Patents

Literature

76results about How to "Increased installation difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

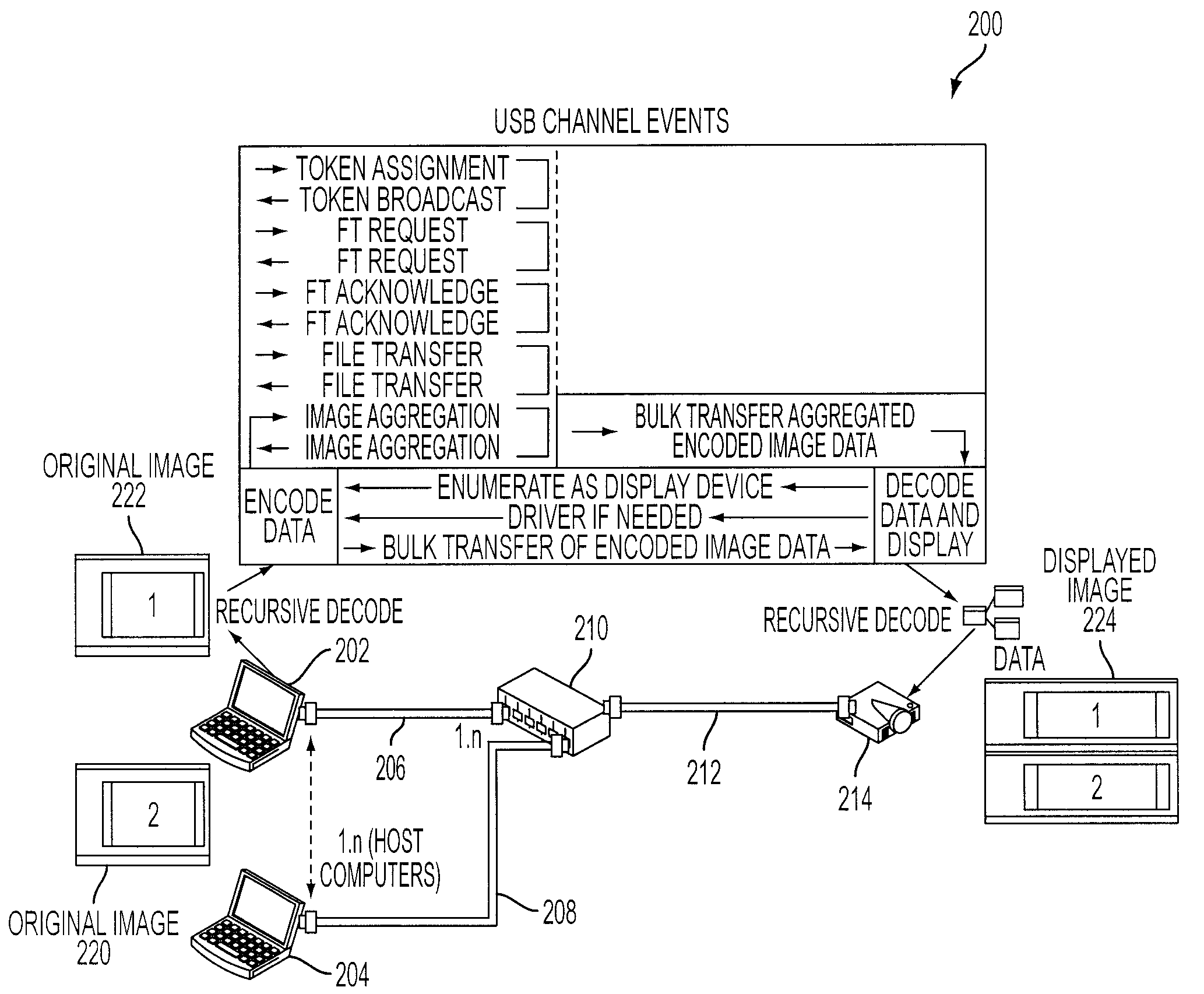

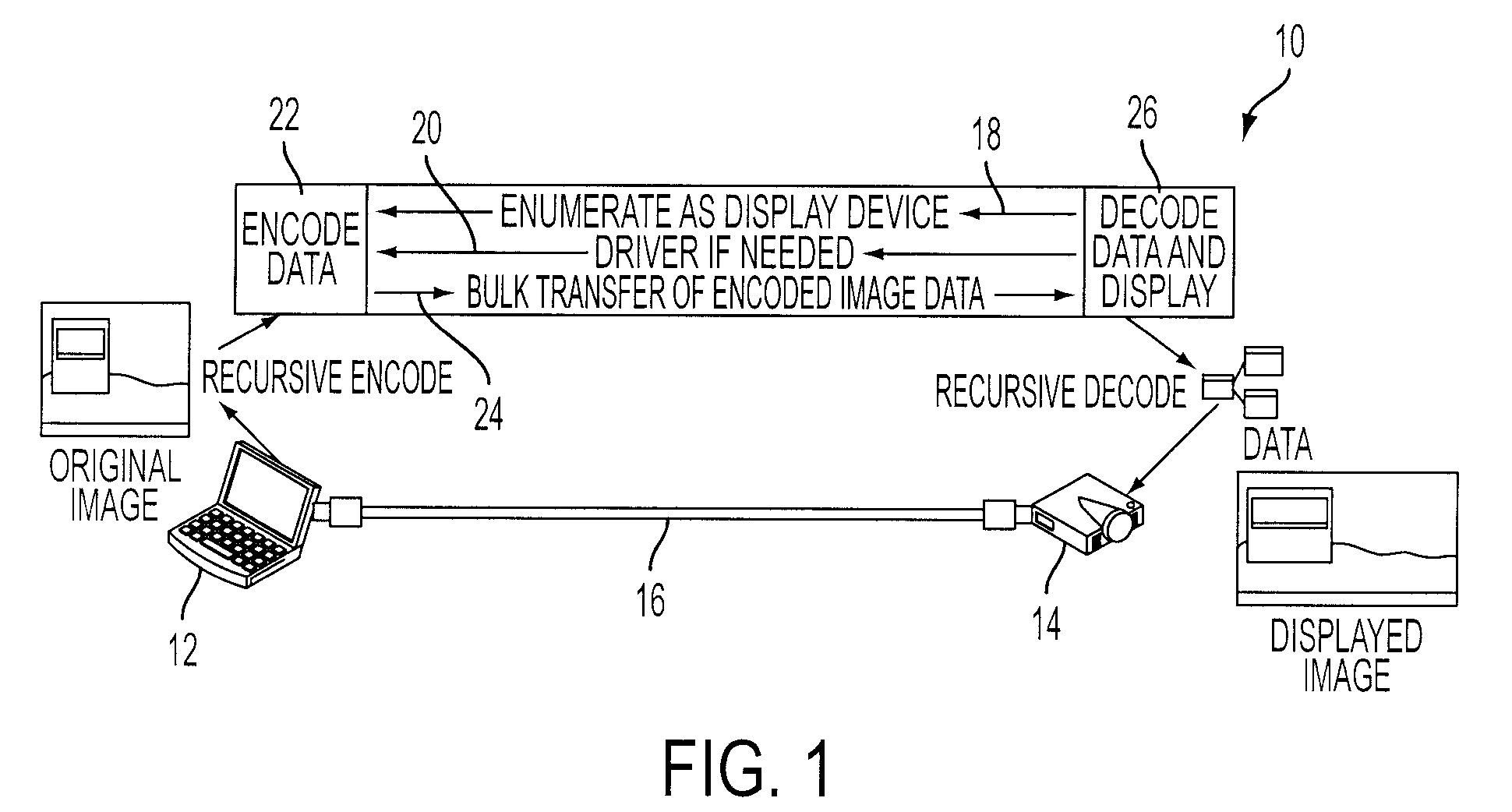

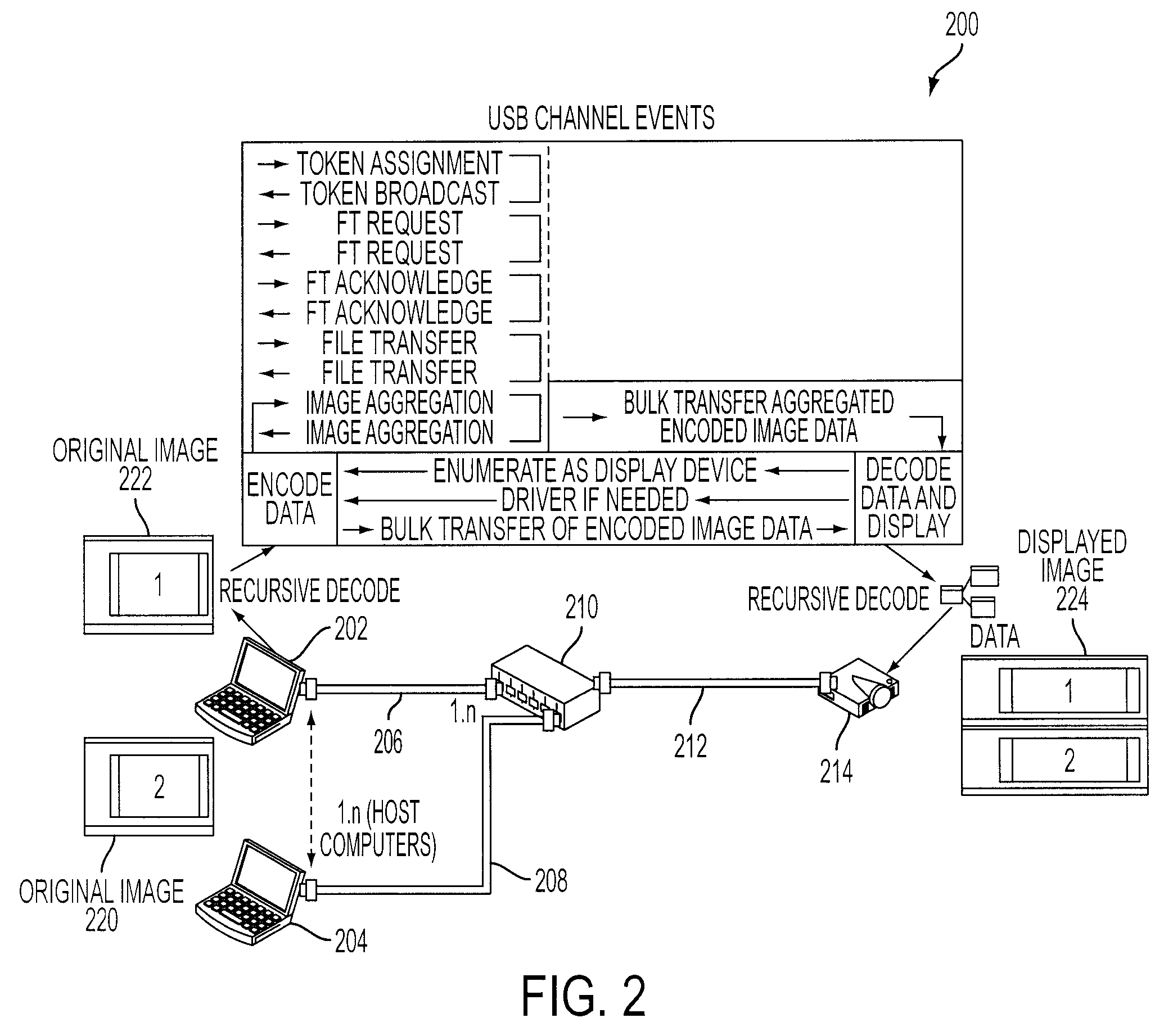

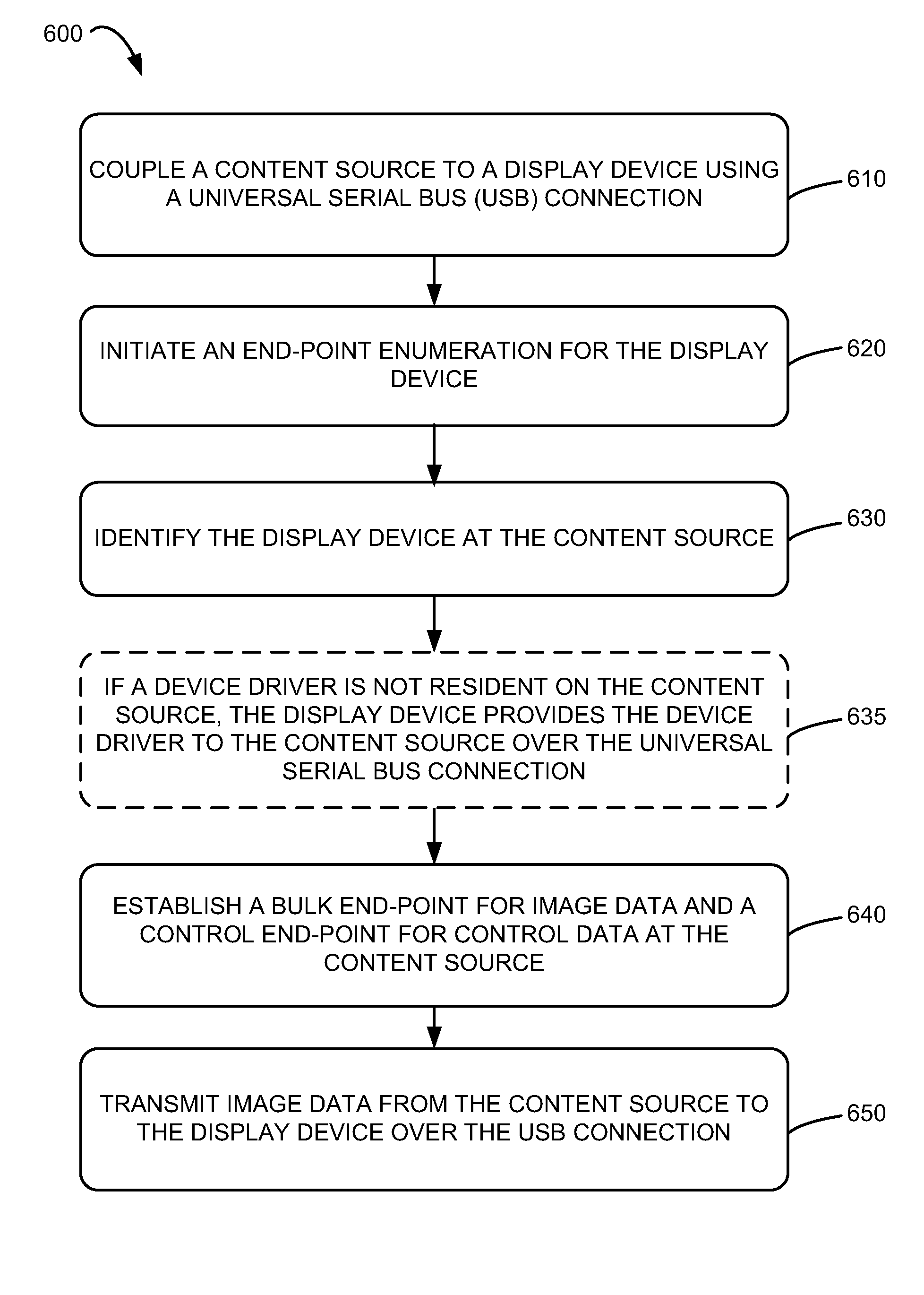

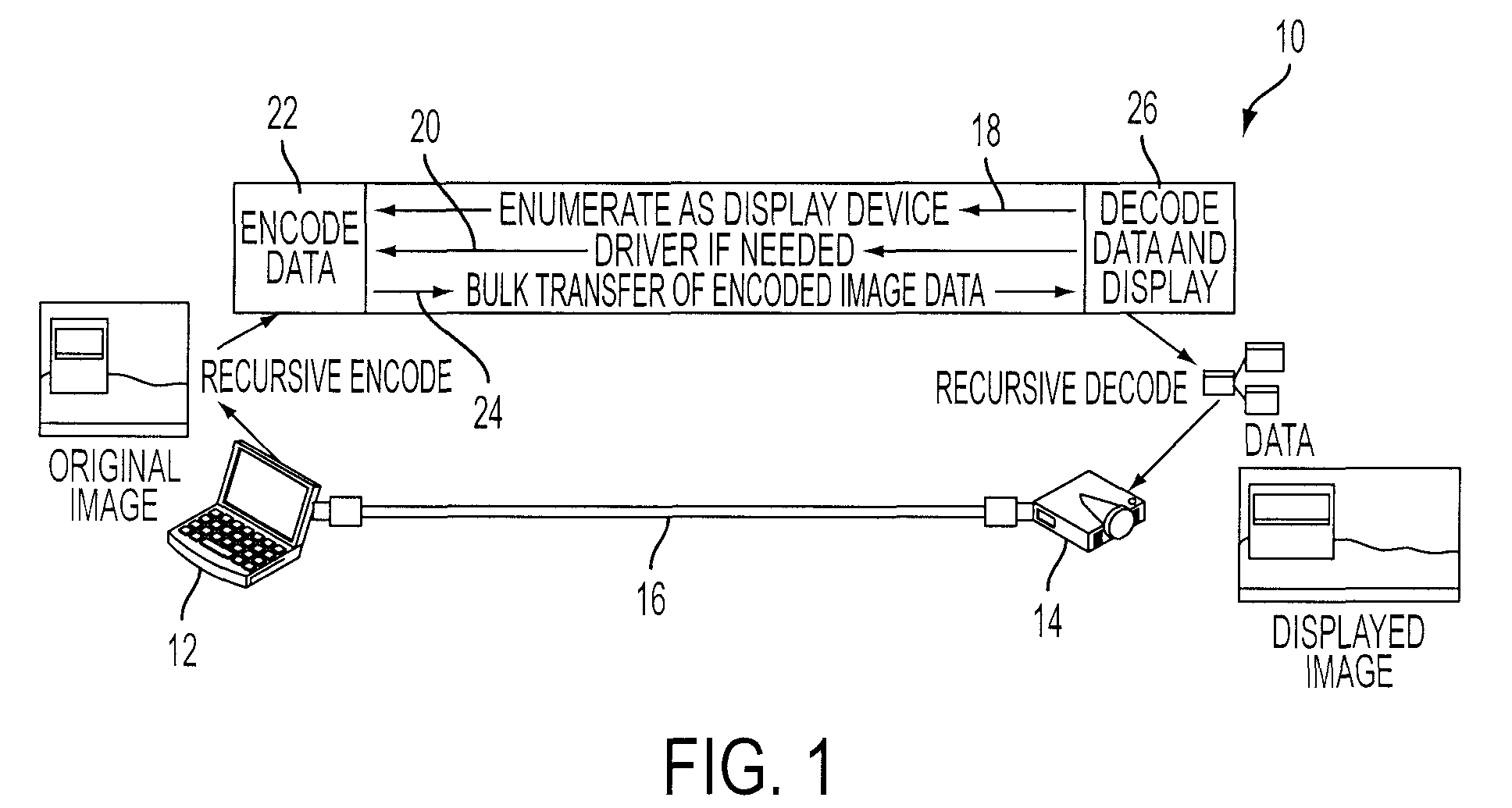

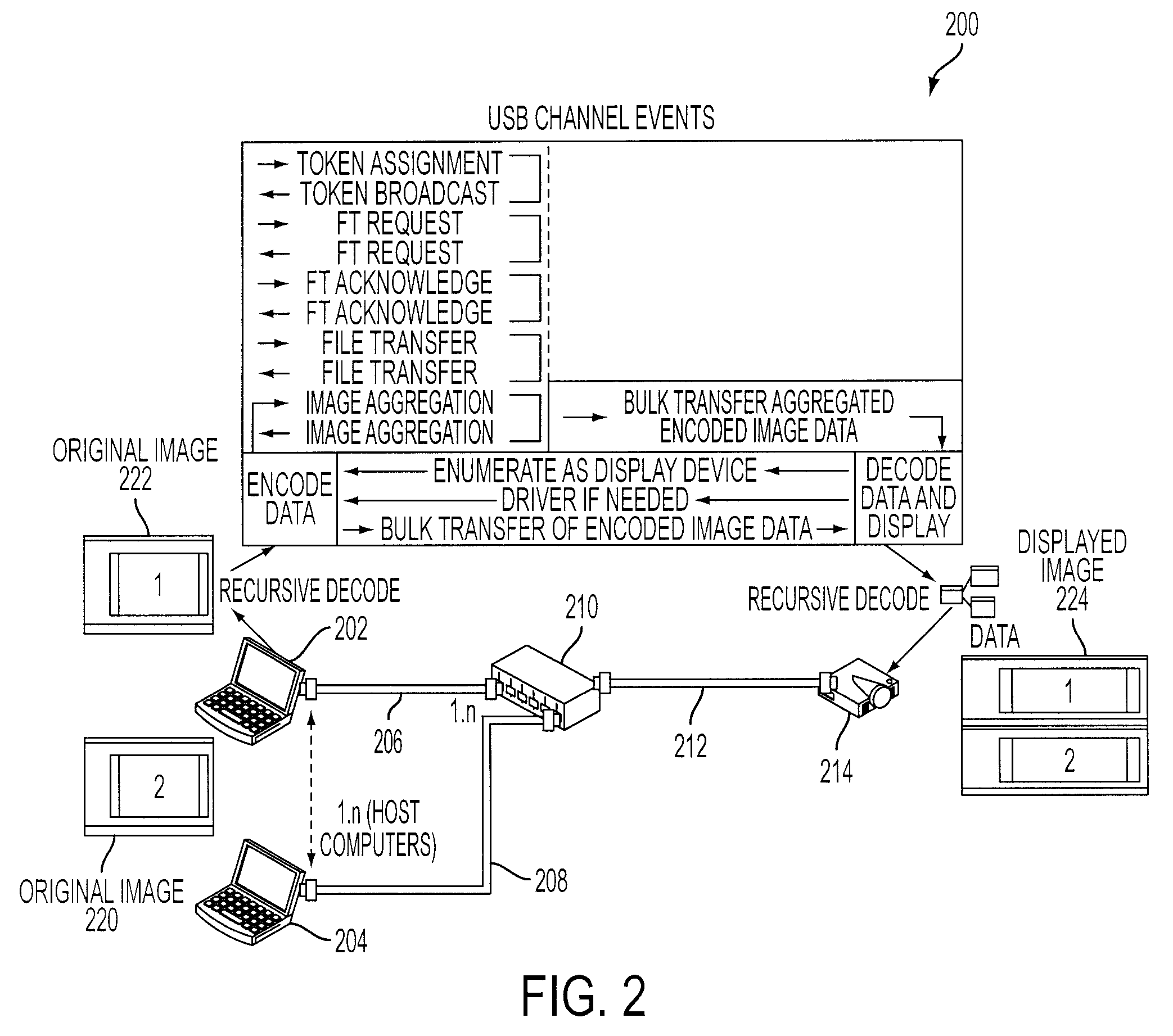

USB Image Transmission System and Device

ActiveUS20080088634A1Increased installation difficultyUser frustrationCathode-ray tube indicatorsDigital output to display deviceDisplay deviceUSB

A USB image transmission system is provided. The USB image transmission system may include a content source configured to be operatively coupled to a USB-enabled display device. Image data may be transmitted over the USB connection from the content source for display by the display device. In some embodiments, a USB collaboration hub may enable multiple content sources to be operatively linked through a USB connection to one or more USB-enabled display devices.

