of a house prefabricated part laminated slab, and relates to the technical field of house prefabricated part production. An outer frame for forming a prefabricated laminated slab bottom plate is defined by four forming side mold assemblies, a bottom mold and a side mold are arranged in each forming side mold assembly, the bottom molds are fixedto a mold table, the side molds are fixed to the bottom molds, overhead gaskets and sealing strips are arranged between the bottom molds and the side molds, and criss-cross rebar ends in the prefabricated laminated slab bottom plate stretch out of the gaps between the bottom molds and the side molds. Each bottom plate is further provided with two or more fixing pressing plates, one ends of the fixing pressing plates are pressed on the upper surfaces of the bottom molds, and the other ends of the fixing pressing plates are fixed to the mold table through bolts. One forming side mold assembly can adapt to the rebar interval change in different prefabricated laminated slab bottom plates, the universality is good, the specifications of the forming side mold assemblies needed for production are greatly reduced, production and use are convenient, the assembly efficiency of the molds is high, demolding is convenient, and the large-scale production advantages of factories can be fully exerted.

Owner:福建鸿生高科环保科技有限公司

Manufacturing method for integral forming of upper plate and lower plate of matched rock structure plane

ActiveCN106564116AShort preparation cycleAvoid safety accidentsMouldsPreparing sample for investigationExperimental testingEngineering

A manufacturing method for integral forming of an upper plate and a lower plate of a matched rock structure plane includes the following steps that (1) an upper plate structure plane shape and a lower plate structure plane shape are selected, a corresponding upper plate structure plane formwork and a corresponding lower plate structure plane formwork are selected according to experimental testing requirements, and it is required that the upper plate structure plane formwork and the lower plate structure plane formwork are matched mutually; (2) the upper plate structure plane formwork and the lower plate structure plane formwork are assembled; (3) the upper plate structure plane formwork and the lower plate structure plane formwork which are connected in a back-to-back abutting mode are connected and fixed to the middle of a bottom board; (4) a left side board and a right side board are placed and fixed on the left side and the right side of the bottom board respectively; (5) a front side board and a back side board are placed and fixed on the other two edges of the bottom board; (6) a release agent is smeared; (7) materials are poured; (8) jolt ramming is carried out; (9) the formworks are dismounted; (10) curing is conducted; and (11) after curing is completed, the upper plate and the lower plate of a structure plane sample are taken out of a curing chamber, and the upper plate and the lower plate of the structure plane are assembled according to the mode that the lower plate is located below the upper plate, so that the matched structure plane sample is formed. The method has the characteristic that the procedures are simple, the effect is good and the period is short.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

