Longitudinal movement trolley and adjusting assembly for single-rail track beam formwork and application method

A technology for adjusting components and track beams, applied in the field of rail transit, can solve problems such as the quality of track beams and hidden dangers of construction safety, and achieve the effects of high mold casting efficiency, time saving and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

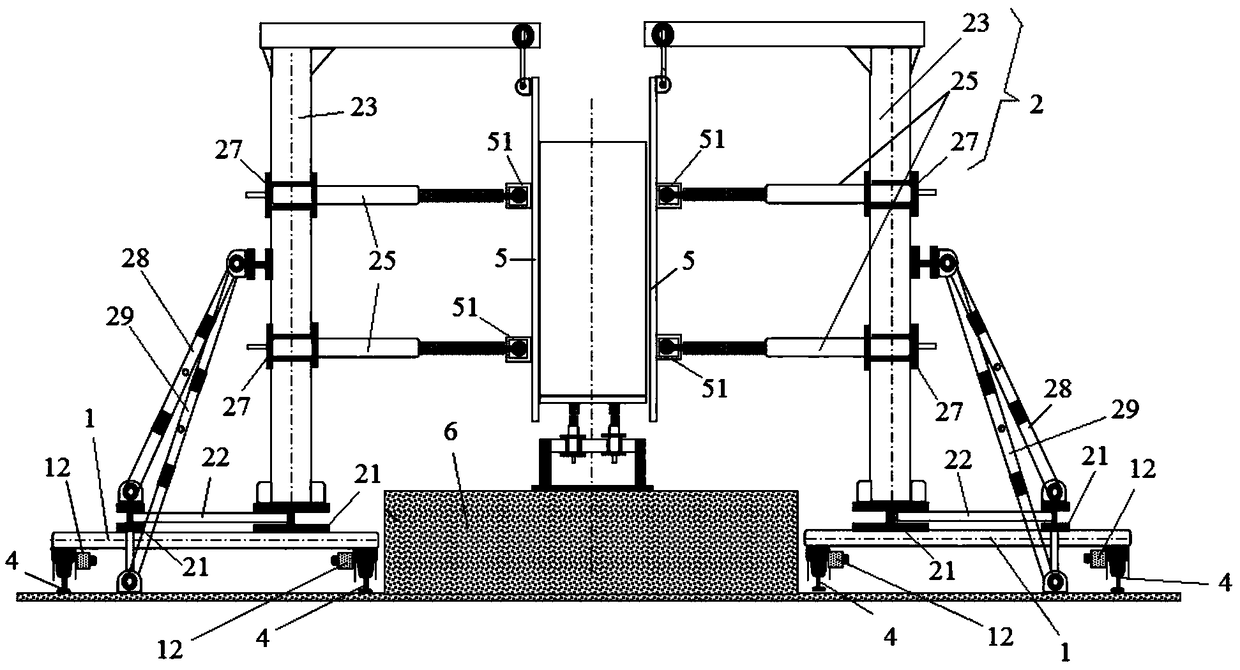

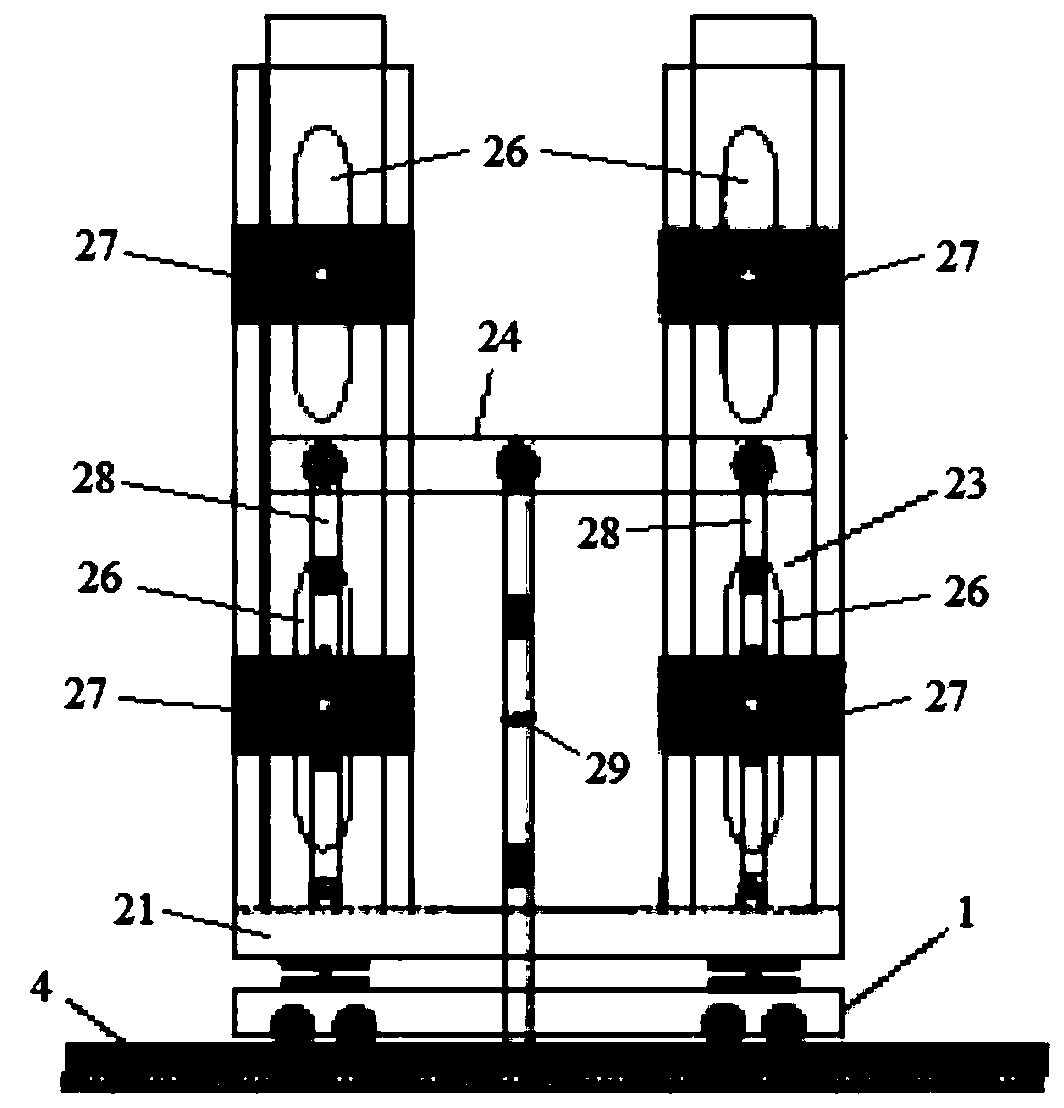

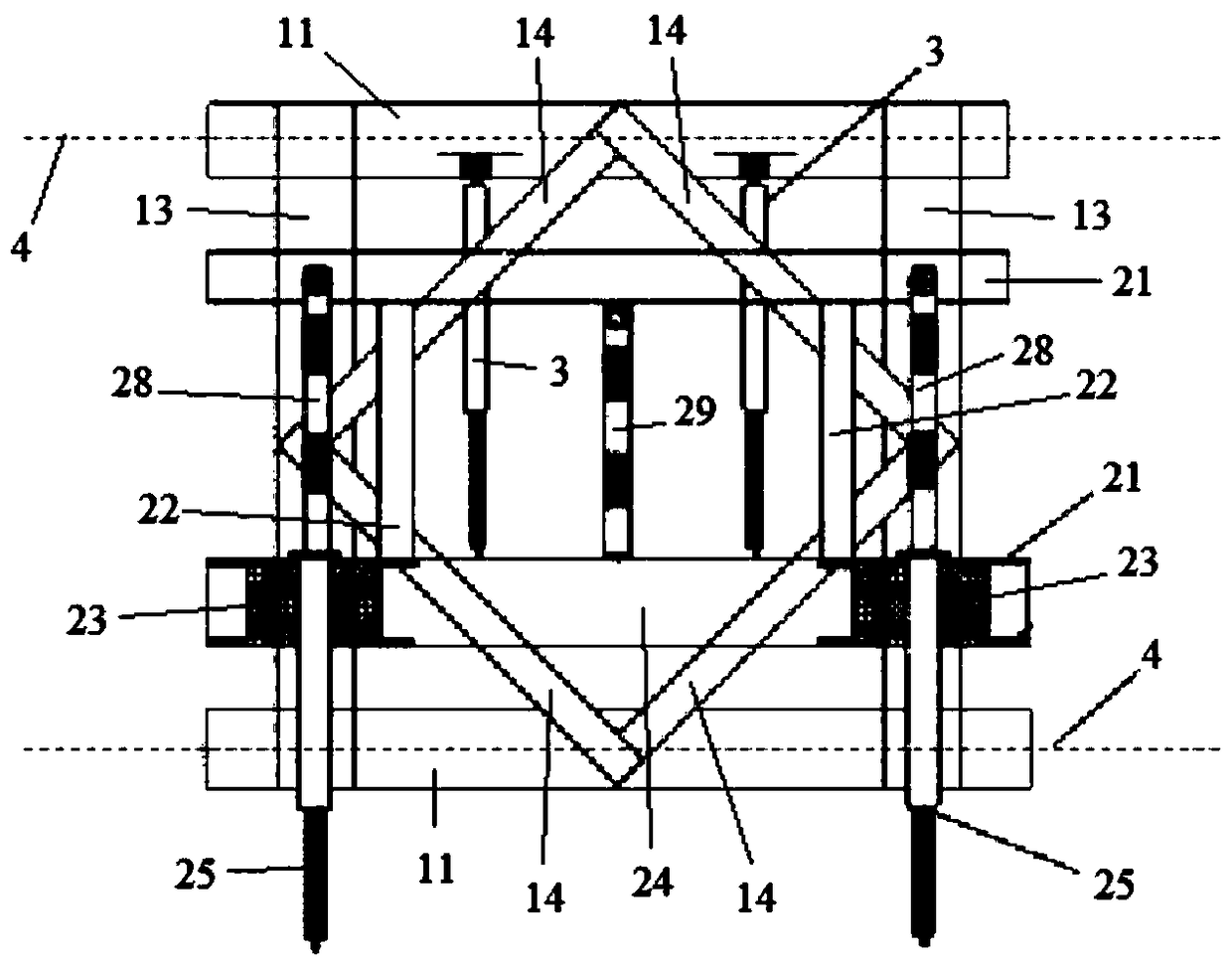

[0038] Such as Figure 1-5 As shown, a longitudinal moving trolley for monorail track beam formwork according to the present invention includes a trolley body 1 , a traverse device 2 and a telescopic device 3 .

[0039] The trolley body 1 is provided with a driving part 12, the trolley body 1 is used to be arranged on two parallel rails 4, and can move along the rails 4, and the traverse device 2 is slidably connected to the trolley body 1. One end of the telescopic device 3 is connected to the trolley body 1, and the other end is connected to the traverse device 2, and the traverse device 2 is used to connect the rail beam formwork 5.

