Floating fan platform mounting method

An installation method and floating technology are applied in the field of floating fan platform installation, which can solve the problems of self-elevating installation platform configuration requirements, high construction cost, waste of resources, etc., so as to reduce installation cost, reduce comprehensive cost, and reduce offshore The effect of the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

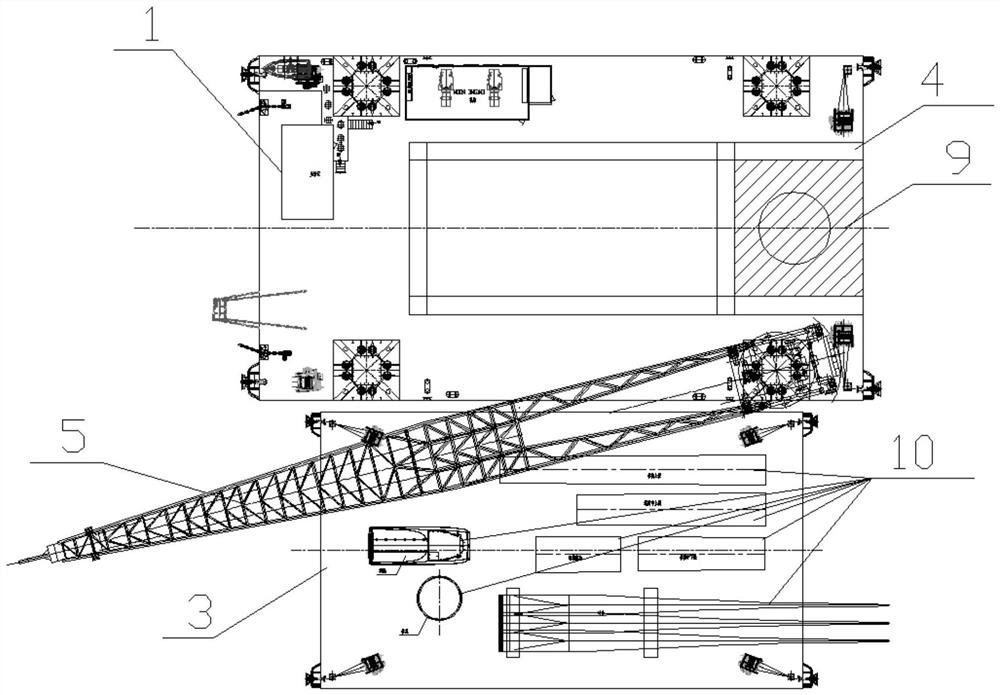

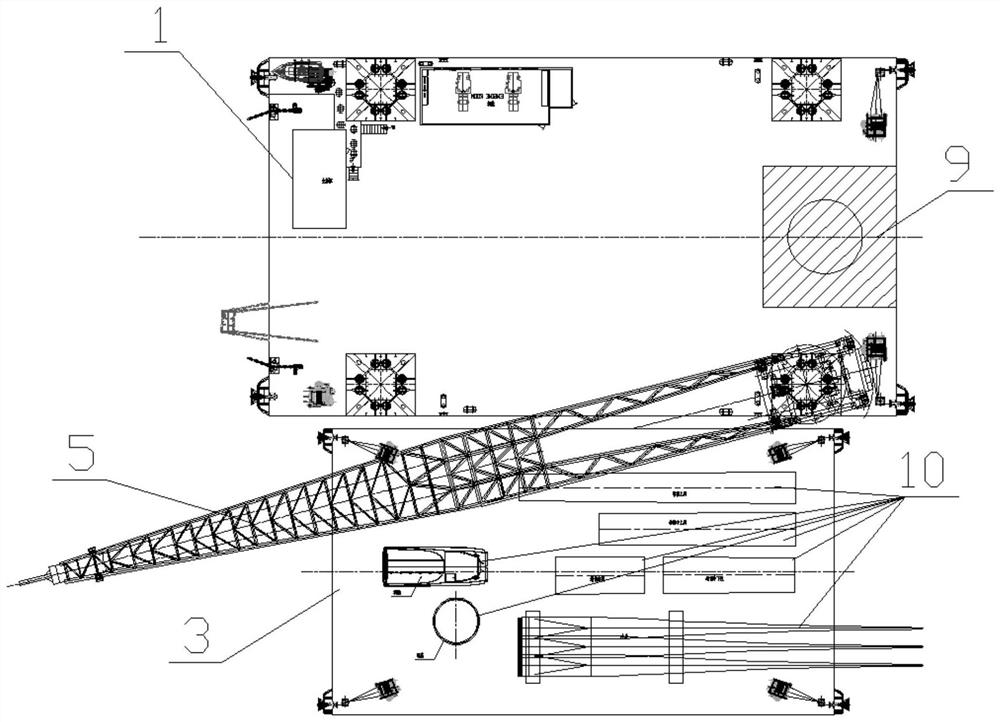

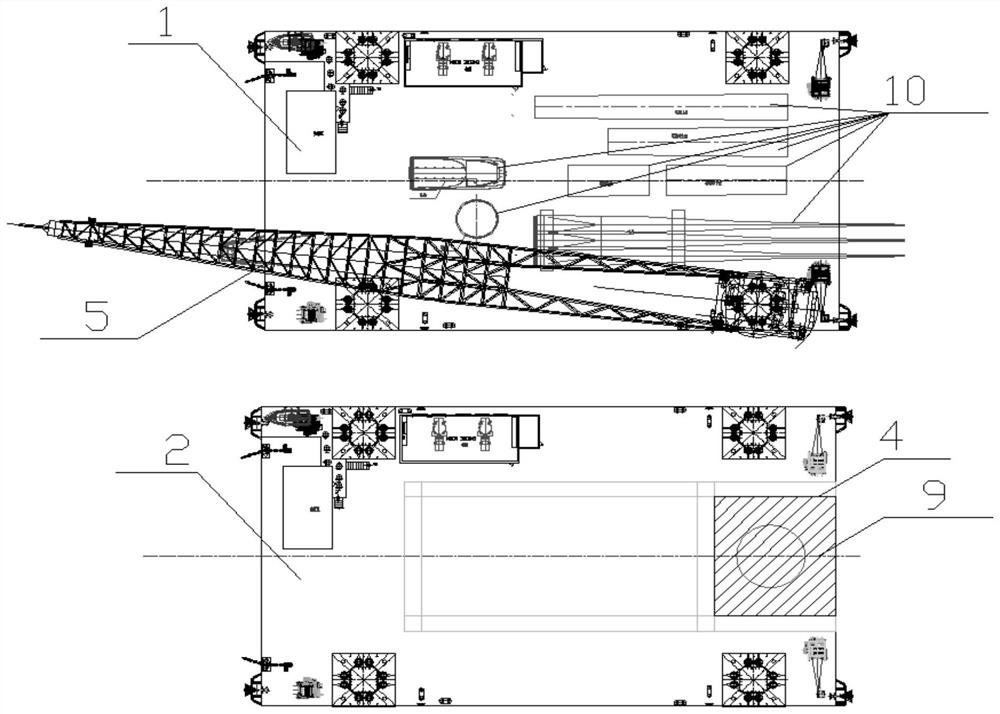

[0028] A method for installing a floating wind turbine platform, in which a self-elevating lifting platform is arranged in a shallow water area, a cantilever beam and a lifting crane are fixed on the self-elevating lifting platform, and a floating barge is docked beside the self-elevating lifting platform ,Such as figure 1 As shown, the wind turbine assembly is placed on the floating barge, and the crane lifts the wind turbine assembly to the cantilever beam. There is an installation area at the end of the cantilever beam. In the installation area of the cantilever beam, the existing offshore wind power plant in shallow water can be used The wind turbines are assembled by piles and offshore wind turbine installation equipment.

[0029] The tugboat tows the floating wind turbine platform to the offshore mooring point, and connects the floating wind turbine platform to the offshore mooring point through mooring cables. type lifting platform, such as Figure 4 As shown, the p...

Embodiment 2

