High-precision dynamic six-direction force sensor

A force sensor, high-precision technology, applied in the field of high-precision dynamic six-way force sensor, can solve the problem that axial force, shear force, bending moment and torque cannot be accurately measured at the same time, force sensor calibration result and measurement result error, measurement performance and measurement function defects, to achieve ideal calibration results, weaken structural coupling, and increase installation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

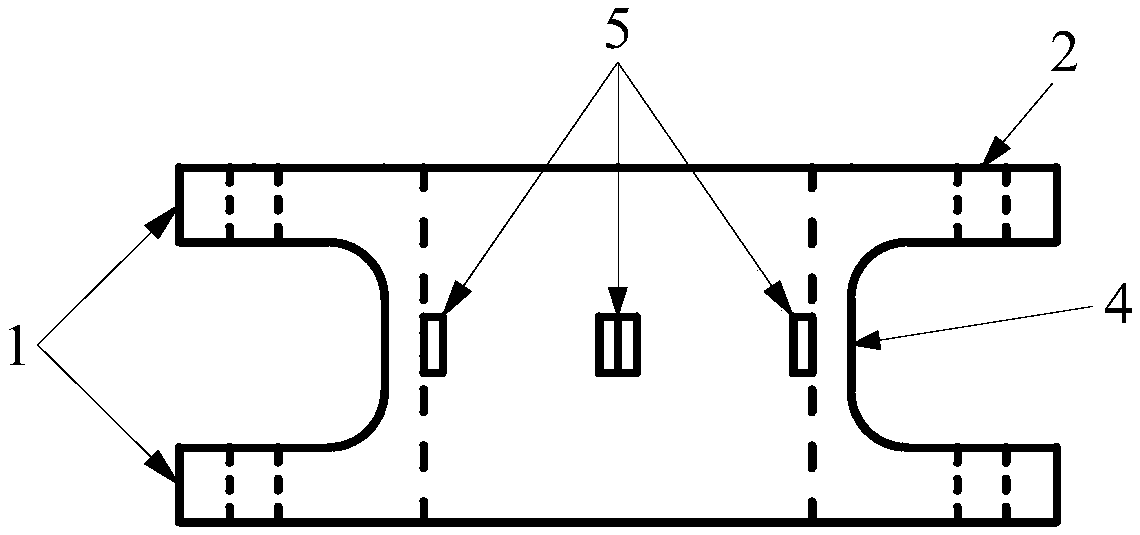

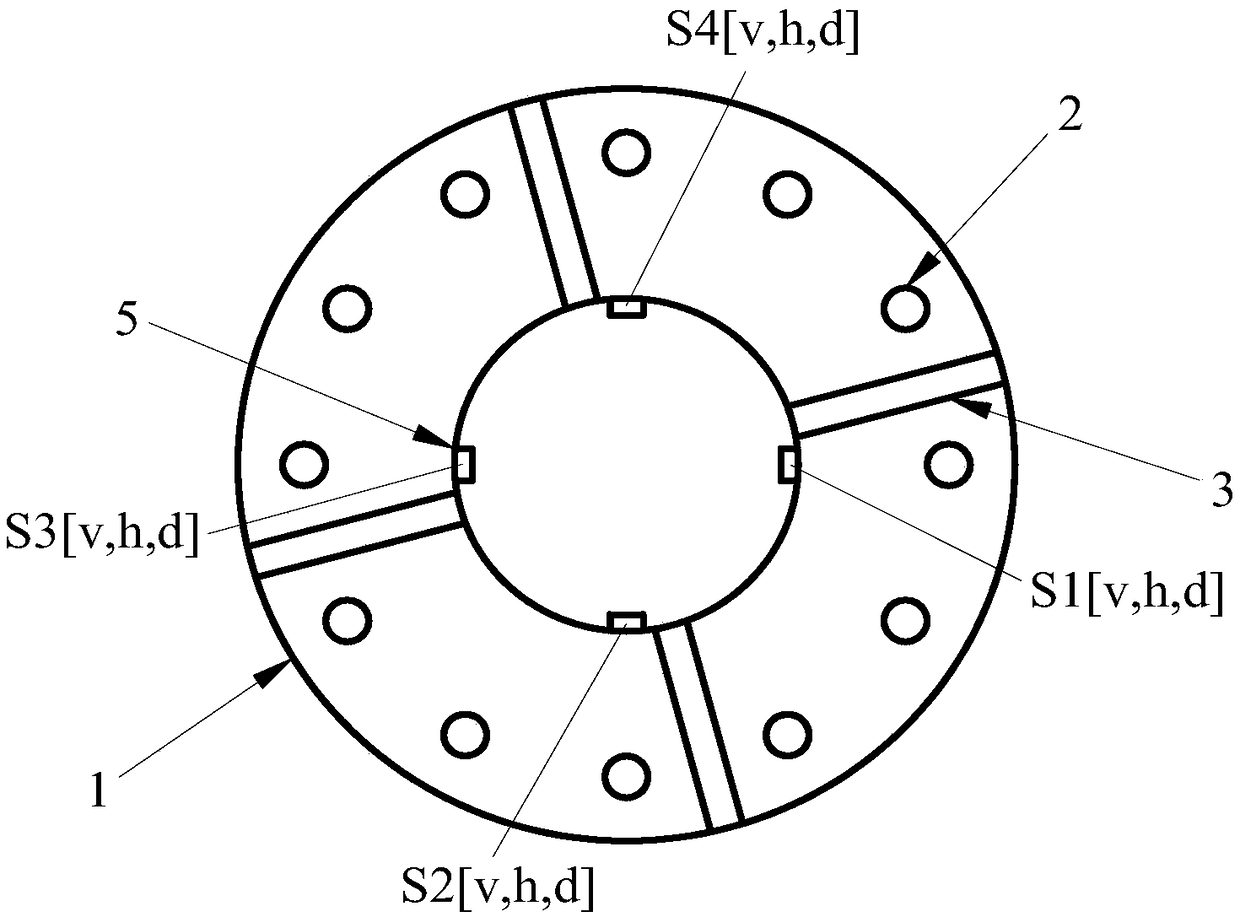

[0027] High-precision dynamic six-direction force sensor device, its structure is as follows figure 1 , figure 2 As shown, it includes a connecting plate 1 , an anchoring hole 2 , a groove 3 , an elastic body 4 and a sensitive element 5 . The connecting plate 1 and the elastic body 4 are integral prefabricated parts with great rigidity, which are made of high-strength homogeneous metal materials, and the transition between them is smooth. The size of the connecting plate 1, the anchor hole 2 on it is used to realize the connection of the force sensor and other structural components, the number of holes, the diameter and the position of the holes can be selected according to the specific connection situation and then processed; the groove 3 is used to lead out the sensitive components 5. The position and size of the connection line with the external data acquisition system can also be reasonably designed and adjusted according to the actual situation. Elastomer 4 is the key ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com