Owner:SEIKO EPSON CORP

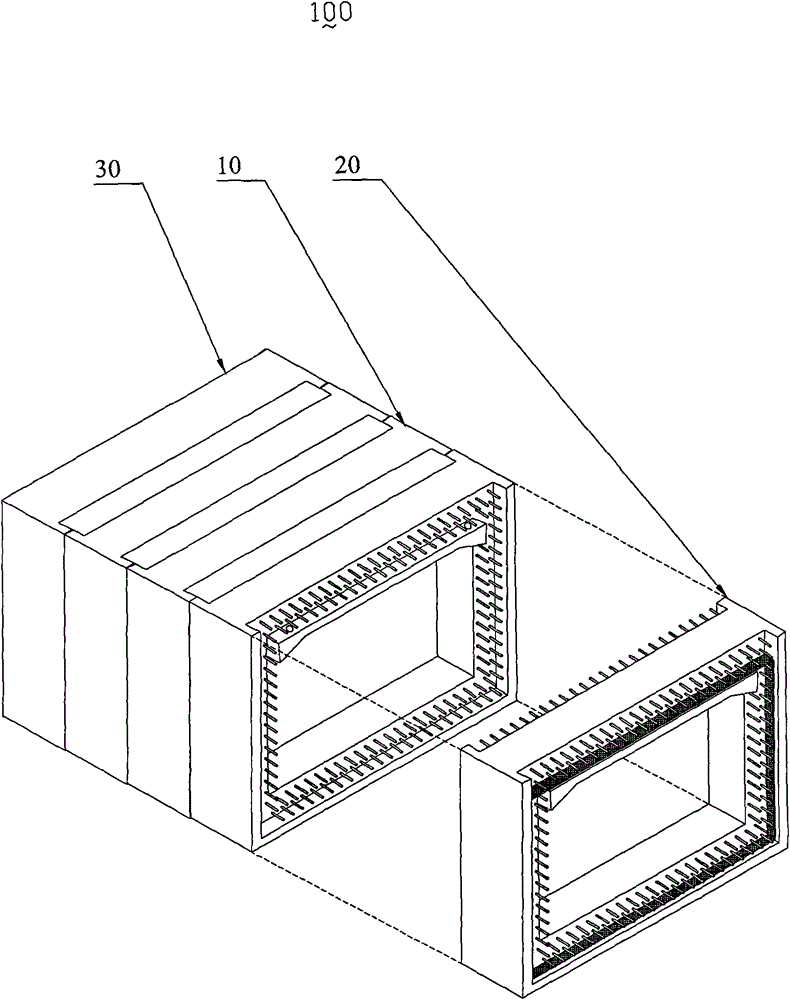

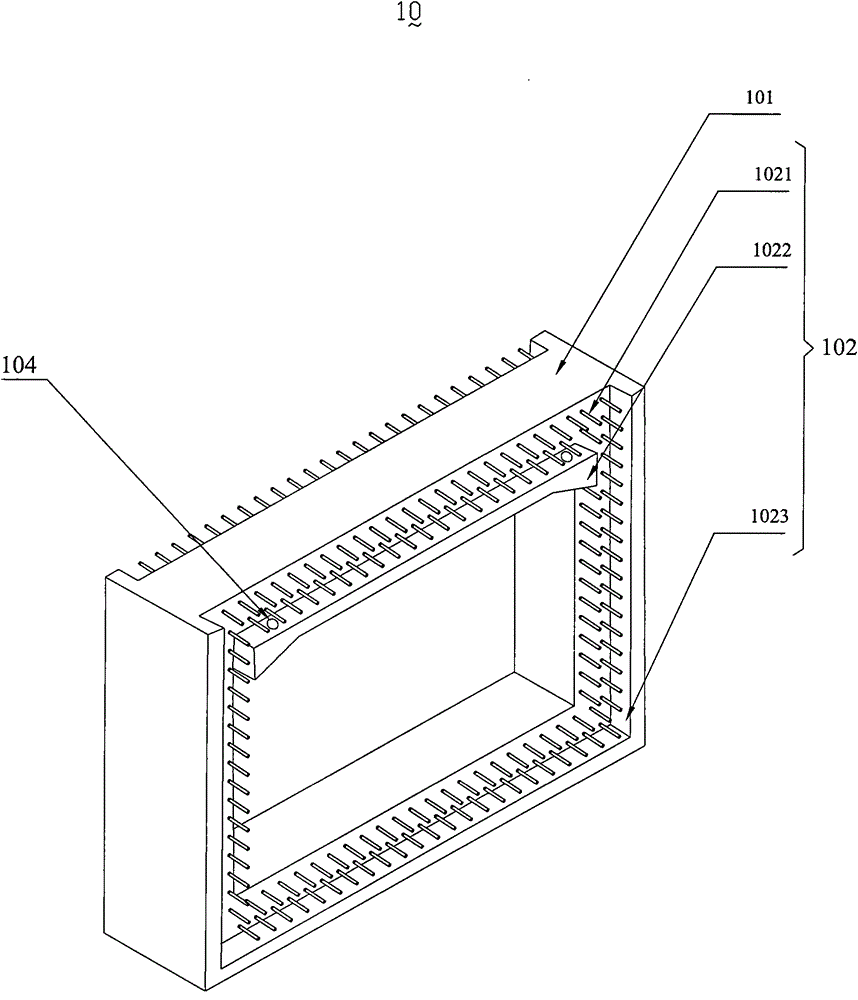

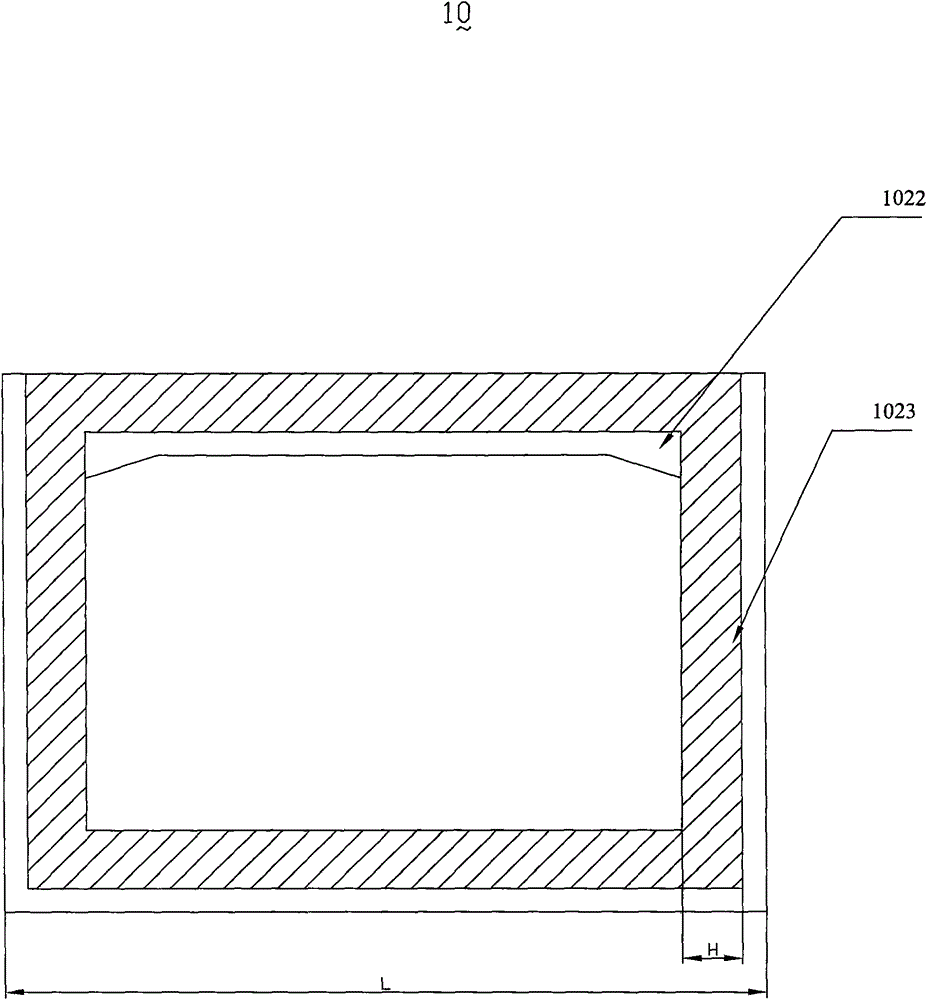

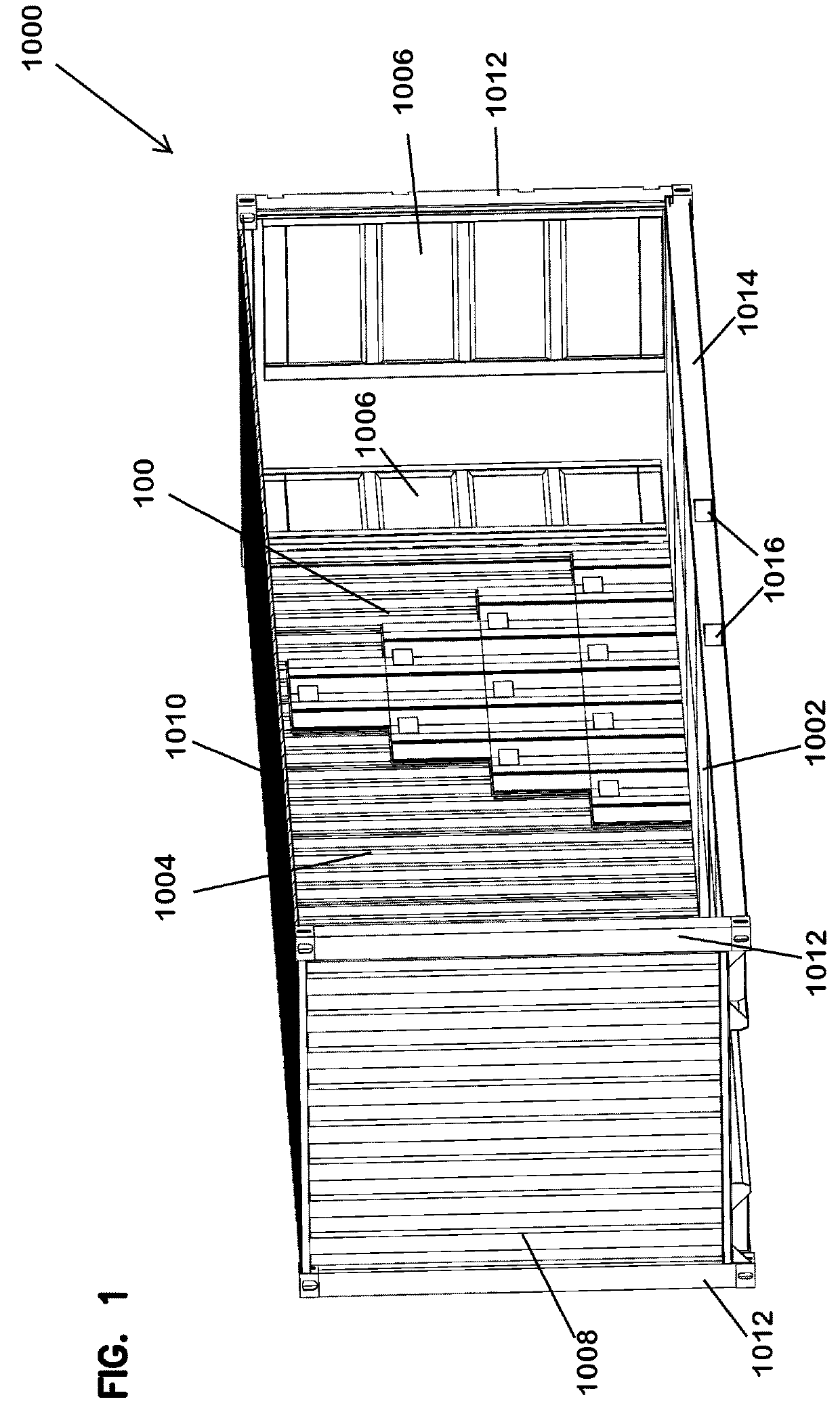

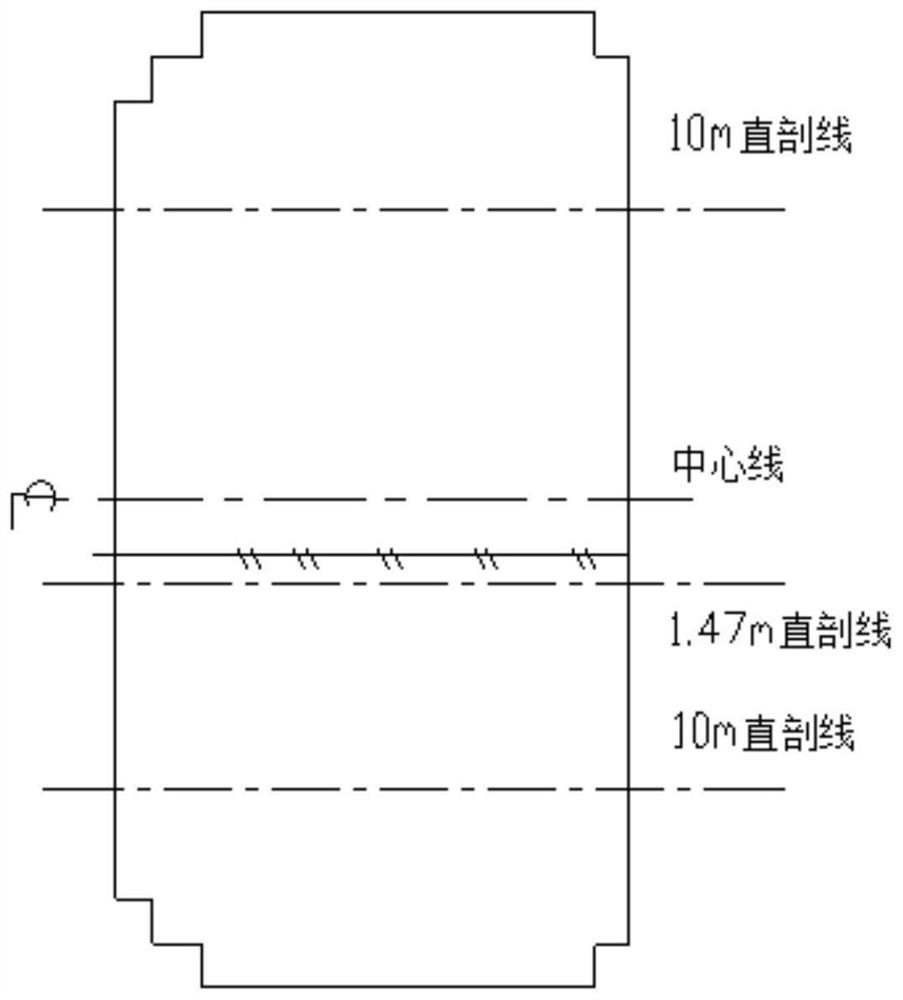

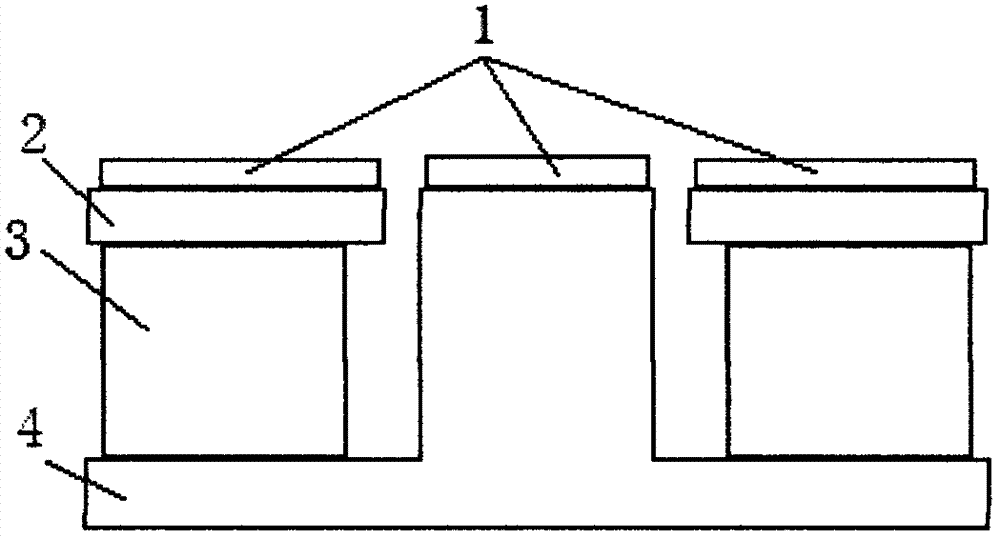

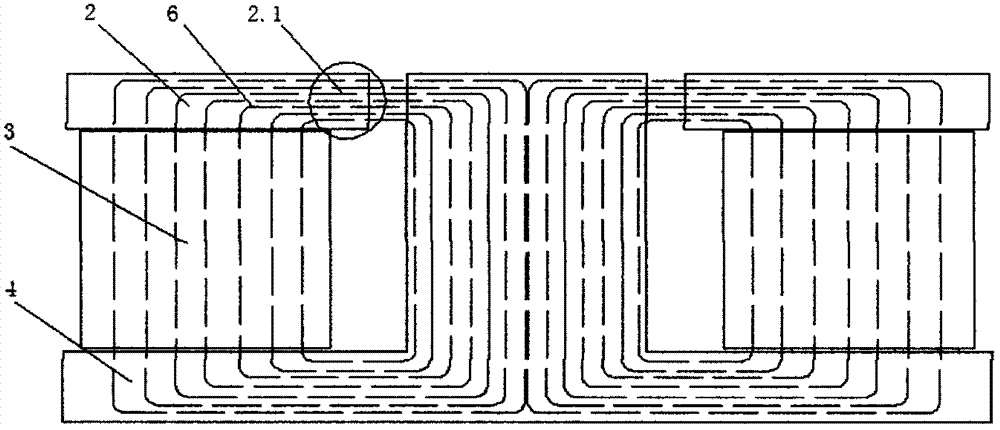

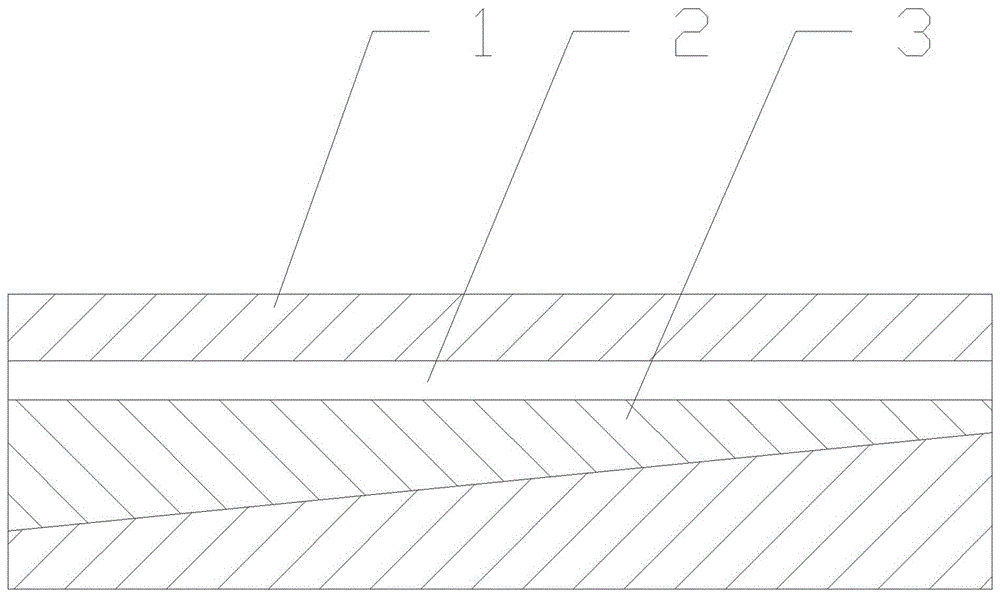

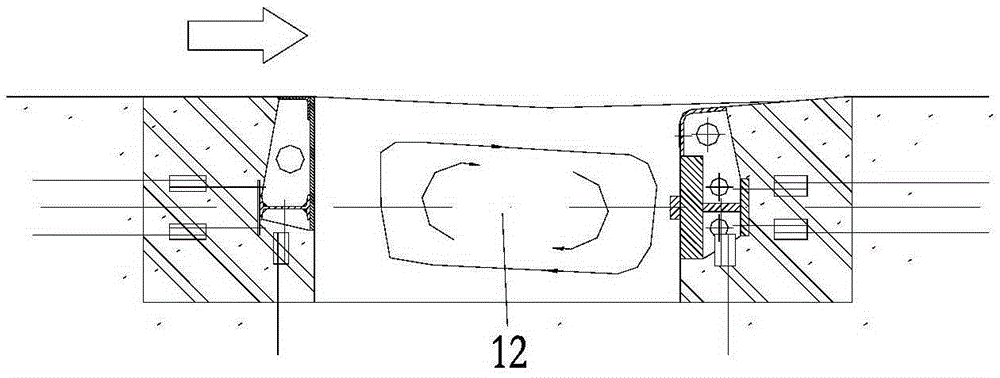

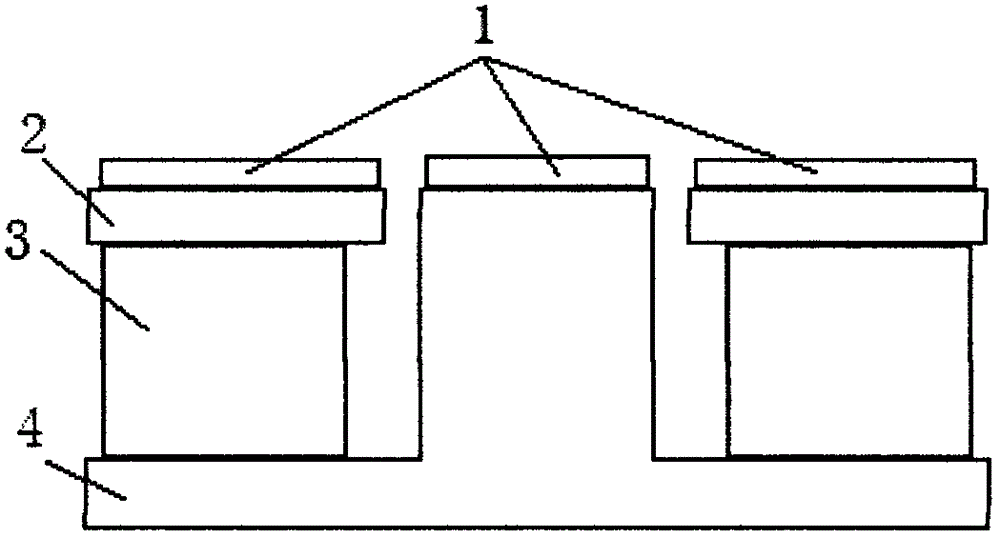

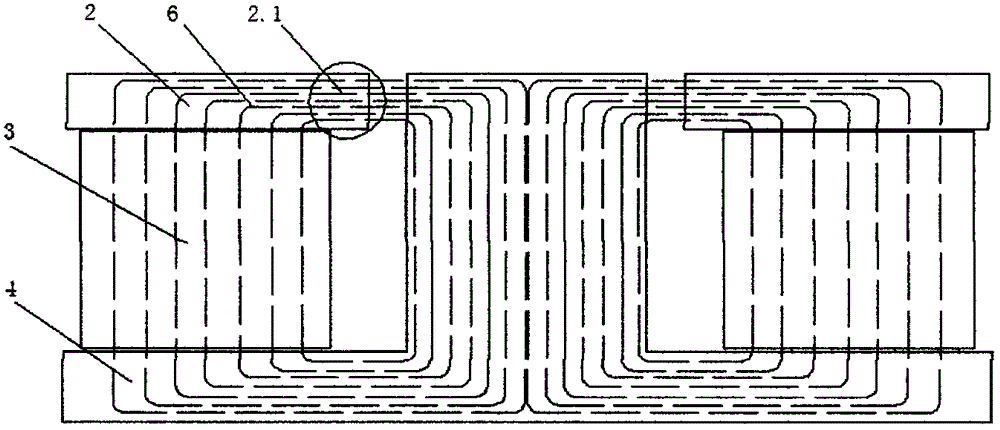

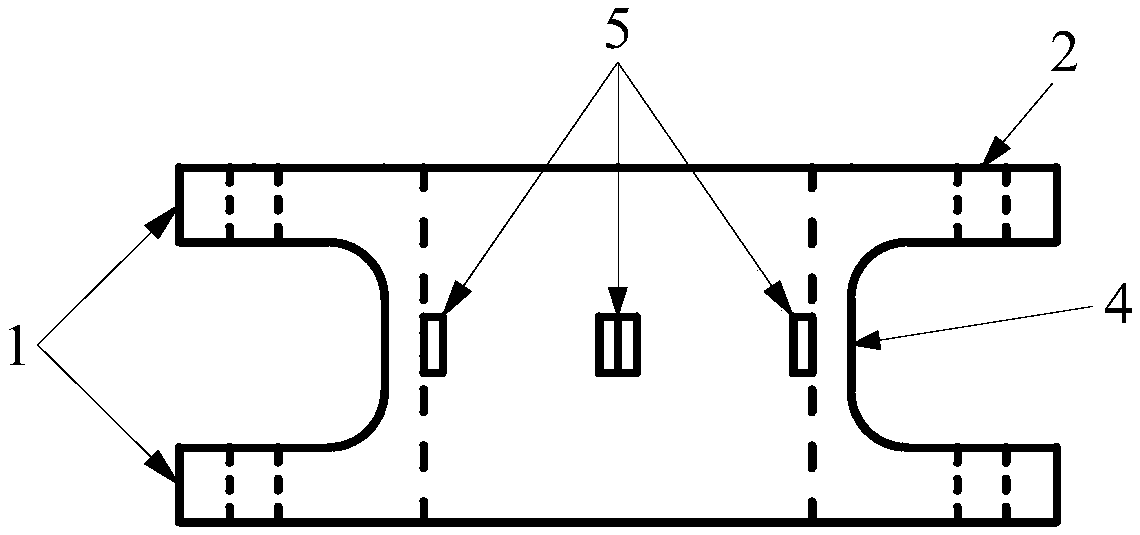

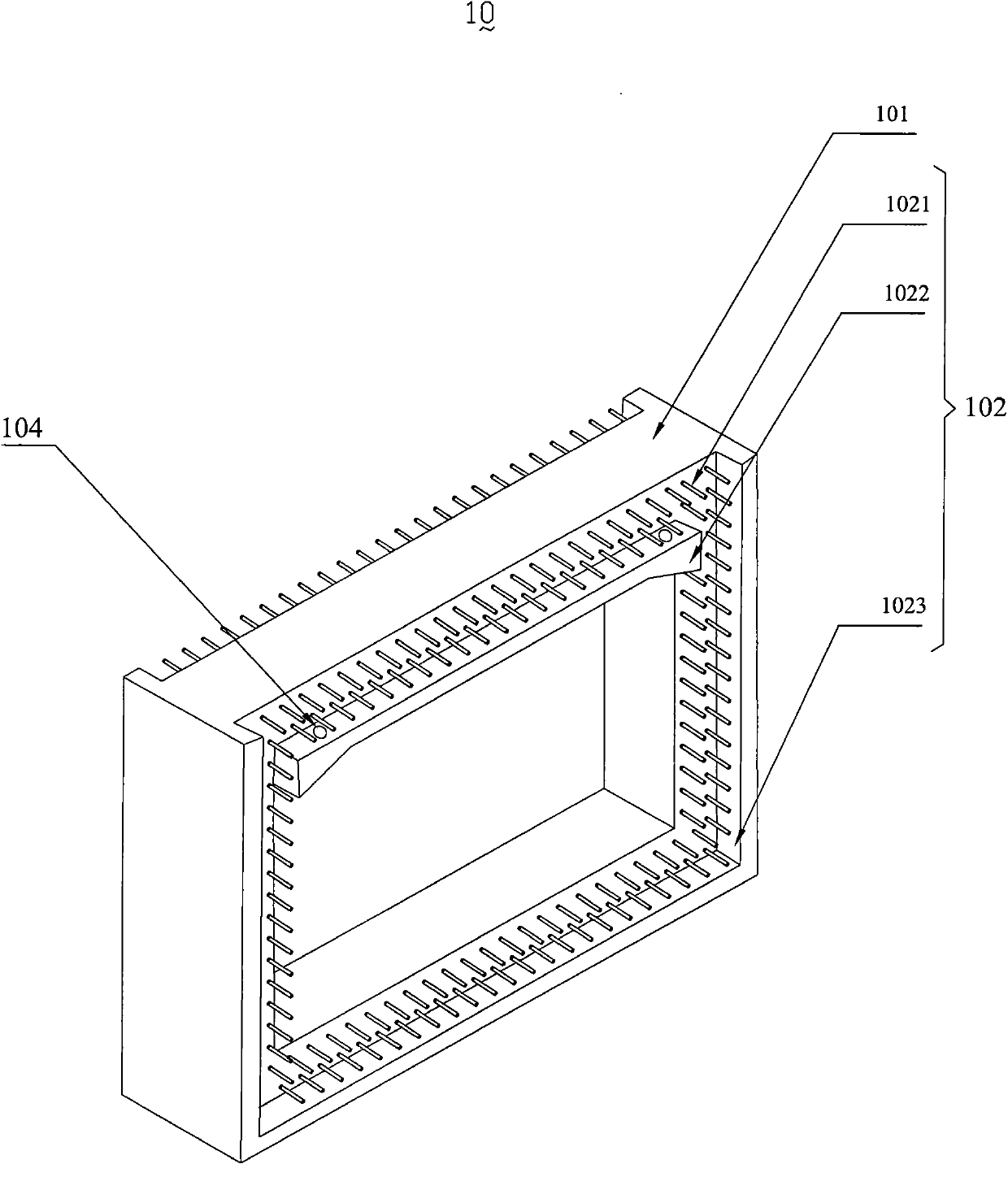

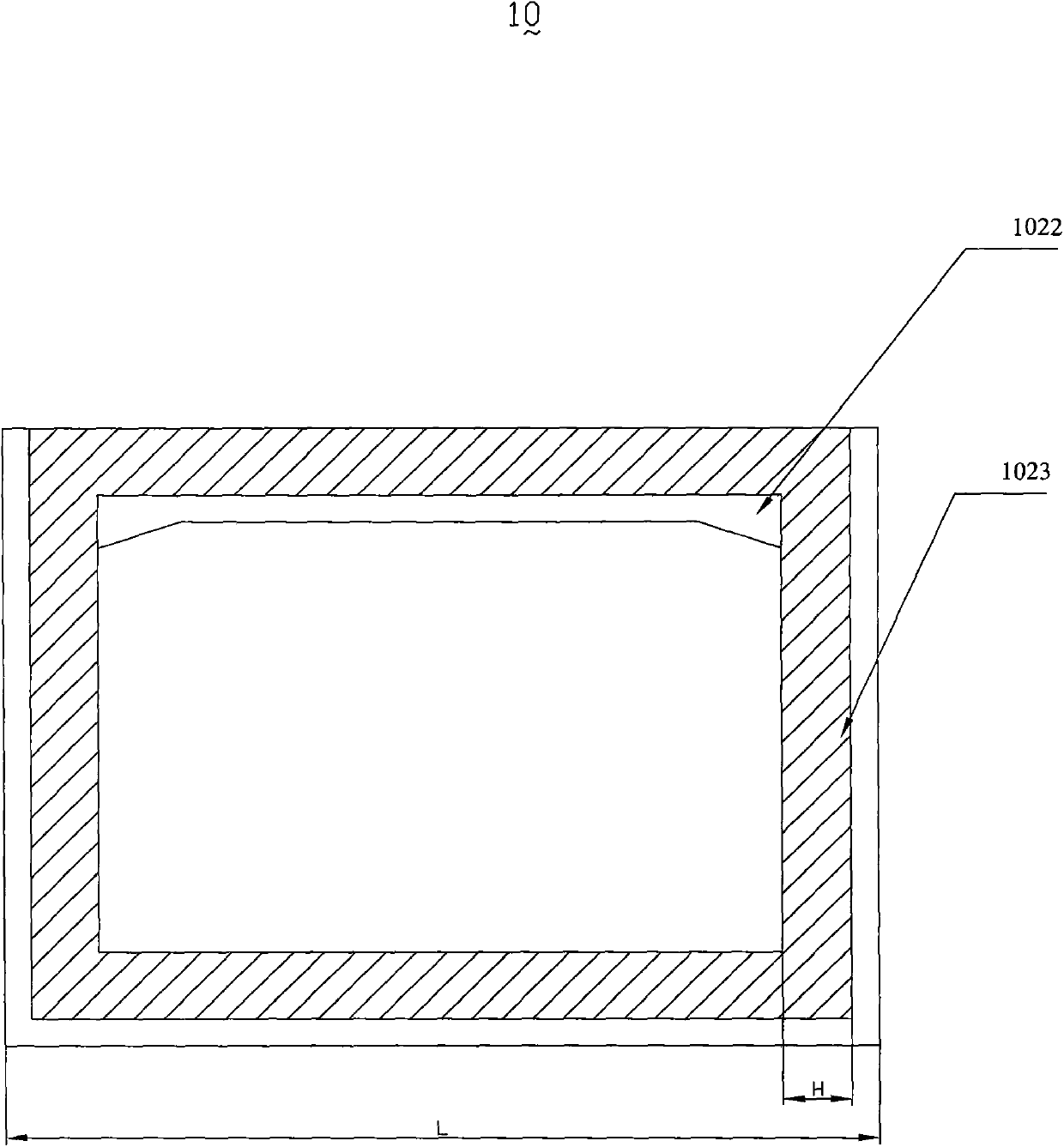

Prefabricated box culvert system and installation method thereof

The invention provides a prefabricated box culvert system. The prefabricated box culvert system comprises at least two prefabricated box culverts. Two prefabricated box culverts are located at the head end and the tail end of the prefabricated box culvert system, the prefabricated box culverts at the head end and the tail end respectively comprise a box body and two connectors, at least one connector of each box culvert comprises a bundle of bars or a pre-buried water stop belt, and the box culverts of the prefabricated box culvert system are connected through bars or the water stop belts formed through overlap welding, and are connected into the integrally-formed box culvert system through poured concrete. The invention further provides an installation method of the prefabricated box culvert system. The installation method is used for connecting the at least two prefabricated box culverts into a whole and laying the box culverts on the bottom face of a road. Compared with the prior art, the prefabricated box culvert system is simple in construction, short in construction period, low in cost, wide in application range, and suitable for municipal engineering and other large-scale traffic construction.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