[0032] Such as figure 2 As shown in the figure, a self-elevating lifting platform is installed in the shallow water area, and a crane is fixed on the self-elevating lifting platform, and a floating barge is docked beside the self-elevating lifting platform, and the fan assembly is placed on the floating barge , the hoisting crane lifts the wind turbine components to the installation area of the self-elevating lifting platform, and the hoisting crane lifts the wind turbine components to the installation area, using the existing offshore wind power piles and offshore wind turbine installation equipment in the installation area in shallow water Assemble the fan.

[0033] The tugboat tows the floating wind turbine platform to the offshore mooring point, and connects the floating wind turbine platform to the offshore mooring point through mooring cables. type lifting platform, such as Figure 4As shown, the pulling direction of the tugboat is opposite to that of the mooring ca...

Embodiment 3

[0036] Such as image 3 As shown, a self-elevating lifting platform is set in the shallow water area, and a crane is fixed on the self-elevating lifting platform. On the lifting platform, a cantilever beam is fixed on the self-elevating auxiliary platform, and the end of the cantilever beam is provided with an installation area. , Offshore wind turbine installation equipment assembles the wind turbine in the installation area.

[0037] The tugboat tows the floating wind turbine platform to the offshore mooring point, and connects the floating wind turbine platform to the offshore mooring point through mooring cables. type lifting platform, such as Figure 4 As shown, the pulling direction of the tugboat is opposite to that of the mooring cable. Therefore, the tugboat and the mooring cable stabilize the floating wind turbine platform on the sea surface. After the floating wind turbine platform is stabilized, the installed wind turbine is transported to the floating On the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com