Preparation method of high-strength low-thermal-conductivity zirconium oxide complex-phase refractory insulating brick

A technology of refractory thermal insulation bricks and zirconia, applied in the field of refractory thermal insulation bricks, can solve the problems of product compressive strength, undisclosed thermal conductivity of load softening starting temperature, high raw material cost, high firing temperature, etc., so as to realize waste recycling. , Conducive to industrial production, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

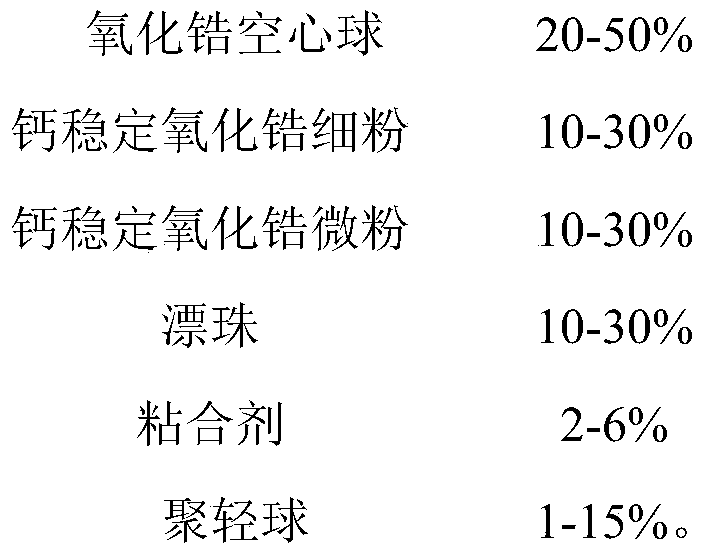

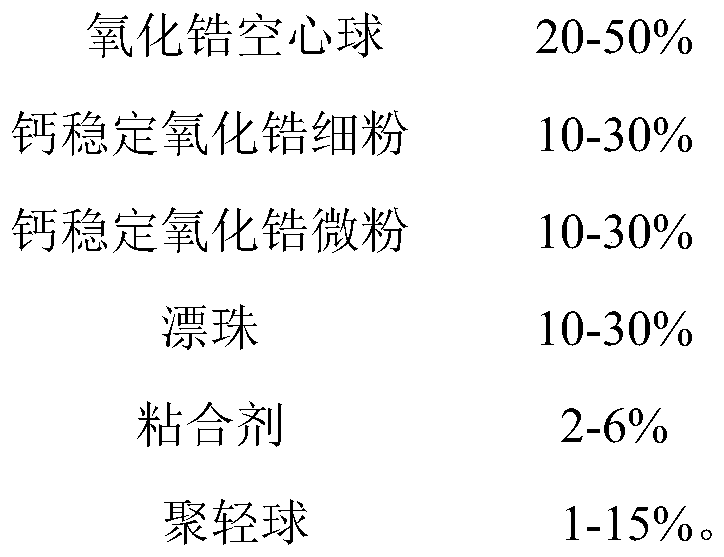

Method used

Image

Examples

Embodiment 1

[0030] (1) Pour an appropriate amount of castor oil into the polylight balls to impregnate, and the castor oil consumption is as the criterion that the polylight balls are all immersed in the castor oil;

[0031] (2) 37.5% of zirconia hollow spheres with a diameter of 1-2mm, 17% of calcium-stabilized zirconia fine powder with a particle size of 20-50 μm, and 13% of calcium-stabilized zirconia fine powder with a particle size of 5-10 μm, with a particle size of 28% of floating beads of 0.5-4mm, 1% of polylight balls with a diameter of 0.5-1mm impregnated with castor oil, 3.5% of 20% concentration of cellulose aqueous solution, mixed for 3 hours, and pressed under a pressure of 40MPa After molding and drying at room temperature for 72 hours, it is fired in a kiln at a firing temperature of 1550°C for 2 hours.

[0032] The refractory insulation bricks made have the following properties:

[0033] Bulk density 1.40g / cm 3 ;

[0034] The compressive strength at room temperature is...

Embodiment 2

[0040] (1) Pour an appropriate amount of castor oil into the polylight balls to impregnate, and the castor oil consumption is as the criterion that the polylight balls are all immersed in the castor oil;

[0041] (2) 30% of zirconia hollow balls with a diameter of 0.5-1mm, 8% of polylight balls with a diameter of 0.5-1mm impregnated with castor oil, and 20% of calcium-stabilized zirconia fine powder with a particle diameter of 50-80 μm, 15% of calcium-stabilized zirconia micropowder with a diameter of 5-10 μm, 23% of floating beads with a particle size of 0.5-4mm, and 4% of a 15% calcium lignosulfonate aqueous solution. Compressed under high pressure, dried at room temperature for 24 hours, then fired in a kiln at 1500°C for 8 hours.

[0042] The refractory insulation bricks made have the following properties:

[0043] Bulk density 1.16g / cm 3 ;

[0044] The compressive strength at room temperature is 7.6MPa;

[0045] 0.1MPa load softening start temperature 1590℃;

[0046]...

Embodiment 3

[0050] (1) Pour an appropriate amount of castor oil into the polylight balls to impregnate, and the castor oil consumption is as the criterion that the polylight balls are all immersed in the castor oil;

[0051] (2) 48% of zirconia hollow balls with a diameter of 0.5-2mm, 5% of polylight balls with a diameter of 0.5-1mm impregnated with castor oil, and 12% of calcium-stabilized zirconia fine powder with a particle diameter of 50-80 μm, 10% calcium stabilized zirconia micropowder with a diameter of 5-10μm, 22% floating beads with a particle diameter of 0.5-4mm, 3% aqueous solution of calcium lignosulfonate with a concentration of 15%, and after mixing for 5 hours, the Compressed under high pressure, dried at room temperature for 36 hours, then fired in a kiln at 1550°C for 4 hours.

[0052] The refractory insulation bricks made have the following properties:

[0053] Bulk density 1.05g / cm 3 ;

[0054] The compressive strength at room temperature is 7.2MPa;

[0055] 0.1MPa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com