Multistation synchronous symmetric mold opening and closing mechanism of ceramic bathroom accessory

A mold opening and closing, multi-station technology, applied in the direction of ceramic molding machines, molds, mold trays, etc., can solve the problems of uneven force, long drying time of embryo body, unqualified embryo body, etc., to ensure reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

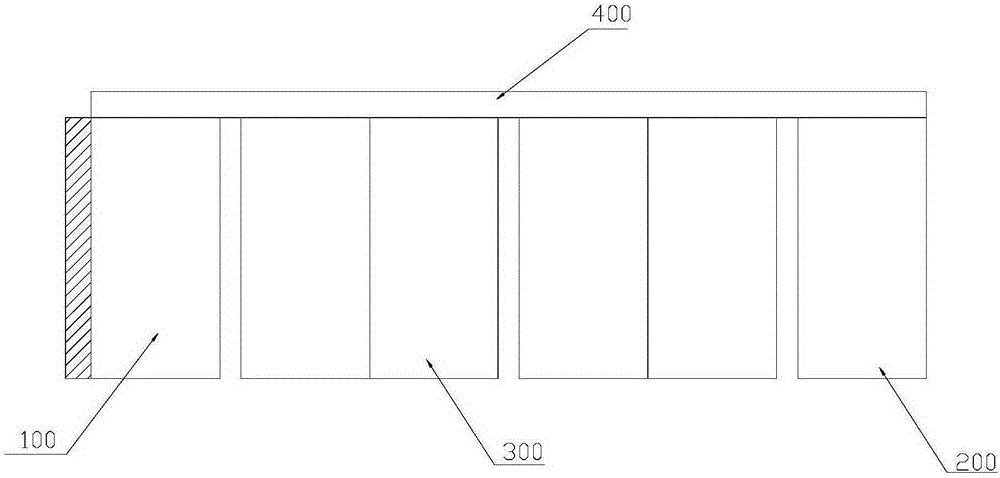

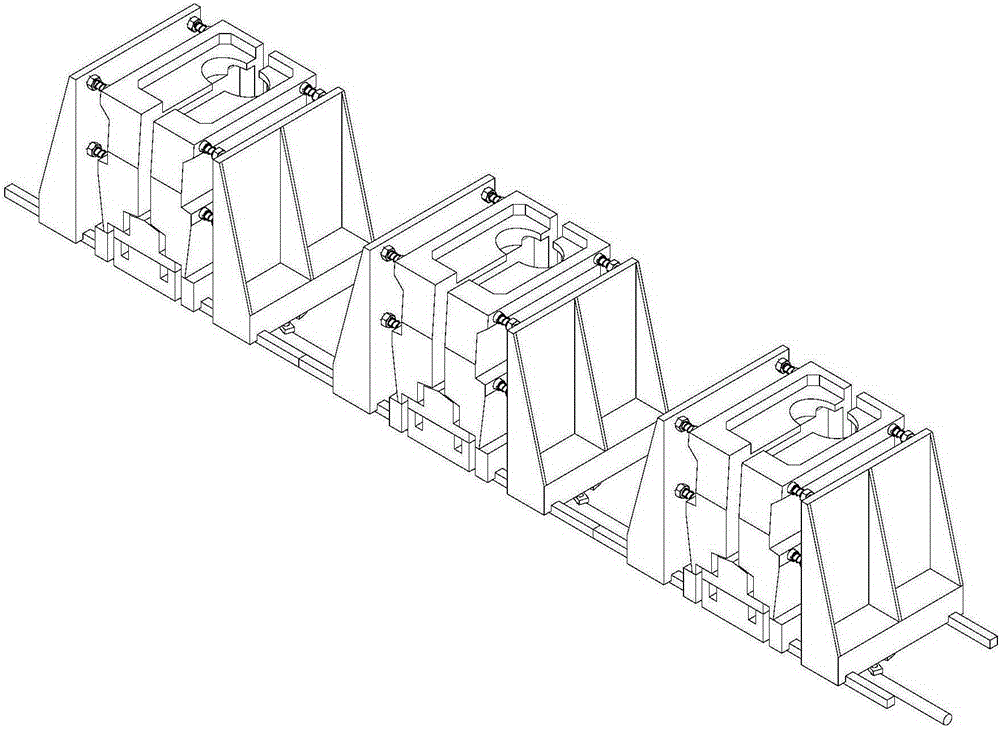

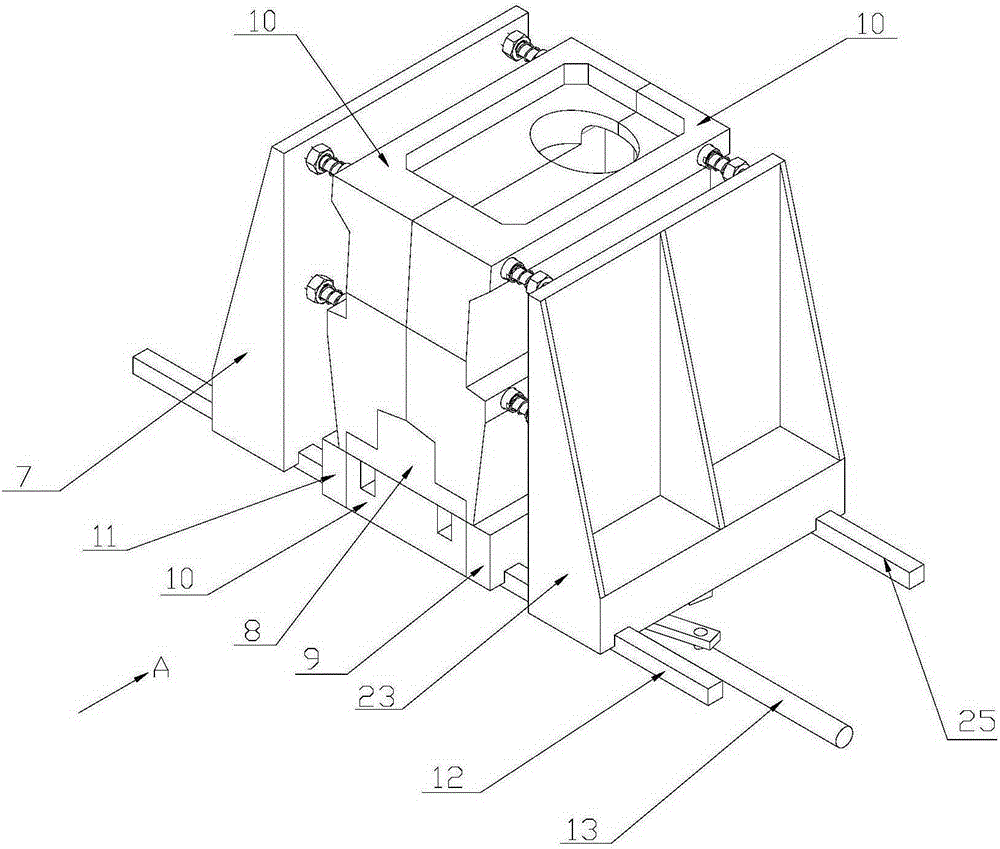

[0043] Please refer to figure 2 As shown, a sanitary ceramic multi-position synchronous symmetrical mold opening and closing mechanism includes multiple sets of molds, each set of molds includes a corresponding left mold 1 and a right mold 24, and in order to ensure the simultaneous opening and closing of multiple sets of molds , during the initial installation, it should be ensured that the distances between the left mold 1 and the right mold 24 of each group are equal. Take a group of molds as an example below, and the structural relationship of other groups of molds is similar (only the positions on the guide rails are different).

[0044] Please refer to Figure 3-6 As shown, it is through the movement of the straight rod 13 that the left mold 1 and the right mold 24 move toward each other at the same time, and the purpose of opening and closing multiple groups of molds has been achieved. It specifically includes a guide rail, an output arm formed by a support mechanism...

Embodiment 2

[0053] Please refer to Figure 10-13 As shown, one of the molds in each group is fixed, and the other moves relative to the fixed mold to realize the synchronous opening and closing of multiple groups of molds. Here, fixing the right mold 24 and moving the left mold 1 is taken as an example, which specifically includes a guide rail, an output arm formed by a support mechanism, an elastic assembly, a translation mechanism and a power mechanism.

[0054] The guide rail is installed on the frame, and the long slide bar 26 slides left and right on the guide rail. The supporting mechanism is two output arms of the left grasping arm and the right grasping arm. The side of the left mold 1 away from the right mold 24 is fixedly connected with the left grasping arm. Right mold 24 is fixedly connected with right grasping arm away from the side of left mold 1.

[0055] The left grasping arm and the connection mode of left mold 1 are identical with the right grasping arm and the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com