Hydraulic T-beam formwork construction device and technology

A technology of construction equipment and beam formwork, which is applied in the direction of mold panels, molds, manufacturing tools, etc., can solve the problems of large formwork amortization, low formwork utilization rate, and long idle time of side forms, so as to improve utilization rate and installation efficiency , The effect of lower hoisting operation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

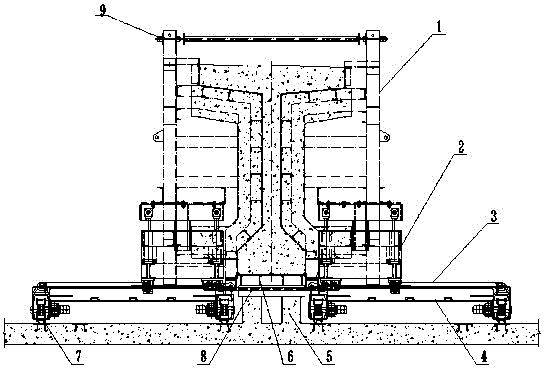

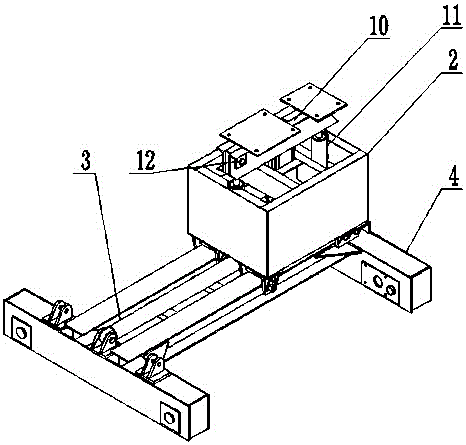

Embodiment 1

[0030] In order to overcome the problems of long idle time of the side molds in the existing device, low template utilization rate and large template amortization, the present invention provides such figure 1 , figure 2 The hydraulic T-beam formwork construction device shown in the figure adopts a hydraulically movable integral formwork, which is convenient and fast for formwork assembly and adjustment, accurate in position, and close-fitting seams; the use of hydraulically movable sideforms not only improves the efficiency of formwork installation , Lower hoisting operation risk, reduce labor intensity of workers, and improve the utilization rate of side forms. Compared with the traditional hydraulic T-beam formwork, it increases the functions of vertical adjustment and vertical beam movement, and the utilization rate of the side formwork system can be increased by 2-3 times.

[0031] A hydraulic T-beam formwork construction device, comprising a side form 1, a beam moving t...

Embodiment 2

[0039] Based on the first embodiment, in this embodiment, the lower part of the connecting shoulder beam 10 is connected to the vertical oil cylinder 11 through the connecting pin 12 .

[0040] The lower end of the vertical oil cylinder 11 is fixed on the beam moving trolley 2 by bolts.

[0041] The lower end of the side mold 1 is fixedly connected with the bottom mold through a bottom tie rod 8 crossing the middle of the bottom mold 6 .

[0042] The bottom mold 6 is set on the concrete foundation surface 5, and a 150*150*20 steel plate is pre-embedded when pouring the concrete pedestal foundation surface, and the bottom mold 6 is welded to the concrete foundation surface 5 pre-embedded steel with 18 I-beams. One.

[0043] The lower part of the connecting shoulder beam 10 is connected with the vertical oil cylinder 11 through a pin connection, and the vertical oil cylinder 11 is located between the left and right side molds 1 .

[0044] The middle part of the side form 1 is ...

Embodiment 3

[0056] On the basis of the above-mentioned embodiments, in this embodiment, a hydraulic T-beam formwork construction process is provided, and the specific steps are:

[0057] Step 1 Check the device, all components are in normal function, and the longitudinal beam stops moving longitudinally when moving to the moving trolley 4 and reaching the end line of the bottom mold 6;

[0058] Step 2: The trolley 2, which moves the crossbeam in the direction of the beam, realizes the lateral movement on the translation equalizing beam through the horizontal translation oil cylinder, and closes the hydraulic system when the distance close to the bottom mold 6 is 1-2 cm;

[0059] Step 3 After step 2 is completed, stick to the bottom mold 6 through the bottom tie rod 8;

[0060] Step 4 After the above steps are completed, the column of the side form 1 is supported on the rigid foundation of the beam-making pedestal, the bottom of the side form 1 is fixedly connected with the bottom form 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com