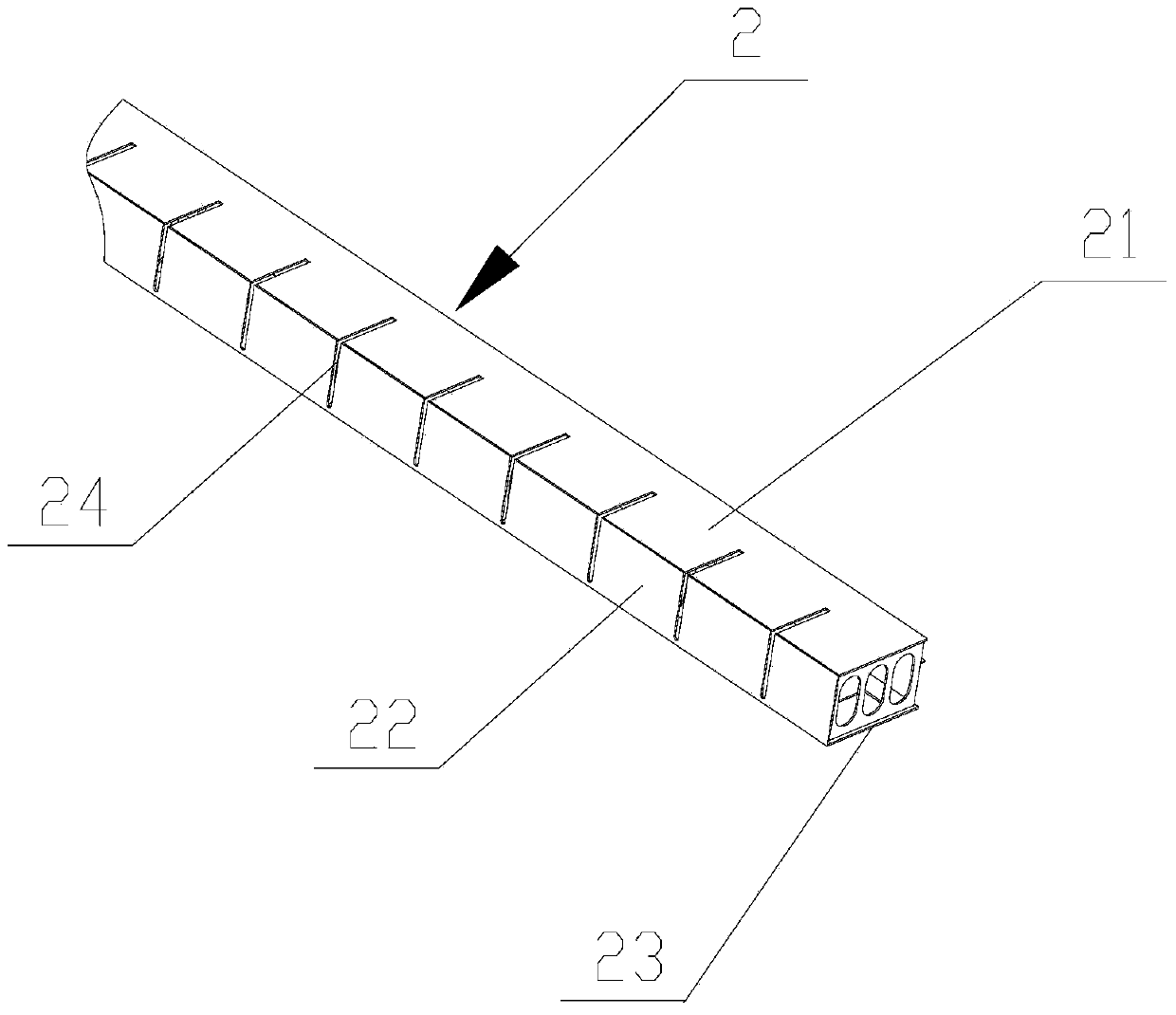

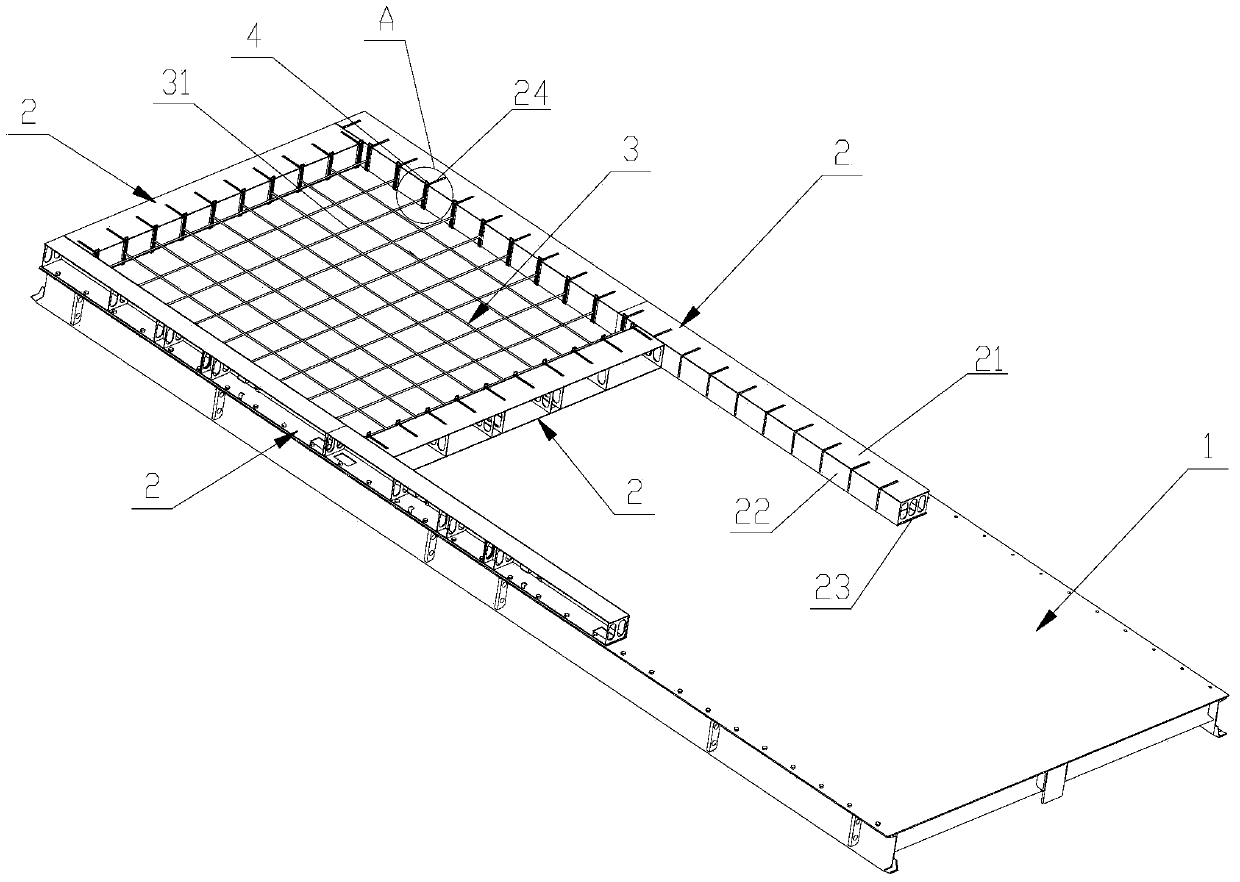

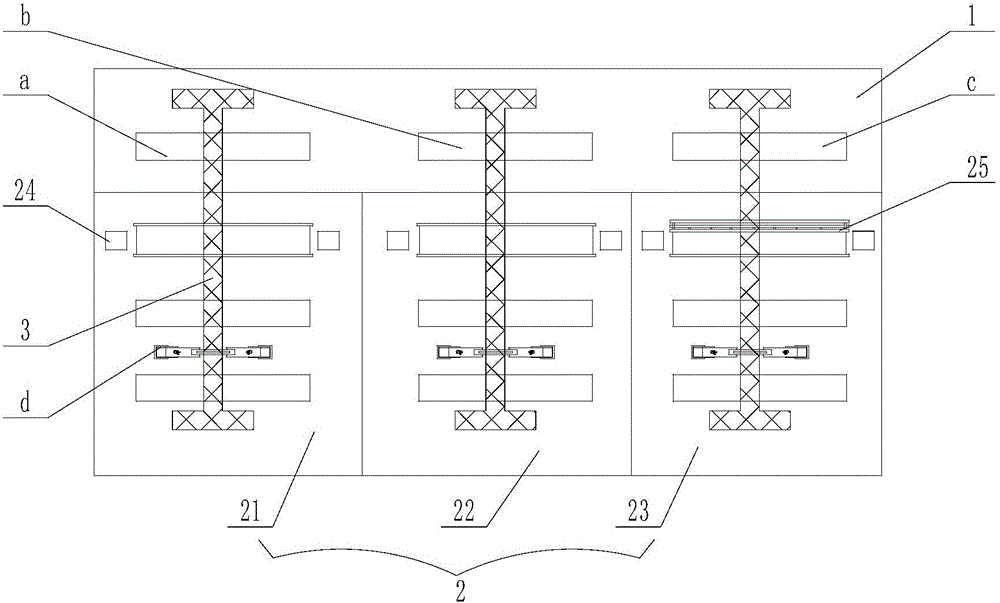

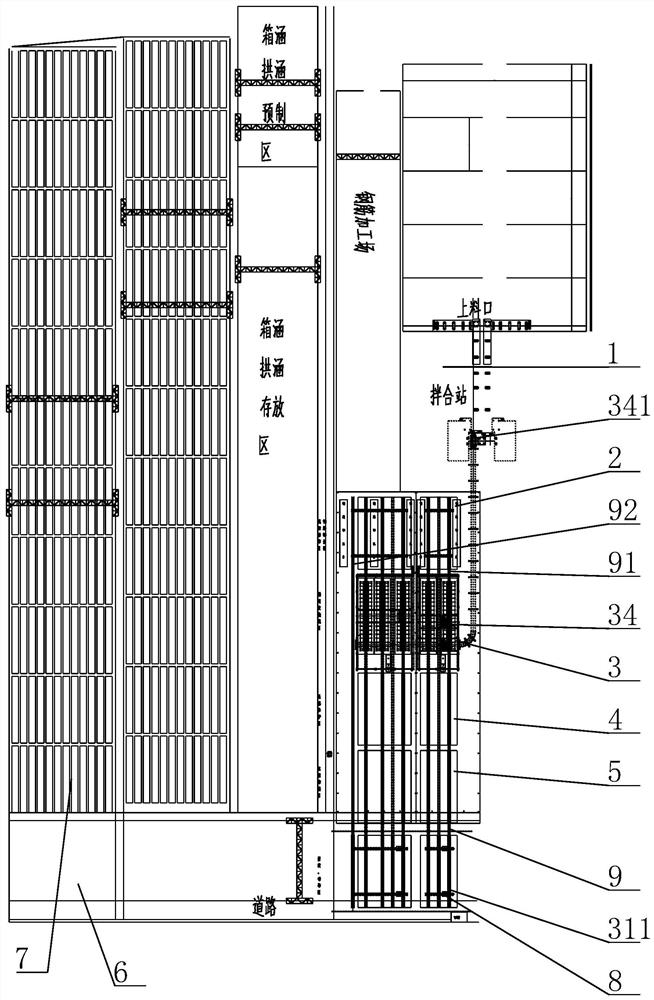

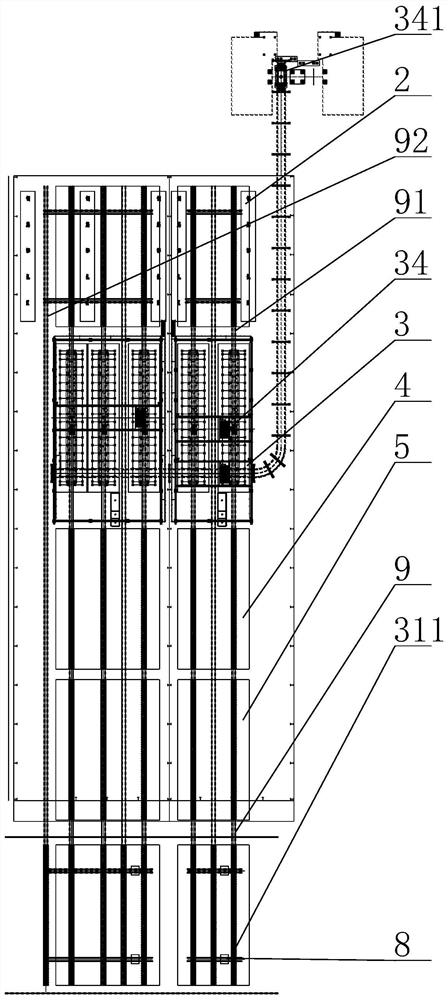

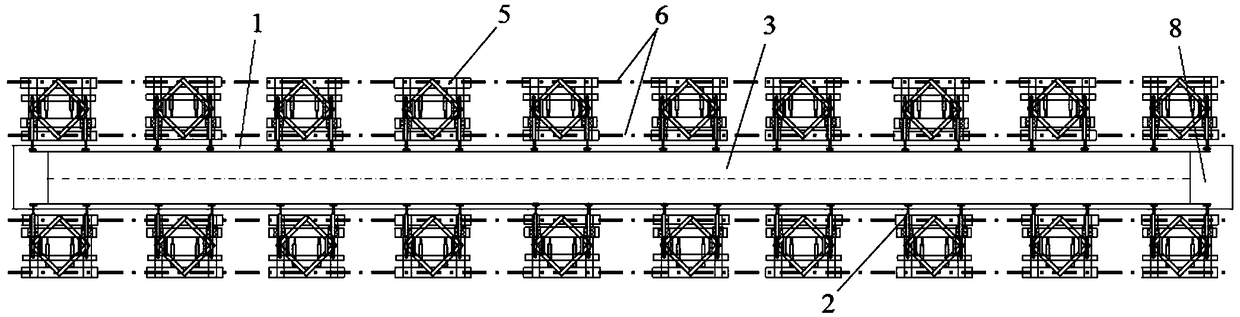

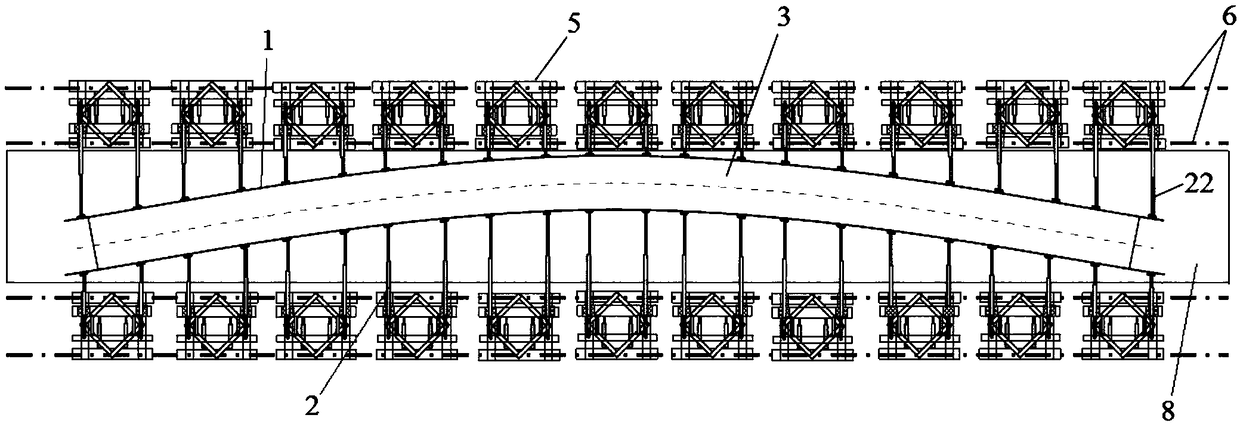

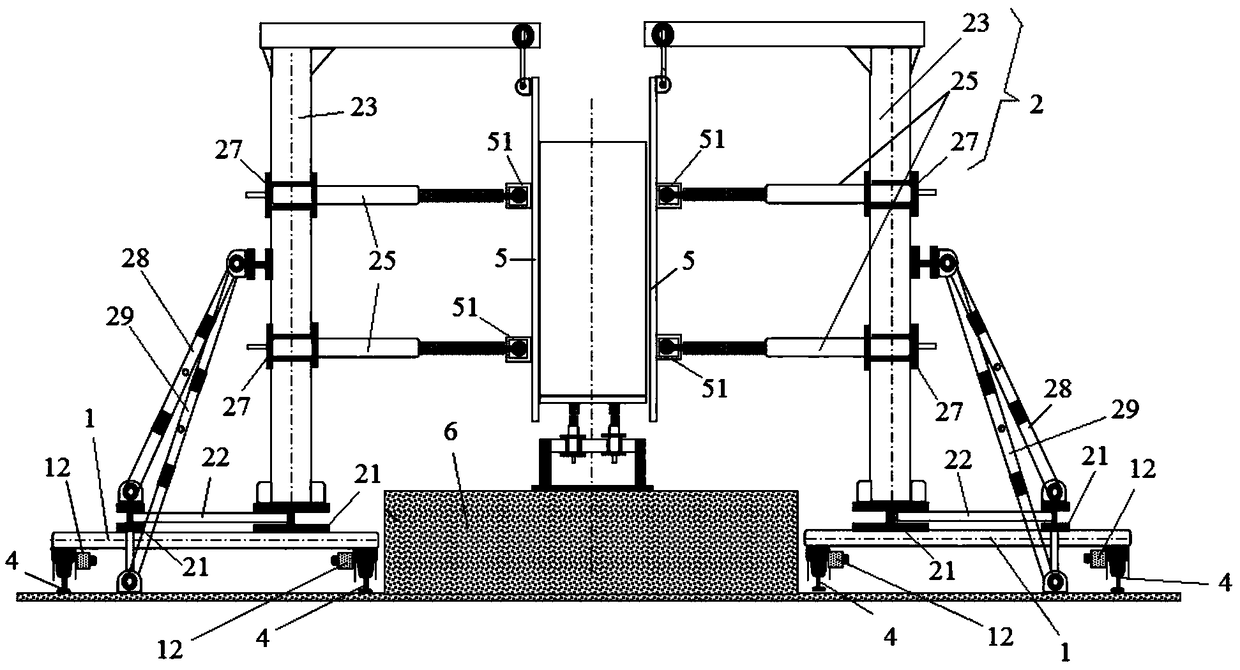

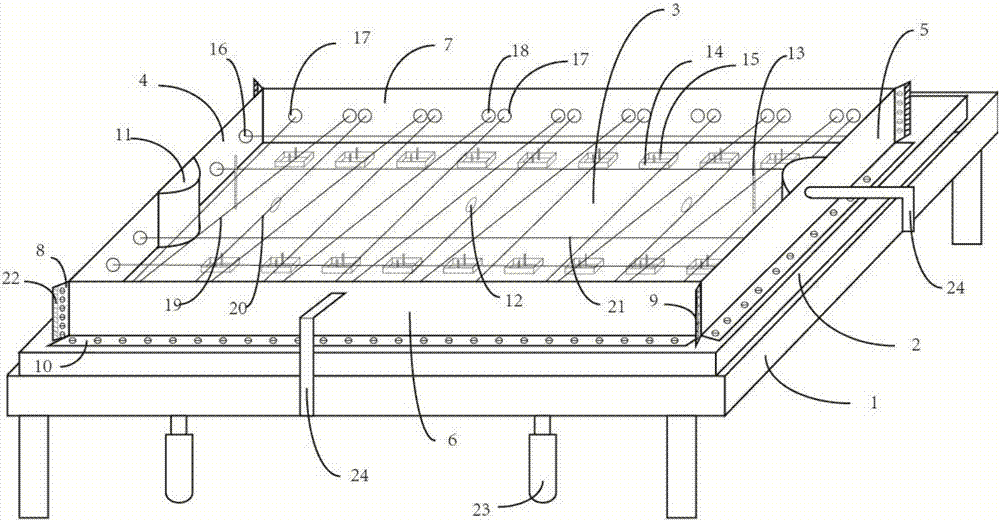

Bridge production system

ActiveCN106042173AReduce erectionLittle impact on trafficCeramic shaping plantsMould panelsRebarGantry crane

The invention discloses a bridge production system. The bridge production system comprises a bridge body steel bar binding area, a bridge body pouring area and a gantry crane arranged on the bridge body steel bar binding area and the bridge body pouring area in a striding manner, and the gantry crane is provided with a lifting and moving device. Compared with the prior art, various bridge body prefabricated web steel bar binding table bases are provided in the scheme, bridge body steel bar framework binding is normalized and standardized, consumption of labor force is greatly reduced, the construction period is shortened, and integrity is high. The various bridge body prefabricated web steel bar binding table bases are formed by splicing steel structural pieces and can be cyclically used, the usage number of the binding table bases is reduced, the construction using land is reduced, and convenience is provided for field management. Rubber drawing and pulling bar penetrating construction can be rapidly finished through a rubber bar drawing and pulling device, a prestress hole channel is embedded, the labor intensity is low, and the work efficiency is high. In a side beam pouring tool, a first supporting plate of an effective supporting part can be independent, the size is small, the mass is low, operation is more flexible and is gradually changed during demolding, and therefore damage to concrete can be reduced.

