Integrated safe driving device

A safe driving, integrated technology, applied in escalators, transportation and packaging, etc., can solve the problems of cumbersome operation, low installation efficiency, long installation time, etc., to ensure speed detection accuracy, improve installation efficiency, and reduce installation difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The specific technical contents and implementation methods of the present invention will be described in detail below in conjunction with the accompanying drawings.

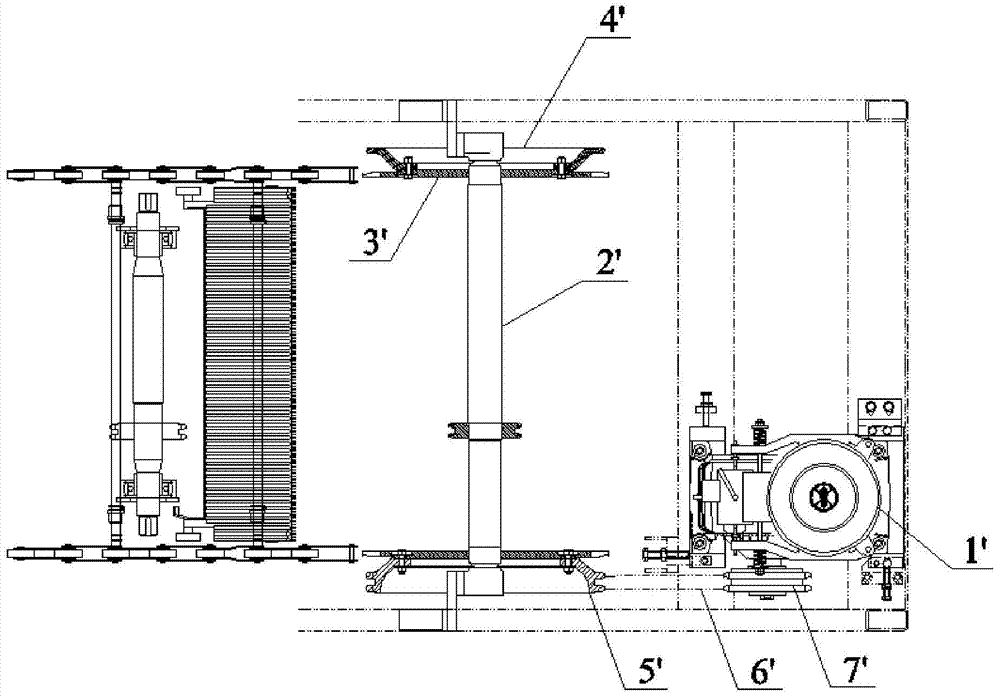

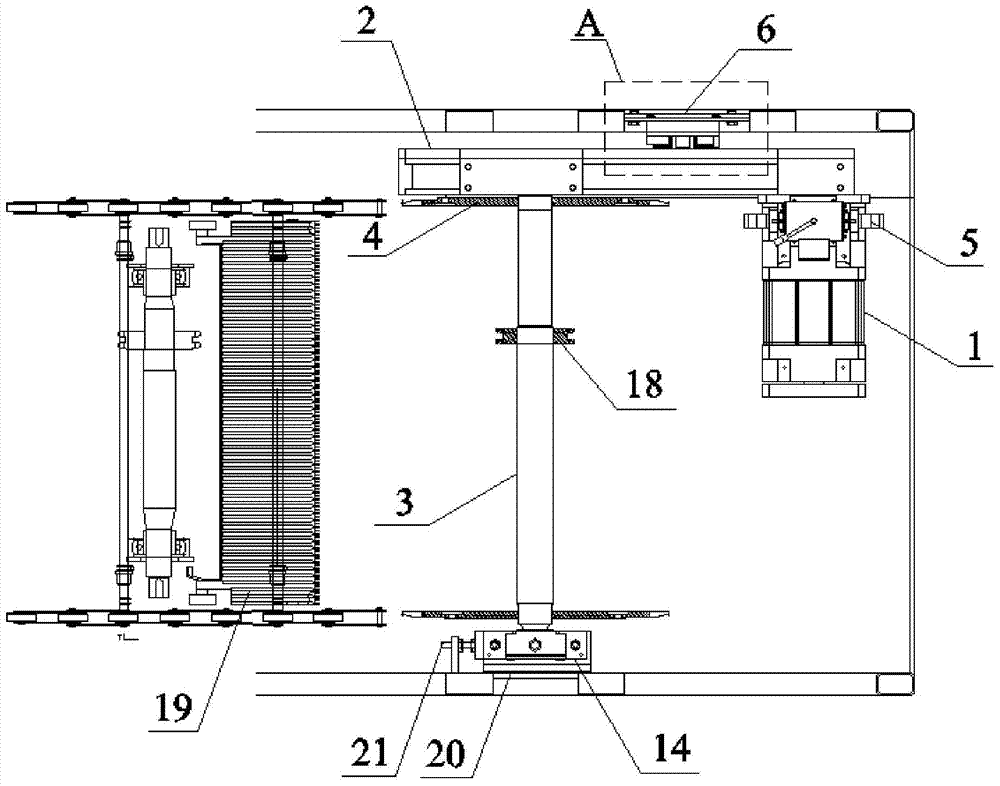

[0086] like figure 2 Shown: an integrated escalator driving device, including a drive motor 1, a reduction box 2, a main drive shaft 3 