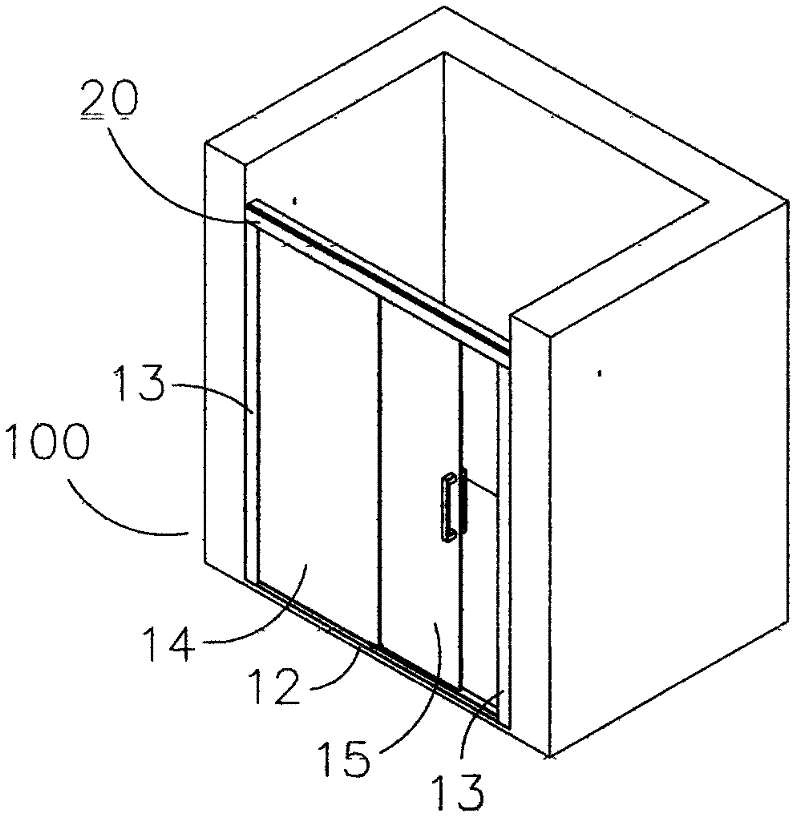

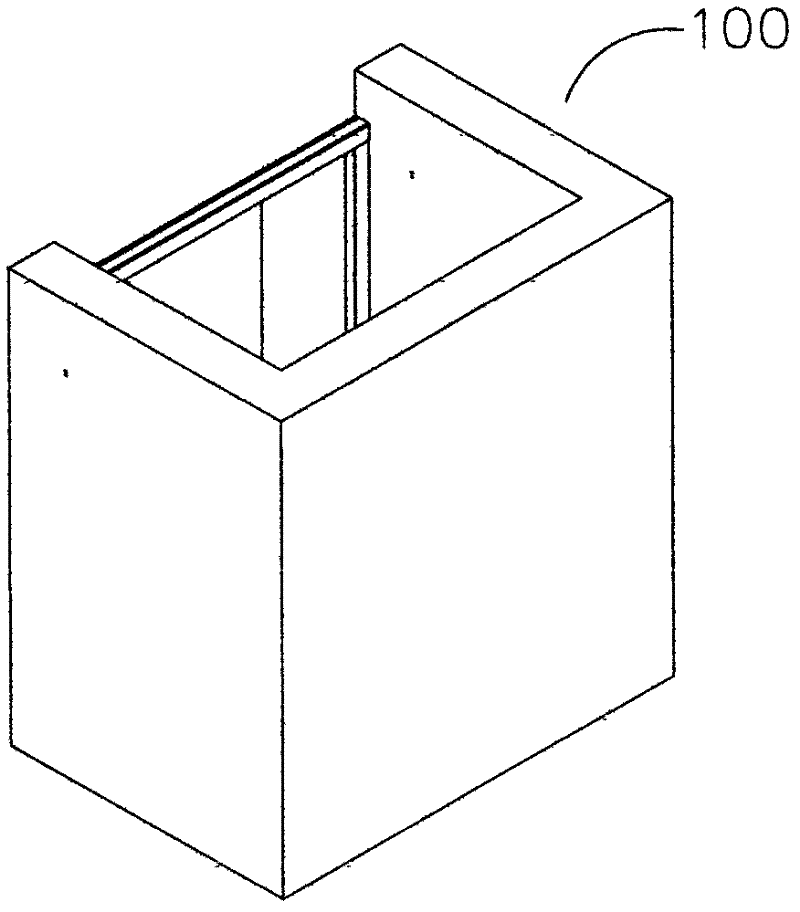

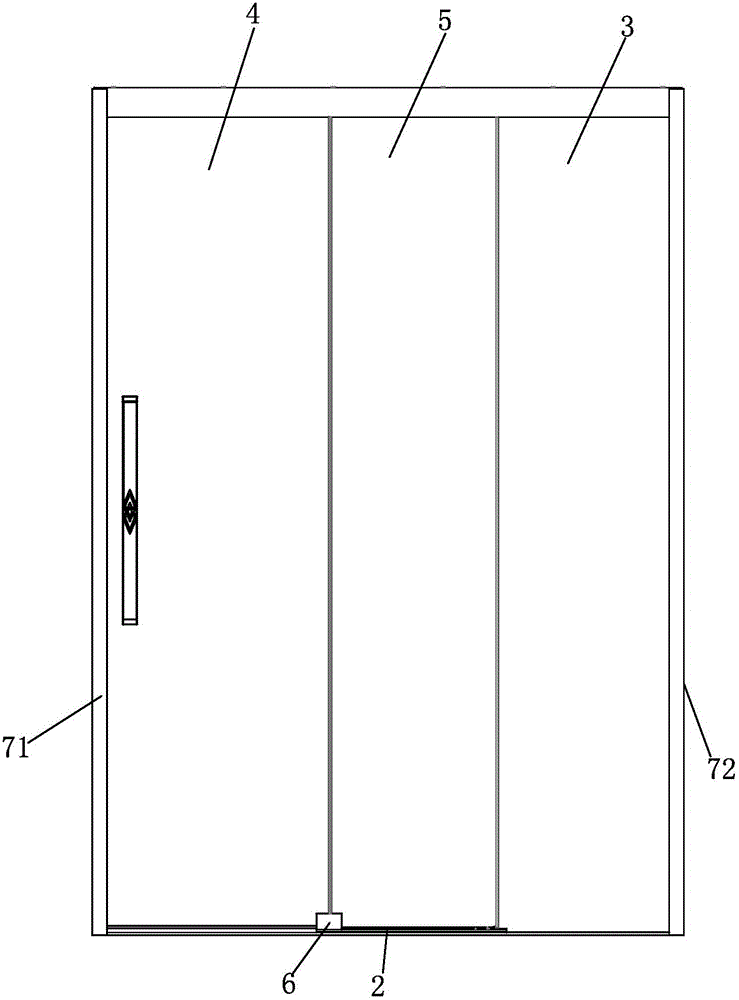

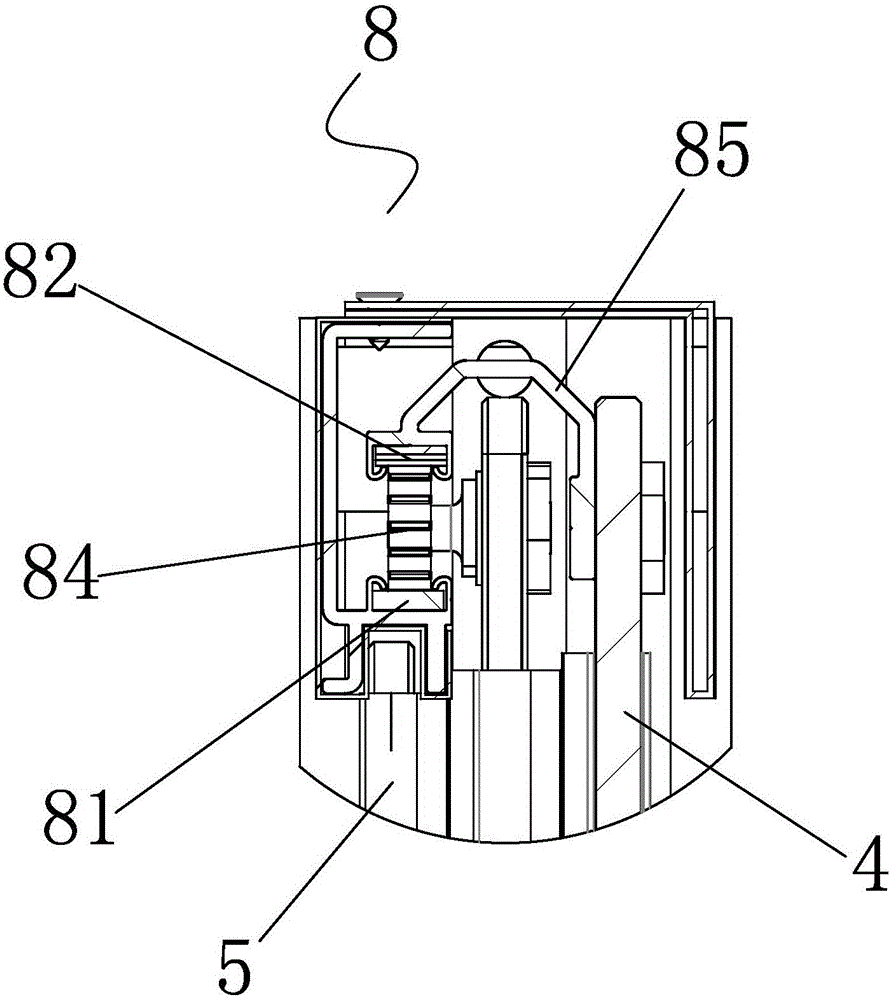

Intelligent induction shower cabin

The invention relates to an intelligent induction shower cabin, which comprises a shower cabin and an inductive control unit, wherein the inductive control unit is used for inducing the position of a human body so as to control the opening or the closing of the shower cabin, and comprises a driving motor, a microcomputer and an infrared inductive probe; when the shower cabin is in practical operation, firstly, the infrared inductive probe detects the existence of the human body and at this time sends a signal to the microcomputer, and the microcomputer commands a driver therein so as to drive the driving motor to work according to a compiled program and to drive a movable door to be opened or closed through the driving motor.

Owner:ZHONGSHAN LENS HOME CO LTD

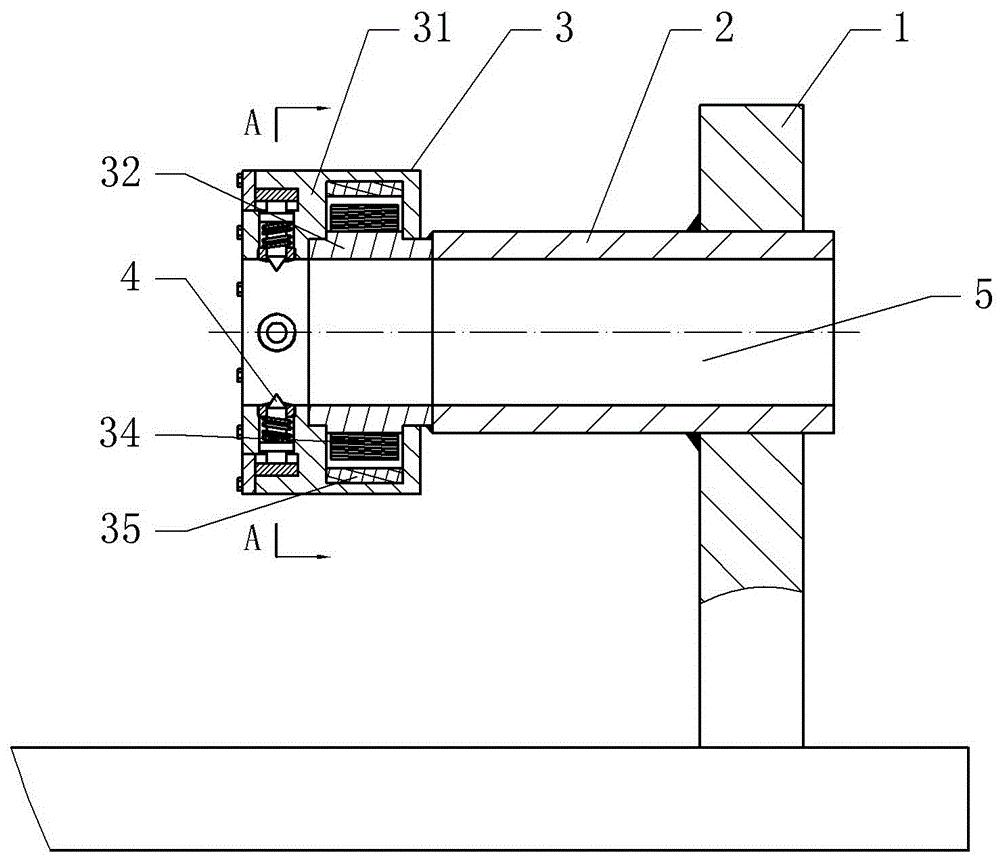

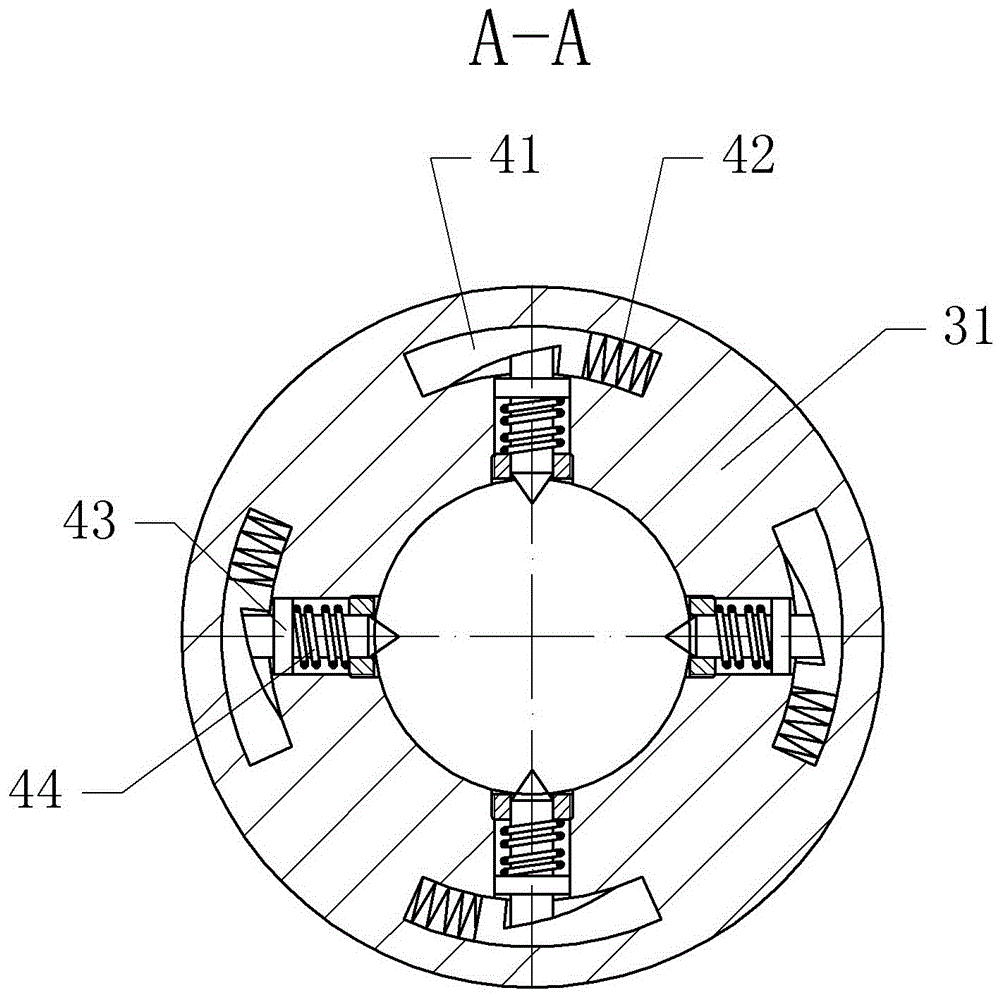

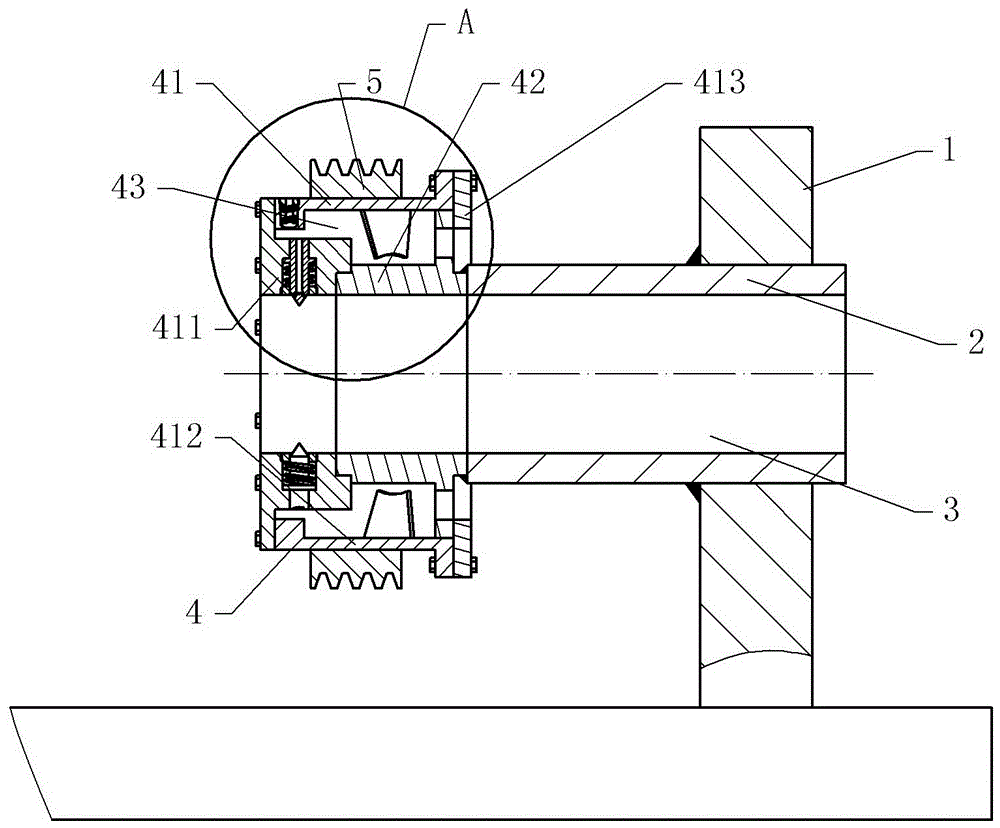

Integrated safe driving device

The invention discloses an integrated safe driving device. The integrated safe driving device comprises a driving motor, a speed reduction box, a main driving shaft and a bearing seat which are pre-integrated and in sequential transmission fit, wherein the bearing seat is arranged at the end, far away from the speed reduction box, of the main driving shaft, installation positions for being fixed to a truss are arranged at the bottoms of the speed reduction box and the bearing box, and an output gear of the speed reduction box and the main driving shaft are positioned through tightly matched conical surfaces. The invention further provides an installation method of the integrated safe driving device. The driving motor, the speed reduction box, the main driving shaft and the bearing seat are pre-integrated, installation of the driving device is facilitated, installation difficulty is reduced, installation accuracy is improved through matching of the conical surfaces, installation efficiency is guaranteed, and products meet national standards and have large market prospects.

Owner:UNITE ELEVATOR

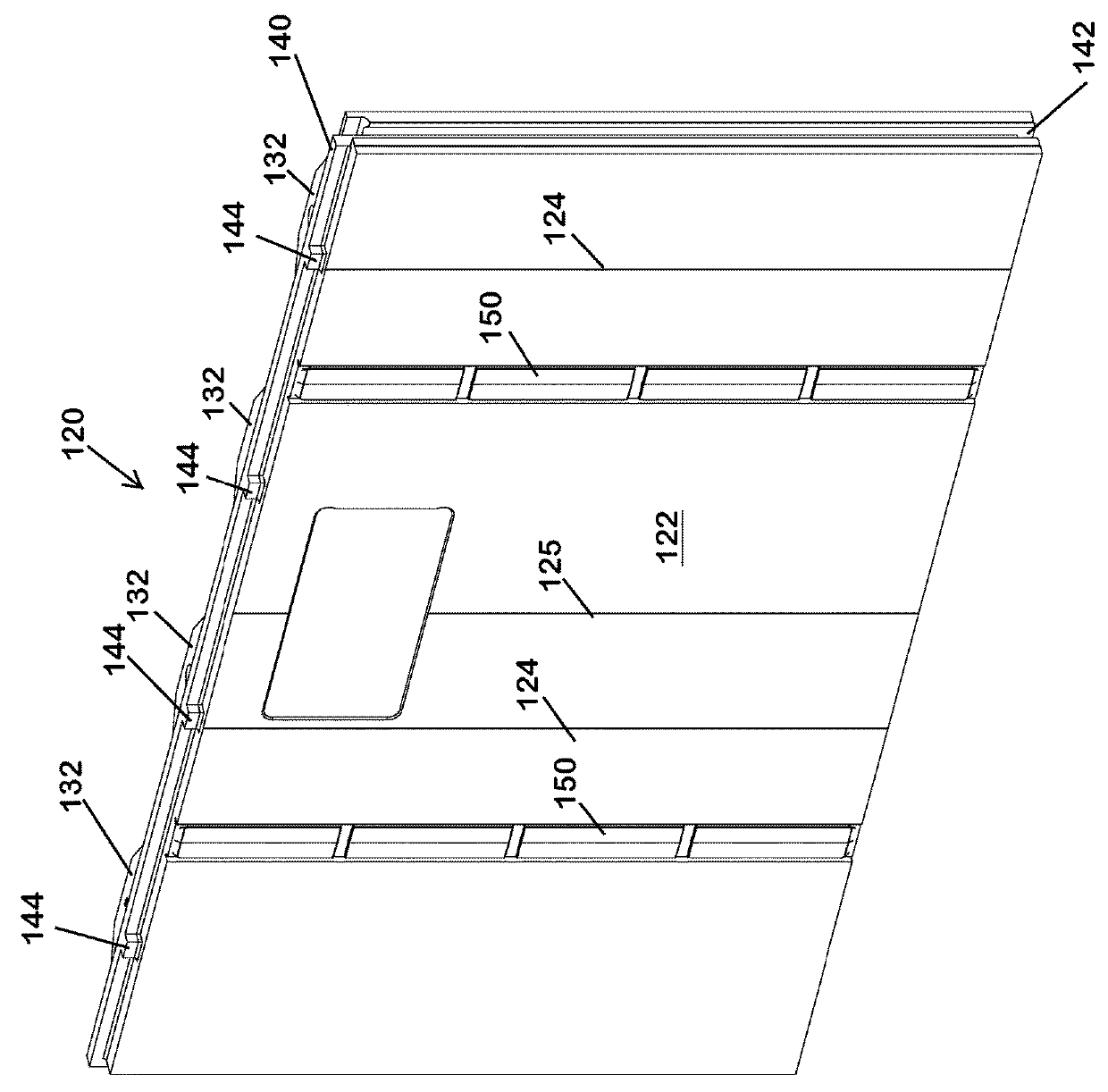

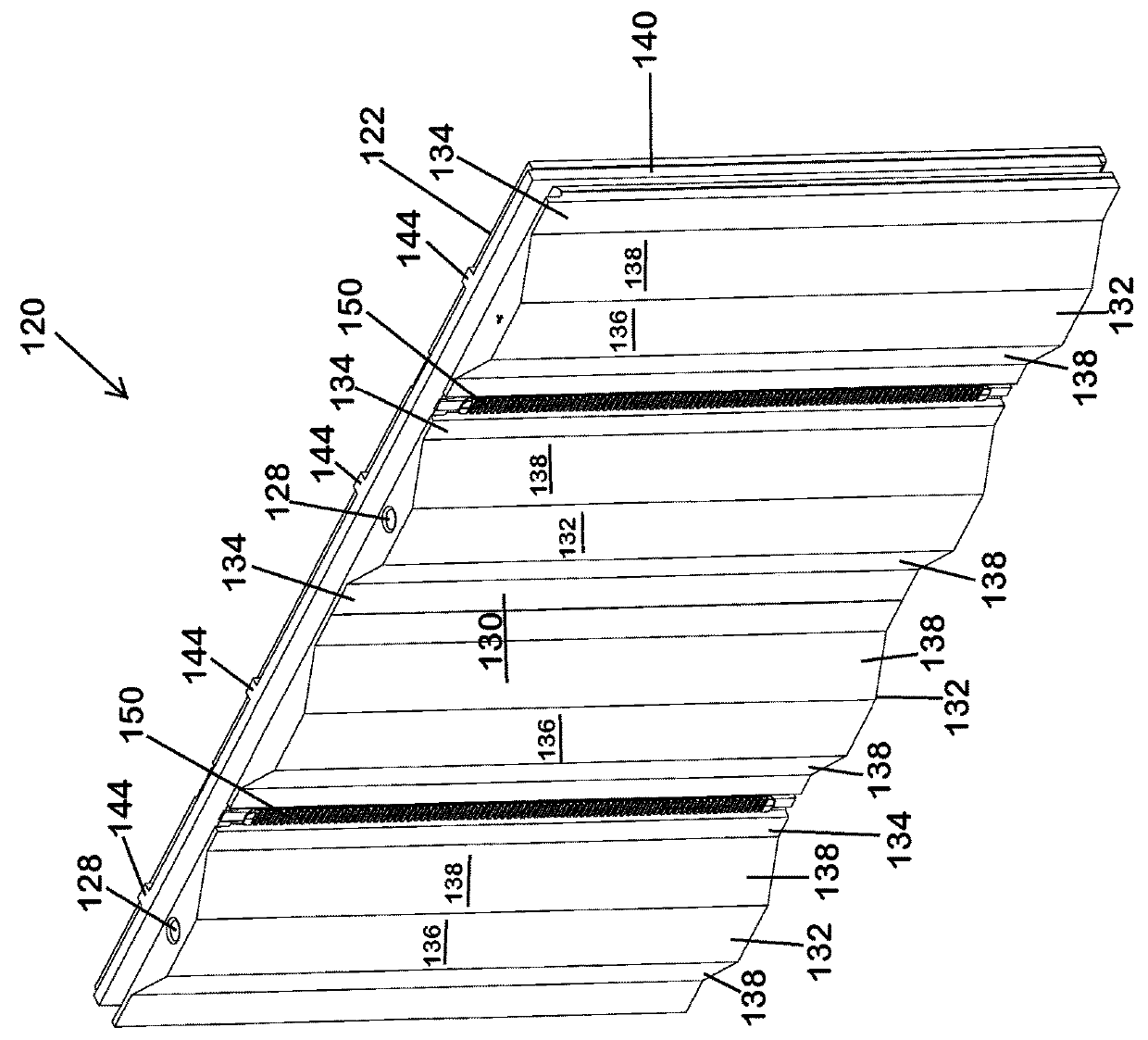

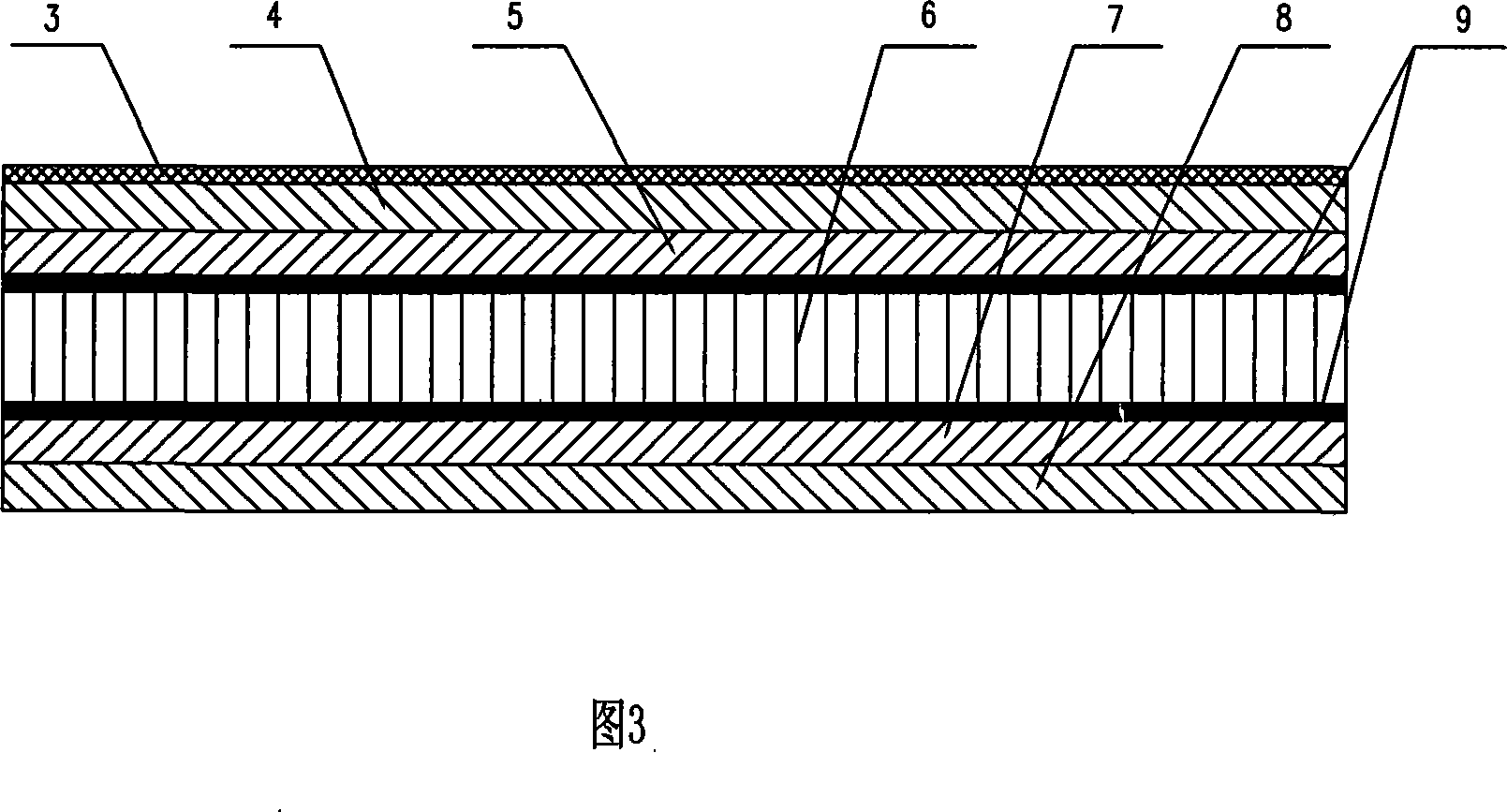

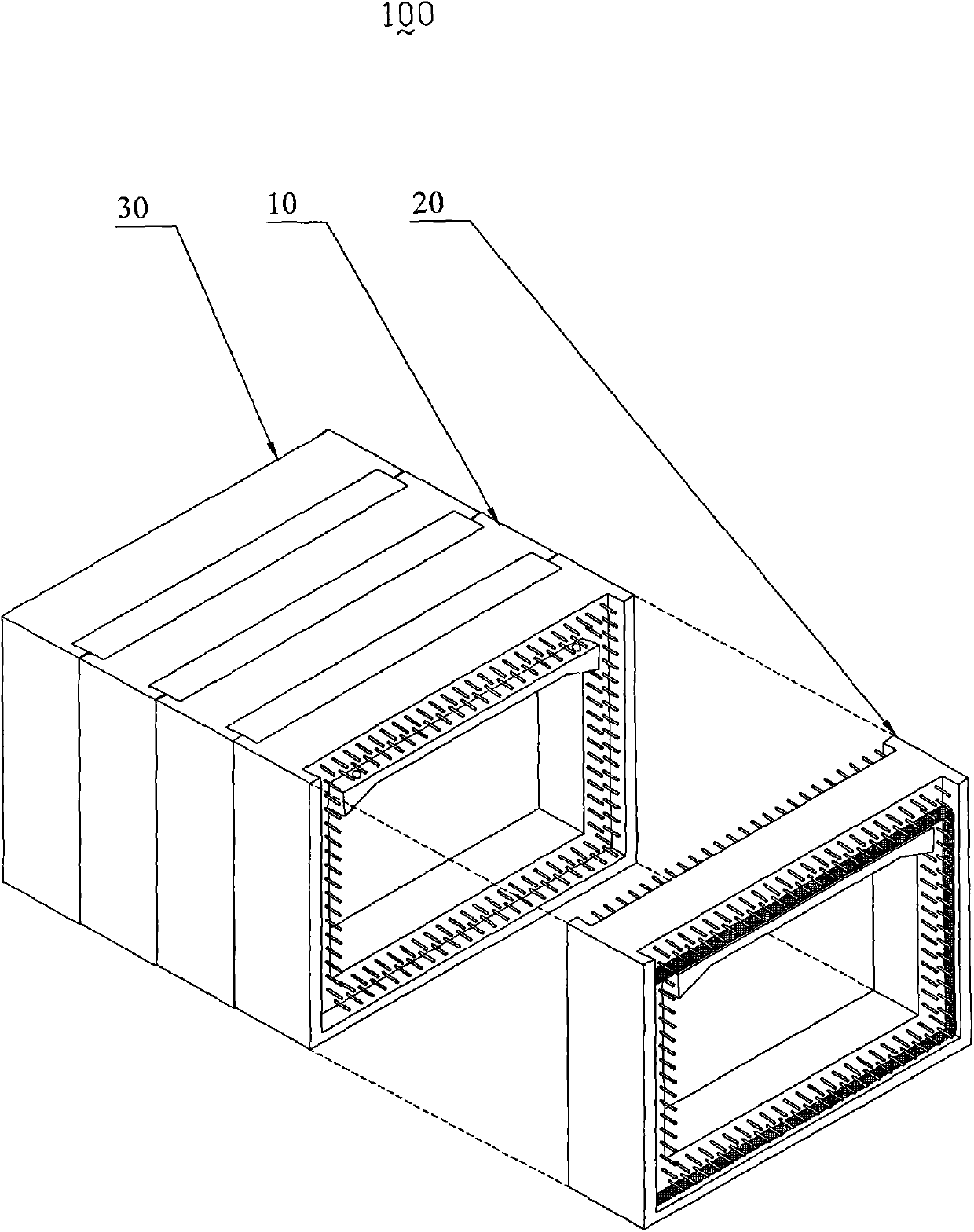

Shipping container insulation panel and installation method

ActiveUS20180273291A1Improve fastnessDifficult to effectively insulateLarge containersBuilding constructionsCouplingEngineering

An insulation system is configured for mounting to corrugated walls such as the walls of a shipping container. A first end has a first coupling surface and a second end opposite the first end has a second complementary coupling surface. Mating alignment portions are on a top surface of the panel and on a bottom surface of the panel. The second face includes a corrugated surface with a protruding first surface parallel to the first face, a recessed second surface spaced apart from and parallel to the first surface, and third and fourth surfaces extending between the first surface and the second surface, the third and fourth surfaces being orthogonal to the first and second surfaces.