Owner:CHINA RAILWAY 16TH BUREAU GRP RAIL TRANSPORT ENG CO LTD

Automatic prefabricated light T-beam system and method

The invention provides an automatic prefabricated light T-beam system and method. The system and the method are characterized in that a mixing station, a reinforcement cage binding area, a prefabricated beam pouring area, a high-temperature steam curing area, a tension finishing area, a lifting beam transverse moving area and a T-beam storage area are arranged; the mixing station is arranged on the outer side of the prefabricated beam pouring area in the width direction, and pouring raw materials are conveyed to a distributing machine above the prefabricated beam pouring area by that a torpedotank passes through a conveying rail; the reinforcement cage binding area is arranged on the front side of the prefabricated beam pouring area in the length direction; a transverse moving trolley isarranged between the longitudinal movement of a steel bar binding area and lifting beam transverse moving area; the high-temperature steam curing area and the tension finishing area are sequentially arranged at the rear side in the length direction of the prefabricated beam pouring area; and the lifting beam transverse moving area is arranged on one side in the width direction of the tension finishing area, and the transverse moving and lifting of a prefabricated light T beam to a T beam storage area is realized through transverse lifting equipment. According to the system and method, reasonable processing layout and flow optimization of the whole T beam can be realized, through the operation of circular processing, the production efficiency is greatly improved, and the design is reasonable.