[0040] As a preferred solution of this embodiment, the trolley body 1 includes two steel boxes 11 arranged in parallel, wheels and the driving parts 12 are arranged at the bottom of each of the steel boxes 11, and the steel boxes 11 on each The wheels are respectively arranged on one of the steel rails 4, two H-shaped steels 13 are arranged b...

Embodiment 2

[0045] Such as Figure 1-5 As shown, an adjustment assembly for a monorail track beam formwork according to the present invention includes several longitudinal moving trolleys as described in Embodiment 1 respectively arranged on both sides of the beam-making platform 6, and all the longitudinal moving trolleys on each side After the telescopic device 3 on the longitudinal moving trolley expands and contracts to different lengths according to the shape of the track beam, the track beam templates 5 connected to each of the traversing devices 2 are sequentially spliced to form side forms for pouring the track beam.

[0046] Using the adjusting assembly for monorail track beam formwork according to the present invention, a single track beam formwork 5 can be moved and set along the rail 4, and a plurality of track beam formworks 5 can be spliced to form a side form for track beam pouring, which can be based on the designed track beam formwork. The linear shape can be adjusted...

Embodiment 3

[0048] Such as Figure 1-5 As shown, a method for using an adjusting assembly for a monorail track beam formwork according to the present invention, using the adjusting assembly as described in Embodiment 2, includes the following steps:

[0049] A. Adjust the position of each trolley body 1 on the corresponding rail 4 according to the designed track beam alignment, and fix the positions of all the trolley bodies 1;

[0050] B. Connect the track beam formwork 5 with the corresponding traversing device 2, adjust each traversing device 2, constrain the corresponding track beam formwork 5 to form the required shape, so that all the track beam formwork 5 form pouring Side forms for track beams;

[0051] C. Adjust each telescoping device 3, drive the corresponding traversing device 2 to the appropriate position, make the side mold of the pouring track beam and the bottom mold on the beam-making platform 6 close the mold, set the end mold, and complete the setting of the pouring mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com