Prefabricated light transmitting concrete plate production mold and manufacturing method thereof

A technology of light-transmitting concrete and mould, applied in the field of concrete, can solve the problem of the concrete slab not having light-transmittance, etc., and achieve the effects of good interior decoration effect, labor reduction and structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

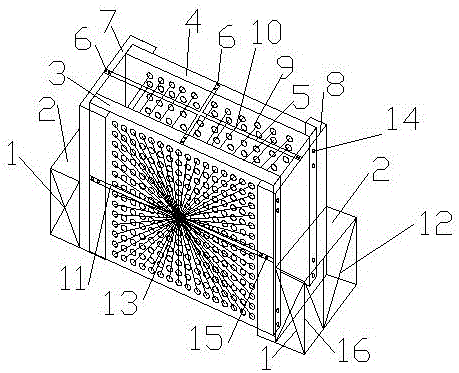

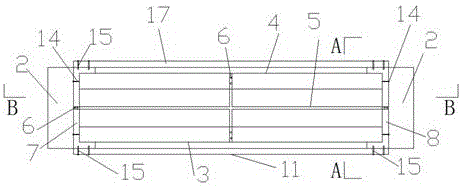

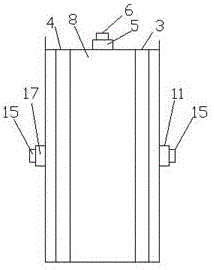

[0026] From Figure 1-4 It can be seen that a prefabricated light-transmitting concrete slab production mold in this embodiment includes a front pedal, a left formwork 3, a right formwork 4, cross-shaped braces 5, brace fixing bolts 6, and a rear U-shaped steel formwork 7. Front side U-shaped steel template 8, optical fiber hole 9, optical fiber 10, left straight brace 11, combined bolt 14, straight brace fixing bolt 15 and right straight brace 17, the front pedal includes horizontal diagonal brace 1, The bearing plate 2, the diagonal bar 12 and the vertical bar 16, the above-mentioned horizontal diagonal brace 1 is composed of two crossed equilateral angle steels, one end is welded on the vertical bar 16, and the other end is welded on the front U-shaped steel formwork 8; the bearing plate 2 The two ends are welded with horizontal diagonal braces 1, and the lateral sides are welded with oblique rods 12 and vertical rods 16; On the bottom surface of the bottom surface, the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com