Device and method for improving artificial feeding efficiency of cotton bollworms

A cotton bollworm and artificial feed technology, which is applied in the direction of animal husbandry and the like, can solve the problems of high mortality of newly hatched larvae, many labors, irregular pupation, etc., to prevent cross infection between larvae, low comprehensive cost and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment is used to illustrate a device for improving the efficiency of artificial breeding of cotton bollworms.

[0024] The main body of the device is a 24-hole plate, and according to the size of the 24-hole plate, a piece of blow-molded paper (purchased in a common stationery store) with the same size as the cover of the 24-hole plate is cut and put into the upper cover.

Embodiment 2

[0026] This example is used to illustrate a method for improving the efficiency of artificial breeding of cotton bollworms.

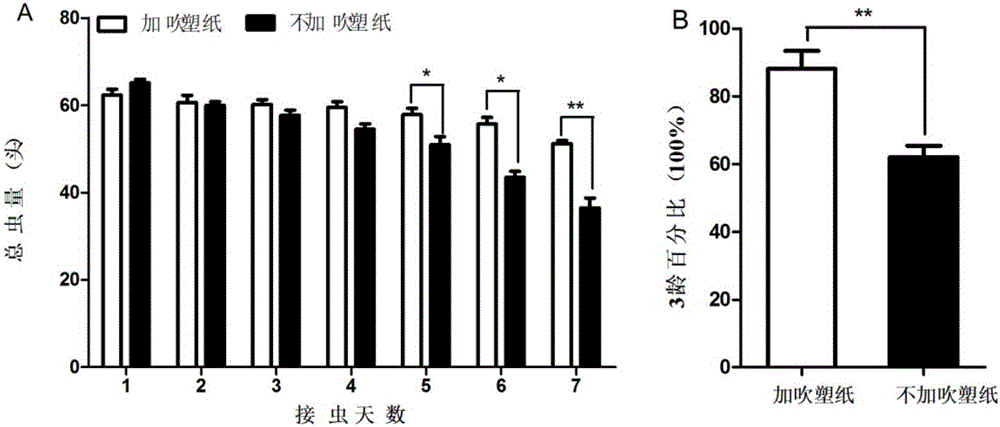

[0027] Get 1g-2g of artificial feed in the 24-well culture box of the device described in Example 1, connect the newly hatched cotton bollworm larvae in the 24-well plate, connect 3 heads in each hole, cover the lid, and put it after binding with a rubber band. Raise under the condition of temperature 27 ± 1 ℃, relative humidity 70 ± 10%, photoperiod 14L: 10D; every treatment repeats three times ( figure 1 ). A 24-well plate that directly covered the upper cover without blown paper was used as a control.

[0028] During the period, the number of cotton bollworm larvae and developmental ages in the 24-well plate were observed every day, and the SPSS 18.0 software was used to analyze the significance of the difference. The t test was used to compare the difference between adding blown paper and not adding blown paper, and evaluating the effect of using b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com