Owner:安徽建工路港建设集团有限公司

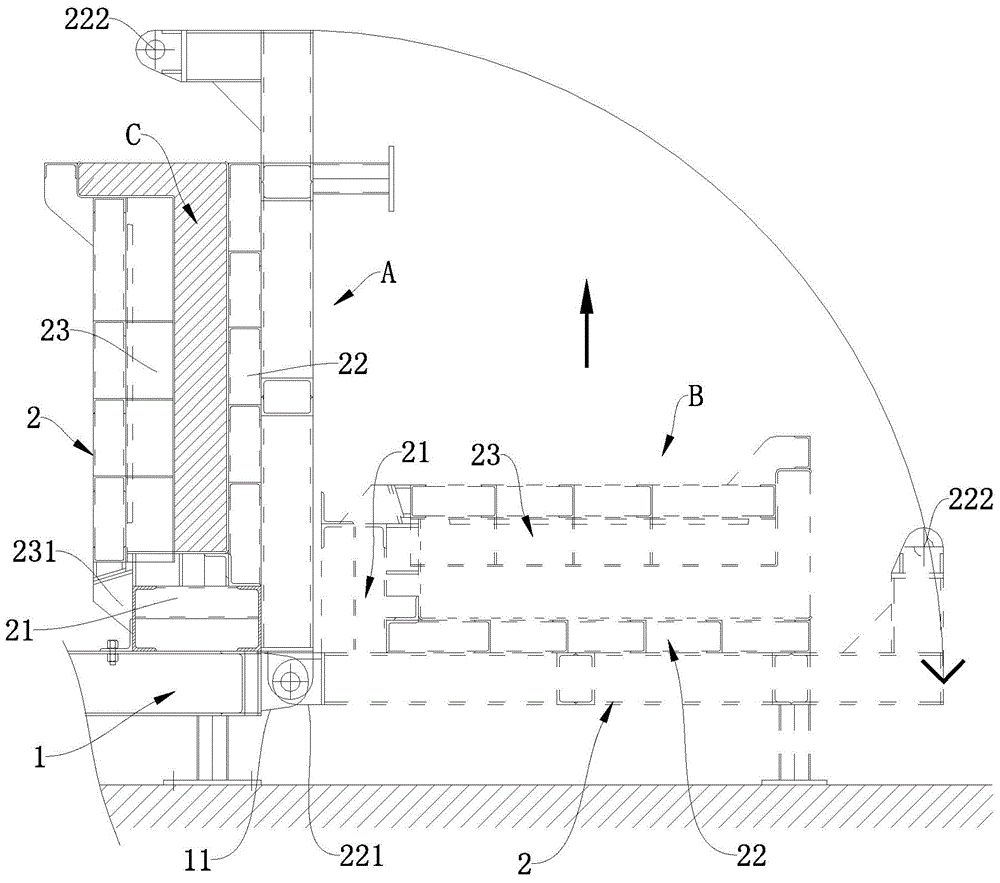

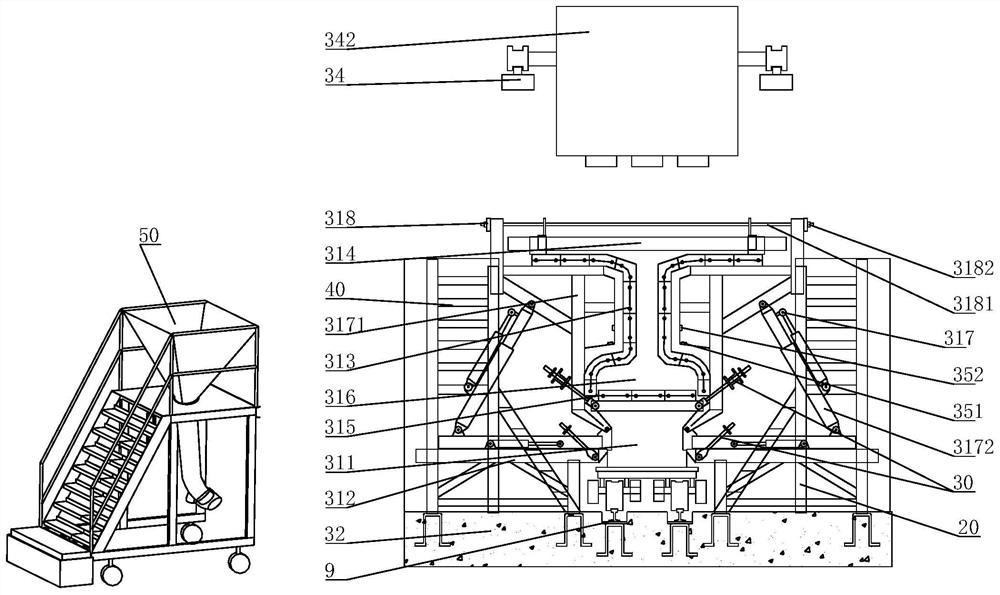

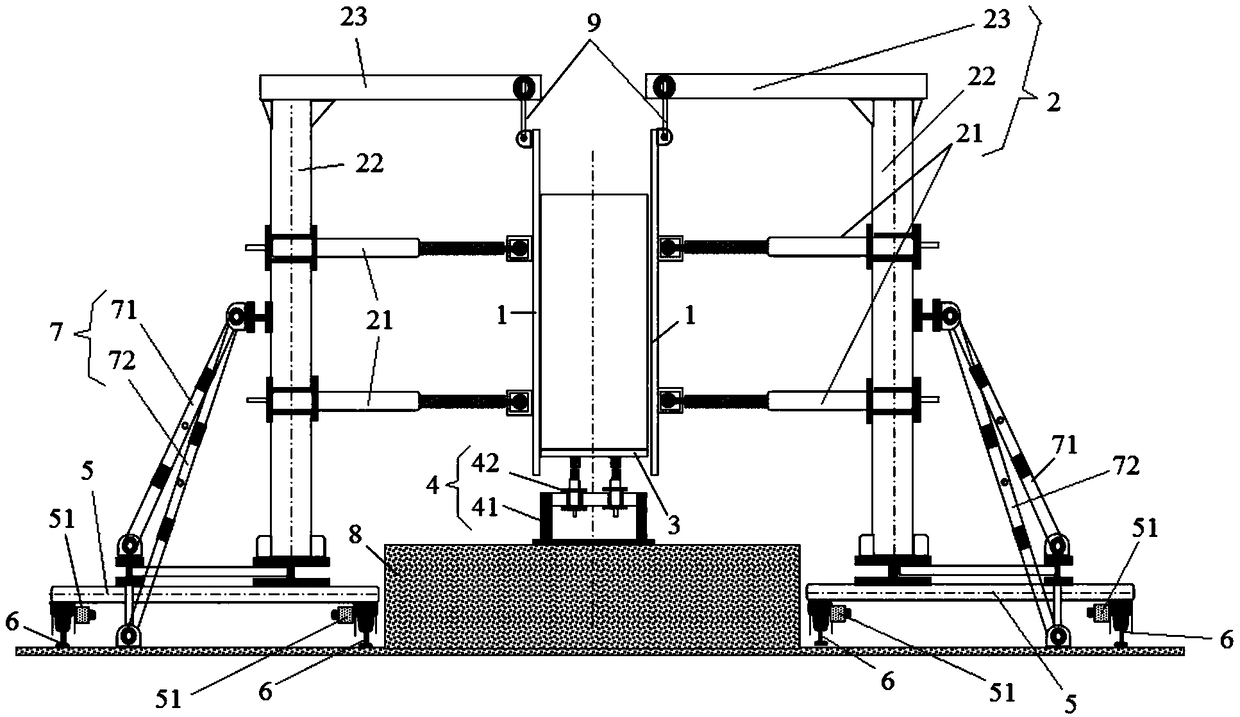

Straddle type single-rail track beam formwork system and application method

PendingCN108638296APrevent rolloverAvoid security issuesMouldsMould auxillary partsEngineeringStraddle