Owner:SCHERRER EDWARD G +1

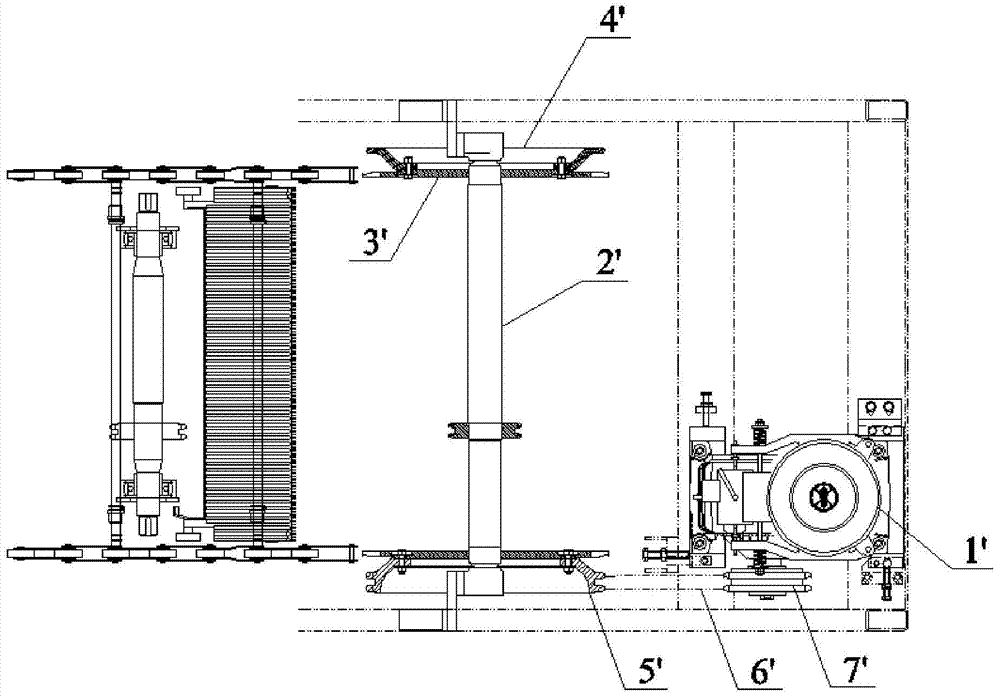

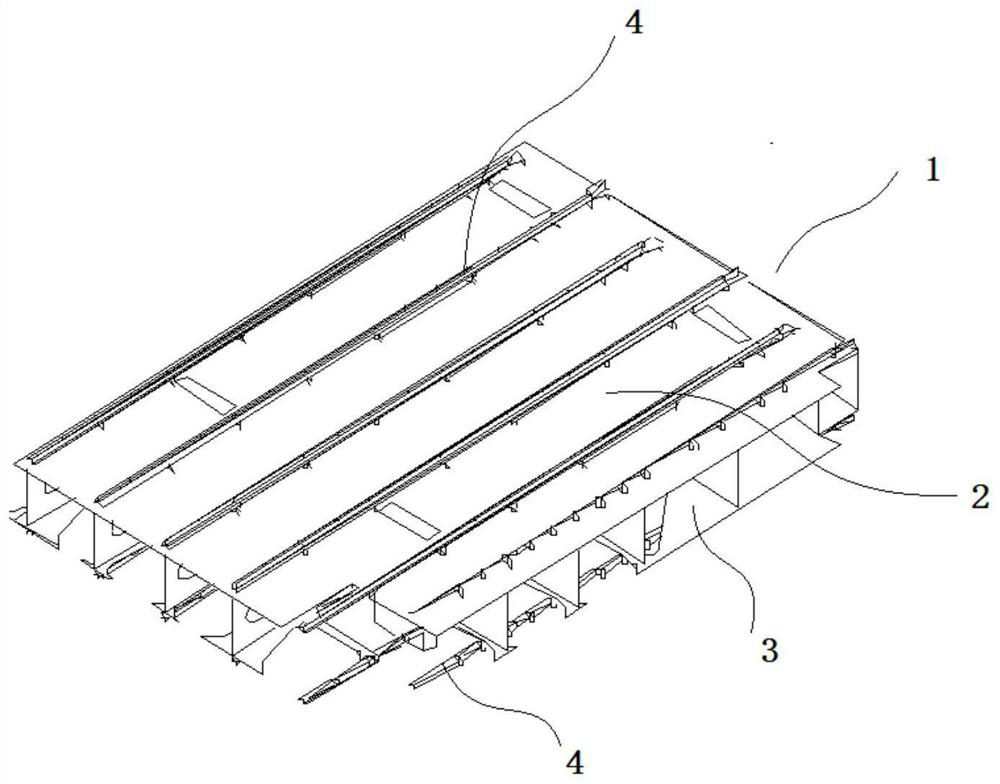

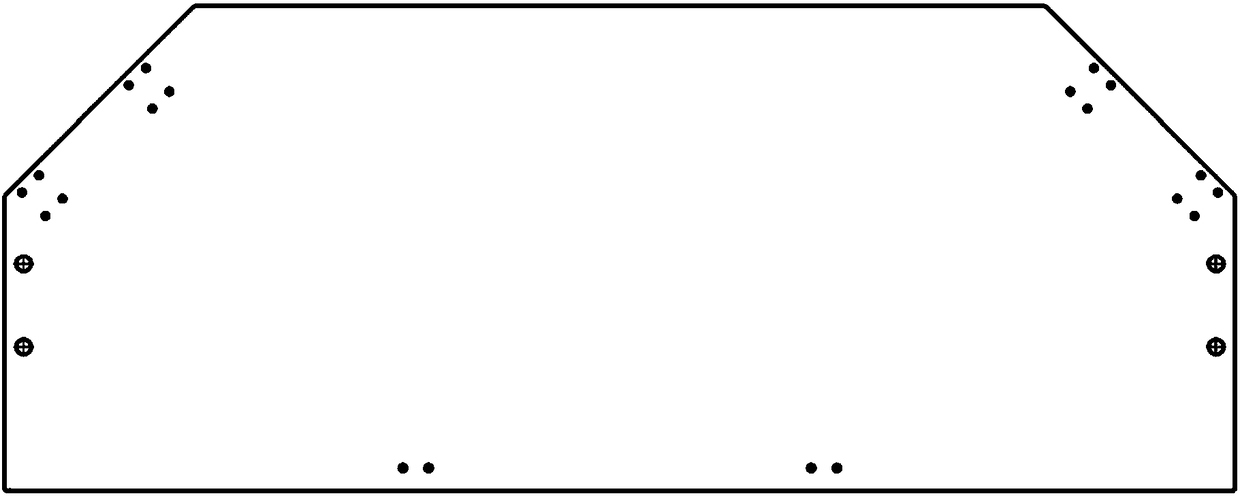

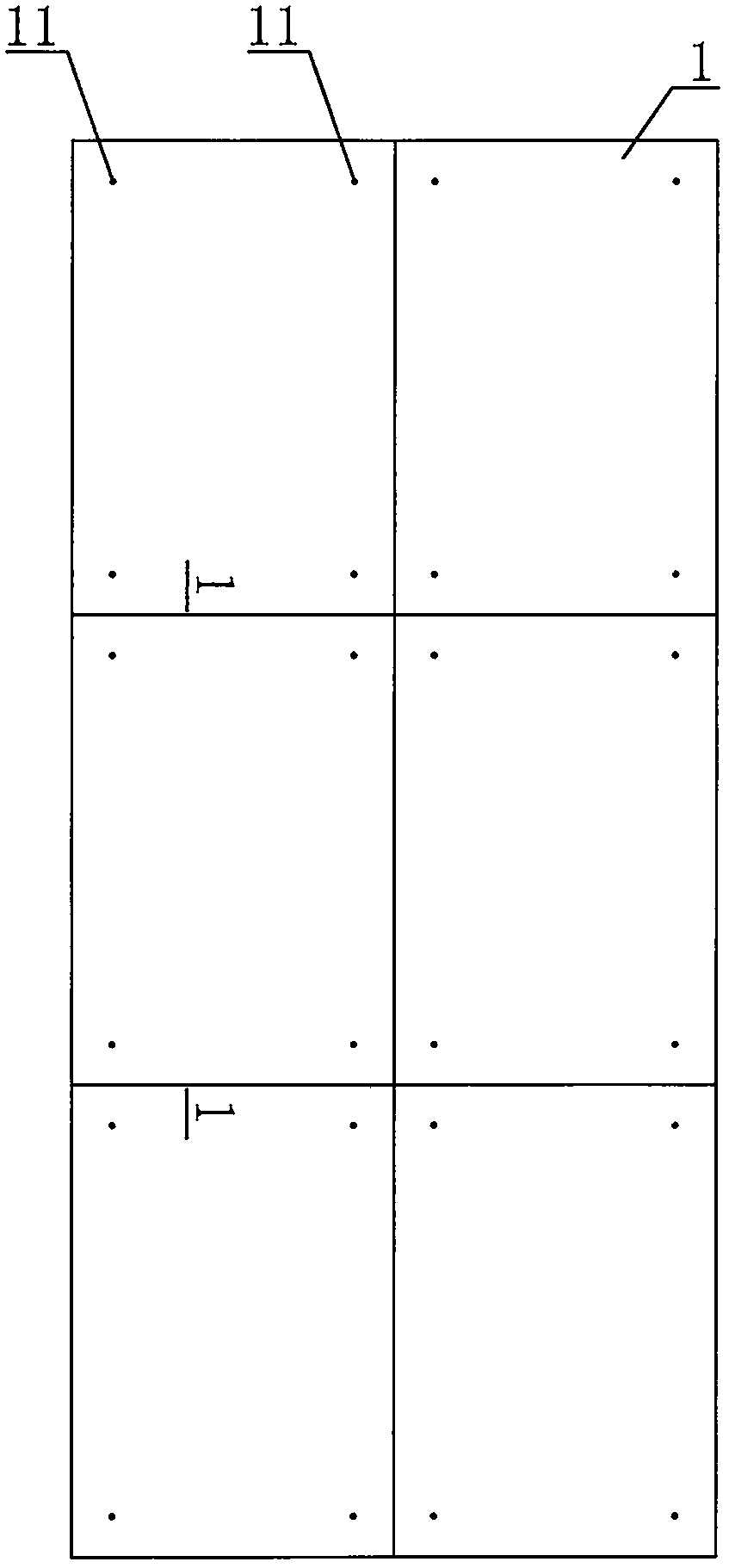

Double-sided preassembling method for bulkhead guide rails on large container ship and bulkhead

The invention relates to a double-sided preassembling method for a bulkhead guide rail on a large container ship. The bulkhead is a non-watertight bulkhead, the bulkhead is of a hollowed-out frame structure, and the installation precision of the bulkhead guide rail installed on the two faces is smaller than 7 mm. The method comprises the following steps: firstly, mounting a guide rail bracket on a horizontal jig frame of a compartment of the container ship; measuring levelness at a bay rib position datum line by taking one surface on which the guide rail bracket is mounted as a rear wall, and marking each hard gear of the bay by a punching point; then, the bay is adjusted to be horizontal again after the bay is turned over, the levelness of the guide rail frame located on the rear wall after installation is ensured, and the reference rib position line, the rear wall guide rail frame and the front wall guide rail frame to be installed are parallel to one another; therefore, the installation reference is determined, and the double-sided guide rail bracket is positioned and preassembled according to the found installation reference. The method is easy to operate, wherein guide rail preassembling can be completed in advance, the total assembling stage time is shortened, so that the pressure of a total assembling site is relieved, the building period in a dock is shortened, and the ship building efficiency is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

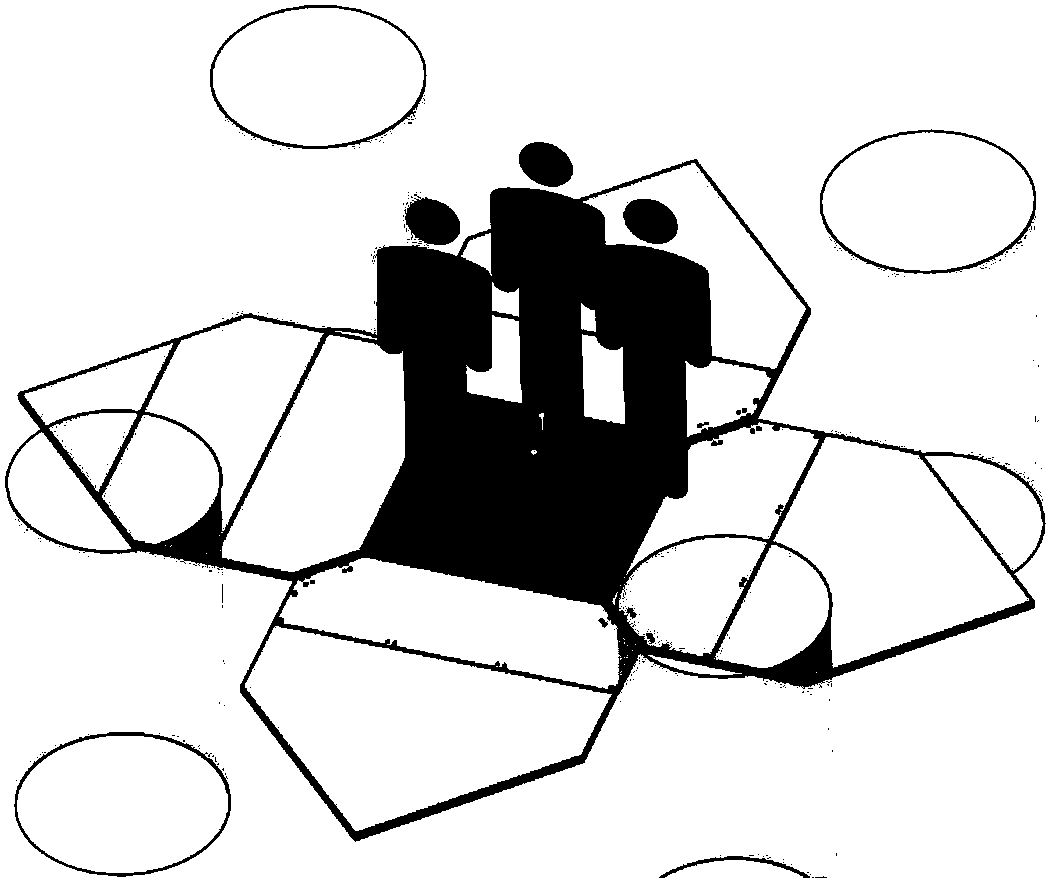

Composite-material core-level cover plate for rocket, and preparation method thereof

The invention discloses a composite-material core-level cover plate for a rocket, and a preparation method thereof. The cover plate comprises nine detachable units, wherein each detachable unit is a composite-material interlayer structure containing an inner framework; and one is a central quadrilateral unit and the other eight detachable units are divided into four groups, the two detachable units in each group are connected together through a hinge, the four sides of the central quadrilateral unit are lapped and fixed to one turned edge of the four groups of detachable units separately, theother sides of the four groups of detachable units are placed on a launching platform installation frame and fixed, and the whole outer edge outline is determined by an installation connector space where the cover plate is located. The invention puts forward for the first time that a light-weight foam interlayer structure containing the inner framework is applied to the core-level cover plate forthe rocket. The composite-material core-level cover plate has the advantages of being convenient to transport, simple to install, rapid to detach, and the like; and the disclosed preparation method has the advantages of ensuring the good forming quality of products, realizing integrated forming, and achieving low cost.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

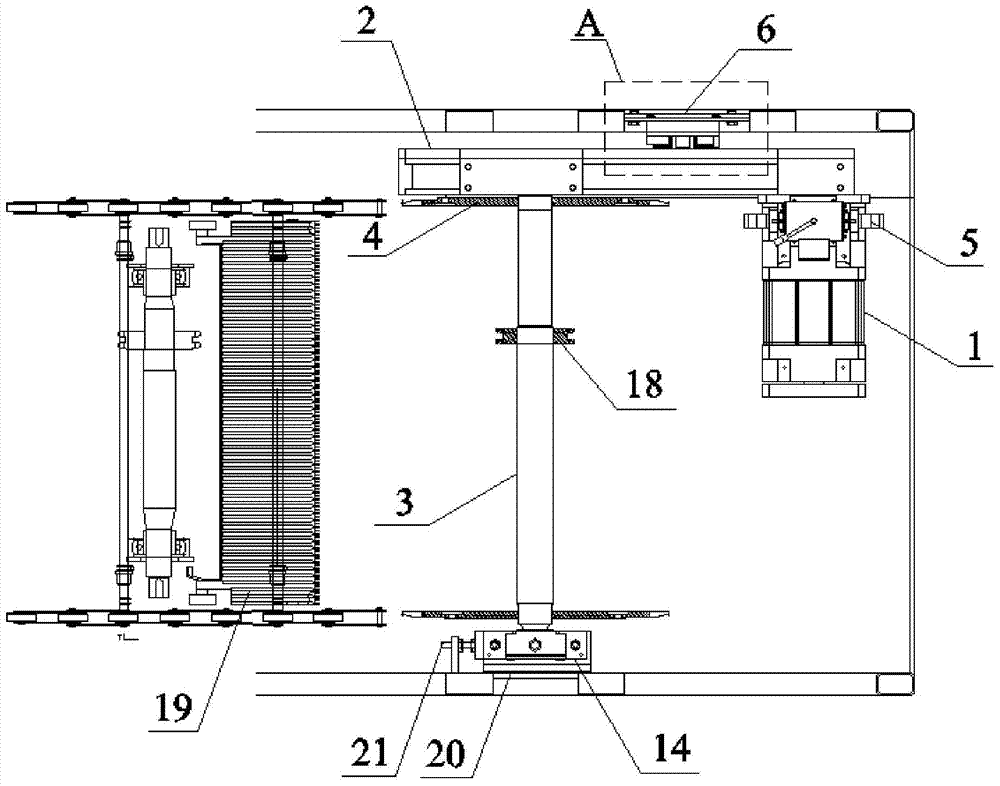

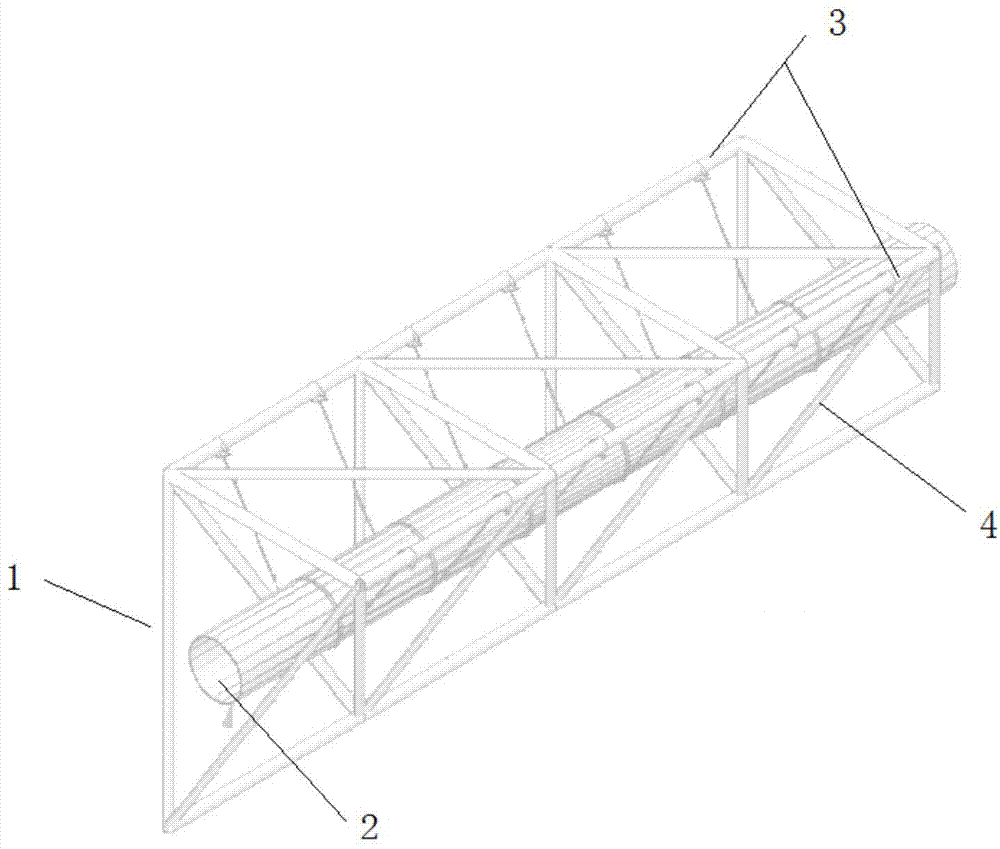

Large stadium pipe truss and spiral duct modularization installation method and combination structure

InactiveCN104763157AImplement a modular processReduce erectionBuilding material handlingVertical ductsEngineeringWork time

The invention discloses a large stadium pipe truss and spiral duct modularization installation method and a combination structure. The installation method includes the steps of module division of pipe trusses and spiral ducts; factory manufacturing of pipe truss module units and spiral duct module units; assembling of pipe truss modules and spiral duct modules on a construction site. The combination structure is formed by arranging the spiral duct module units into the pipe truss module units through a plurality of fixing units in a penetrating mode. According to the large stadium pipe truss and spiral duct modularization installation method and the combination structure, truss structures and the spiral ducts are modularly assembled on the ground according to design models, the trusses and the ducts are hoisted at the same time, so a mechanical and electrical installation construction procedure and a steel structure construction procedure are combined into one, working time is greatly shortened, work high above the ground and setting up of auxiliary facilities are greatly reduced, the technical level and the efficiency are improved, meanwhile installation time is shortened, and safety of constructors is guaranteed.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

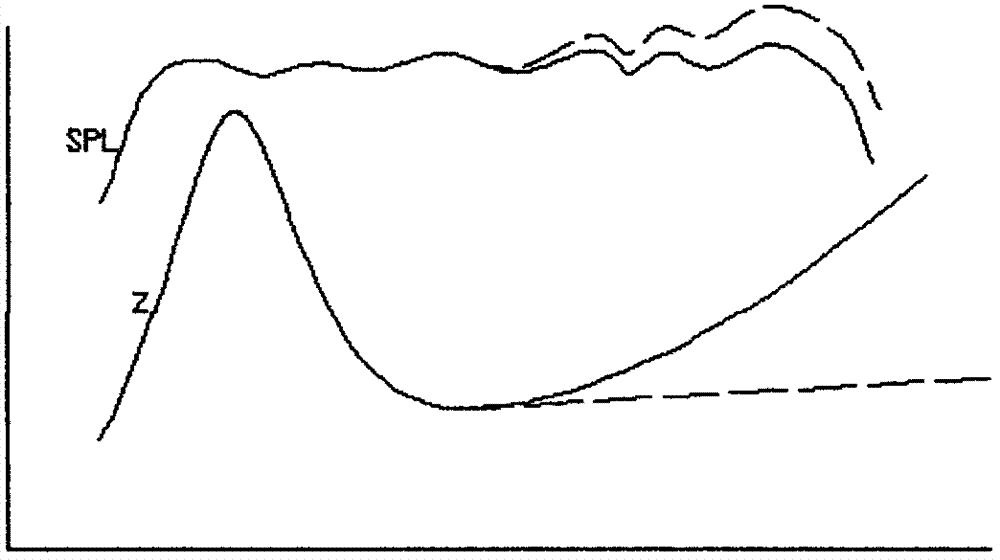

Film short circuit ring of electromagnetism actuator

ActiveCN103200489AMagnetic field stabilizationEliminates the effects of hysteresisFrequency/directions obtaining arrangementsHysteresisActuator

The invention discloses a designing scheme of a high conductivity metallic film short circuit ring which does not change (or slightly changes) basic performance of a speaker while leading edge transient response of the speaker is obviously improved. In an irony member of a magnetic path near a voice coil, some parts of the irony member are in a highfield and high magnetic saturation state, the high magnetic saturation parts of the irony member are closely attached to the voice coil and are main sources of hysteresis damping received by the voice coil movement. The high conductivity metallic film short circuit ring needs arranging on the inner sides or the outer sides of the high magnetic saturation parts, the high magnetic saturation parts of the irony member are enabled to be placed in an inner and outer side strong affecting area of the short circuit ring, the adjustment on the interior magnetic field of the strongest magnetic field of the irony member by a voice coil current is reduced, therefore, a hysteresis damping effect is reduced, the leading edge transient response is improved, and the occurrence that voice coil inductance is blindly canceled or reduced greatly is avoided.

Owner:张百良

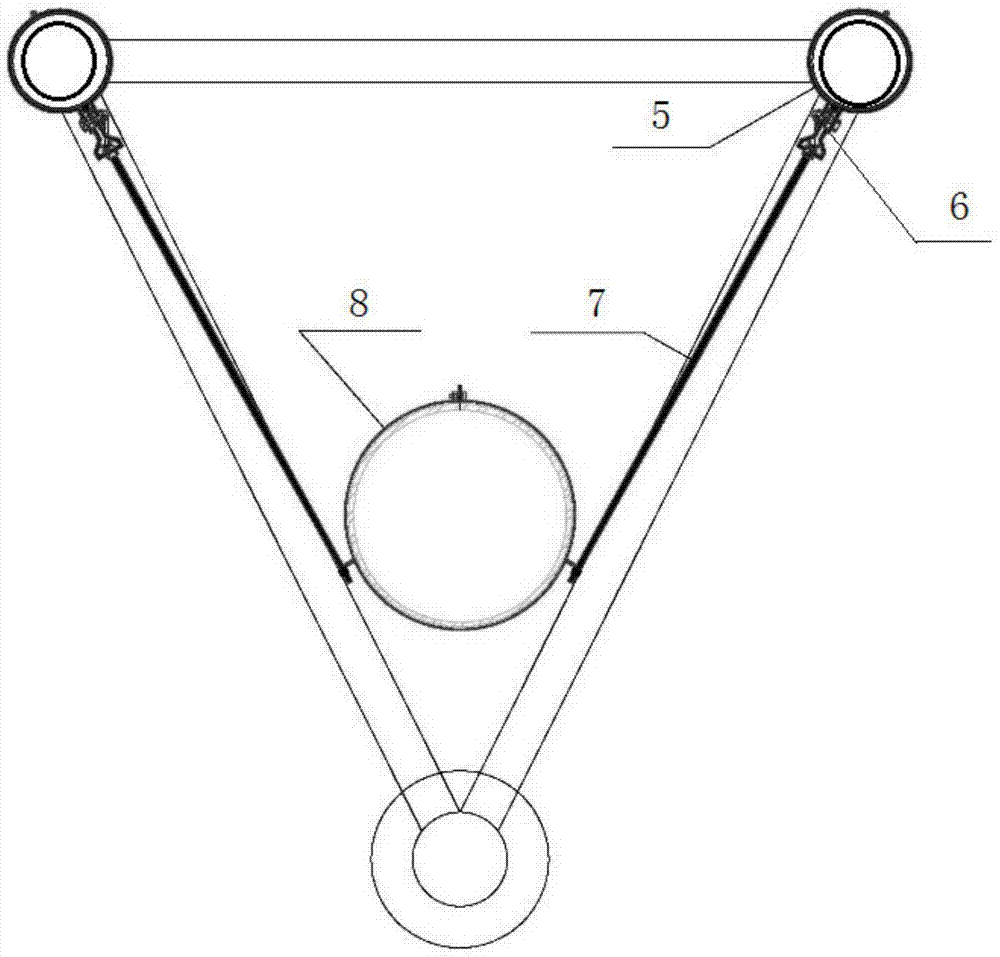

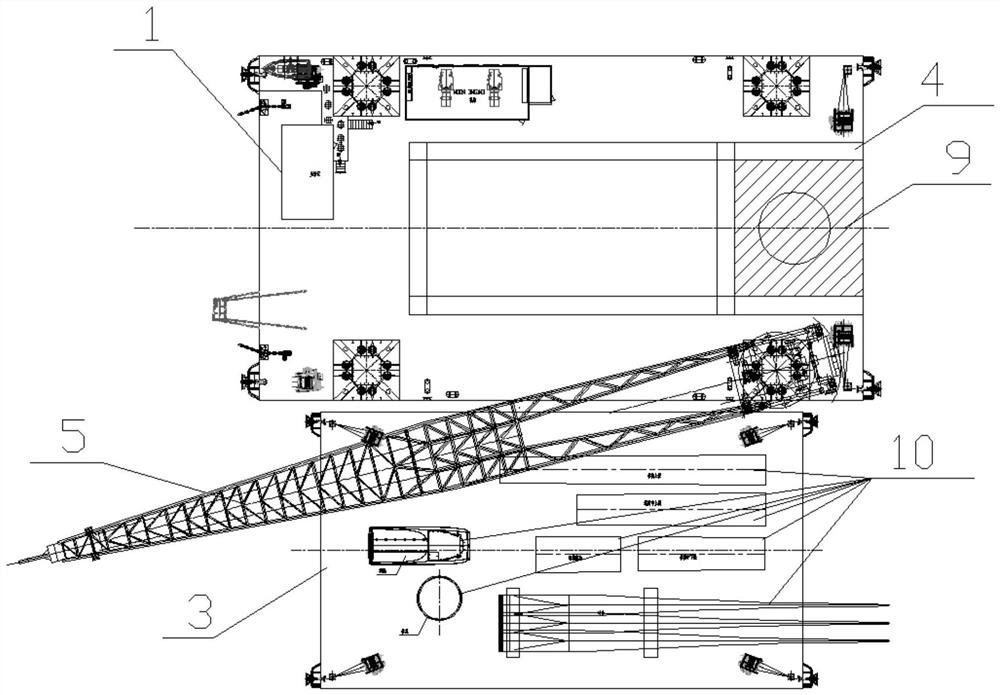

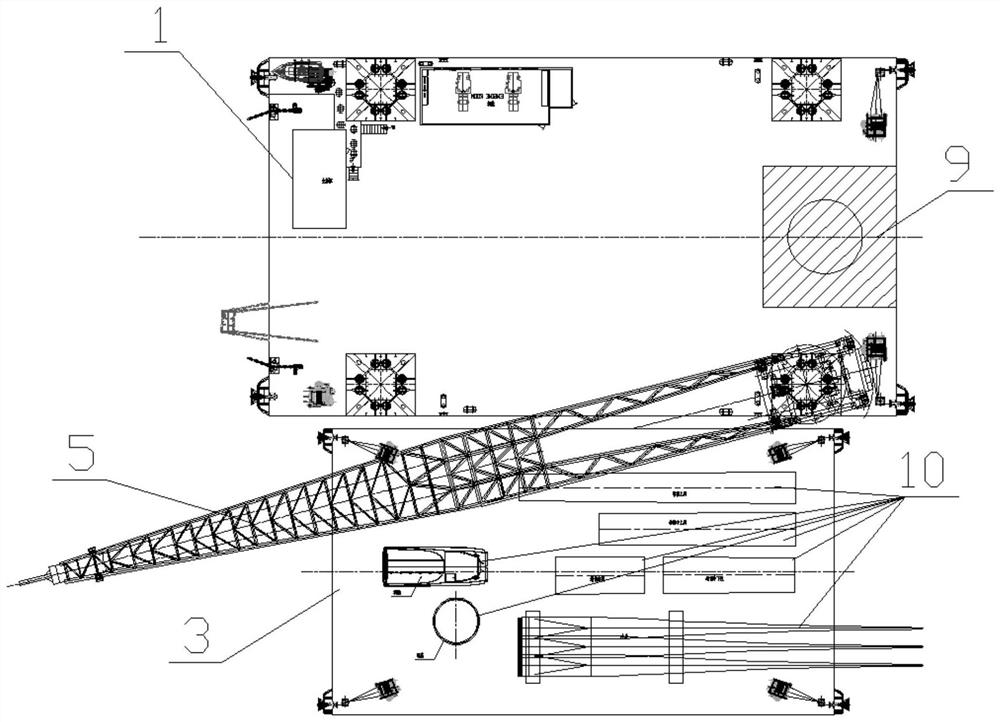

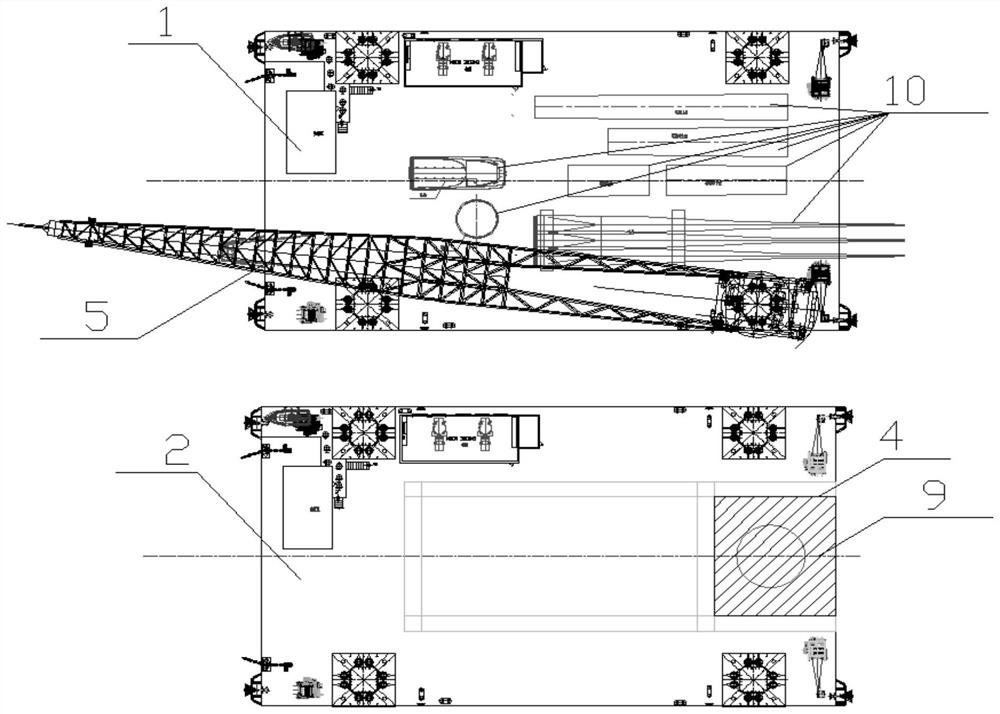

Floating fan platform mounting method

PendingCN114179983ALow comprehensive costReduce the difficulty of offshore installationTugsFloating buildingsFloating platformCantilevered beam

According to the floating type draught fan platform installation method, a self-elevating type lifting platform is arranged in a shallow water area, a lifting crane and a cantilever beam are fixed to the self-elevating type lifting platform, and a draught fan assembly is placed on a floating type barge. The lifting crane lifts the fan assembly to the cantilever beam for installation, the tugboat drags the floating fan platform to a shallow water area from the shore side, one end of the floating fan platform is connected with an offshore mooring point through a mooring rope, and the tugboat continues to drag the floating fan platform to the position beside the self-elevating lifting platform at the other end. And the cantilever beam conveys the assembled fan to the floating fan platform for installation, and after the fan is installed on the floating fan platform, the final operation sea area of the floating platform is fixed. According to the method, wind power installation equipment in the existing shallow water area is used for pre-installing the floating type wind power platform draught fan (hereinafter referred to as draught fan), an installation platform does not need to be additionally built for the deep water floating type wind power platform, and the comprehensive cost of draught fan installation and operation is reduced.

