Preparation method for polyamide imide foam

A polyamide-imide and foam technology, applied in the field of polymer synthesis, can solve the problems of high performance and high price of polyimide foam, low performance and low price of polymer foam, etc., achieve high cost performance, reduce overall cost, and promote The effect of promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

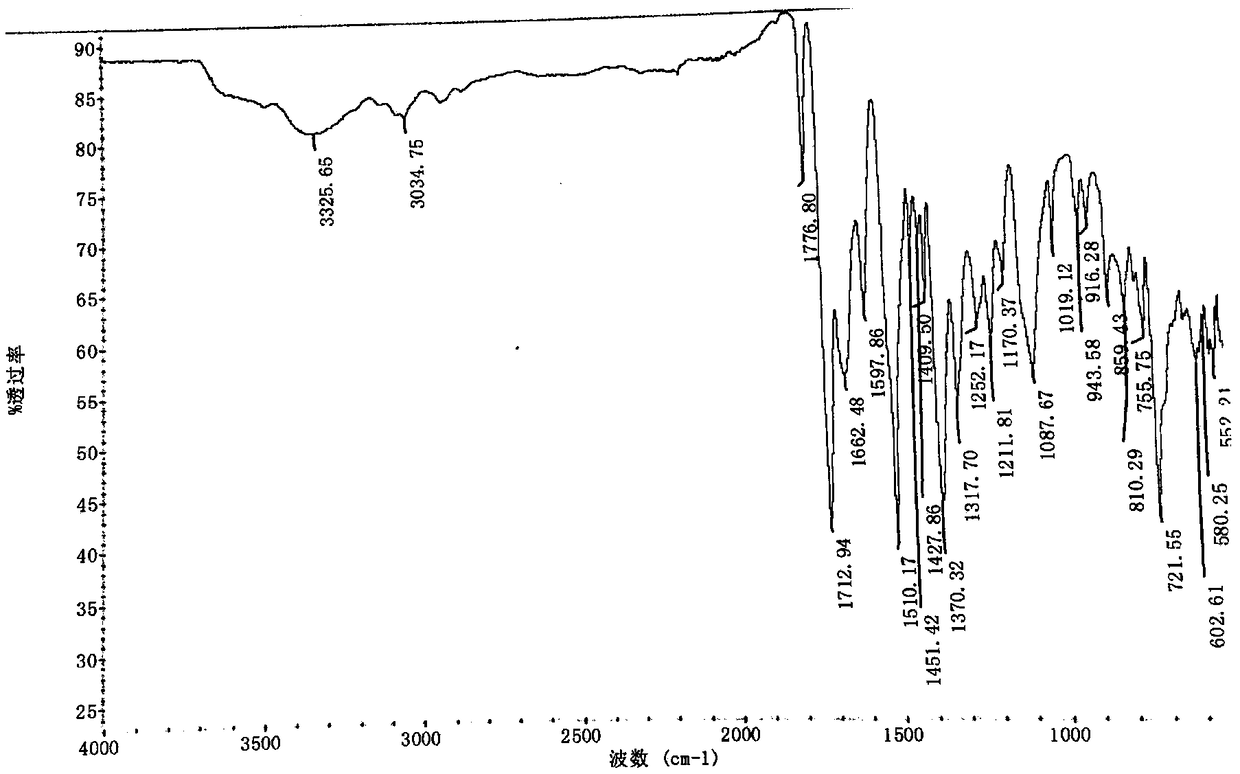

Image

Examples

preparation example Construction

[0026] The preparation method of the polyamide-imide foam of the present embodiment may further comprise the steps:

[0027] 1) According to parts by weight, take 168-250 parts of diisocyanate, 125-192 parts of trimellitic anhydride, 0-113 parts of aromatic dianhydride, and 1-3 parts of catalyst;

[0028] 2) First add diisocyanate and trimellitic anhydride (and aromatic dianhydride) into the reaction kettle, after heating to 135-175°C, carry out constant temperature stirring and dispersion at a stirring speed of 200-800r / min, then add catalyst and continue constant temperature Stir and react to obtain the prepolymer, then pour out the cooled prepolymer and use a pulverizer to pulverize the cooled prepolymer to obtain the foam precursor powder;

[0029] 3) Spread the obtained foam precursor powder in a mould, after high-temperature foaming and imidization, let stand to cool down to room temperature naturally, and demould to obtain a polyamide-imide foam material.

[0030] Pref...

Embodiment 1

[0032] According to parts by weight, successively get 250 parts of diphenylmethane diisocyanate, 192 parts of trimellitic anhydride, 3 parts of 1,3,5-tris(dimethylaminopropyl)-1,3,5-hexahydrotriazine; Add diphenylmethane diisocyanate and trimellitic anhydride into the reaction kettle, and stir at a constant temperature for 3-5 minutes at a temperature of 135-175°C and a rotational speed of 200-800r / min. After the trimellitic anhydride is uniformly dispersed, then add the catalyst into the reaction kettle. Then, at a temperature of 135-175°C and a rotation speed of 200-800r / min, after stirring at a constant temperature for 30-60 minutes, pour out the resin in the kettle while it is hot, cool it to room temperature naturally, and then use a pulverizer to pulverize the cooled solid resin into Foam precursor, sieved with 60 mesh for future use. Spread the obtained foam precursor in the mold, place the mold in an oven at 190-260°C, foam and age at a constant temperature for 60-120 ...

Embodiment 2

[0034] According to parts by weight, successively get 174 parts of toluene diisocyanate, 192 parts of trimellitic anhydride, 2 parts of 1,3,5-tris(dimethylaminopropyl)-1,3,5-hexahydrotriazine; Add diisocyanate and trimellitic anhydride into the reaction kettle, and stir at a constant temperature for 3-5min at a temperature of 135-175°C and a rotation speed of 200-800r / min. -175°C, rotation speed 200-800r / min, after stirring at constant temperature for 30-60min, pour out the resin in the kettle while it is hot, cool it down to room temperature naturally, and then crush the cooled solid resin into a foam precursor with a pulverizer. 60 mesh sieve for later use. Spread the obtained foam precursor in the mold, place the mold in an oven at 190-260°C, foam and age at a constant temperature for 60-120 minutes, then remove the mold from the oven, let it stand and cool down to room temperature naturally, and demould to obtain polyamide imide foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com