The invention discloses a straddle type single-rail track beam formwork system and an application method. The formwork system comprises side molds, side mold stress application mechanisms, a bottom mold, a bottom mold stress application mechanism, a movable platform, tracks and supporting mechanisms. By application of the formwork system, the distribution position of each transverse movement assembly relative to the corresponding side mold can be independently adjusted, then, accurate adjustment of the side mold stress application positions can be achieved, and accordingly it is ensured that the side mold line shapes can meet the forming requirements of complex section space composite curve as well as straight line and curve transition section track beams. After track beam pouring and initial setting, the side mold stress application mechanisms drive the side molds for demoulding, the movable platform drives the side mold stress application mechanisms and the side molds to move to thenext pouring position, the initially-set track beams can be stored and completely cured and formed on the site, and the problems about potential safety hazards and quality of lateral overturning and cracking during track beam movement due to movement after initial setting like an existing manner are solved. The formwork system is simple in structure, convenient to use, high in mold reversing efficiency and capable of saving time.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

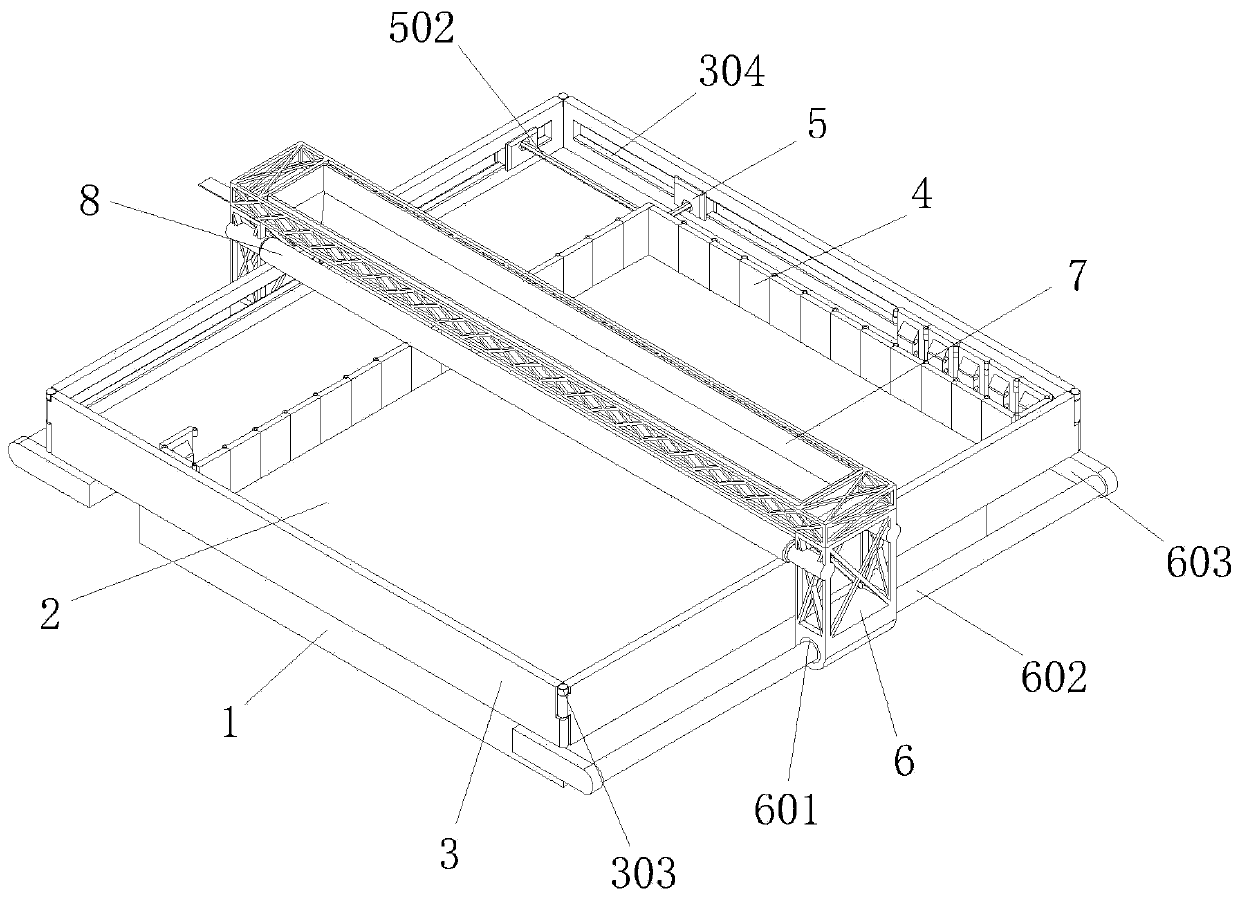

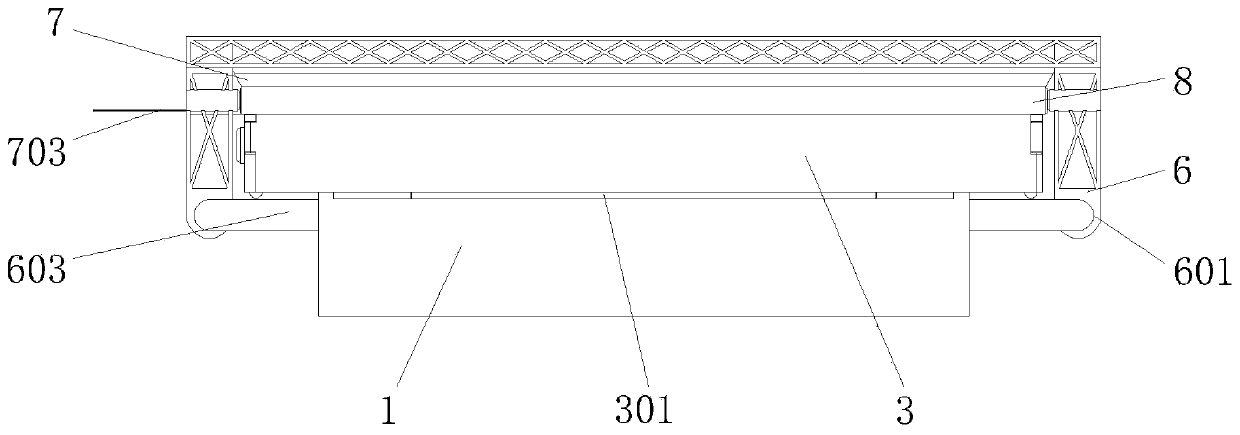

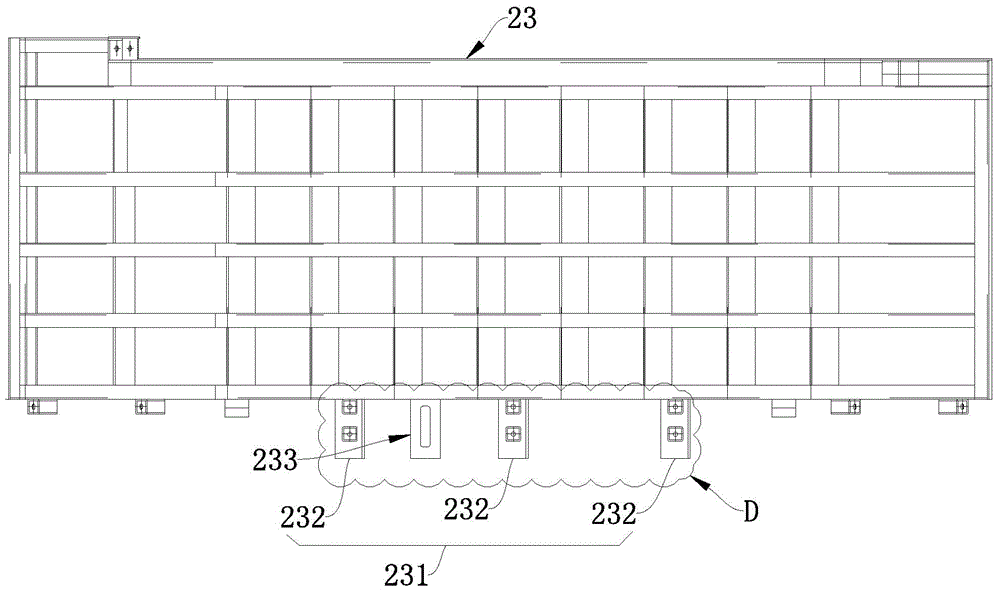

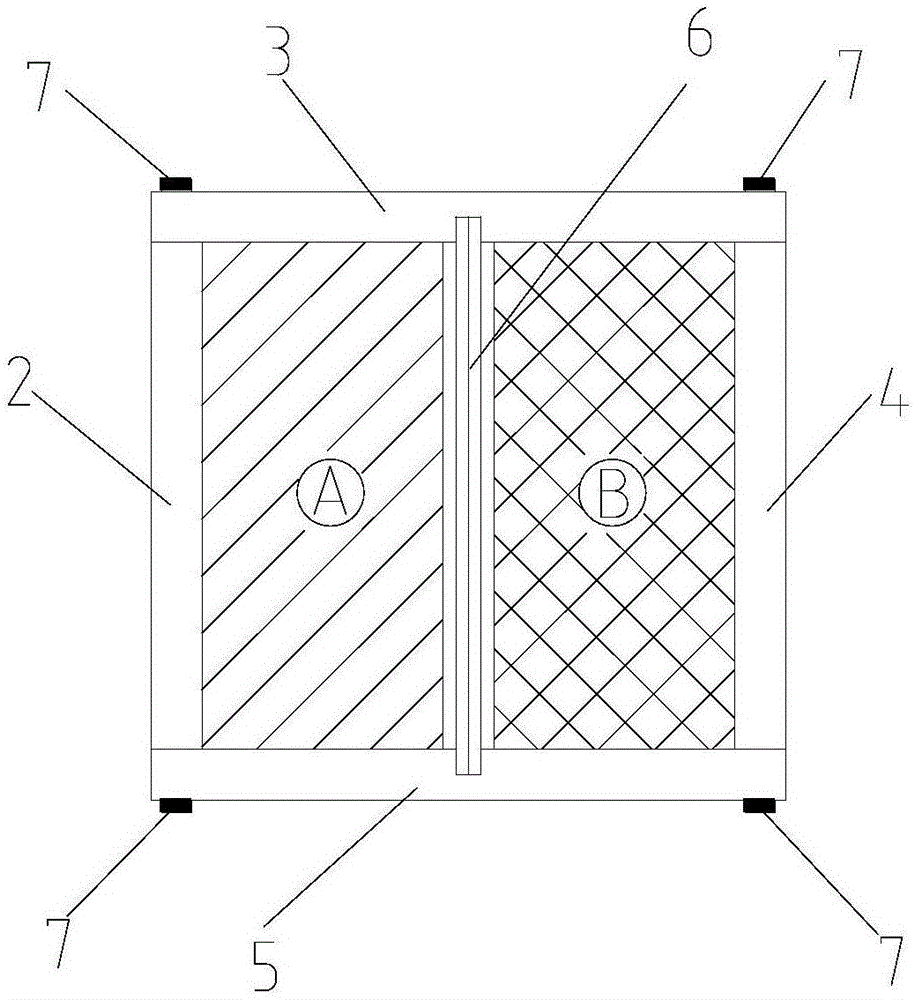

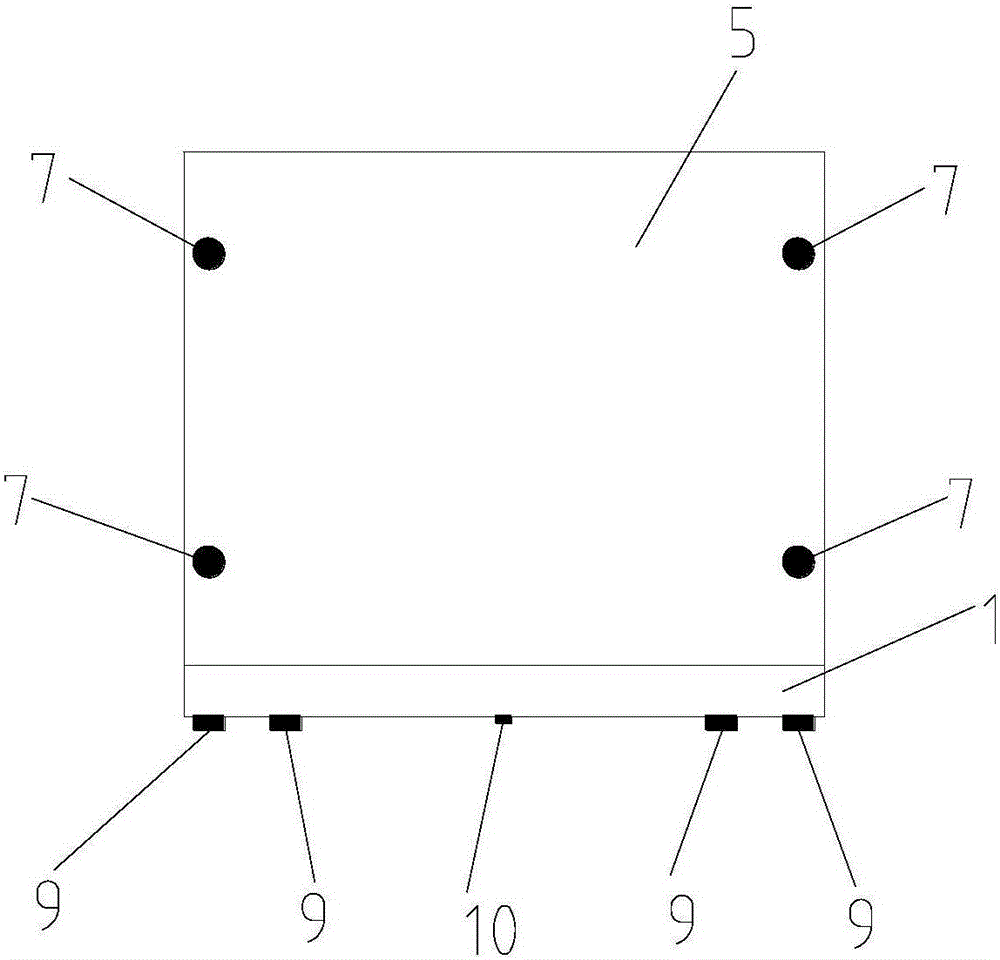

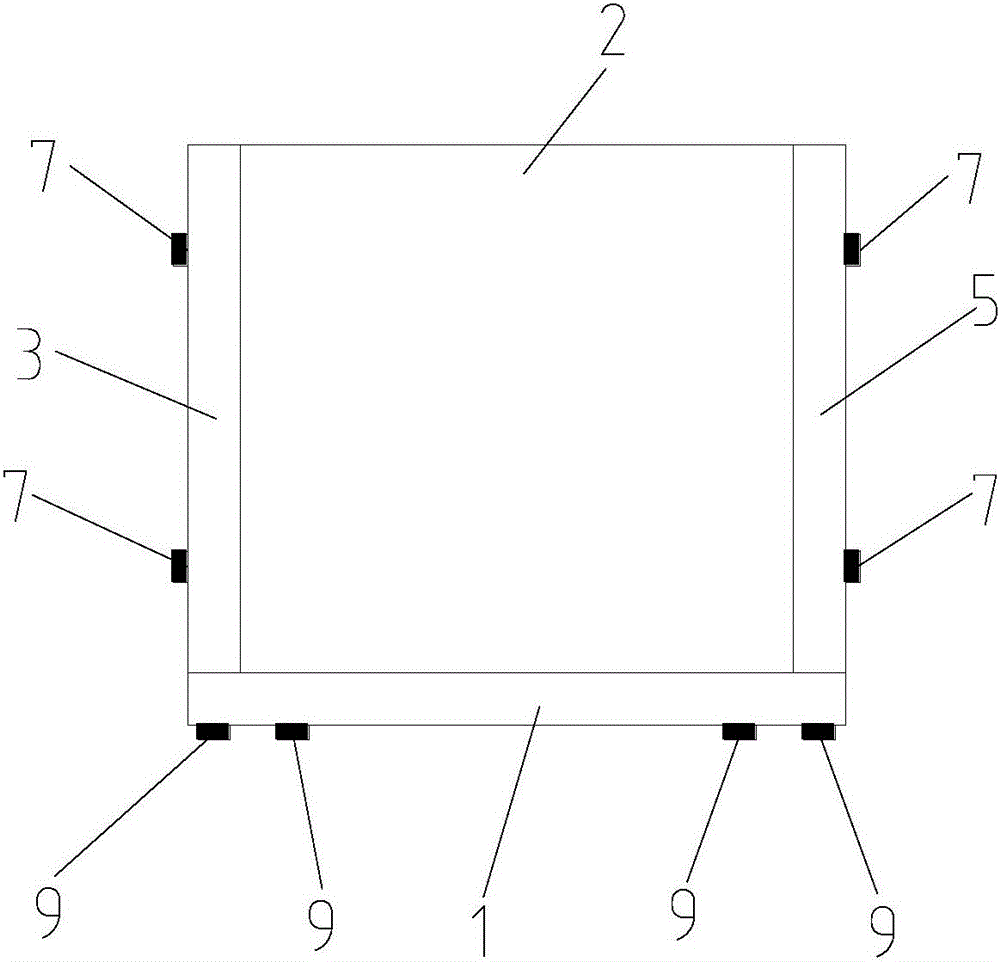

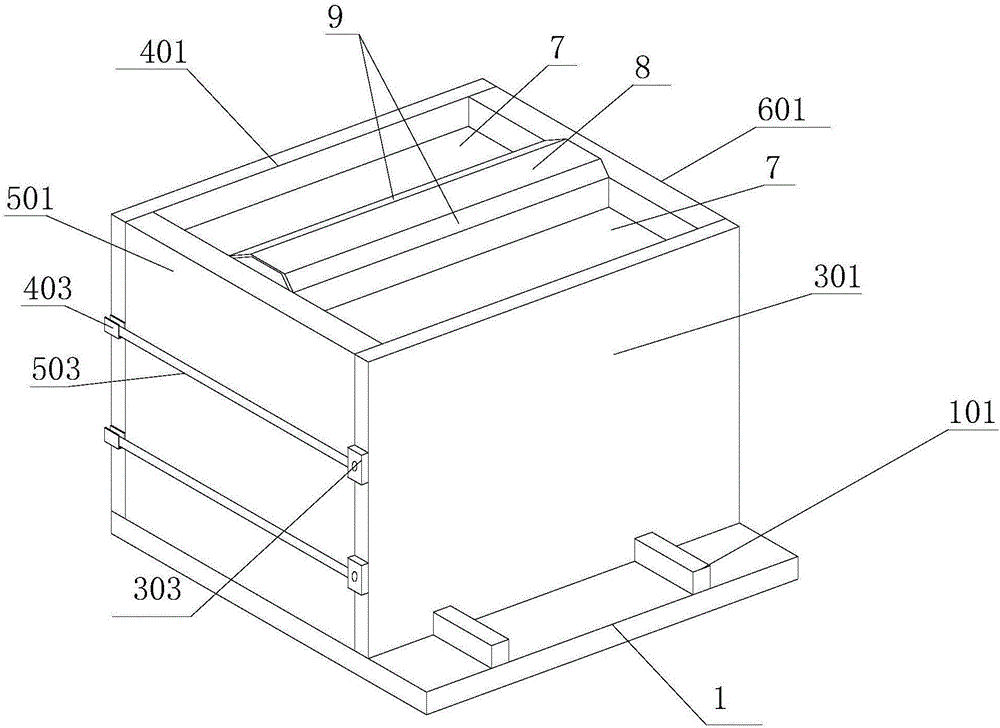

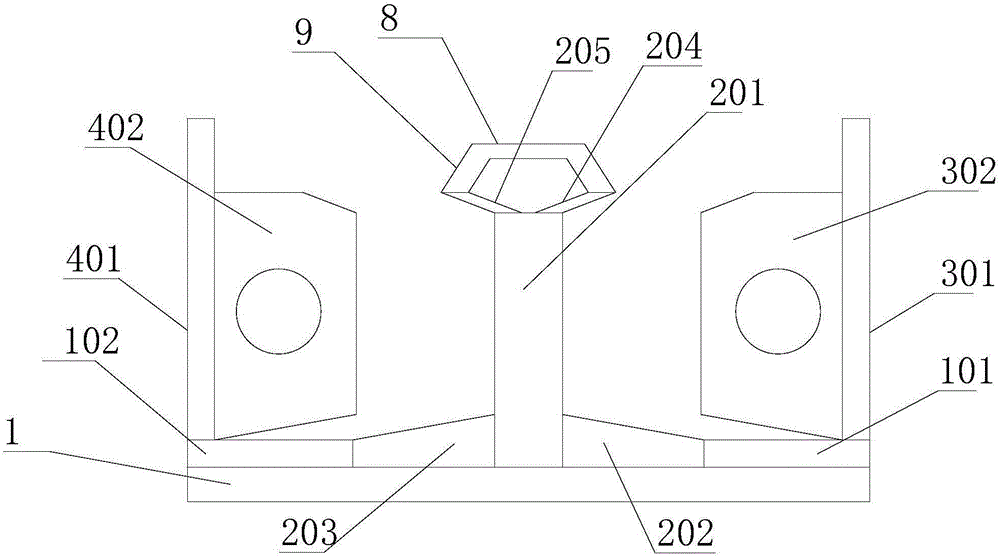

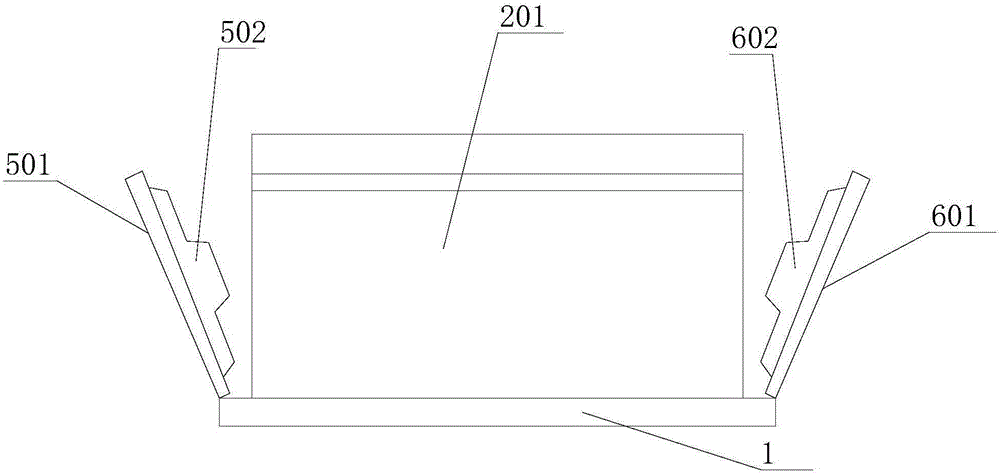

Light composite wallboard forming mold

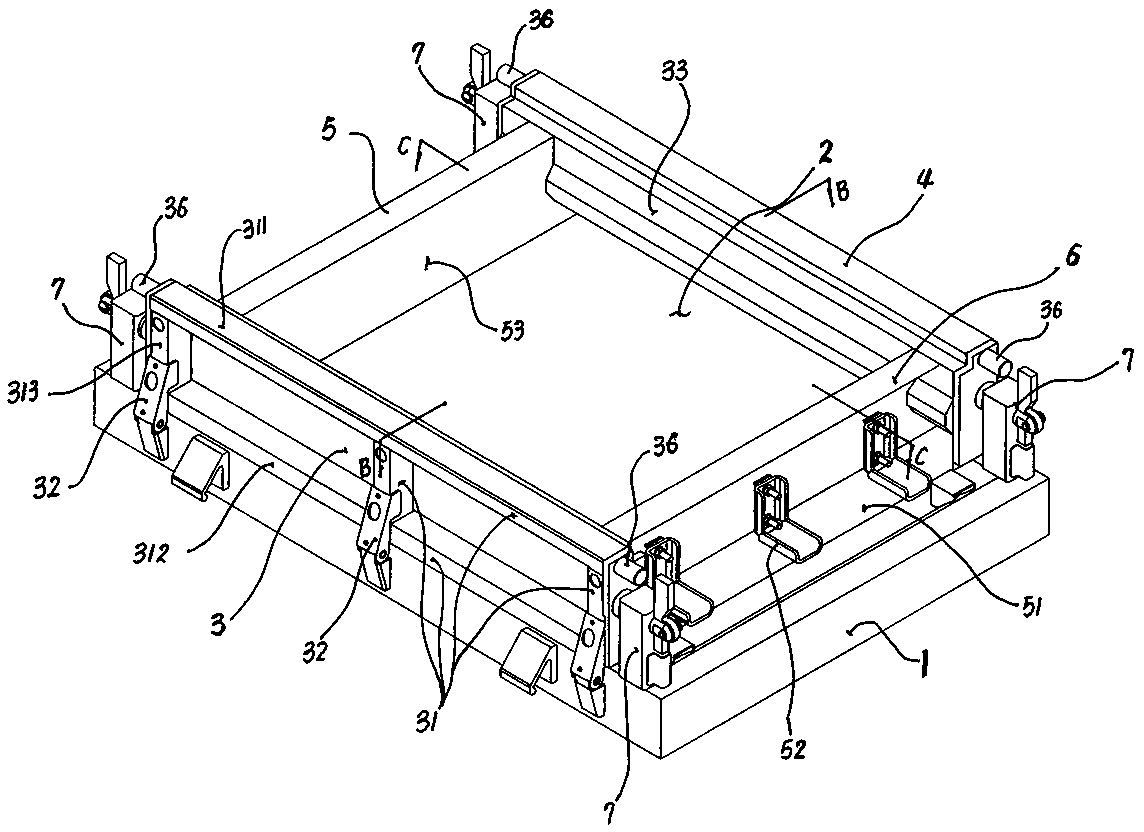

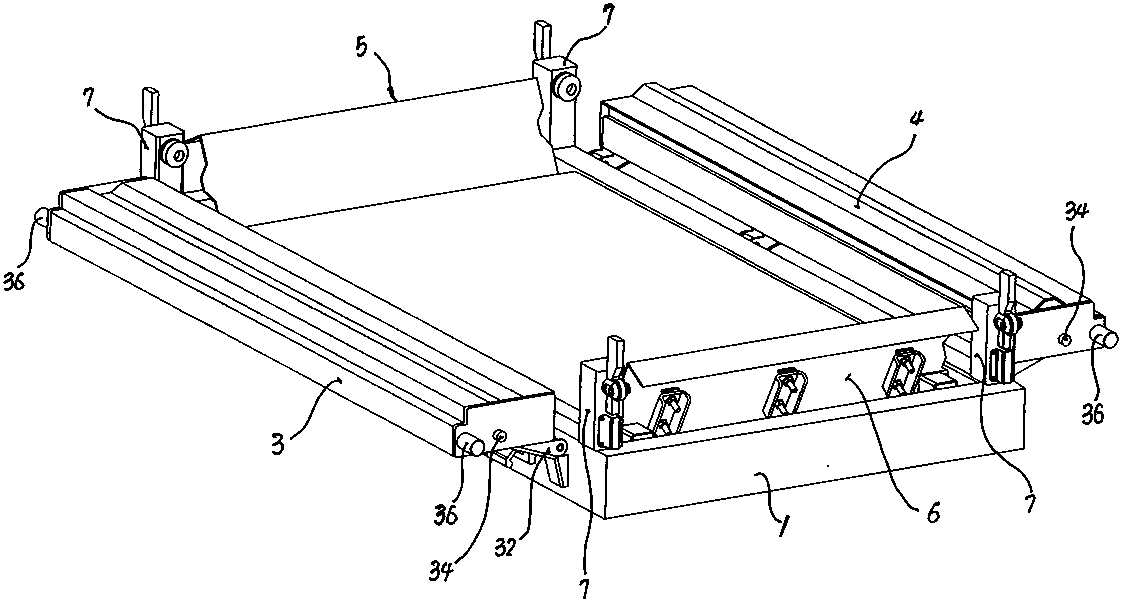

