Side mould, sealing clamp and mould and method for producing reinforced wall

A technology of sealing clips and side molds, applied in molds, mold trays, mold panels, etc., can solve the problems of low production efficiency and high labor intensity of workers, and achieve the effects of simple operation, low labor intensity of workers, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

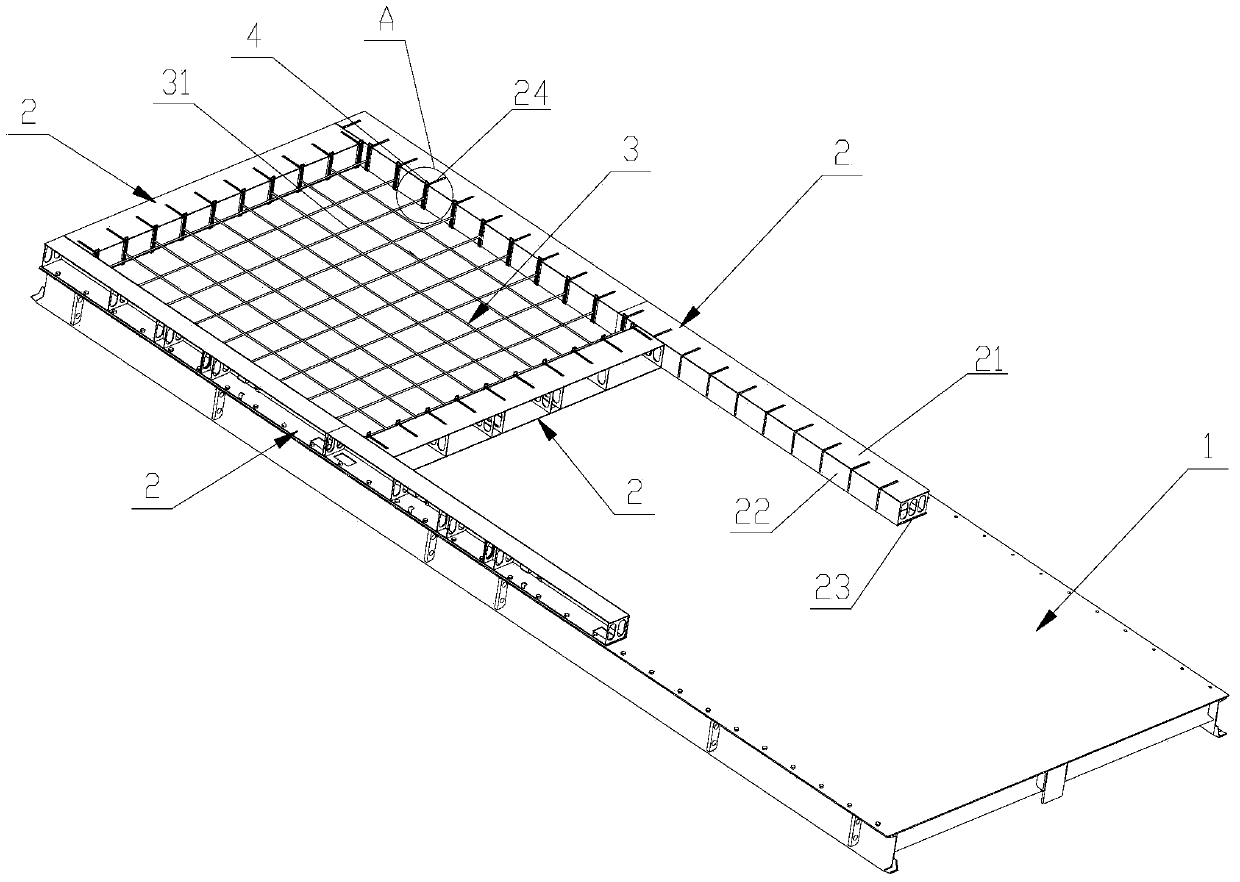

[0035] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. Attached below Figures 1 to 5 Specific examples of the present invention will be described in detail.

