Manufacturing equipment and mold of metal spiral-wound gasket

A technology for metal wound gaskets and manufacturing equipment, applied in metal processing equipment, manufacturing tools, metal processing, etc., can solve the problems of difficult installation, warped winding ring 4a, low production efficiency, etc., and achieve high flatness and smoothness , It is not easy to warp or be crushed, and the installation difficulty is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

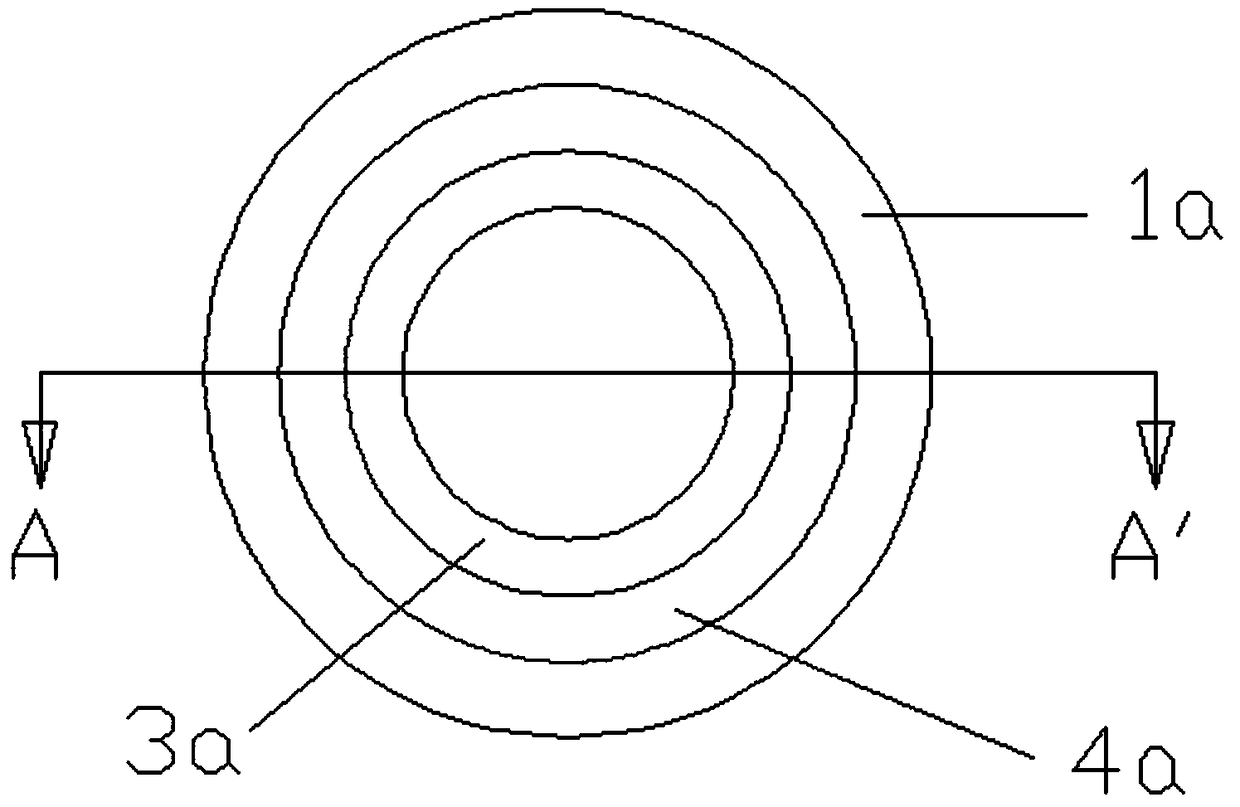

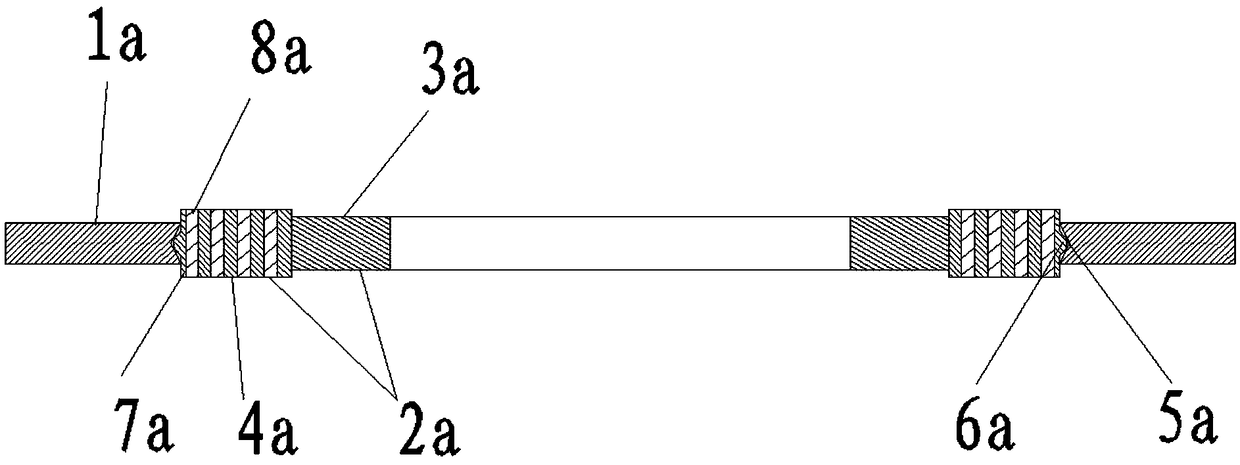

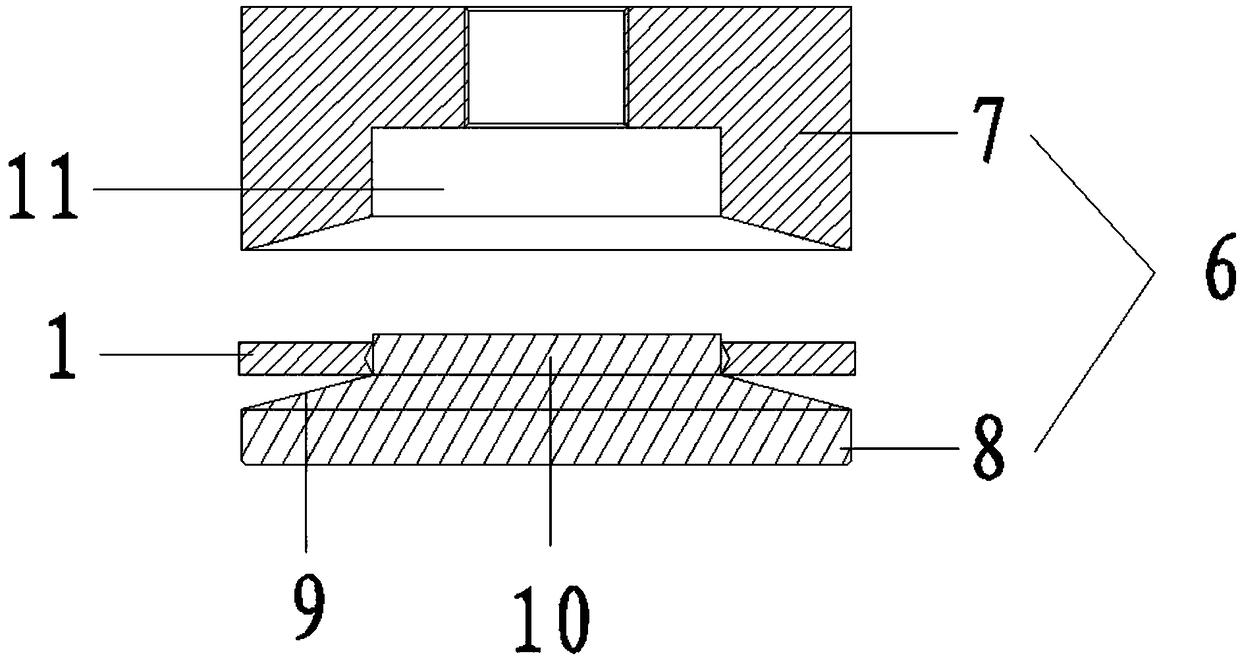

[0033] A kind of manufacturing equipment of metal wound gasket, comprising outer ring deformation device 22 and inner and outer ring automatic ring leveling device 23, said outer ring deformation device 22 includes outer ring deformation mold 6, said outer ring deformation mold 6 includes the first Three upper molds 7 and a third lower mold 8, when the third upper mold 7 and the third lower mold 8 are pressed together, the outer ring 1 is deformed for the first time, so that the outer ring 1 is lifted upward from the bottom and the outer ring 1 The inner diameter of the top is expanded, and the inner and outer ring automatic collar leveling device 23 includes a first table body 26, a first multi-station indexing plate 27 arranged on the first table body 26, a collar mold 12 and an outer ring leveling device. Flat die 17, the collar die 12 includes a first upper die 13 and a first lower die 14, the outer ring leveling die 17 includes a second upper die 18 and a second lower die ...

Embodiment 2

[0051] A metal wound gasket manufacturing mold, which includes an outer ring deformation mold 6 for the first deformation treatment of the outer ring 1 so that the outer ring 1 is lifted upward from the bottom and the inner diameter of the top of the outer ring 1 is enlarged. The inner ring 2 is completely pressed into the outer ring 1 so that the annular protrusion 4 of the inner ring 2 is completely embedded in the ring groove 5 of the outer ring 1. The ring mold 12, and the outer ring 1 for the second Outer ring leveling mold 17 for deforming to restore the upper and lower surfaces of the outer ring 1 to be flat.

[0052] The manufacturing mold of the metal wound gasket of the present invention is provided with an outer ring deformation mold 6, a collar mold 12 and an outer ring leveling mold 17, so that the inner ring 2 can be installed into the outer ring 1 through the enlarged inner diameter of the top of the outer ring 1, and When pressing in, because the top and bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com