The invention discloses a light composite wallboard forming mold. The forming mold comprises a base (1), a bottom surface mold plate (2), a front side mold plate assembly (3), a rear side mold plate assembly (4), a left side mold plate assembly (5), a right side mold plate assembly (6) and positioning and locking devices (7) which correspondingly cooperate with the left end and the right end of the front side mold plate assembly (3) and the left end and the right end of the rear side mold plate assembly (4), wherein the front side mold plate assembly (3) and the rear side mold plate assembly (4) are symmetrical and are consistent in structure, and the left side mold plate assembly (5) and the right side mold plate assembly (6) are symmetrical and are consistent in structure. According to the light composite wallboard forming mold, the left side mold plate assembly (5) and the right side mold plate assembly (6) can rotate to be opened and can adjust the length of a formed light composite wallboard through change of the bottom surface mold plate (2) with the different length, and moreover, the thickness of the formed light composite wallboard can be adjusted, so that production of the light composite wallboards with different specifications can be met, production efficiency is high, the product quality is good, and the mold is particularly suitable for being used in an automaticproduction line.

Owner:丹东众力机械有限公司

Longitudinal movement trolley and adjusting assembly for single-rail track beam formwork and application method

The invention discloses a longitudinal movement trolley for a single-rail track beam formwork. The longitudinal movement trolley comprises a trolley body, a transverse movement device and a telescopicdevice. The trolley body is provided with a drive component and used for being arranged on two parallel steel rails and can move along the steel rails. The transverse movement device is in sliding connection to the trolley body. One end of the telescopic device is connected to the trolley body, the other end of the telescopic device is connected to the transverse movement device, and the transverse movement device is used for being connected with