Owner:DALIAN SHIPBUILDING IND

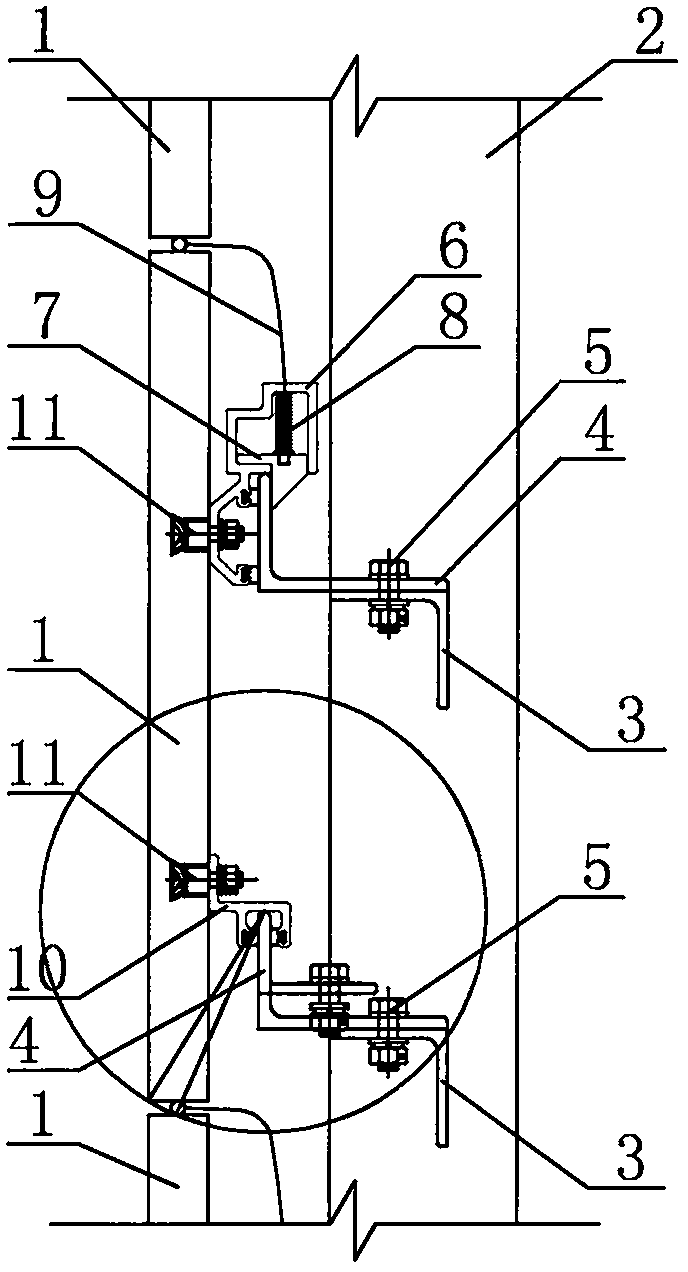

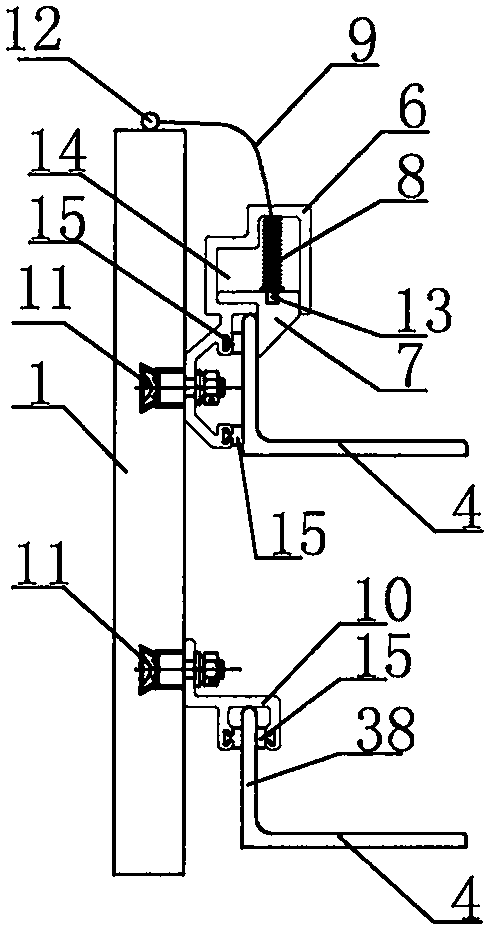

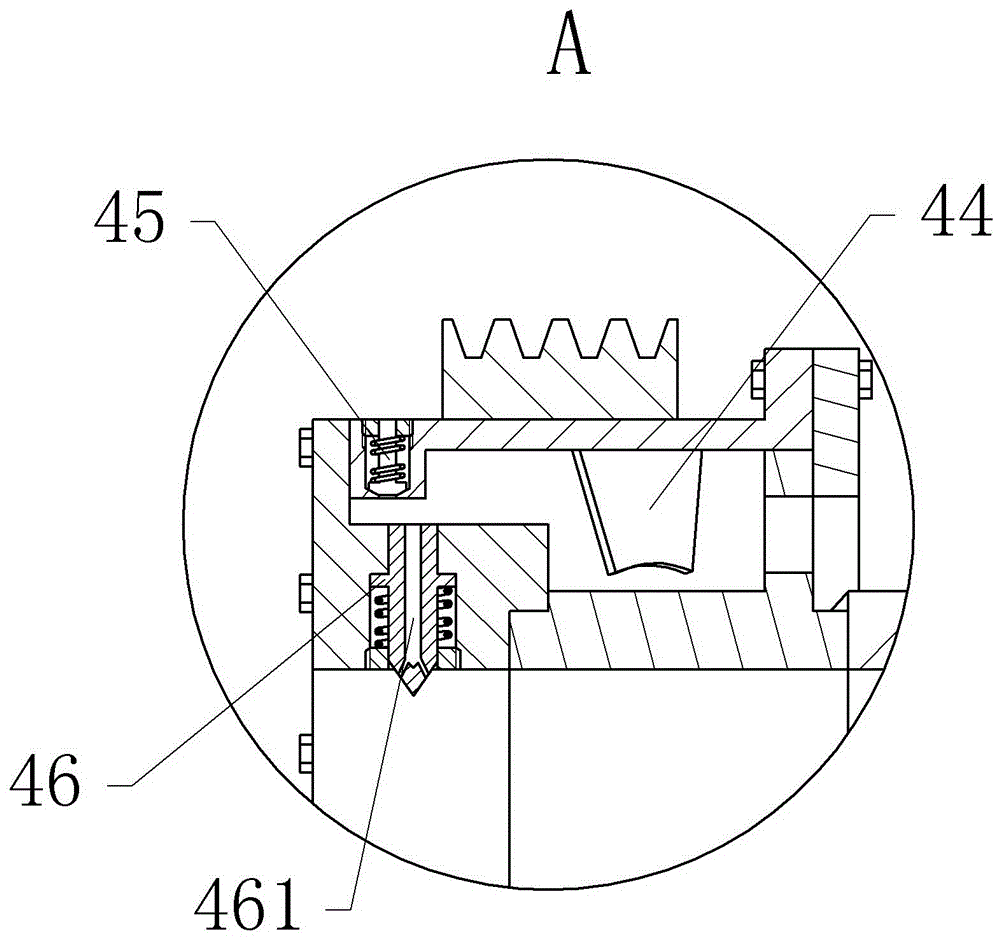

Connecting system for back-bolt type stone curtain wall

InactiveCN109138233AIncreased installation difficultyIncrease installation costWallsStructural engineering

The invention provides a connecting system for a back-bolt type stone curtain wall. According to the connecting system for the back-bolt type stone curtain wall, by arranging a locking device on a back-bolt connecting member at the upper end of a stone plate, locking and opening of the back-bolt connecting member at the upper end of the stone plate and a metal supporting piece on a curtain wall frame cross beam are realized in situ; a back-bolt connecting member at the lower end of the curtain wall stone plate and an L-shaped metal supporting piece on the curtain wall frame cross beam rotate for a certain angle so that the stone plate can be changed and mounted at will. The connecting system for the back-bolt type stone curtain wall has the advantages that the construction method is flexible; without any effect on the mounting quality, the stone curtain wall can be mounted from any position of the stone curtain wall according to the actual situation of the site; the curtain wall stoneplate can be conveniently detached and changed; by using a locking device on the connecting system on the back of the curtain wall stone, the locking and opening between the connecting member and themetal supporting piece on a curtain wall frame can be realized in situ so as to detach and change the curtain wall stone plate in situ; the maintenance is convenient; by using the connecting system, the curtain wall stone plate is changed in an original position; the stone curtain wall is very convenient to maintain; and for the originally mounted stone curtain wall, the stone plate can also be conveniently maintained and changed by using the connecting system.

Owner:邱建平 +2

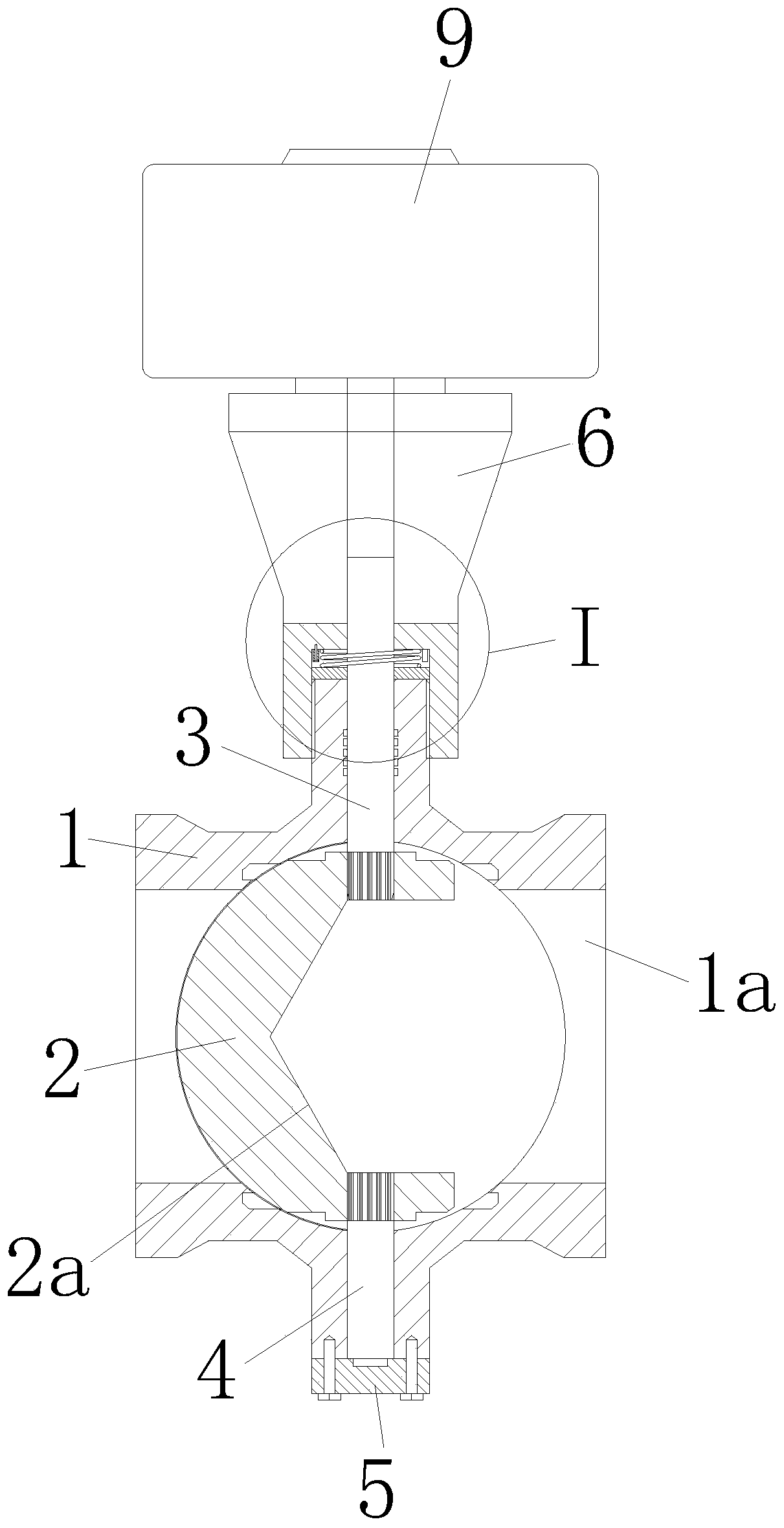

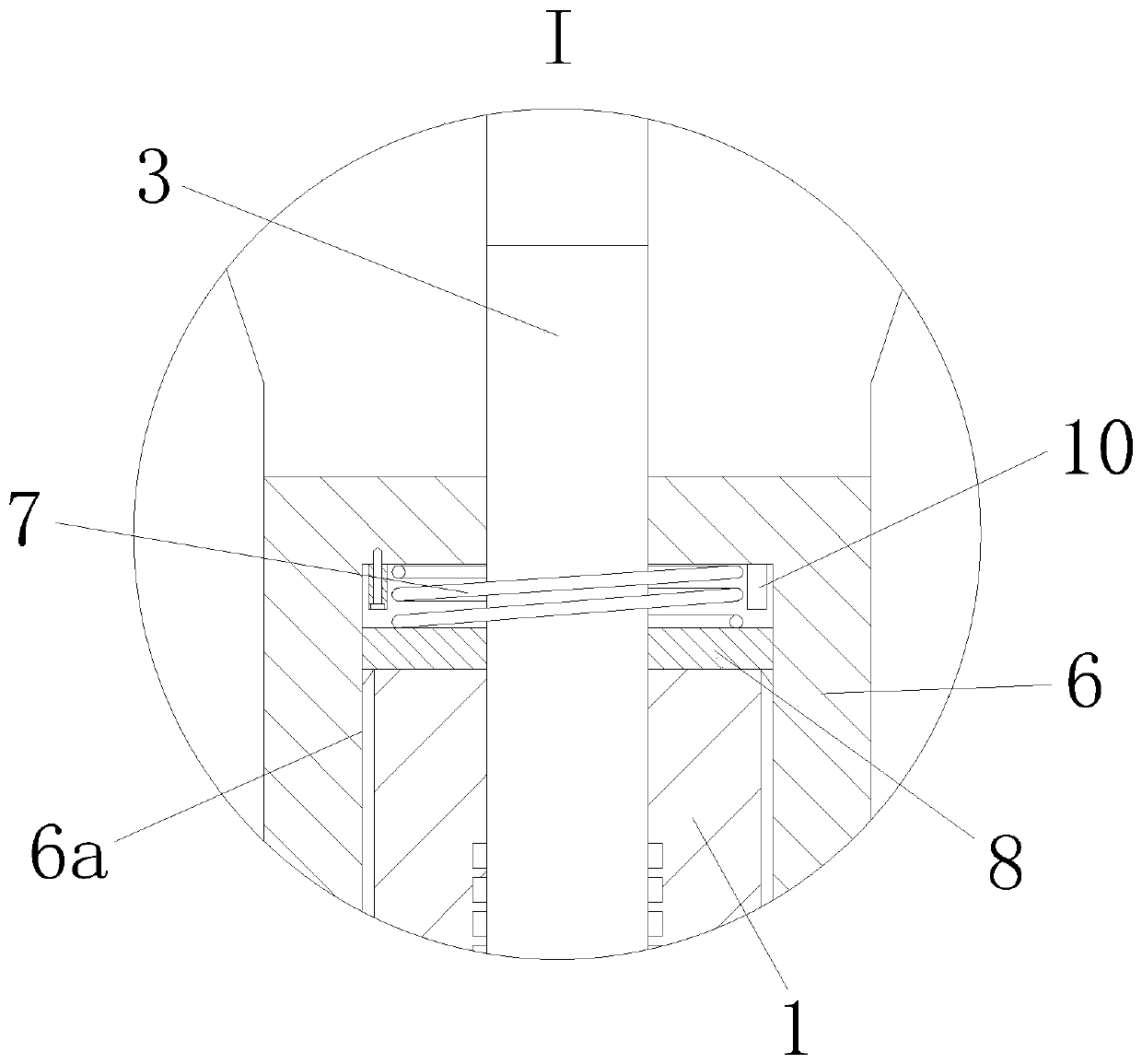

Flange connected fluorine lined pneumatic V-shaped ball valve

The invention discloses a flange connected fluorine lined pneumatic V-shaped ball valve which comprises a ball valve body. A circulating channel I is arranged in the ball valve channel, a rotating cavity is formed in the circulating channel I, a rotatable V-shaped ball body is mounted in the rotating cavity, an upper rotating rod is arranged on the ball valve body, the lower end of the upper rotating rod is mounted on the upper part of the V-shaped ball body, a lower rotating rod is arranged on the ball valve body, a lower end cover is arranged on the lower end part of the lower rotating rod,a connecting part is arranged on the upper end part of the ball valve body, a supporting seat is mounted on the outer wall of the connecting part, a spring is mounted in the supporting seat, an upperend plate is fixed to the lower end of the spring, and a pneumatic executing part is mounted on the supporting seat. According to the flange connected fluorine lined pneumatic V-shaped ball valve provided by the invention, the supporting seat is arranged on the upper end part of the ball valve body to seal the ball valve body, so that the supporting seat, together with the pneumatic executing part, can rotate a certain angle, and the valve is sealed effectively. The flange connected fluorine lined pneumatic V-shaped ball valve is suitable for being used in a narrow space, and the mounting efficiency and the mounting difficulty of an integral pipeline are improved.

Owner:ANHUI NANFU CHEM EQUIP CO LTD

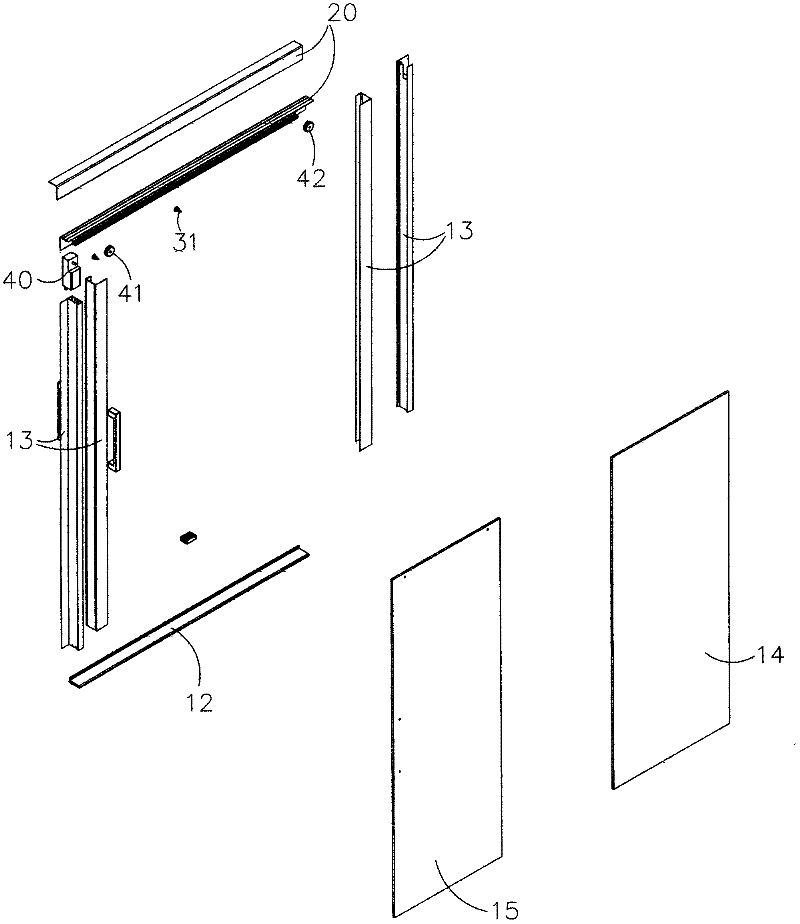

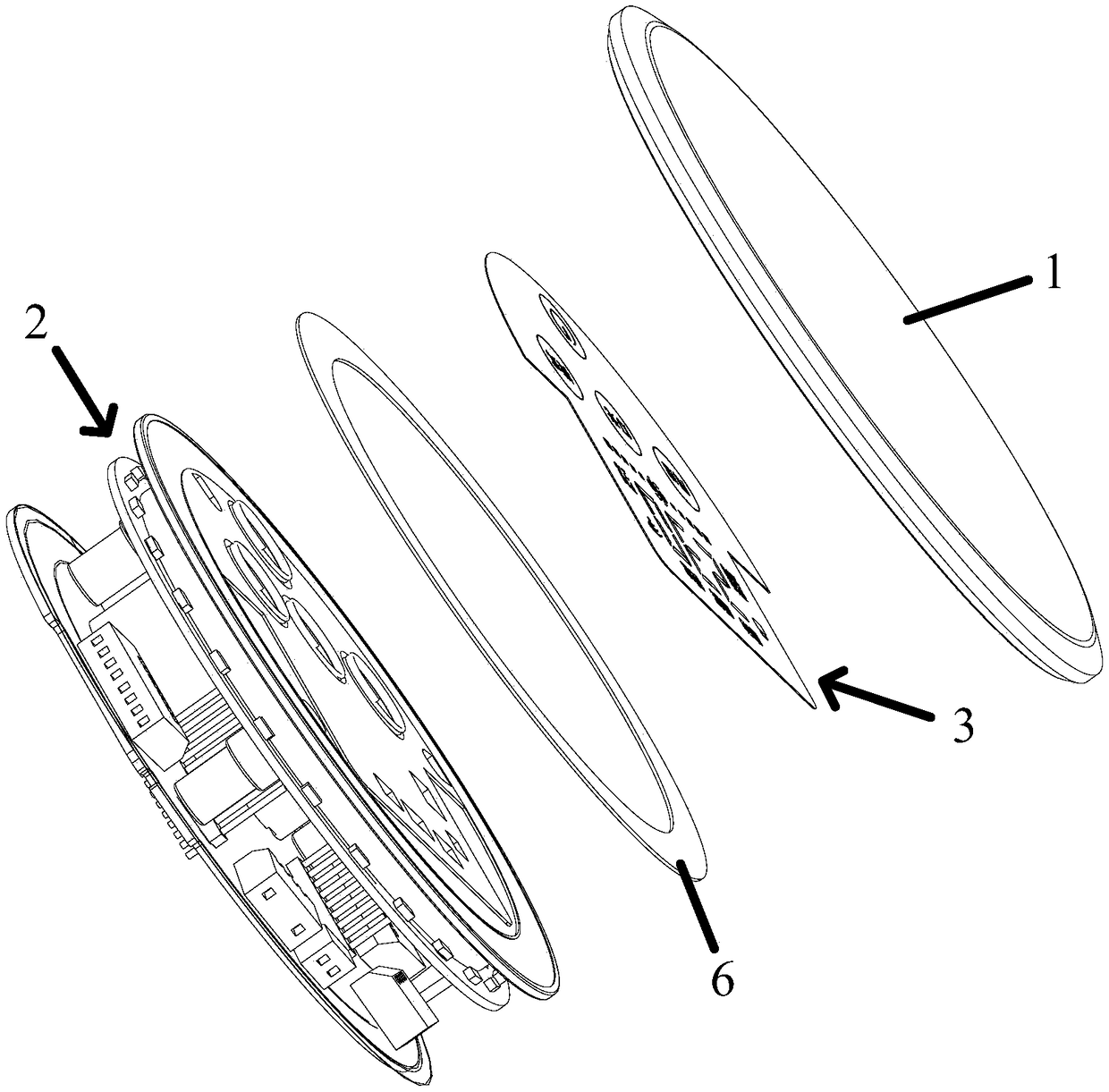

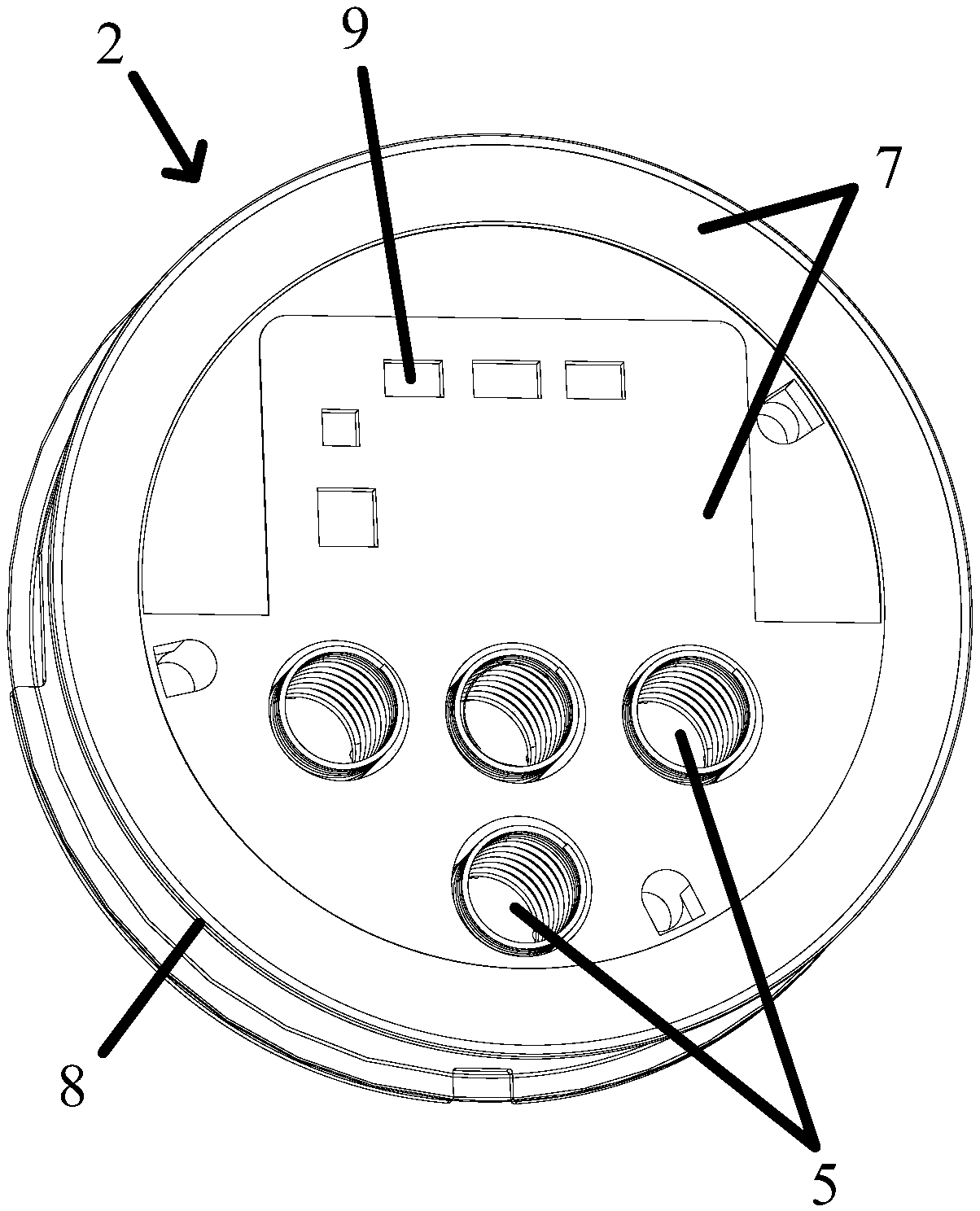

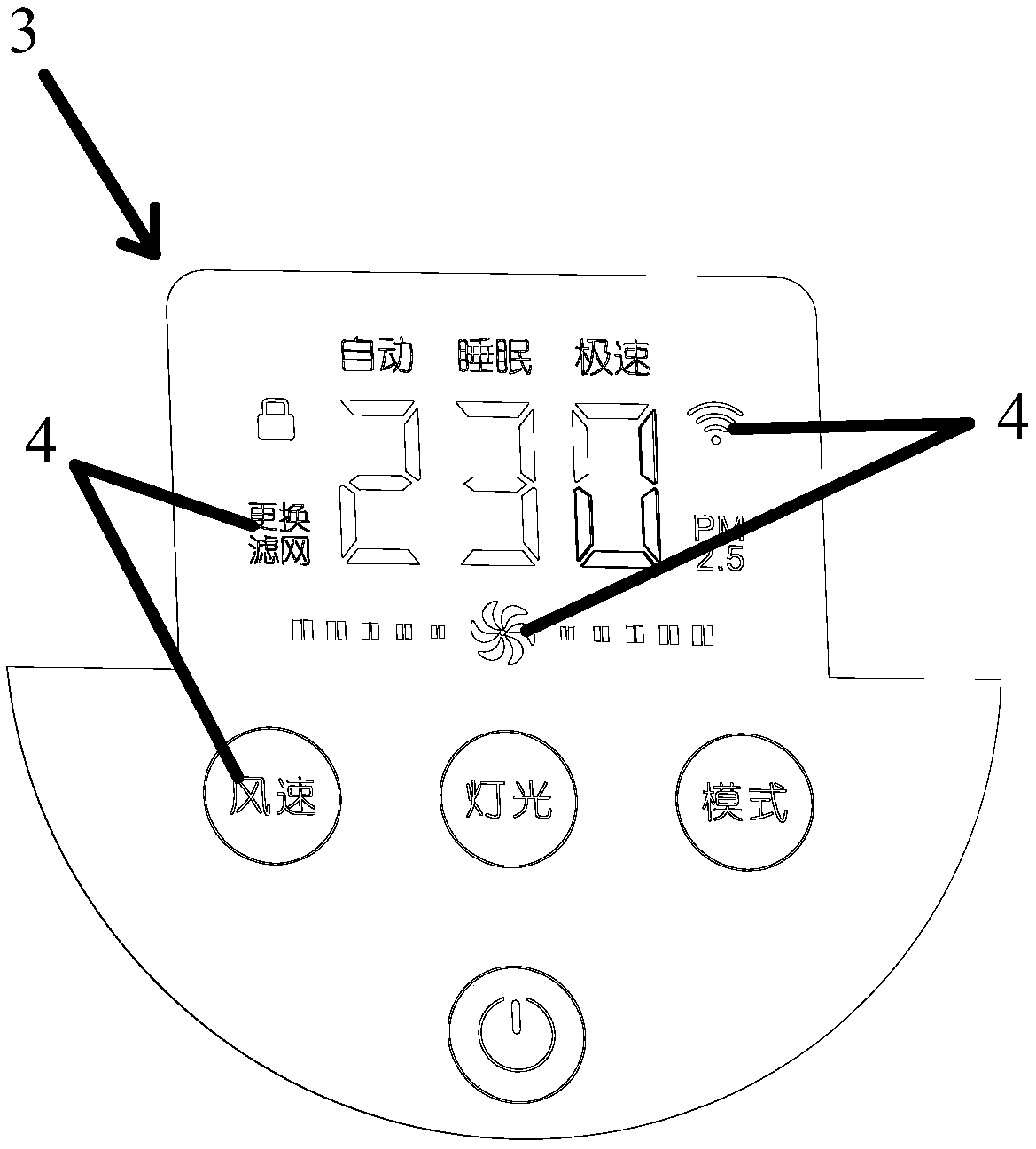

IMD panel and display device provided with IMD panel and installation method of IMD panel

