Prefabricated wall plate with heat preservation interlayer and manufacturing method thereof

A technology of prefabricated wall panels and thermal insulation interlayers, applied in the direction of mold panels, manufacturing tools, mold fixing devices, etc., can solve the problems of weather influence, extension of construction date, environmental damage, etc., to achieve positioning, improve positioning firmness, Use clever effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] For ease of understanding, the attached Figure 1-10 , the concrete structure and working mode of the present invention are further described as follows:

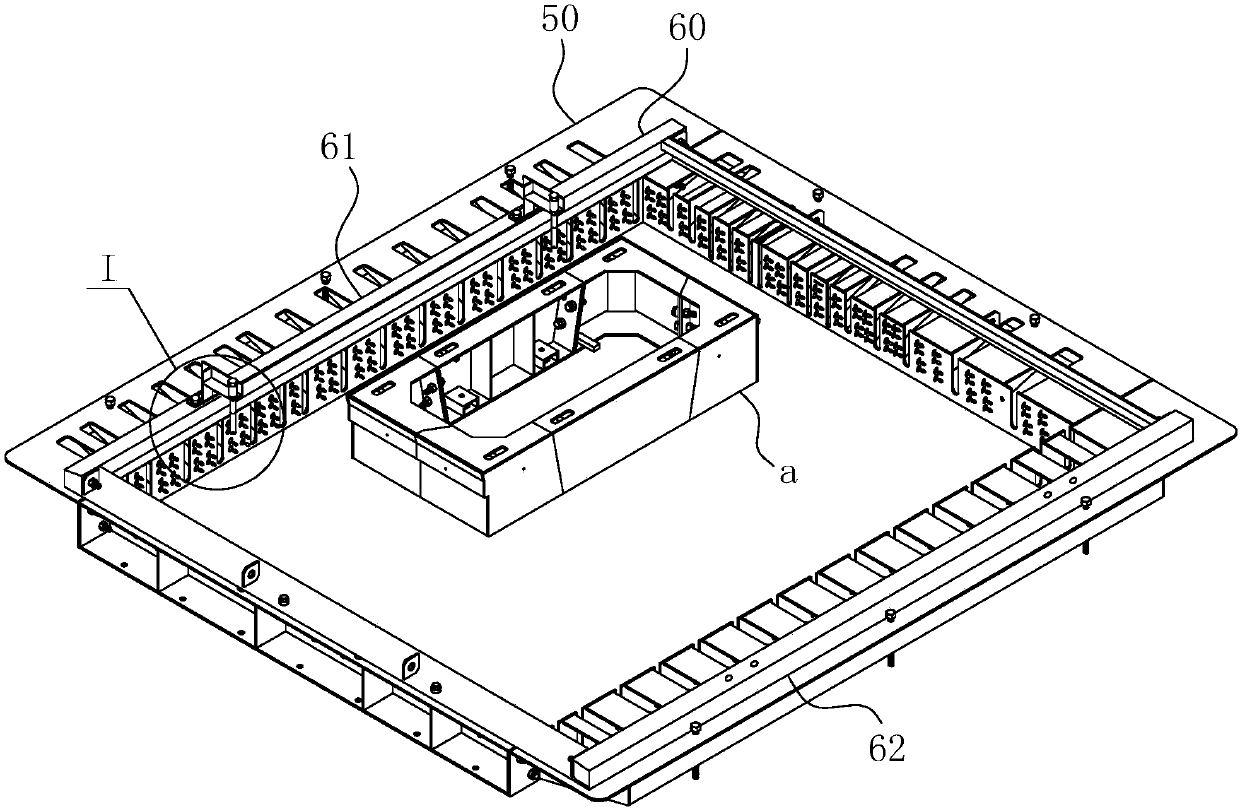

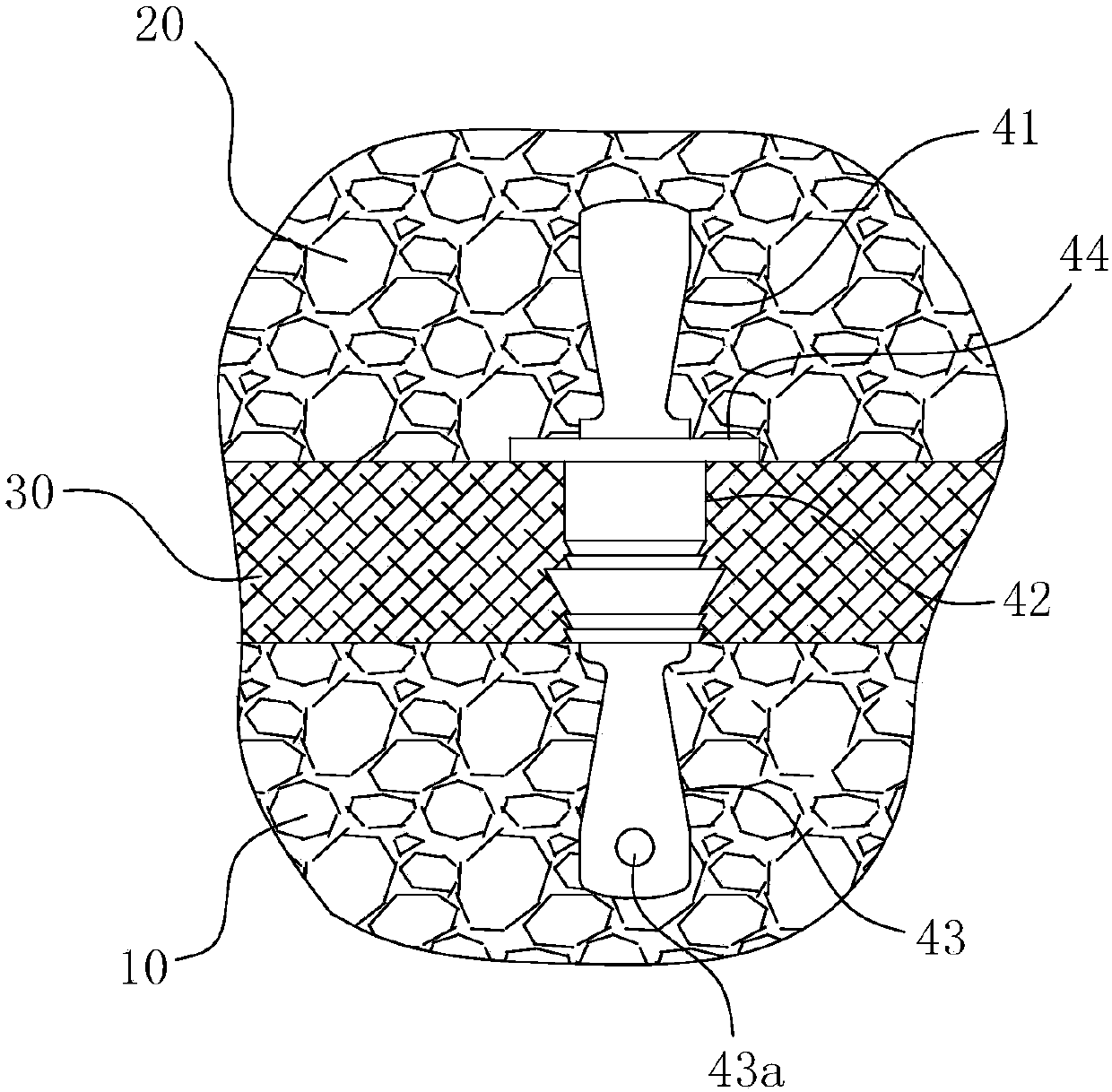

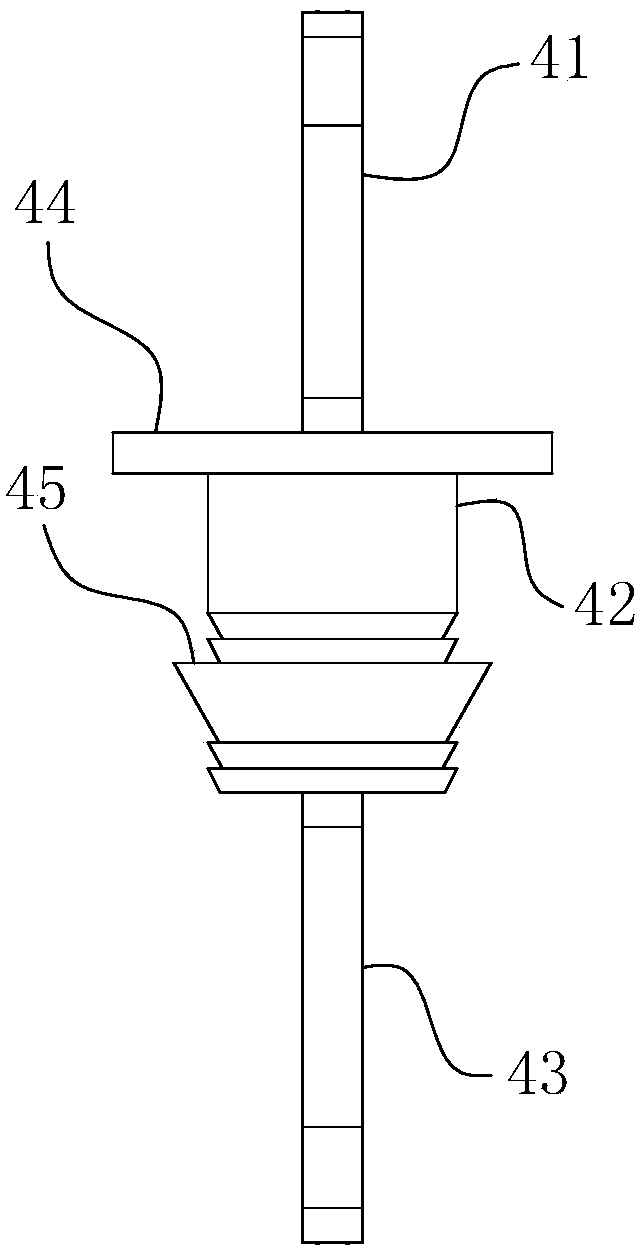

[0055] The specific application environment of the present invention is figure 1 shown as an example. figure 1 It is a wall panel mold, which includes an inner leaf wall module, a window opening module a for being arranged in the mold cavity of the inner leaf wall module, and an outer leaf wall module located at the top surface of the inner leaf wall module. The window opening module a is the same as the inner leaf wall module when in use, and is placed horizontally on a certain mold surface, and the mold surface is referred to as "base surface" here. The "vertical direction" described later refers to the direction perpendicular to the base plane. When the window opening module a and the inner leaf wall module are as a whole figure 1 When it is placed on the base surface as shown, the space between the window ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com