thetrack beam formwork. By application of the longitudinal movement trolley for the single-rail track beam formwork, after track beam pouring and initial setting, the telescopic device drives the transverse movement device to move so that the track beam formwork can be demoulded, the trolley body drives the transverse movement device and the track beam formwork to move to the next pouring position, an initially-set track beam can be stored and completely cured and formed on the site, and the problems about potential safety hazards and qualityof lateral overturning and cracking during track beam movement due to movement after initial setting like an existing manner are solved. The longitudinal movement trolley is simple in structure, convenient to use, high in mold reversing efficiency and capable of saving time.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Stepped type retaining wall building block die

The invention provides a stepped type retaining wall building block die. The stepped type retaining wall building block die comprises a base, and a middle die, a first moving die, a second moving die, a first fixed die and a second fixed die, which are mounted on the base, wherein the first moving die, the first fixed die, the second moving die and the second fixed die are sequentially distributed at the periphery of the middle die; the first moving die and the second moving die are symmetrically arranged along the middle die; the first fixed die and the second fixed die are symmetrically arranged along the middle die; when the middle die, the first moving die, the second moving die, the first fixed die and the second fixed die are in a die assembly state, two cavities which are symmetrically arranged along the middle die are formed through the mutual cooperation of the middle die, the first moving die, the second moving die, the first fixed die and the second fixed die; and two pouring gates communicating with the two cavities are separately formed in the top end of the die. The stepped type retaining wall building block die can simultaneously produce two retaining wall building blocks. The structure is simple. The die can be continuously closed and opened, and the retaining wall building blocks can conveniently and reliably taken out, so that the production efficiency is greatly increased.

