Bridge production system

A technology for production systems and bridges, which is applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., to achieve the effects of reduced cost, simple production, and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

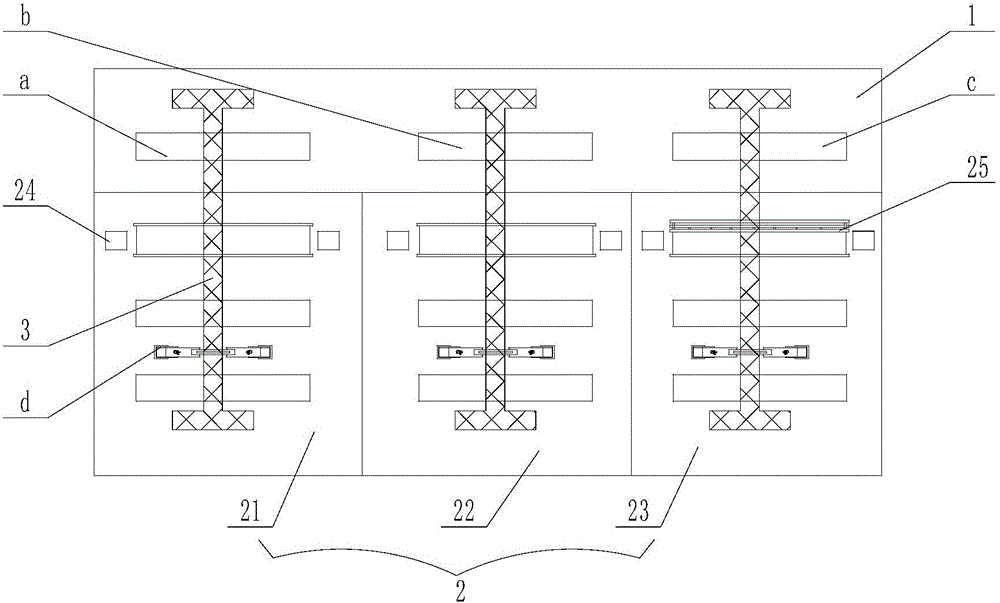

[0038] Such as Figure 1-12 As shown in , a bridge production system includes a beam body reinforcement binding area 1, a beam body pouring area 2 and a gantry crane 3, and the gantry crane 3 is set across the beam body reinforcement binding area 1 and the beam body pouring area 2 On, the gantry crane 3 is provided with a lifting device d;

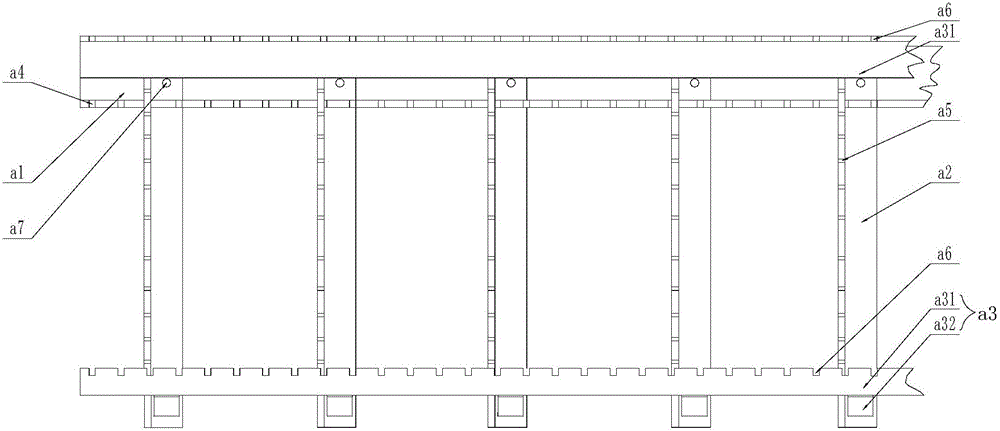

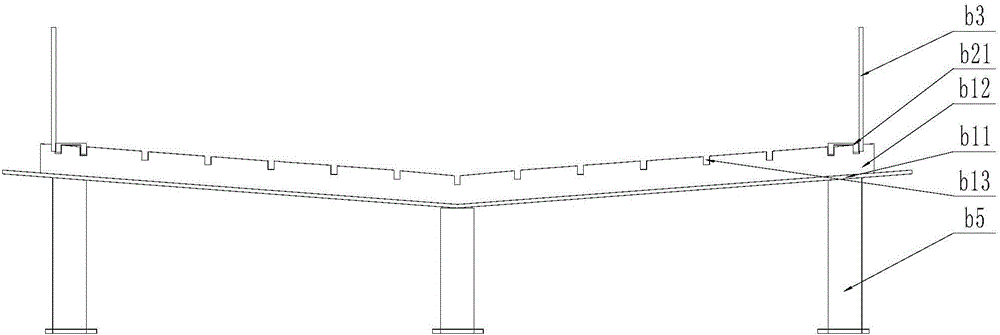

[0039] In the beam body reinforcement binding area 1, there is a T-beam prefabricated web reinforcement binding platform a, a center girder bridge deck reinforcement binding platform b, and a left and right side beam reinforcement integral binding platform c; Girder area 21, center girder bridge deck girder area 22 and left and right side girder area 23, in said T girder area 21, center gird...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com