Large stadium pipe truss and spiral duct modularization installation method and combination structure

A technology of spiral air duct and installation method, which is applied in the direction of vertical pipes, building components, building structures, etc., can solve the problems of difficult electromechanical systems, high construction risk, and high steel structure height, so as to reduce high-altitude operations and ensure safety , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

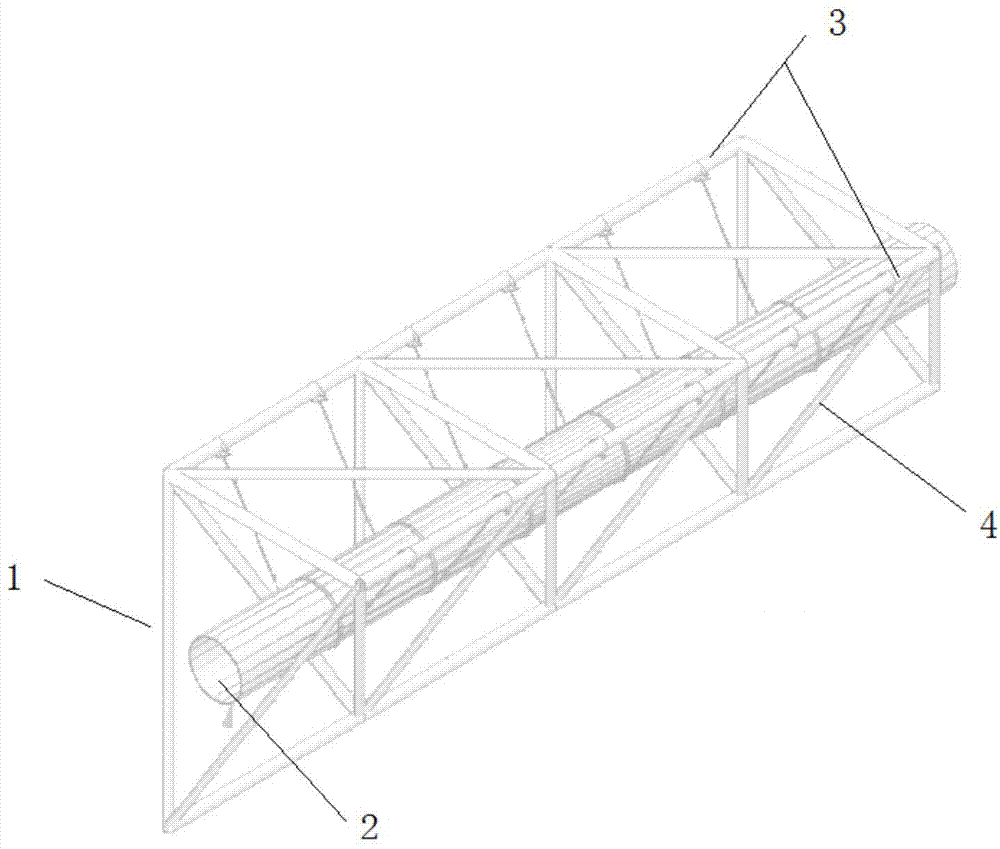

[0023] Example 1: The spiral air duct on the truss of the exhibition hall A of a certain exhibition center is a circular air duct, the main specifications are Φ1400mm, Φ1200 mm, Φ1000 mm, Φ900 mm, Φ700 mm, Φ500 mm, and the area of the air duct is about 8400m 2 . Considering that the diameter of the spiral air duct is relatively large, and the truss height of exhibition hall A is 43m, and the net height is about 27m, from the perspective of construction safety and rationality, the air duct on the truss is assembled on the ground, hoisted synchronously with the truss, and finally uses hanging baskets, elevators and other equipment Partial installation is carried out, including the following steps:

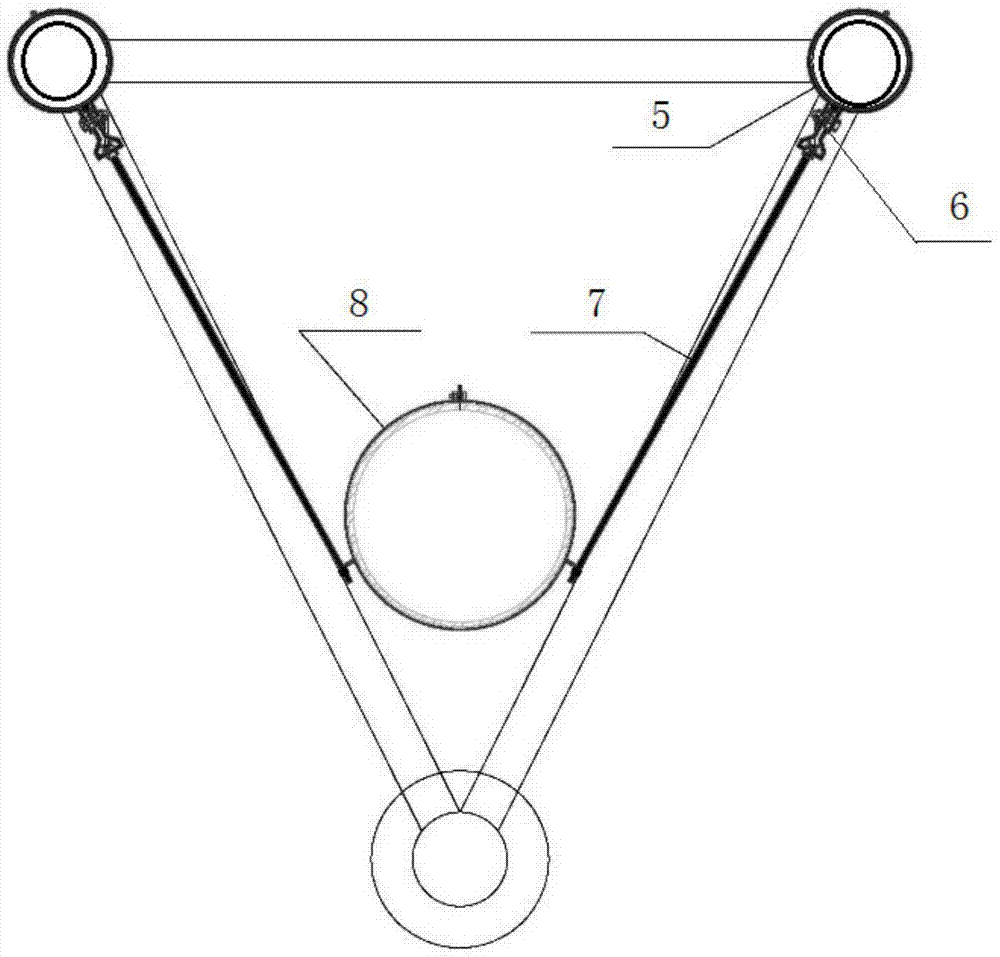

[0024] (1) Module division of pipe trusses and spiral air ducts: According to the design documents and drawings, the installation simulation of pipe trusses and spiral air ducts is carried out through BIM technology, the relative installation position of the spiral air ducts is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com