Prefabricated box culvert system and installation method thereof

An installation method and box culvert technology, applied in the construction, road bottom and other directions, can solve the problems of poor waterproof effect, weak connection, cumbersome construction, etc., and achieve the effect of fast installation time, avoiding poor waterproofness, and low construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

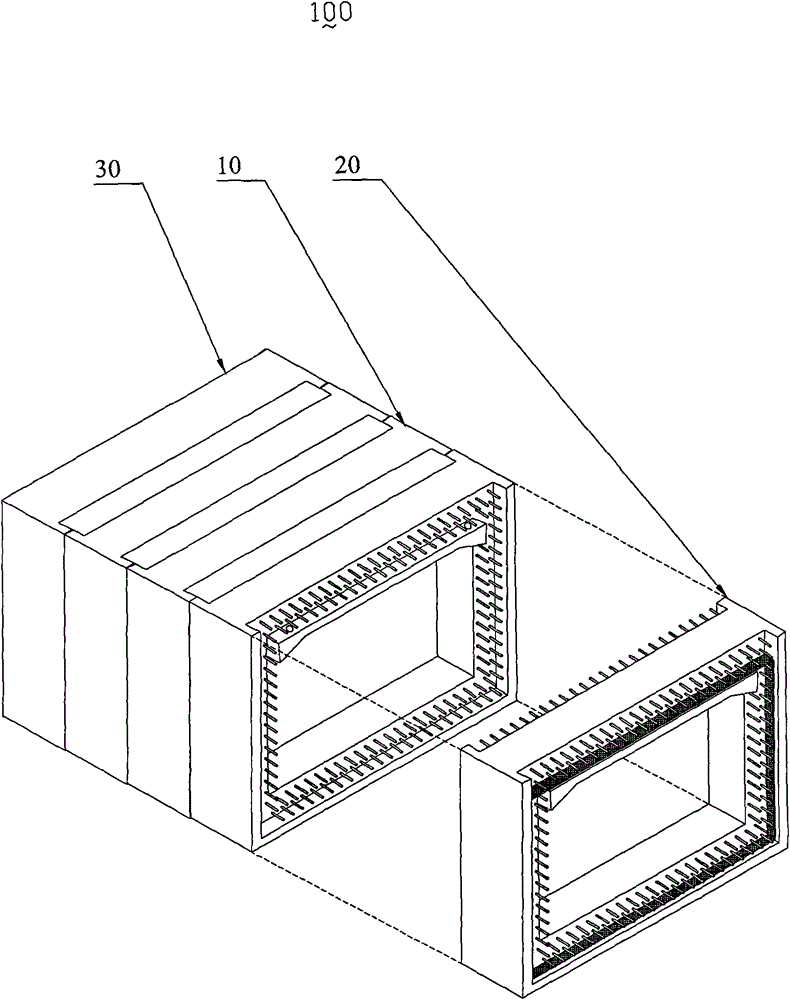

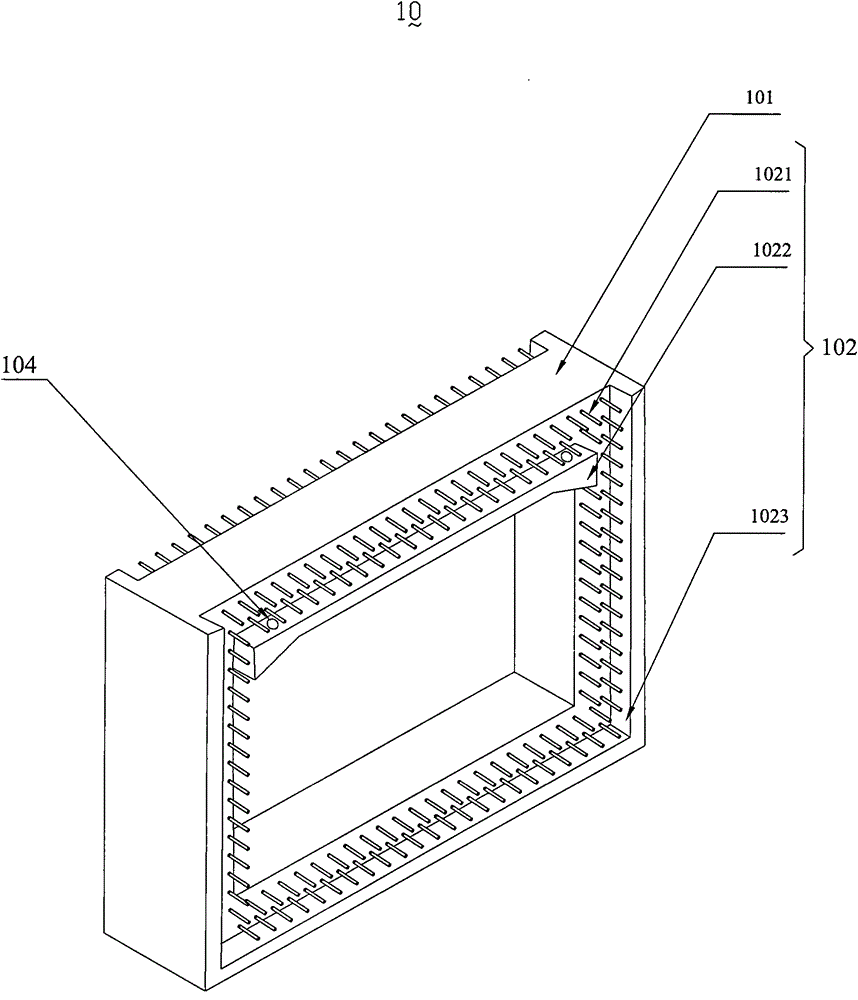

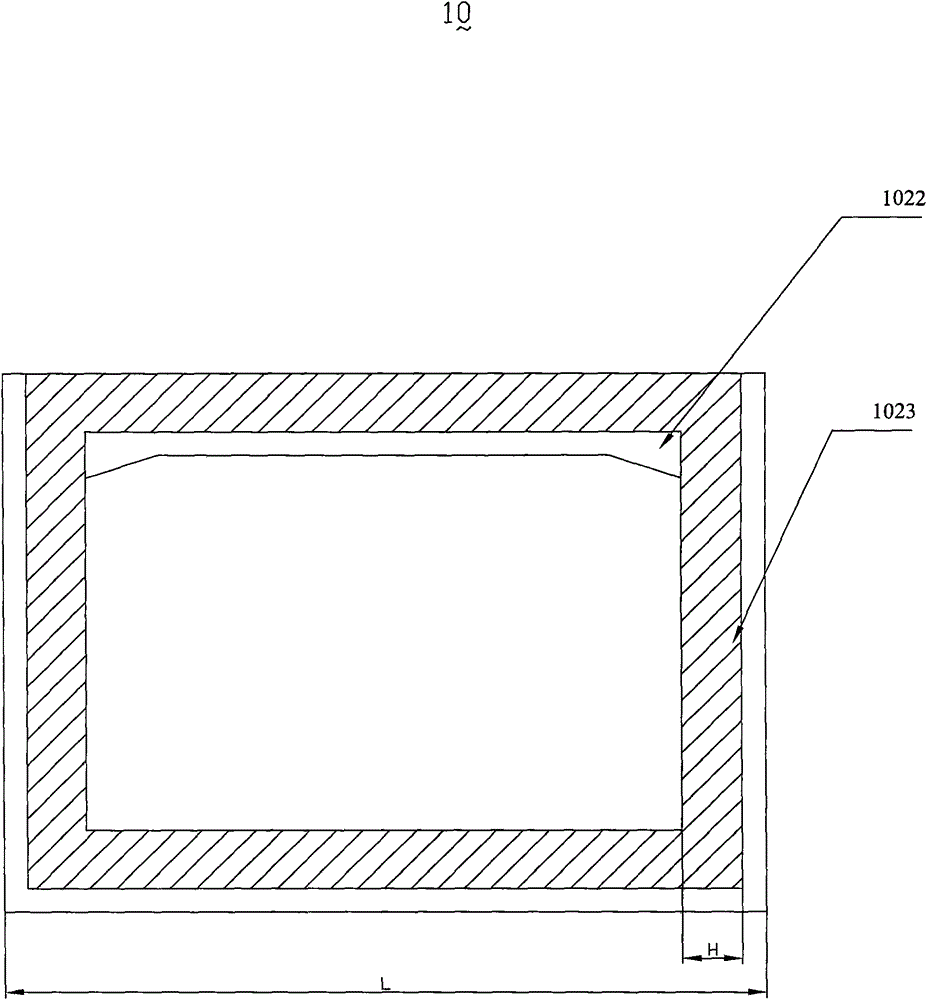

[0029] see Figure 1-Figure 3 , the prefabricated box culvert system 100 of the present invention includes a first component, an inner box culvert 10 , a second component, a connecting box culvert 20 and a component three, an outer box culvert 30 . The inner box culvert 10 includes a box body 101 and two interfaces 102 . The two interfaces 102 are located on both sides of the box body 101 . The box body 101 is a rectangular parallelepiped with a transparent center. The structures of the two interfaces 102 are the same, including steel tendons 1021 , platforms 1022 and grouting grooves 1023 . The grouting g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com