and a bearing housing 14 that are sequentially transmitted and coordinated. The main drive shaft 3 is provided with a step sprocket 4 and a handrail sprocket 18 , the main shaft of the drive motor 1 is provided with a main brake 5, and at least one intermediate shaft in the reduction box 2 is provided with an additional brake 6.

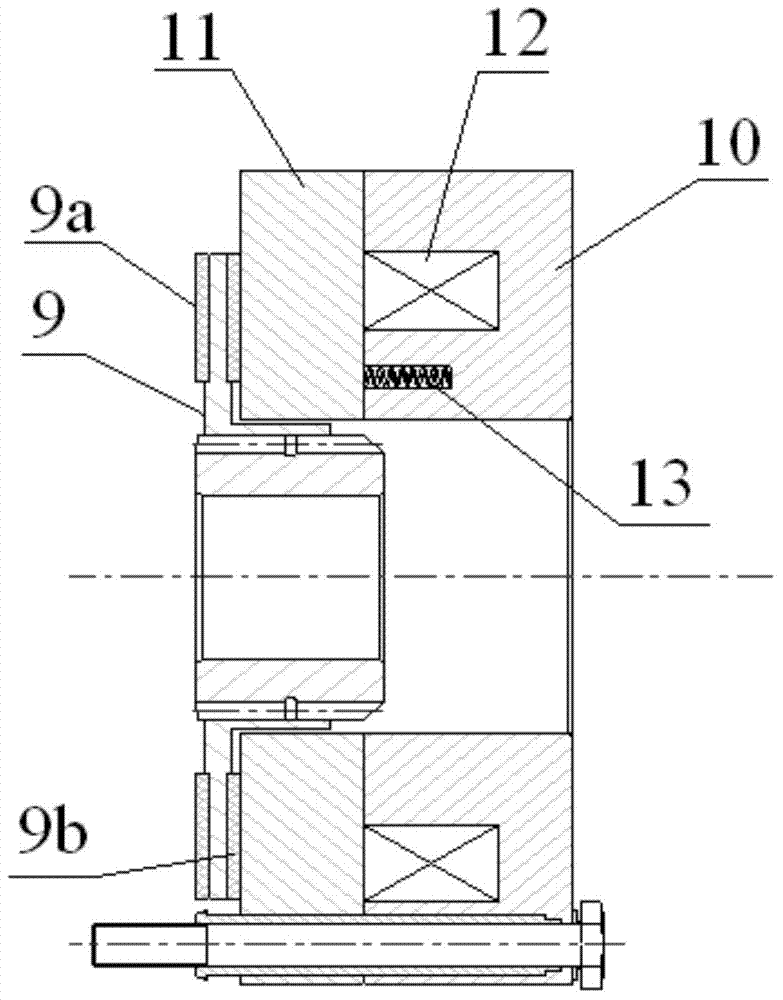

[0087] like image 3 and Figure 4 As shown, the additional brake 6 includes a housing 7, and the housing 7 is provided with: a brake disc 9 fixed on the outer periphery of the intermediate shaft 8; a static friction plate 9a and a dynamic friction plate 9b acting on both sides of the brake disc 9, and a dynamic friction plate acting on the dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com