PendingCN109377895AIncreased installation difficultyEasy to seeInput/output processes for data processingIdentification meansDisplay deviceEngineering

The invention discloses an IMD panel and a display device provided with the IMD panel and an installation method of the IMD panel. The IMD panel comprises a cover plate and a light-proof mask, whereinthe cover plate is semi-light-transmitting and is arranged on a display module, the light-proof mask is arranged between the cover plate and the display module, the surface of the light-proof mask isprovided with light-transmitting identification information, the identification information and a light emitting device of the display module are arranged correspondingly, so that the light emitted by the light emitting device is projected onto the cover plate through the identification information, by arranging the identification information on the light-proof mask, the problems are solved thatthe IMD panel is low in assembly efficiency and high in rejection rate due to the fact that an IMD panel in the prior art is high in assembly difficulty and difficultly achieves the assembly precisionrequirement.

Owner:GREE ELECTRIC APPLIANCES INC

Plastic granulating device

The invention discloses a plastic granulating device, and relates to the field of plastic processing. The plastic granulating device comprises a frame; a cantilever is fixed on the frame; one end of the cantilever is fixed on the frame; a cutting motor is arranged at the other end of the cantilever, and includes a rotor, a stator and a cutting mechanism; the stator is fixed on the cantilever; the rotor is rotationally connected with the stator; a center through hole penetrates through the centers of the rotor, the stator and the cantilever; multiple chutes and cutters uniformly distributed in the center of the rotor; slide blocks capable of sliding in the chutes are arranged in the chutes; the cutters can slide in the radial direction along the rotor; tips of the cutters extend into the center through hole; the tail ends of the cutters are matched with the wedge surfaces of the slide blocks; and the cutters are coated with return springs. When the plastic granulating device cuts plastic pipes, the plastic pipes are uniformly stressed; and the plastic pipes are still located in the center through hole after cutting, so that the damage of the plastic pipes can be prevented.

Owner:重庆敏驰塑胶有限公司

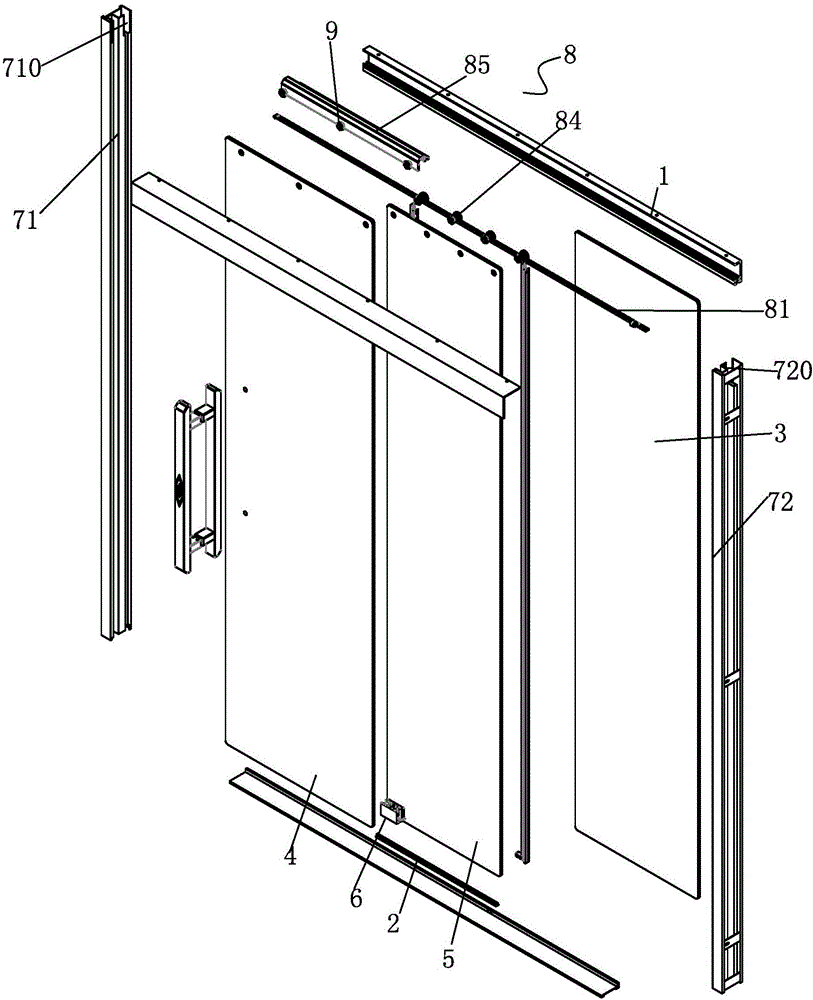

Sliding rail type low-barrier linkage shower room and mounting method

ActiveCN105840050AEasy accessAvoid shakingWing operation mechanismsBathsEngineeringMechanical engineering

Owner:FUJIAN XIHE SANITARY WARE TECHNOLOGY CO LTD

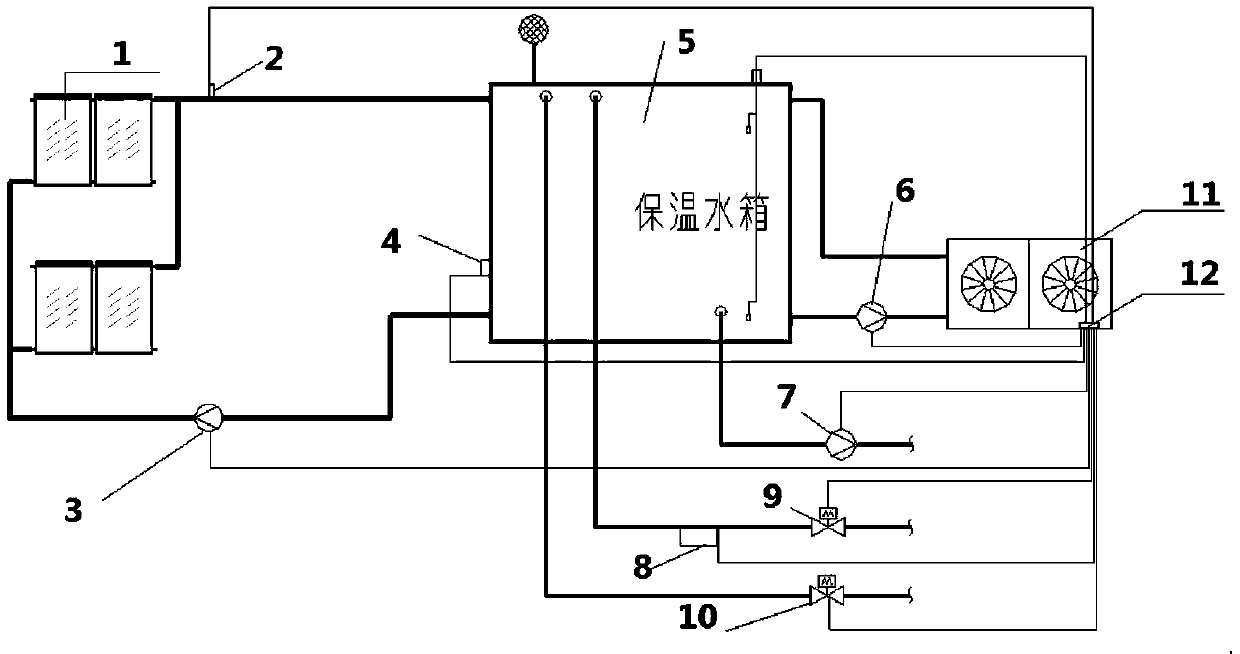

Air source heat pump water heater

ActiveCN103471254AIncreased installation difficultySimplify the difficulty of installationSolar heat devicesSolar thermal energy generationThermodynamicsCirculator pump

An air source heat pump water heater comprises a solar energy collector, a heat pump circulating pump, a water supply pump, a water feeding electromagnetic valve, a solar energy circulating pump, a water tank temperature sensor, a panel and a heat pump controller. The air source heat pump water heater is characterized by also comprising a collector temperature sensor; the collector temperature sensor and the water tank temperature sensor are connected with the heat pump controller and temperature signals are input into the heat pump controller; the heat pump circulating pump, the water supply pump, a water return electromagnetic valve and the water feeding electromagnetic valve which are connected with the heat pump controller are controlled by the heat pump controller to switch on and switch off; the heat pump controller intelligently judges whether to start the solar energy collector or a heat pump to heat water according to the temperature difference of the solar energy collector and a water tank. According to the technical scheme of the air source heat pump water heater, solar energy and the heat pump water heater can be simultaneously controlled based on the original heat pump controller without an additional controller and accordingly the installation is simple and convenient and the cost is saved.

Owner:广东派沃新能源科技有限公司

Plastic smelting device

The invention discloses a plastic smelting device and relates to the field of plastic machining. The plastic smelting device comprises a rack and a driving motor. A cantilever is fixed on the rack. One end of the cantilever is fixed on the rack and the other end of the cantilever is provided with a cutting mechanism. The cutting mechanism comprises a stator which is fixed on the cantilever and a rotor which is rotationally connected with the stator. A center through hole interpenetrates the centers of the rotor, the stator and the cantilever. An air suction cavity is arranged between the stator and the rotor. A rotary vane rotating with the rotor is arranged in the air suction cavity and the air suction cavity is divided into a pressure chamber and an air inlet passage by the rotary vane. The air inlet passage communicates with the outside. A plurality of cutters which are uniformly distributed along the center of the rotor are arranged on the rotor and the cutters can slide radially along the rotor. Tensioning springs sleeves outside the cutters. The rotor can be driven to rotate by the driving motor. According to the plastic smelting device, a plastic pipe can be uniformly forced when cut and located in the center through hole after cut, so that damage of the plastic pipe can be prevented.

Owner:重庆敏驰塑胶有限公司

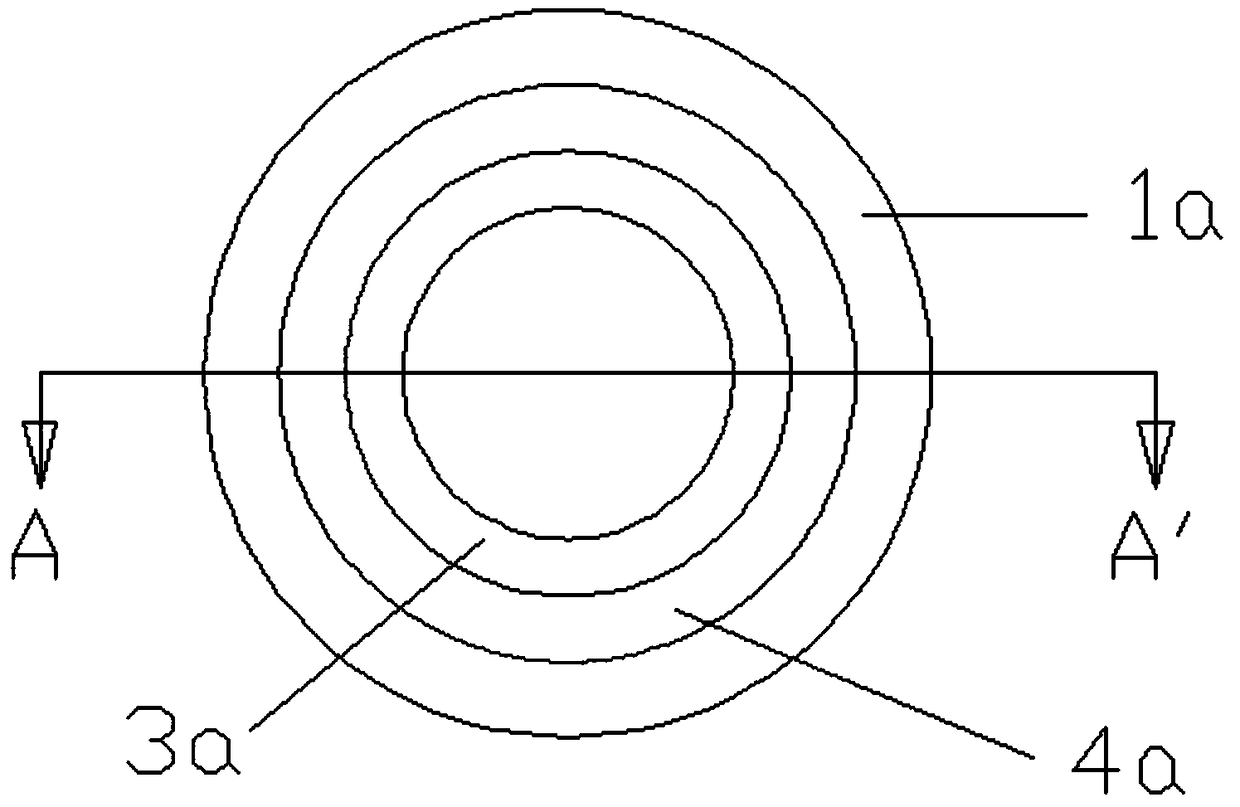

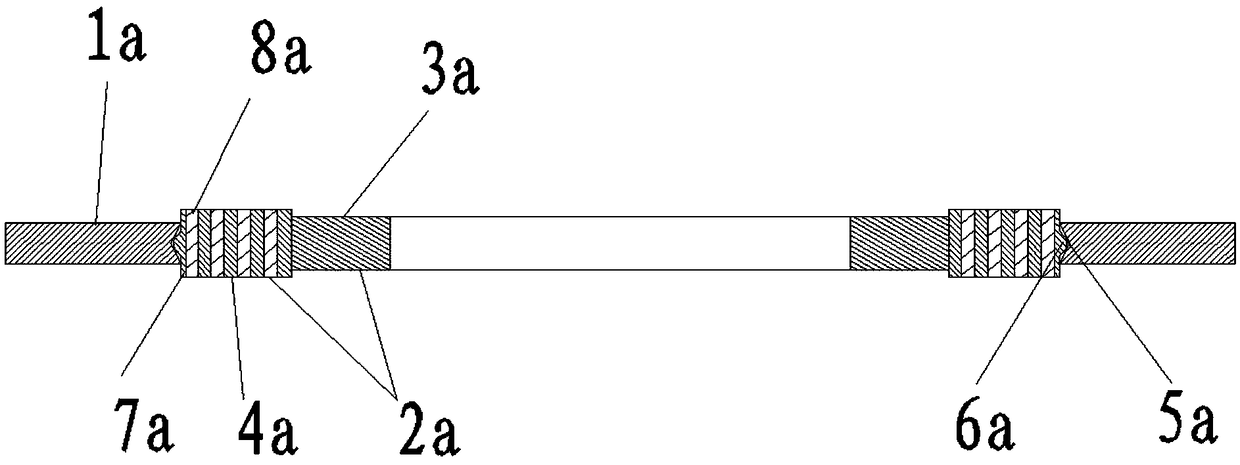

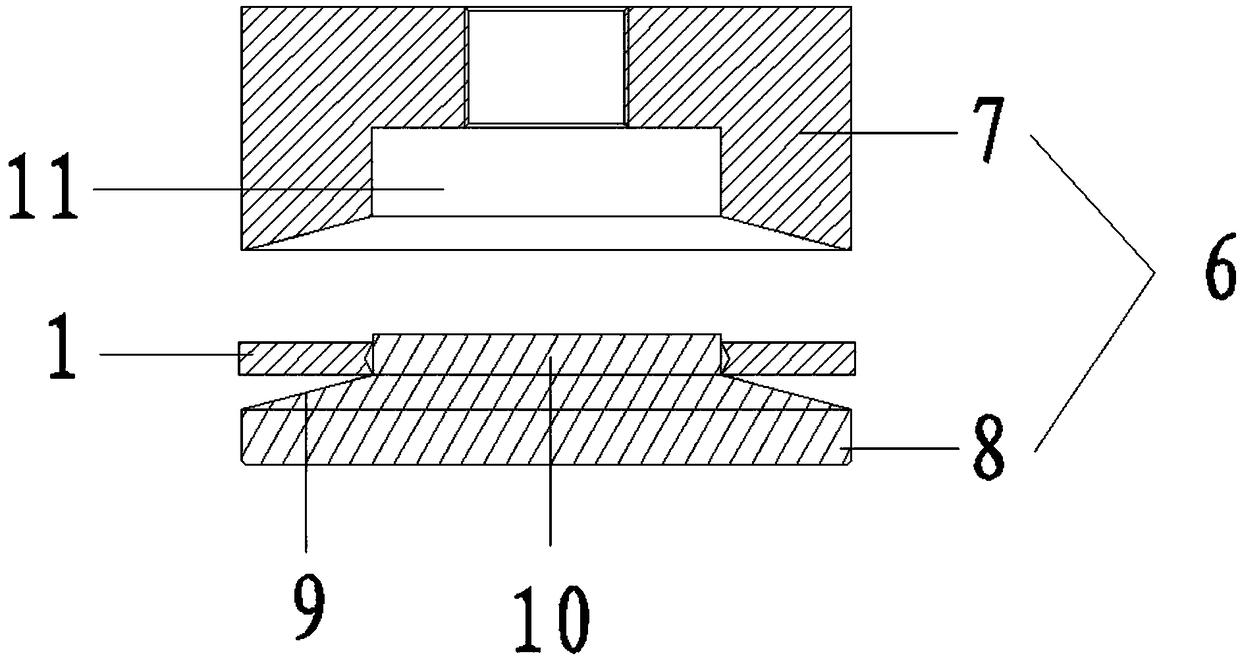

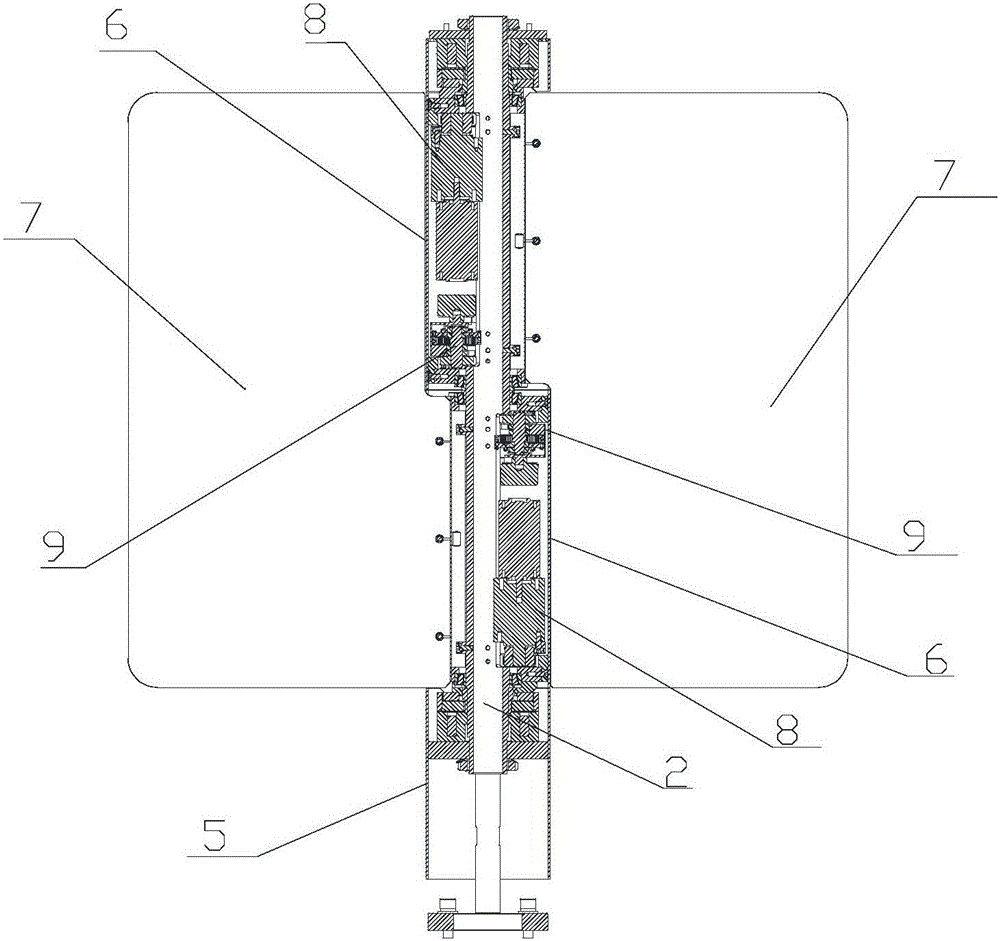

Manufacturing equipment and mold of metal spiral-wound gasket

ActiveCN109093023AEasy to pressEasy to installShaping toolsMetal working apparatusSpiral woundAutomation

The invention discloses manufacturing equipment of a metal spiral-wound gasket. The manufacturing equipment is characterized by comprising an outer ring deformation device and an inner and outer ringautomatic lantern ring leveling device. The outer ring deformation device comprises an outer ring deformation mold used for achieving first deformation of an outer ring, enabling the outer ring to jack up from bottom to top, and expanding the inner diameter of the top of the outer ring. The inner and outer ring automatic lantern ring leveling device comprises a first platform body, a first multistation index plate, a lantern ring mold and an outer ring leveling mold arranged at the first platform body. The lantern ring mold is used for completely compressing an inner ring into the outer ring.The outer ring leveling mold is used for achieving second deformation of the outer ring and leveling the upper and lower surfaces of the outer ring. According to the manufacturing equipment of the metal spiral-wound gasket, during the installation process of the inner ring and the outer ring, annular protrusions at the outer surface of a winding ring of the inner ring are not liable to upwarp or be crushed, flatness and finish degree of the product surface are high, and the automation degree is high. The invention further provides a manufacturing mold of the metal spiral-wound gasket.

Owner:慈溪红叶密封制品有限公司

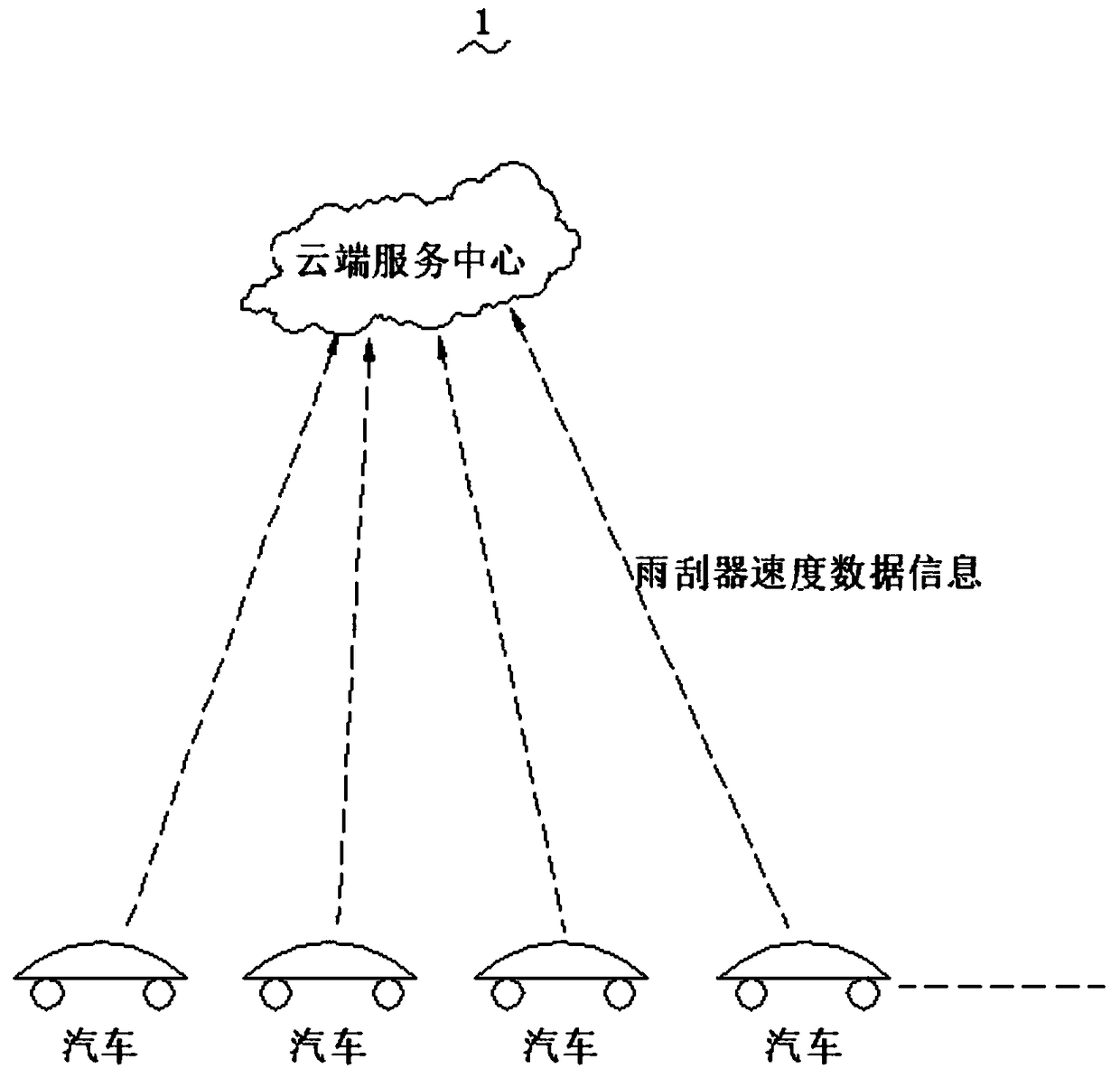

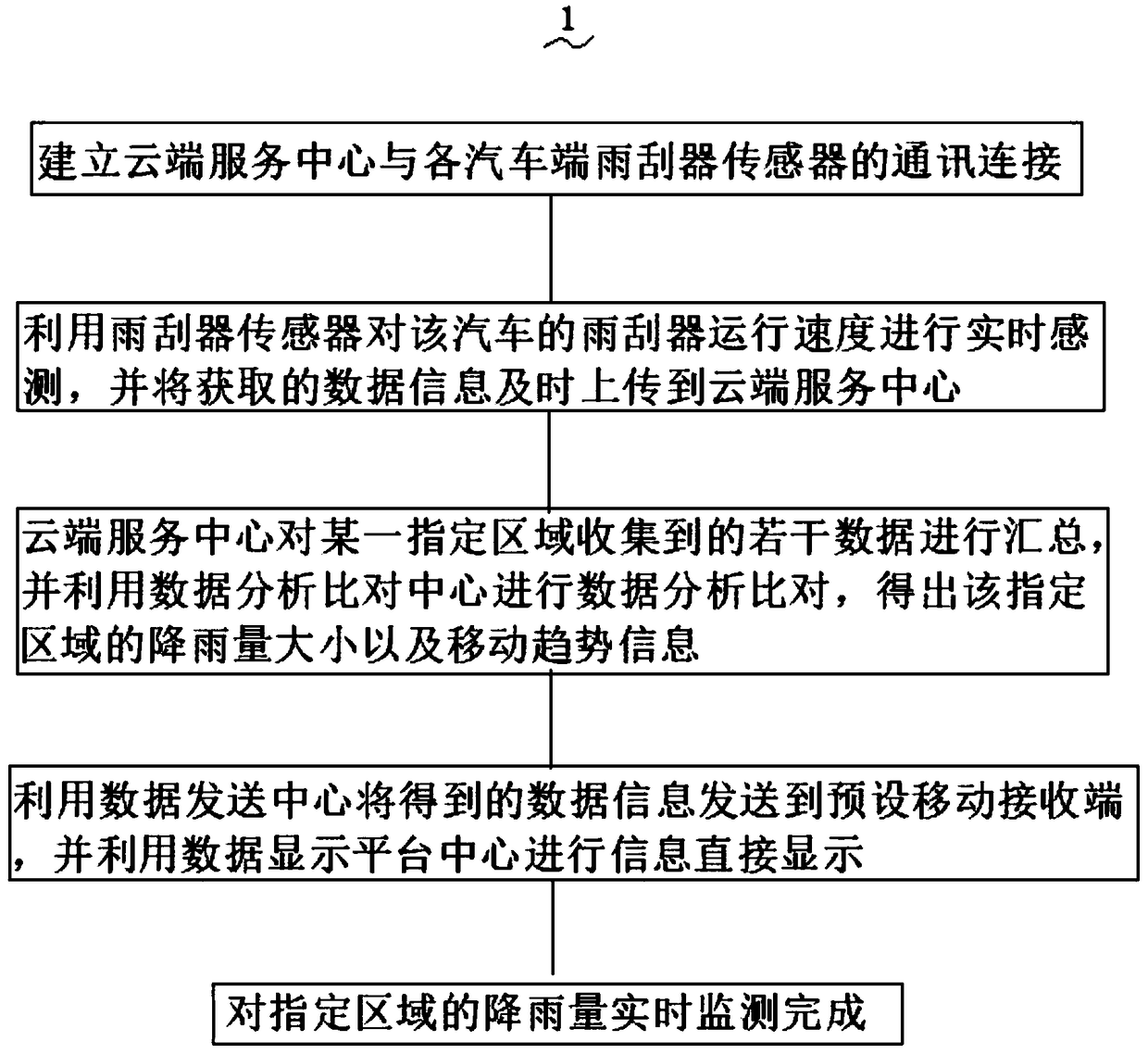

Real-time rainfall monitoring system and method based on automobile wipers

PendingCN109343155AReduce installation difficultyLow costRainfall/precipitation gaugesICT adaptationData informationEngineering

The invention provides a real-time rainfall monitoring system and method based on automobile wipers. The system includes a cloud service center and wiper sensors installed on automobiles and used forsensing the running speeds of corresponding automobile wipers. The wiper sensors of the automobiles sense the running speed information of the wipers and upload the acquired data information to the cloud service center in time. The cloud service center analyzes the collected big data to obtain the rainfall and movement trend information of a corresponding region. The rainfall and movement trend ofa region are obtained through big data analysis, and drivers around are reminded not to go to places prone to landslide or culvert water accumulation during a rainstorm. Thus, a safety warning effectis achieved. Moreover, the system and the method have the advantages of low installation difficulty, low cost and accurate data.