Owner:安徽城洁环境科技有限公司

Ballastless-track-slab die

PendingCN107214816APrevent back and forth, side to side movementImprove connection fixation effectMouldsMould auxillary partsClassical mechanicsBolt connection

The invention provides a ballastless-track-slab die. The ballastless-track-slab die comprises a bottom die and a rectangular cavity defined by left and right end dies and front and back side dies. The rectangular cavity is used for manufacturing a track slab, a bottom die slab is fixedly installed on a bottom die frame, and the bottom die frame is fixedly installed on a base; the lower extended sections of the left and right end dies and the front and back side dies are connected with the bottom die through bolts, the left extended sections and the right extended sections of the left and right end dies and the left extended sections and the right extended sections of the front and back side dies are connected correspondingly through bolts, and fastener bolt-hole embedded parts are transversely and symmetrically installed in a bearing-rail-bed preformed groove; and a track-slab connecting bolt-hole embedded part is vertically installed in a track-slab connecting preformed hole, semi-circle terrace dies are arranged in the middles of the inner side walls of left and right end die slabs, a plurality of longitudinal prestress stretch-draw-rod mounting holes are further formed in the left and right end die slabs, and a plurality of transverse prestress stretch-draw-rod mounting holes and slant prestress stretch-draw-rod mounting holes are formed in side die slabs. According to the ballastless-track-slab die, the airtightness is good, and the high-strength and firmly and stably connected track slab can be manufactured.

Owner:TIANJIN YINLONG HIGH TECH NEW MATERIAL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com