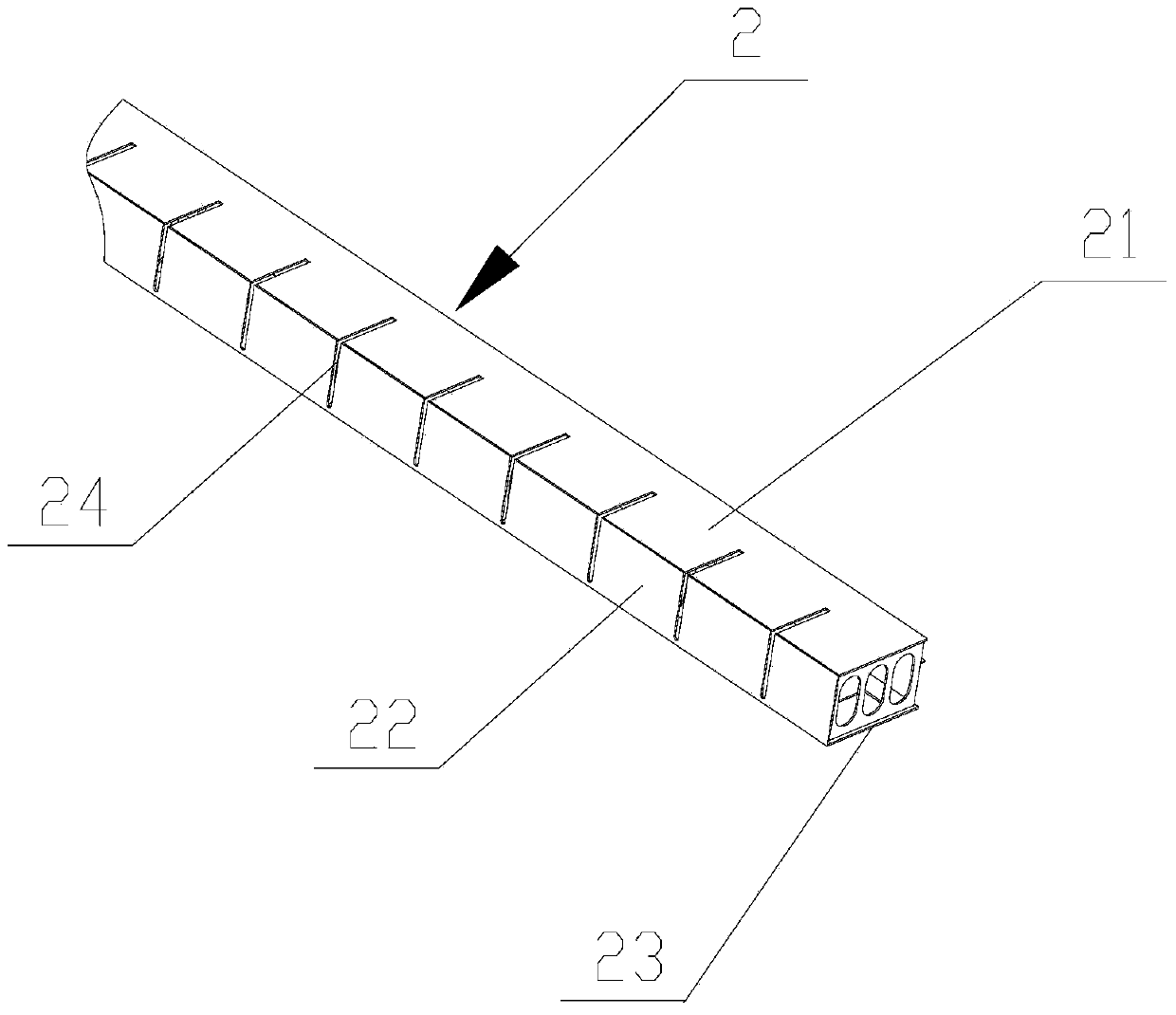

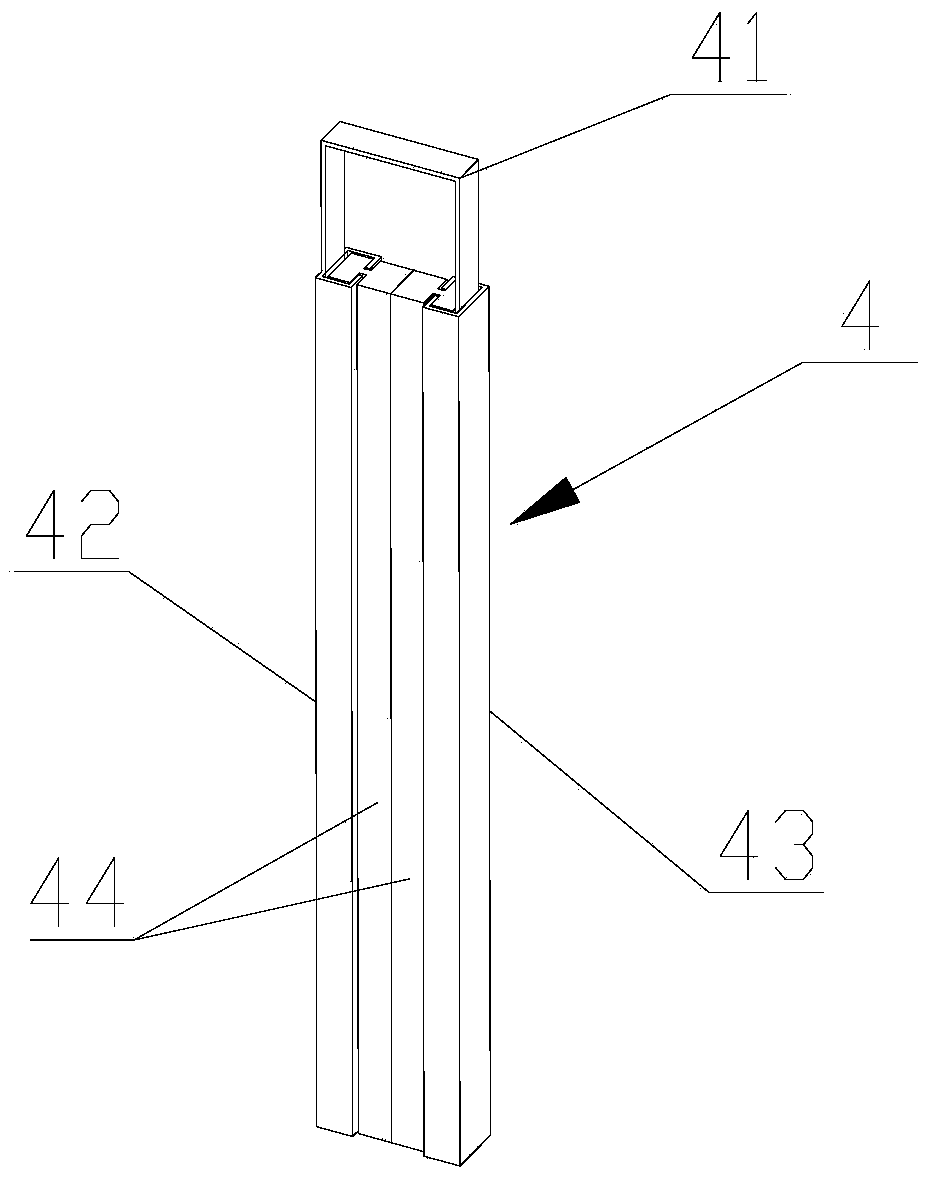

[0036] The mold that the concrete embodiment of the present invention proposes is used to produce rib wall and comprises side mold 2 and sealing clamp 4, as figure 1 As shown, the side formwork 2 is provided with a base plate 23, a side plate 22 and a top plate 21, and a predetermined number of vertical notches 24 are arranged at intervals on the side formwork 2, and the vertical notch 24 runs through the side plate 22 and the top plate 21; figure 2 As shown, the sealing clip 4 includes a U-shaped elastic piece 41, a first clamping arm 42 and a second clamping arm 43, and the first clamping arm 42 and the second clamping arm 43 are connected to the two ends of the U-shaped elastic piece 41 respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com