Owner:姚宇轩

Clamp specialized for graphite grounding rope

InactiveCN105789927ASimple structureEasy constructionConnection contact member materialCorrosion resistantEngineering

The invention relates to a high voltage iron tower grounding tool, and particularly relates to a clamp specialized for a graphite grounding rope. The clamp specialized for the graphite grounding rope comprises a clamp body. The clamp specialized for the graphite grounding rope is characterized in that the clamp body is made of anti-corrosion nonmetallic material. The middle part of the clamp body is provided with a communicated connecting port. The upper surface of the internal part of the connecting port has a planar structure, and the lower surface has a slant wedge structure. The connecting port is internally provided with a fastening inserting plate which is matched with the wedge structure. The upper surface of the fastening inserting plate has the planar structure, and the lower surface has the slant wedge structure. The clamp specialized for the graphite grounding rope of the structure has the advantages of being simple in structure, convenient in construction, corrosion-resistant, pollution-free to soil, convenient to transport and economical in cost.

Owner:XUCHANG SIDA ELECTRIC POWER EQUIP

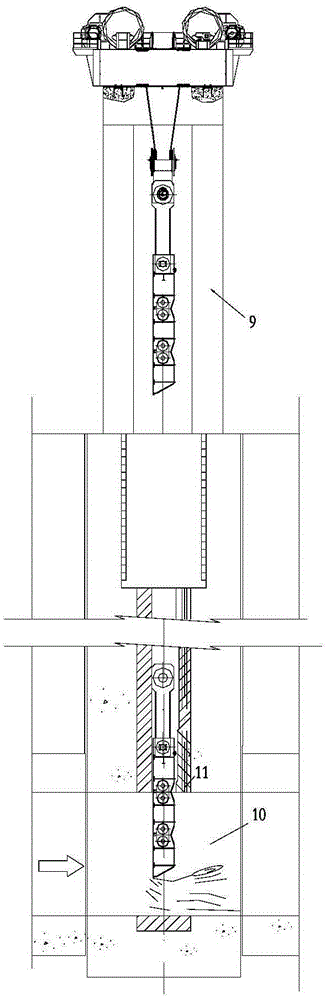

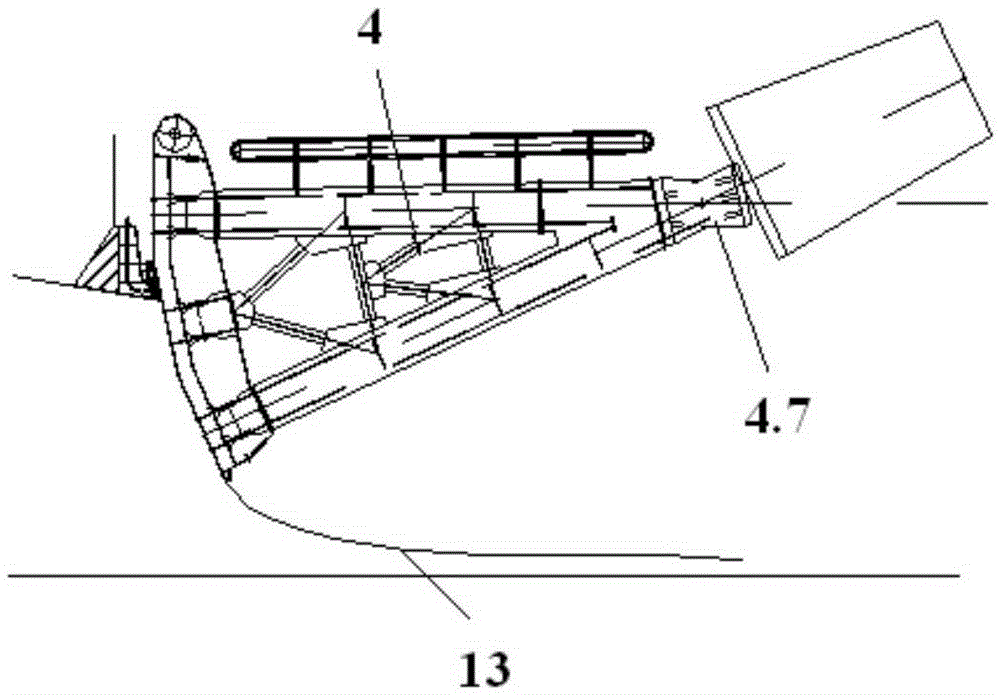

Method for blocking tail gate of diversion tunnel by adopting arc-shaped gate

InactiveCN105401561ASignificant securitySignificant social benefitsBarrages/weirsSocial benefitsWater flow

The invention discloses a method for blocking a tail gate of a diversion tunnel by adopting an arc-shaped gate. According to the method, a diversion tunnel (8) is provided; an opening and closing machine room (1) and an arc-shaped gate chamber (2) are excavated inside the diversion tunnel (8); the opening and closing machine room (1) is positioned above the arc-shaped gate chamber (2); a partition beam (1.2) is arranged between the opening and closing machine room (1) and the arc-shaped gate chamber (2); an arc-shaped gate (4) is mounted inside the arc-shaped gate chamber (2) and is positioned on a concrete structure body (7); the arc-shaped gate (4) rotates about an arc-shaped gate supporting and articulating rotation center (4.7) which is mounted on the concrete structure body (7). The method disclosed by the invention has the advantages of overcoming the defect that water easily flows in a cavity because of sudden changes of water flow boundary close to a gate slot in the prior art, safely and reliably blocking a dynamic water tail gate by utilizing the arc-shaped gate, being safe and realizing remarkable social benefits.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

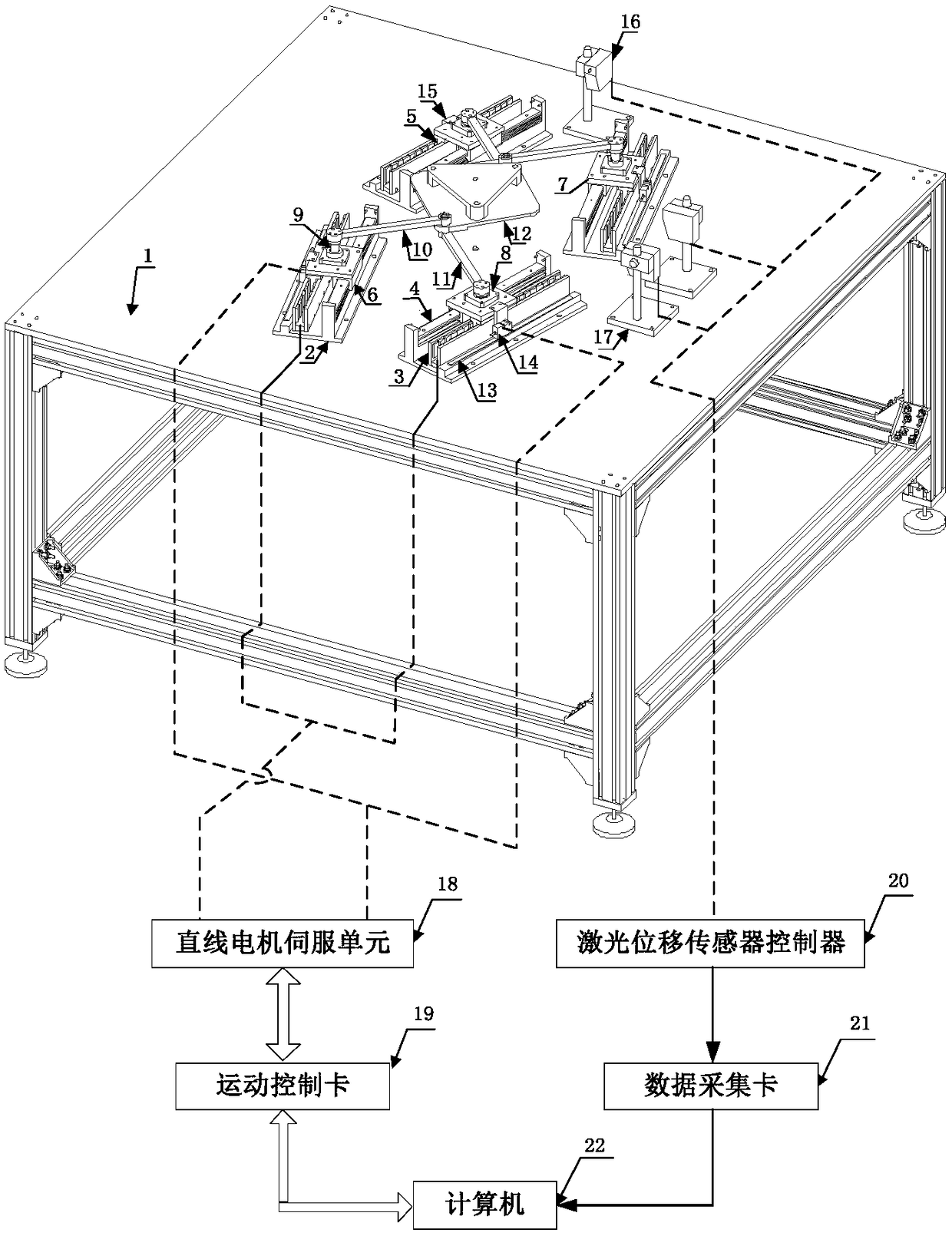

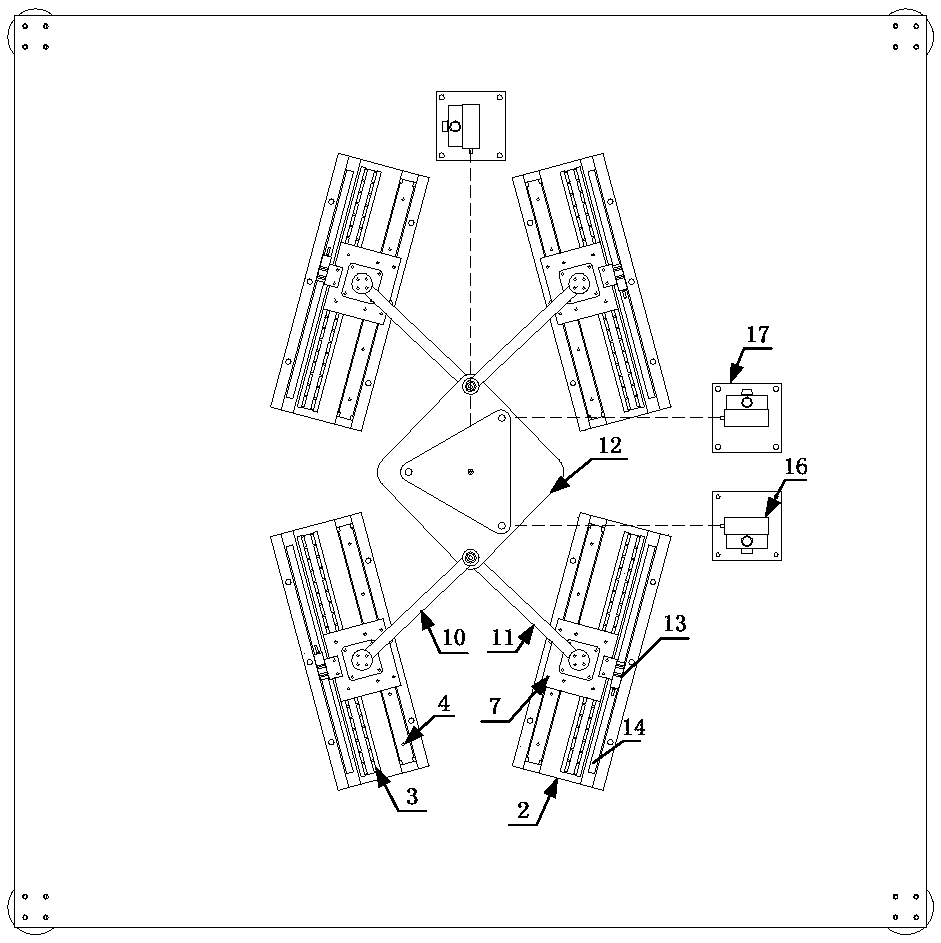

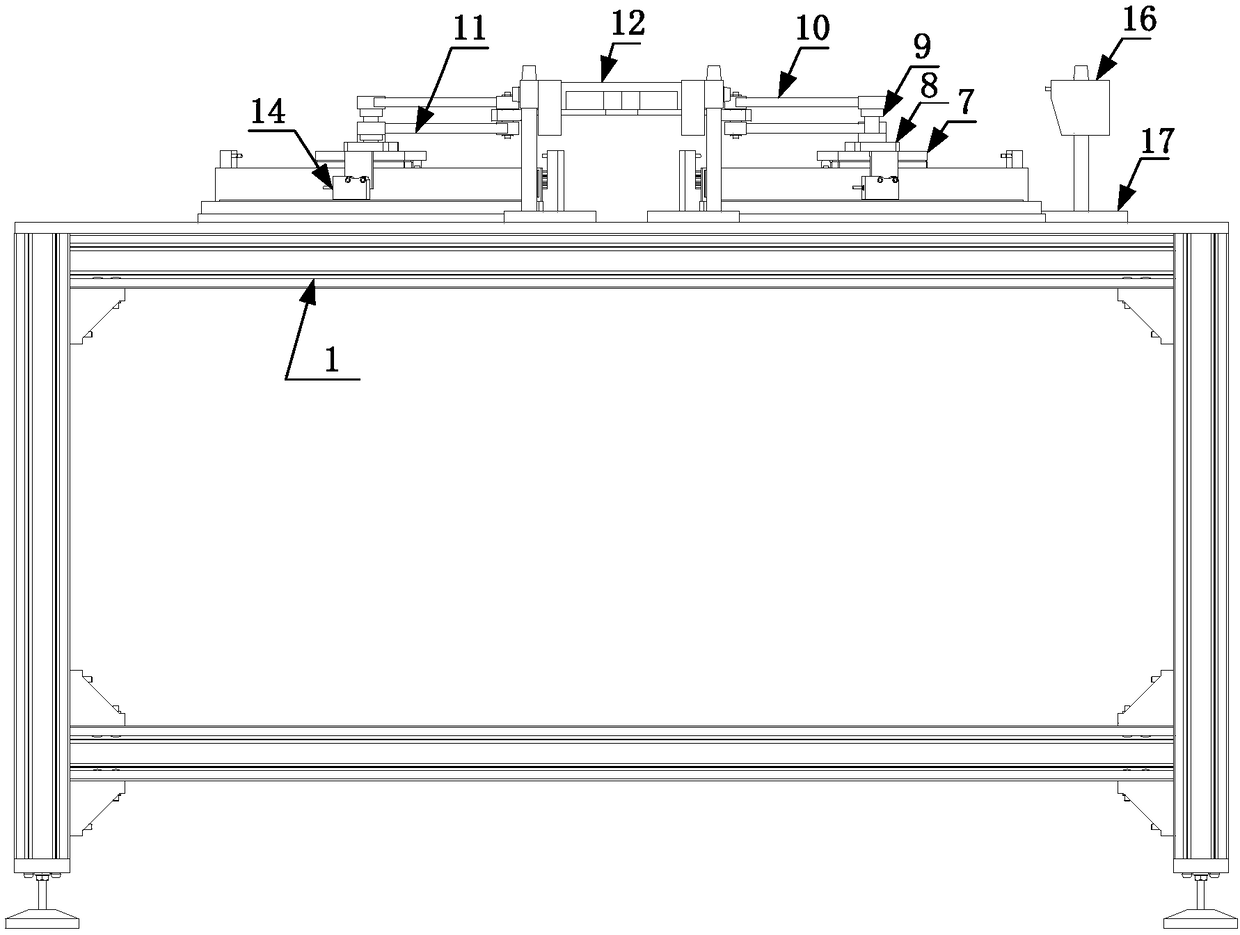

Planar parallel mechanism device driven by double five-bar mechanisms, and control method thereof

ActiveCN109129427AEliminate the effects ofReduce frictionProgramme-controlled manipulatorTotal factory controlControl signalClosed loop feedback

The invention discloses a planar parallel mechanism device driven by double five-bar mechanisms, and a control method thereof. The planar parallel mechanism device comprises a parallel mechanism bodypart, a detection part and a control part; the parallel mechanism body part comprises the two planar five-bar mechanisms, a dynamic platform and a static platform; a laser displacement sensor mountedon the static platform is used for measuring displacement and attitude information of the dynamic platform; and a magnetic railing ruler sensor is used for measuring position information of motors, the position information is processed through a computer, then a control signal is output to control movement of the linear motors, and then movement of the dynamic platform is controlled. The planar parallel mechanism device takes the two five-bar mechanisms as a driving branch chain, the influences of gaps on a system are eliminated, the laser displacement sensor is utilized to conduct position closed-loop feedback, and thus the advantages of high positioning accuracy, fast closed-loop control response, good control performance and the like are achieved.

Owner:SOUTH CHINA UNIV OF TECH

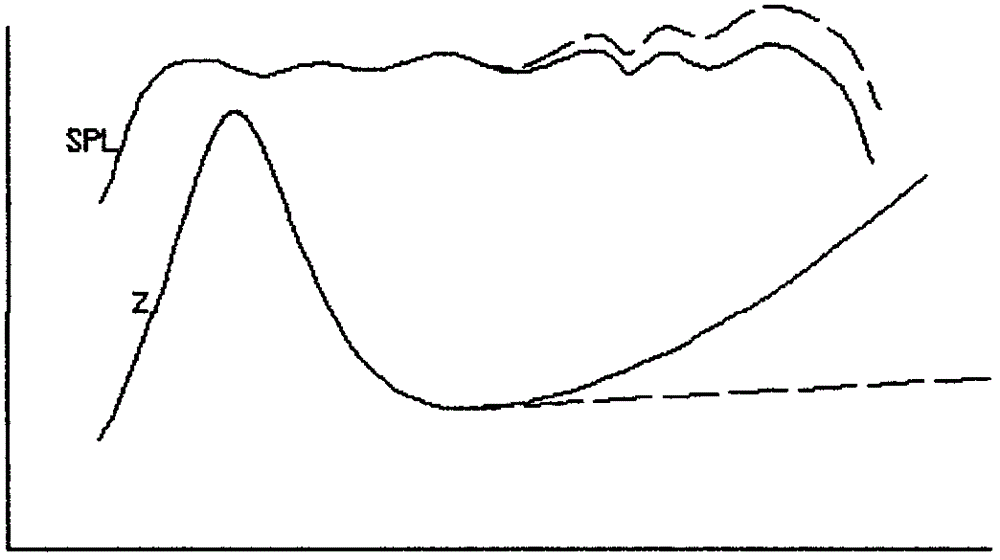

A thin-film short-circuit ring for an electromagnetic driver

ActiveCN103200489BMagnetic field stabilizationEliminates the effects of hysteresisFrequency/directions obtaining arrangementsHysteresisLeading edge

The invention discloses a designing scheme of a high conductivity metallic film short circuit ring which does not change (or slightly changes) basic performance of a speaker while leading edge transient response of the speaker is obviously improved. In an irony member of a magnetic path near a voice coil, some parts of the irony member are in a highfield and high magnetic saturation state, the high magnetic saturation parts of the irony member are closely attached to the voice coil and are main sources of hysteresis damping received by the voice coil movement. The high conductivity metallic film short circuit ring needs arranging on the inner sides or the outer sides of the high magnetic saturation parts, the high magnetic saturation parts of the irony member are enabled to be placed in an inner and outer side strong affecting area of the short circuit ring, the adjustment on the interior magnetic field of the strongest magnetic field of the irony member by a voice coil current is reduced, therefore, a hysteresis damping effect is reduced, the leading edge transient response is improved, and the occurrence that voice coil inductance is blindly canceled or reduced greatly is avoided.

Owner:张百良

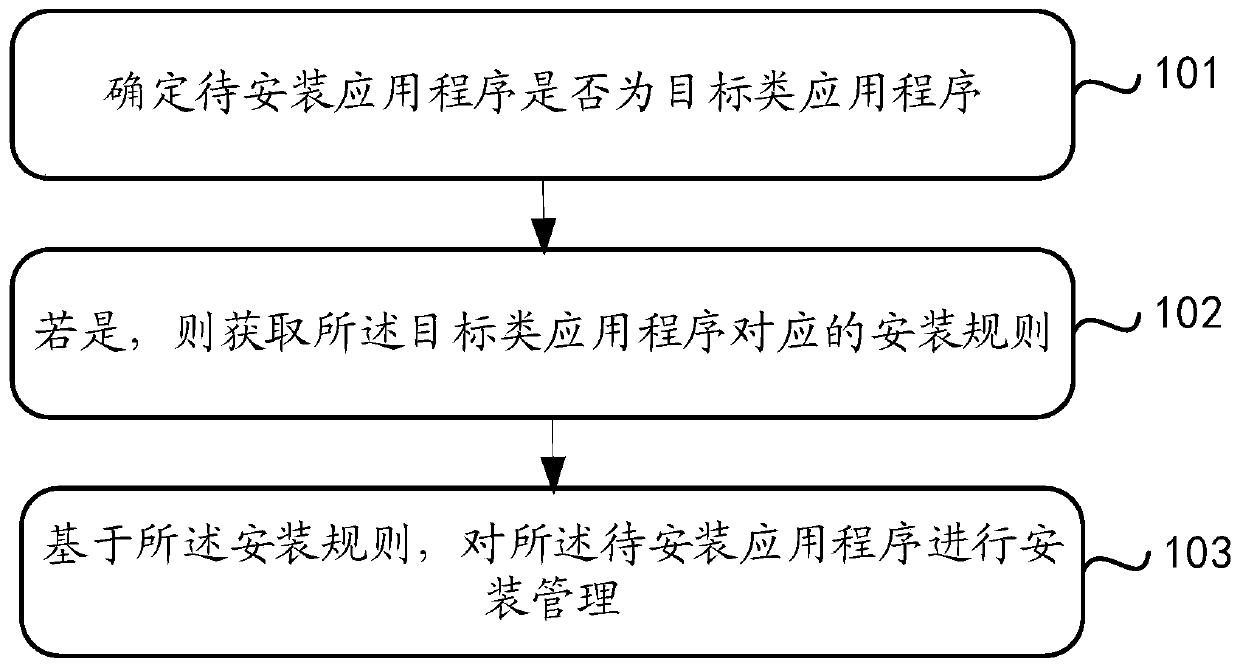

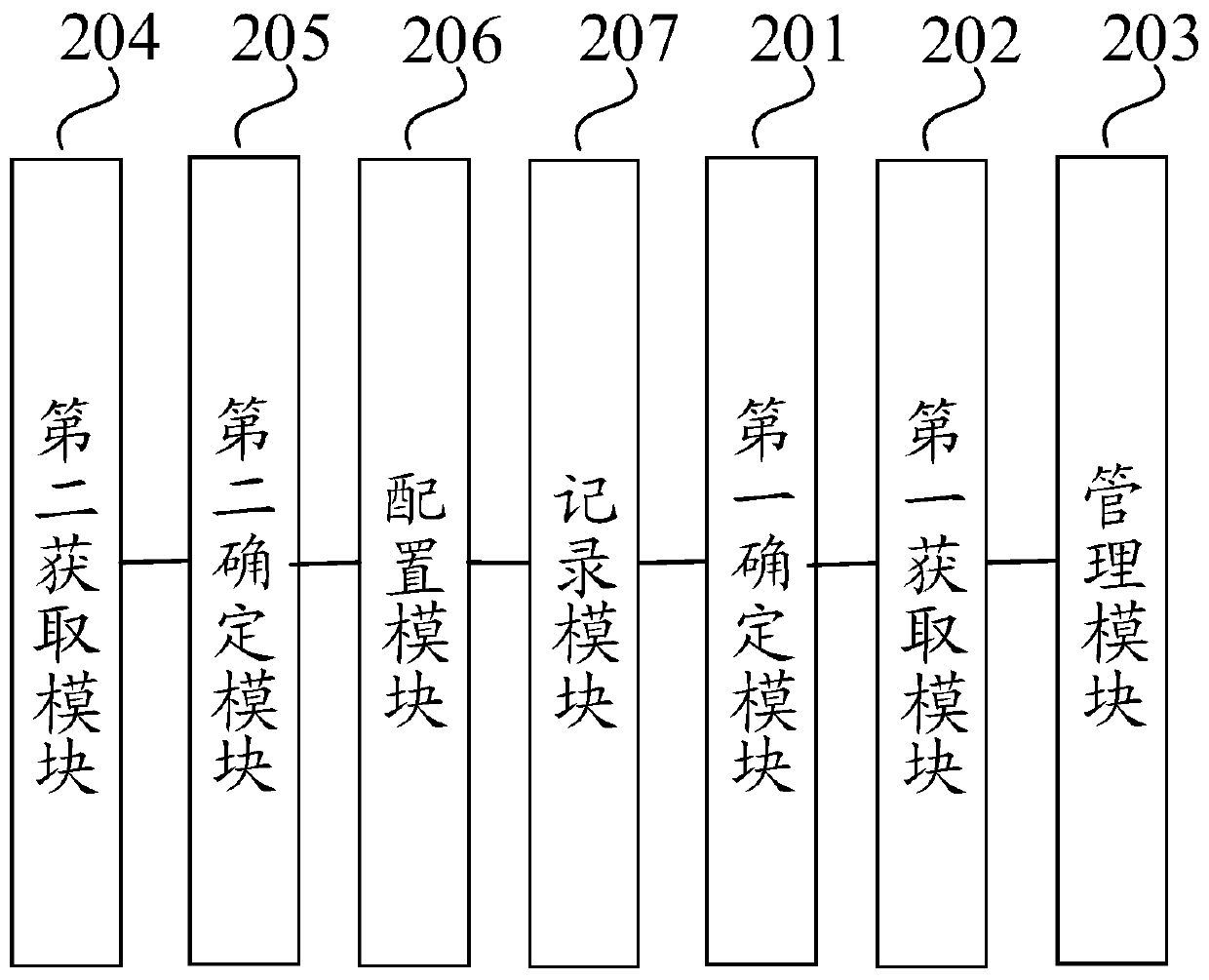

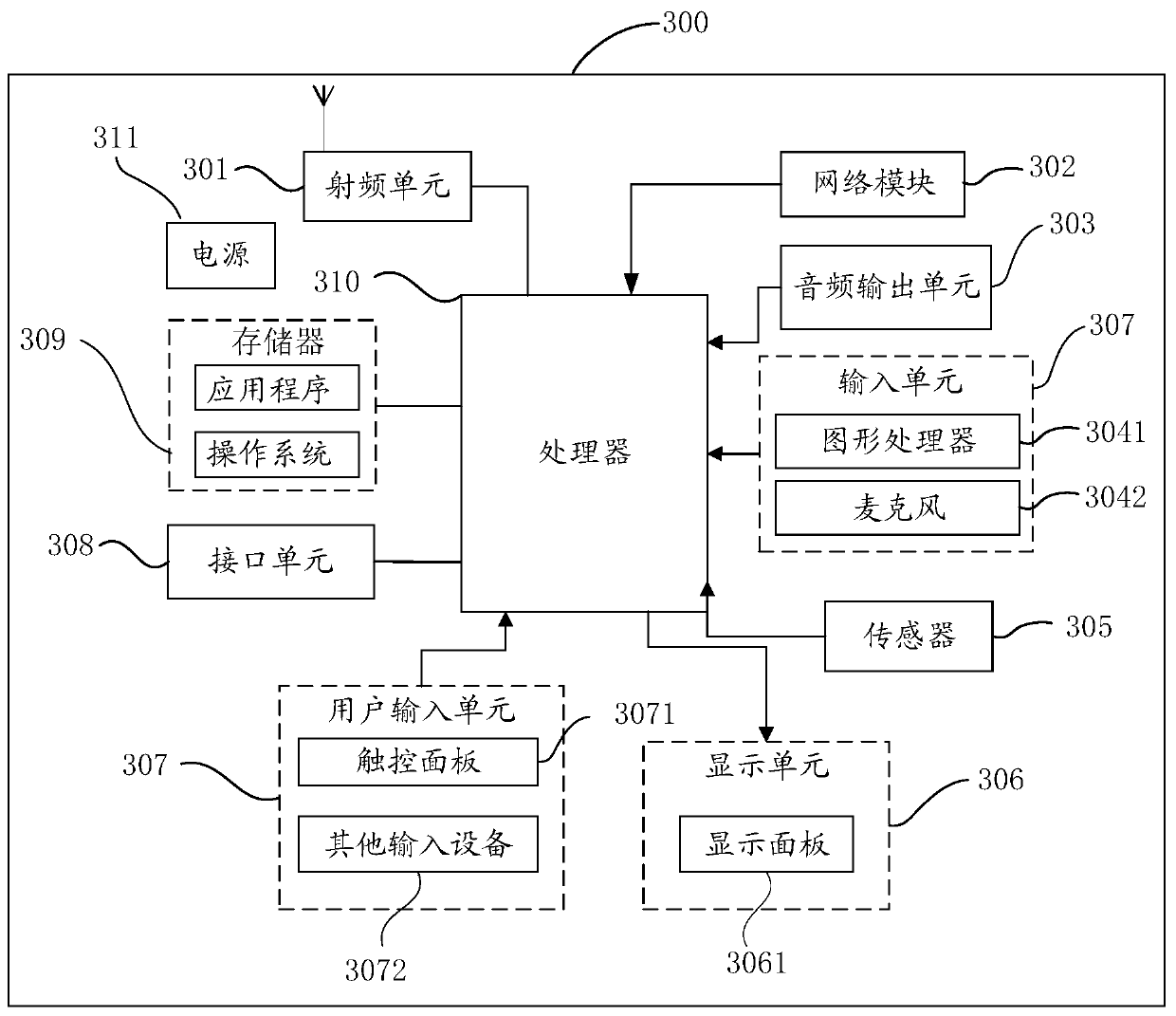

Installation method of an application program and terminal equipment

ActiveCN109799999AIncreased installation difficultyQuit addictionSoftware deploymentTerminal equipmentInstalled base

The invention discloses an installation method of an application program and terminal equipment. The method comprises the following steps: determining whether a to-be-installed application program isa target application program or not; If yes, obtaining an installation rule corresponding to the target application program; and based on the installation rule, carrying out installation management onthe to-be-installed application program, so that the to-be-installed application program needs to be installed based on the installation rule, the installation difficulty of the to-be-installed application program can be increased, a user is effectively helped to reject the addiction to the application program, and the time of the user is saved.

Owner:VIVO MOBILE COMM CO LTD

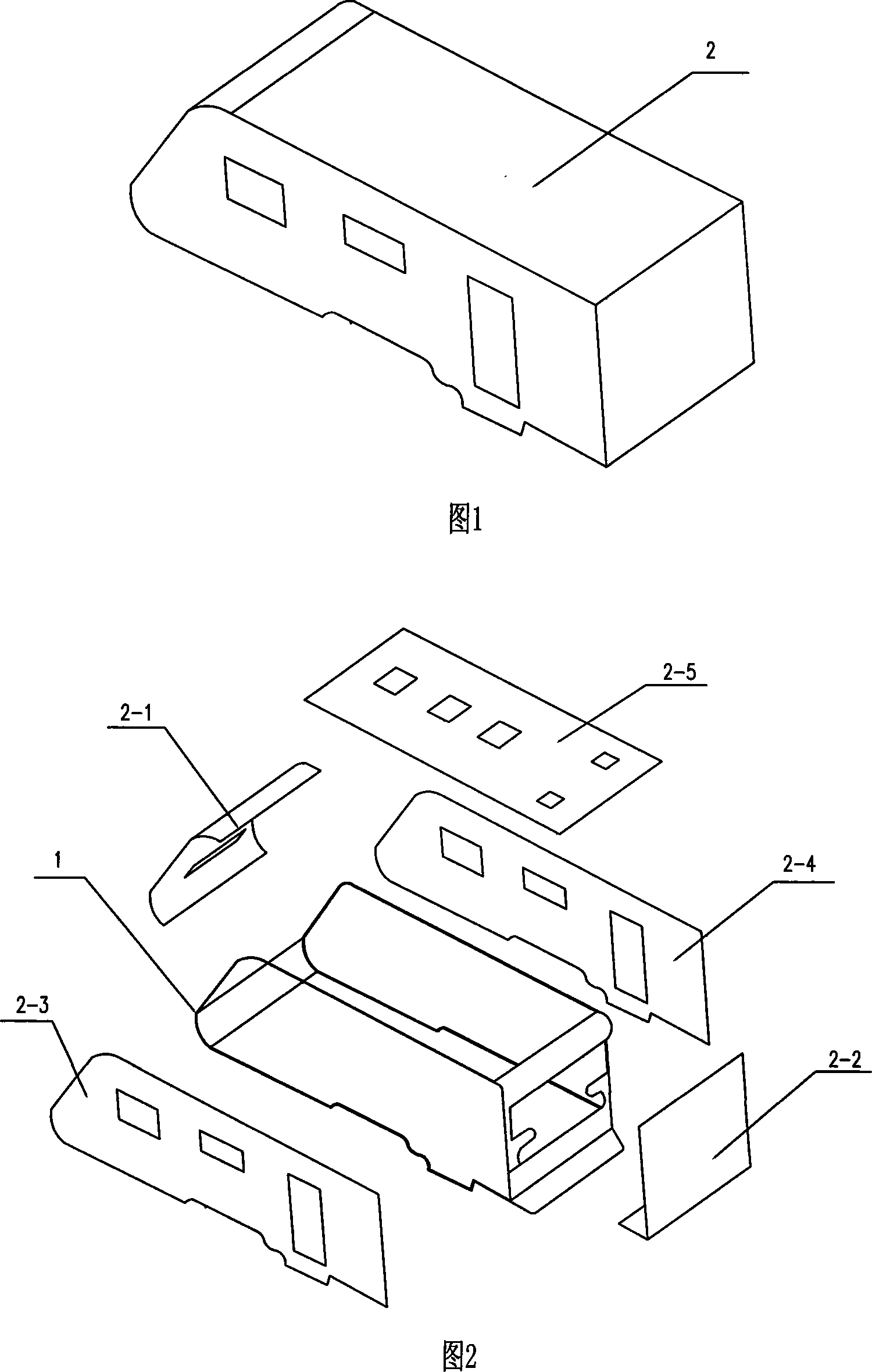

Vehicle body assembling technique and vehicle body structure

The invention discloses a vehicle body assembly method and a relative vehicle body structure, which is characterized in that a honeycomb caravan plate is pressed with a plurality of shaped honeycomb caravan plates to form the vehicle body, the door, window, and important portions of the shaped honeycomb caravan plates are arranged with a skeleton, wire slots, and pipelines, the invention uses aluminum section bar as support frame to assemble the shaped honeycomb caravan plates, the shaped honeycomb caravan plates via the aluminum section bar frame are fixed integrally. The invention uses navigation technique and honeycomb structure, shapes and produces large compartment plate in one time, which has the advantages of low weight, high strength and rigidity, fireproof, damp-proof and non-deformation properties, easy detachment and transmission, firm structure, low cost, and wide application.

Owner:曾展飞

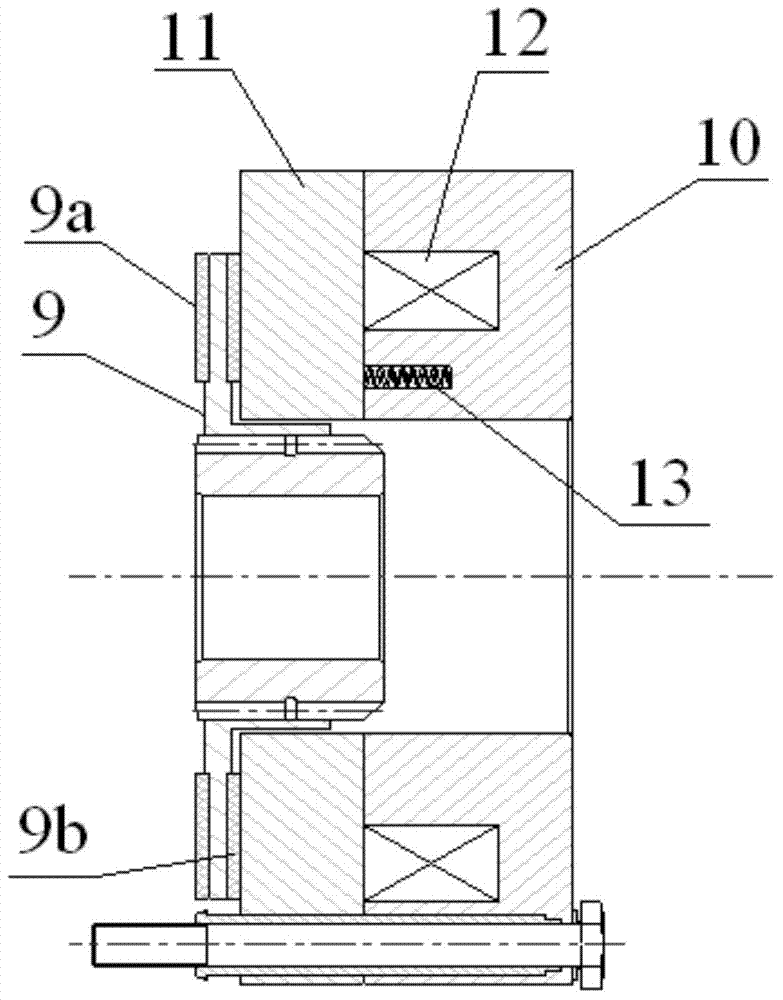

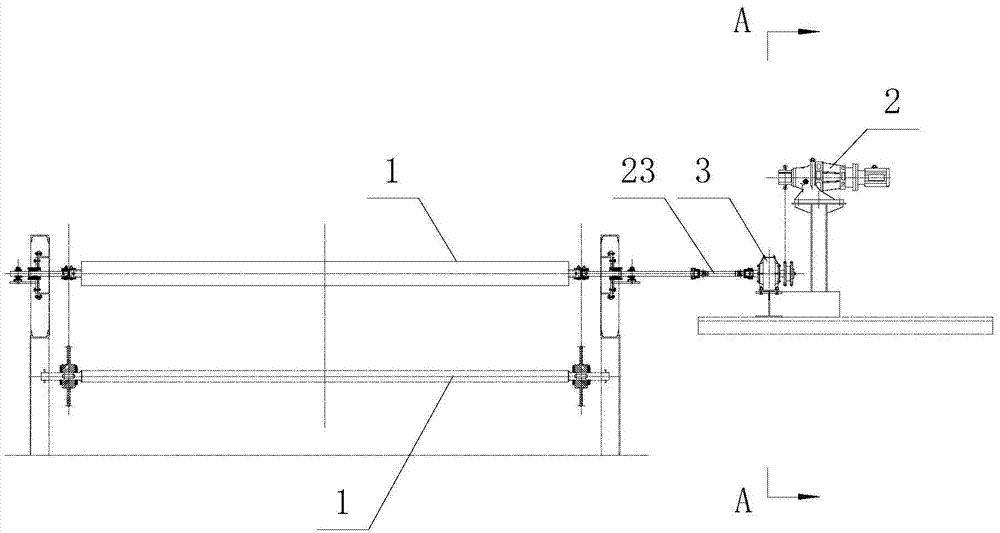

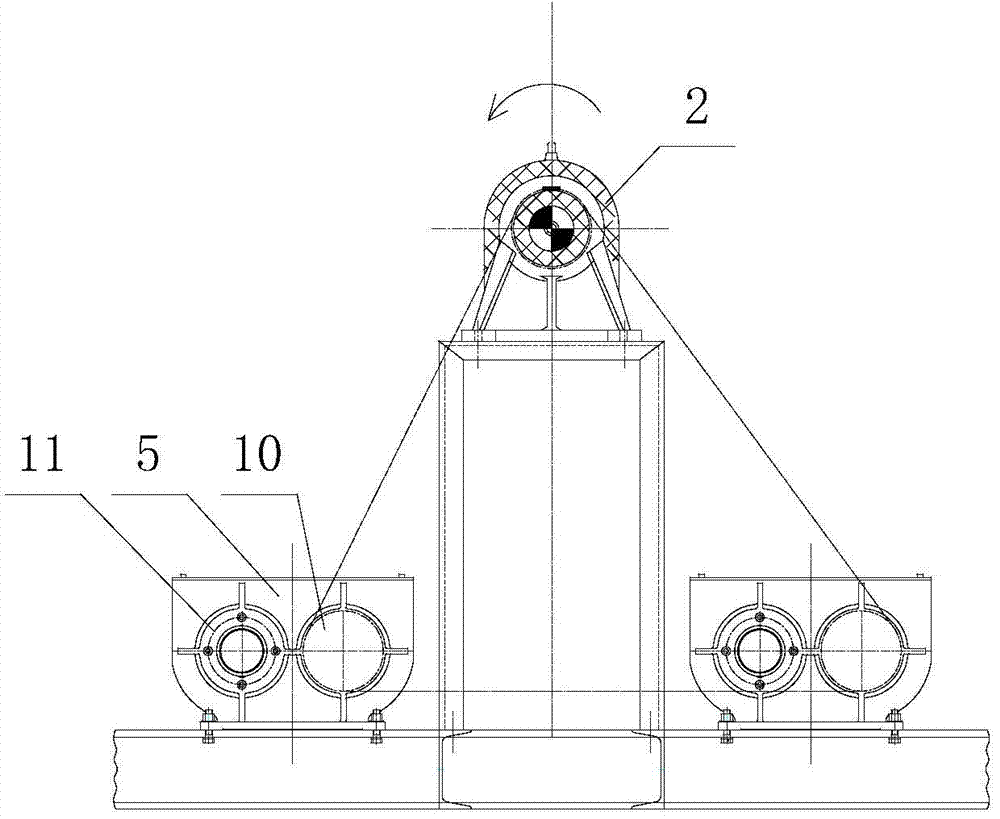

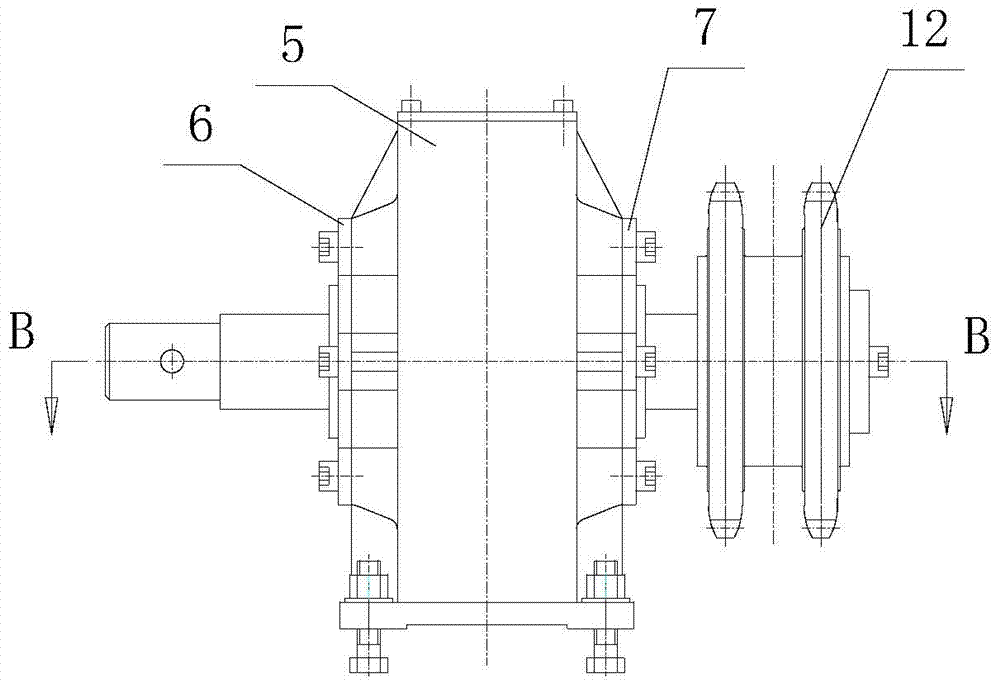

Rotation electrode type electrostatic precipitator

InactiveCN103785541AImprove working environmentShorten the lengthElectrode constructionsElectrodes cleaningDrive shaftElectric machinery

The invention discloses a rotation electrode type electrostatic precipitator comprising at least one group of ash removal brush components, a driving motor which provides power for the ash removal brush components, and a closed transmission device through which the driving motor is connected with the ash removal brush components, wherein the closed transmission device comprises a shell with a cavity, a front end cover and a rear end cover through which the cavity in the shell is closed, a driving gear and a driven gear which are arranged in the cavity of the shell, a driving shaft which is connected with the driving gear, and a driven shaft; the front part of the driving shaft penetrates through the front end cover while the rear part of the driving shaft penetrates through the rear end cover; the rear part of the driven shaft is connected with the driven gear while the front part of the driven shaft penetrates through the front end cover; a chain wheel which is in chain transmission with the driving motor is arranged at the rear part of the driving shaft. The rotation electrode type electrostatic precipitator has the advantages that the closed transmission device is adopted, a box-type overall structure is formed, an operating environment of the gear is improved, the service life of the gears and bearings is prolonged, the closed transmission device can be wholly transported to an installation site after being installed in a workshop, the field installation difficulty is reduced, the field installation process is reduced due to overall installation, and the installation quality is improved.

Owner:浙江菲达环保科技股份有限公司

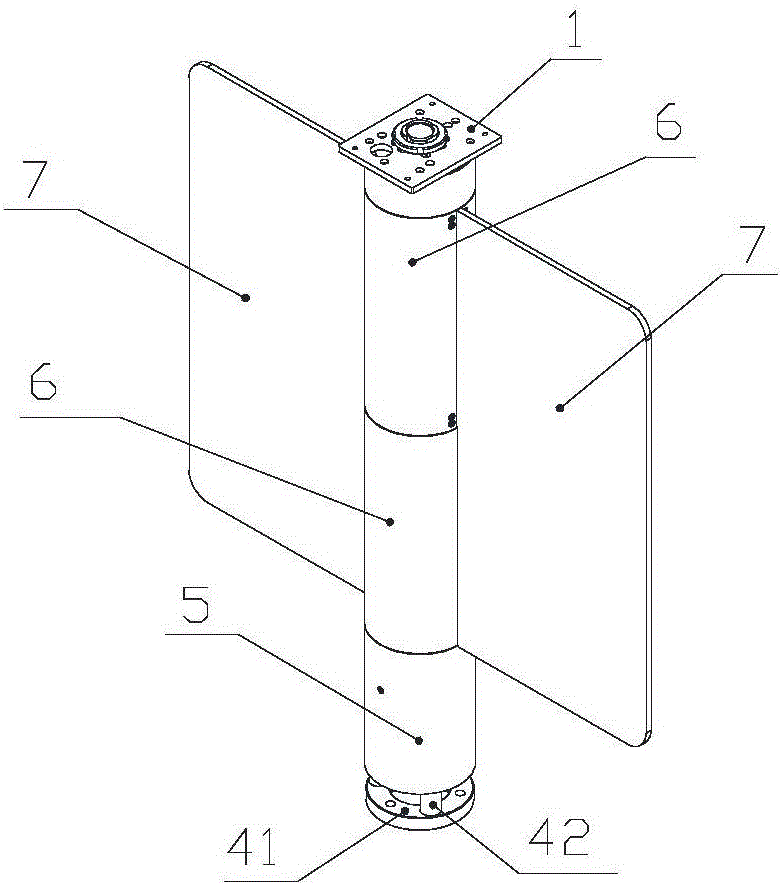

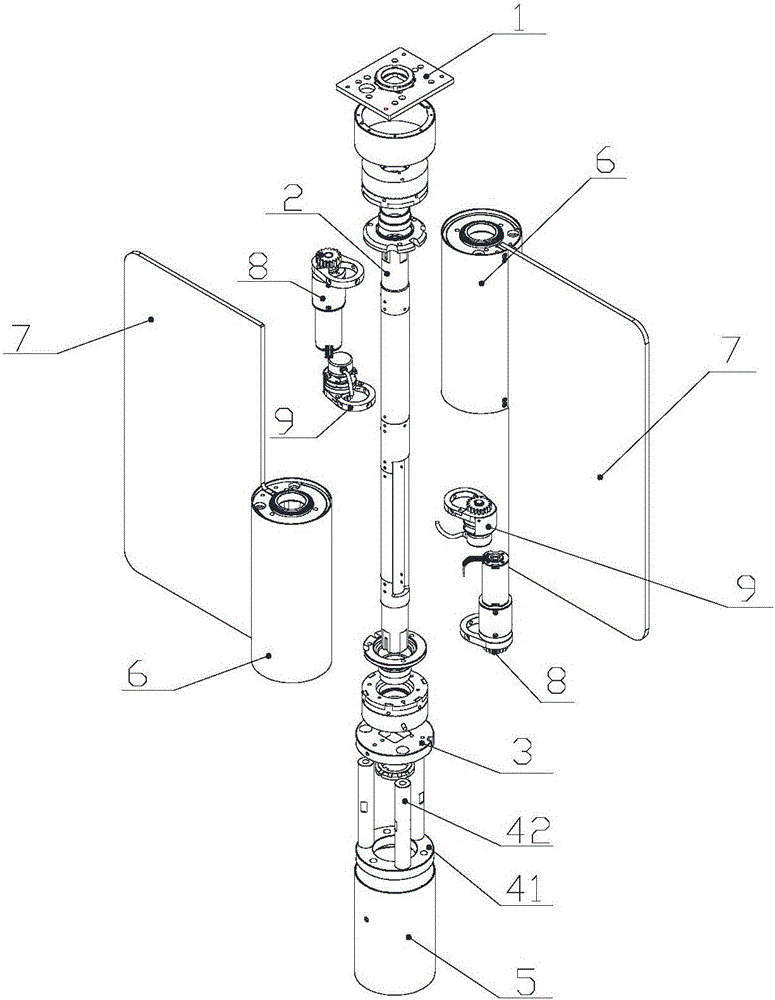

Novel swinging brake with coaxial double core

The invention discloses a novel swinging brake with coaxial double core. The novel swinging brake comprises a core shaft and rotators, wherein each of the rotators comprises a swinging door, a rotating drum cover and a motor; the swinging door is fixedly arranged on the rotating drum cover; the hollow core shaft is penetrated into the rotating drum cover and is in rotatable connection with the rotating drum cover; the motor is located in the rotating drum cover and is fixedly connected with the core shaft; a rotating shaft of the motor is fixedly connected with a first gear; a first tooth ring is fixedly arranged on an inner wall of the rotating drum cover; the first tooth ring is meshed with the first gear; the swinging door and the motor are respectively located on the two sides of the core shaft; preferably, the quantity of the rotators is two and the swinging doors of the two rotators are on a same plane and respectively located on the two sides of the core spindle when the two rotators are both located on initial positions. The coaxial double core structure is adopted by the novel swinging brake, the rotation of the swinging doors is realized through the eccentric arrangement of the motors, the space is saved and the floor space is reduced.

Owner:深圳市西莫罗智能科技有限公司

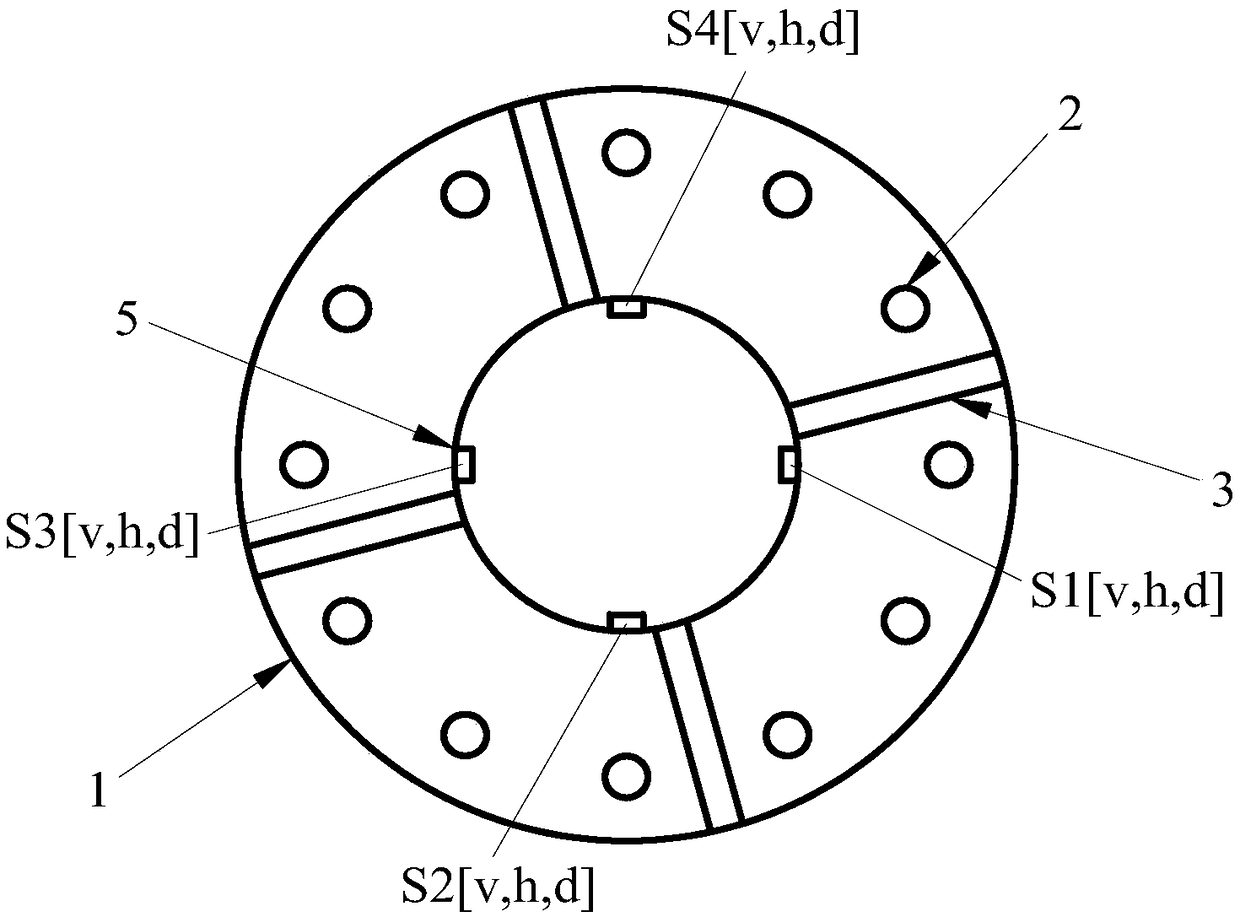

High-precision dynamic six-direction force sensor

InactiveCN109000832AEasy to install and replaceIncreased installation difficultyForce measurementBending momentEngineering

The invention relates to a high-precision dynamic six-direction force sensor, comprising an elastic body and a connecting plate connected to upper and lower surfaces of the elastic body, wherein the connecting plate is provided with a groove, the inner surface of the elastic body is pasted with a sensitive component, and the connecting line of the sensitive component is induced through the groove.Compared with the prior art, the high-precision dynamic six-direction force sensor is applicable to various engineering structure tests, can accurately measure the axial force, shear force, bending moment and torque in the test model at the same time, and has powerful functions, stable performance, high and strong durability, and the measurement result, especially the dynamic measurement result is accurate and reliable.

Owner:TONGJI UNIV

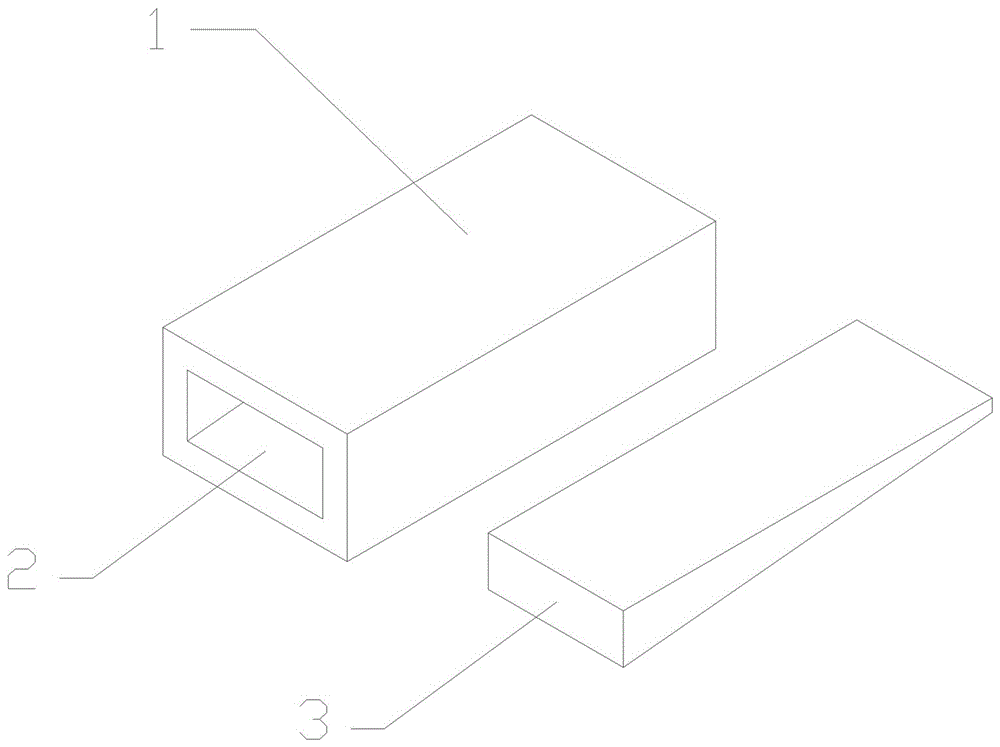

Prefabricated box culvert system and its installation method

The invention provides a prefabricated box culvert system. The prefabricated box culvert system comprises at least two prefabricated box culverts. Two prefabricated box culverts are located at the head end and the tail end of the prefabricated box culvert system, the prefabricated box culverts at the head end and the tail end respectively comprise a box body and two connectors, at least one connector of each box culvert comprises a bundle of bars or a pre-buried water stop belt, and the box culverts of the prefabricated box culvert system are connected through bars or the water stop belts formed through overlap welding, and are connected into the integrally-formed box culvert system through poured concrete. The invention further provides an installation method of the prefabricated box culvert system. The installation method is used for connecting the at least two prefabricated box culverts into a whole and laying the box culverts on the bottom face of a road. Compared with the prior art, the prefabricated box culvert system is simple in construction, short in construction period, low in cost, wide in application range, and suitable for municipal engineering and other large-scale traffic construction.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

USB image transmission system and device

ActiveUS8035630B2Increased installation difficultyUser frustrationCathode-ray tube indicatorsDigital output to display deviceDisplay deviceUSB

A USB image transmission system is provided. The USB image transmission system may include a content source configured to be operatively coupled to a USB-enabled display device. Image data may be transmitted over the USB connection from the content source for display by the display device. In some embodiments, a USB collaboration hub may enable multiple content sources to be operatively linked through a USB connection to one or more USB-enabled display devices.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com